Reimagining the Cybersecurity Workforce

Prepared for a cyber war? As cybercrime targets proliferate, manufacturers will need an army of cybersecurity experts to repel the hackers. MxD has identified 247 cyber roles that manufacturers need to consider.

By Chandra Brown

Once cyber attackers successfully penetrated an unnamed German steelmaker’s corporate network with a spear-phishing attack, they were free to roam through the company’s computer systems, including the production network. That’s when the real trouble started.

The hackers knew their way around IT security systems and the specialized software used to operate the plant. After they compromised a number of industrial control systems, including industrial components, the system failures avalanched. Plant operators scrambled to avert catastrophe but were unable to shut down a blast furnace properly, causing massive damage.

This is not the synopsis of a disaster film, but an account of a cyberattack from 2014, according to Germany’s Federal Office of Information Security and reported by BBC News.

As Industry 4.0 increases the digital connectivity of manufacturing, more targets become vulnerable to cyberattacks. There has never been a greater need for an army of cybersecurity experts to protect and defend these networks.

And now consider this: There were about 805,000 cybersecurity experts working in the U.S last year, according to a 2019 ISC2 workforce study. And this: The report said we need 500,000 more.

An Urgent Call to Action

While the stakes are high and the task is daunting, MxD sees an opportunity as well as a challenge.

We believe that to address the threat posed by cybercrime, we must reimagine cybersecurity. We must enlist the resources, expertise, and innovation found in the public and private sectors to create the infrastructure to train those half-million experts. And more fundamentally, MxD believes manufacturers won’t become truly secure until cybersecurity becomes the responsibility of all employees.

MxD lays out the case for these changes and offers concrete steps companies can take now in our free, downloadable report, “The Hiring Guide: Cybersecurity in Manufacturing.” It outlines the roles that government, academia, and industry can play, and it identifies 247 cybersecurity roles in manufacturing — some current, and some that will be needed in the future.

The report is not a white paper to shelve for later reading. It is a call to action and a blueprint for every manufacturing executive, human resources department, educator, and policymaker interested in cybersecurity.

Time for a New Plan

In 2018, the Department of Defense designated MxD as the National Center for Cybersecurity in Manufacturing to help create awareness and solutions for manufacturers to handle our unique cybersecurity risks. We took that mandate seriously.

We canvassed our members and asked them what they were worried about. Time and again, we heard, “I know there is a risk, but I don’t know where to start. I don’t know what kind of technology we need, or what types of skills my workforce needs to ensure that my organization is secure. I don’t know the appropriate amount to invest in developing or acquiring these skills.”

Working closely with ManpowerGroup over an intense 10 months, MxD researched the issues and stress-tested solutions. We called in experts from government, particularly the National Institute for Standards and Technology, and combined their perspectives with those from academia and industry to consider not just what is necessary now, but what kind of jobs will be needed in the future.

The Hiring Guide should inform educators at high schools, community colleges, and universities interested in updating curriculum to prepare students for attractive, high-tech careers that will be in high demand.

“There were about 805,000 cybersecurity experts working in the U.S last year, according to a 2019 ISC2 workforce study — and the report said we need 500,000 more.”

Acknowledge Business Realities

U.S. manufacturing is operating under pressure not seen since the Great Recession, and the uncertainties created by the COVID-19 pandemic make forecasting and planning difficult. Even before the pandemic struck, increasing investment in cybersecurity was complicated by companies not knowing how best to spend the money.

That is why we focused on roles, not jobs, so that manufacturers of any size and level of cyber maturity can begin adapting now to the challenges they face.

The Hiring Guide recommends how to train current workers to handle these new functions and outlines the skills, career paths, and the education they’ll need. The guide also addresses future technology horizons, including AI/machine learning, blockchain, cyber-physical systems integration, 5G networking, cloud and edge computing, and biometrics.

Essential Roles Breakdown

MxD recognizes that the number of roles — 247 — can by itself be intimidating. We break down the report in a number of ways so users can access the information they find most useful. For instance, the report lists 26 roles deemed immediately critical.

The guide then goes in-depth to fully explore the responsibilities and potential of four roles identified by industry and academia to be especially crucial to the future of cybersecurity. They are:

The Cybersecurity IT/OT Integration Engineer is a primary designer for cross-functional engineering, technical, and operations security programs. As the traditional closed manufacturing environment becomes more interconnected through Internet of Things (IoT) devices, more complicated supply chains, and cloud computing, the need for convergence between information and operation technologies is vital. Securing these networks is even more essential. These engineers assess risk and opportunity at a high level, and then design and implement the needed systems and policies. They are critical players in breaking down barriers between corporate IT and production and bridging various plant/facility operations.

The Secure Design Product Life Cycle Manager is a product-value–driven visionary, orchestrator, advocate, and point of assurance for the secure design and development of a product. As smart toilets perform in-home medical lab tests, ovens are operated remotely, and infant car seats adjust straps automatically for a baby’s weight and height, the need for security continues long after the product leaves the factory floor.

The Supply Network Cybersecurity Compliance Manager recognizes that the supply chain represents a juicy target for hackers. These managers, armed with experience in supply chain management, cyber governance, and procurement management, must deliver on improving the honest collaboration between supplier and contractor communities and manufacturers.

“An important tipping point will come when employees at each step of the manufacturing process – from research and design to supply chain to production and sales, and from the factory floor to the corporate suite – incorporate cybersecurity best practice in their work.”

The Manufacturing Cybersecurity Systems Operator is an entry-level role that serves as the eyes, ears, and voice for Information Technology and Operational Technology. These operators’ primary focus is to monitor, record, detect, and report security system performance and functions, while also bridging gaps between IT and OT, a capability that becomes ever more important as plants upgrade to interconnected machinery, automation, and data-driven operations. This role has great growth potential, providing wide-ranging experience to someone looking to get into cybersecurity or for companies looking to diversify their cyber workforce.

The report not only identifies and describes these roles, but also details key responsibilities, competencies, the experience and education needed, and the business case for each position.

MxD will continue to build out and publish detailed explanations for the rest of the roles on the critical list as partners step forward to help fund the development of those roles.

The Siemens Foundation has been an early partner in funding the development of the in-depth role profiles, and in coming months, we will be updating the Hiring Guide to include several more. Interested foundations and companies are welcome to join us in building out these success profiles.

More Than Just Insurance

It is easy for CEOs to see their cybersecurity budget as another type of insurance payment, only good in the hopes of blocking an attack or as a hedge against a likely breach. Certainly, the statistics illustrate the stark realities of that view.

- Cybercrime will cost companies $6 trillion globally by 2021, doubled from just five years ago, according to predictions from Cybersecurity Ventures. Manufacturing is the third most common target — and growing quickly.

- Hackers attack every 39 seconds, according to a University of Maryland study.

- Cyberattacks on IoT devices tripled in 2019, according to CSO Online. The average financial impact of such an attack is $330,000, according to the 2019 Deloitte and MAPI Smart Factory Study.

Indeed, cybersecurity could also be considered a business continuity expense, especially for small and mid-sized manufacturers, which employ fewer than 20 people and account for the majority of all firms in the sector. These are the same firms coming under an increasing number of attacks.

“MxD recognizes that the number of roles — 247 — by itself can be intimidating.”

A successful breach or ransomware attack can disrupt or hobble business for days, weeks, or in some cases months, a timeframe that makes even large manufacturers sweat.

Cybersecurity Is Everyone’s Business

In the process of listening to our members, researching the issues, and developing this report, we discovered there is an equally compelling business decision for manufacturers to build a robust full-cycle cybersecurity system. We believe progressive CEOs, eager to take advantage of exciting new technologies such as virtual and augmented reality, AI, and the immense potential of IoT, will see the competitive advantage their companies can achieve by including cybersecurity in every aspect of their business.

An important tipping point will come when employees at each step of the manufacturing process — from research and design to supply chain to production and sales, and from the factory floor to the corporate suite — incorporate cybersecurity best practices in their work.

It is not hard to envision — if we aren’t there already — that the cybersecurity of commercial devices, the ability to deliver a much-needed product despite a concerted cyberattack, or the care taken to protect a partner’s valuable intellectual property will become central selling points.

MxD stands with manufacturers nationwide and will continue to work with all parties to develop policies and regulations, fortify the educational pipeline, and disseminate best practices so we can begin to turn the tide against cybercriminals.

This report marks just the latest step in MxD’s commitment to its members and the nation. We will build on this foundation and continue to seek out innovative solutions. I want to personally thank our partners at ManpowerGroup and the generous support of the Siemens Foundation that is already making possible follow-up work to update our research in a dynamic and ever-changing field.

MxD helps manufacturers solve problems that are too big for any one company to handle alone. Cybercrime is just such a problem — and it’s going to take the combined efforts of industry, government, and academia to solve. MxD is committed to supporting industry as we define our needs, identify solutions, and build partnerships to tackle this growing threat.

Learn more by downloading the Hiring Guide at www.mxdusa.org/hiringguide. You also can view a related webinar, “Cybersecurity Hiring Guide for Manufacturers,” at this link: https://www.manufacturingleadershipcouncil.com/mxd_hiringguide/.

We urge interested executives, hiring managers, and cybersecurity experts who want more information or to join us in this work to reach out to Lizabeth Stuck, Senior Director of Workforce Development, at [email protected]. M

1 Sath Rao, “Digital Innovation: Scaling for the Fast and Furious Future,” Manufacturing Leadership Journal, April 2020, https://www.manufacturingleadershipcouncil.com/2020/04/10/digital-innovation-scaling-for-the-fast-and-furious-future/

2 Jared Spataro, “2 Years of Digital Transformation in 2 Months,” Microsoft 365 (blog), April 30, 2020, accessed August 10, 2020, https://www.microsoft.com/en-us/microsoft-365/blog/2020/04/30/2-years-digital-transformation-2-months/

3 Sath Rao, “The Case of the Missing Insights,” Manufacturing Leadership Journal, October 2019, https://www.manufacturingleadershipcouncil.com/2019/10/04/the-case-of-the-missing-insights/

4 Knut Alicke, Richa Gupta and Vera Trautwein, “Resetting Supply Chains for the Next Normal,” McKinsey & Company, July 21, 2020, https://www.mckinsey.com/business-functions/operations/our-insights/resetting-supply-chains-for-the-next-normal

5 Joglekar N., Parker G., and Srai J. S., “Winning the Race for Survival: How Advanced Manufacturing Technologies Are Driving Business-Model Innovation,” https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3604242

6 Sath Rao, “Digital Innovation.”

7 Fleming Shi, “Threat Spotlight: Coronavirus-Related Phishing,” Barracuda, March 20, 2020, https://blog.barracuda.com/2020/03/26/threat-spotlight-coronavirus-related-phishing/

8 Edward Barriball, Katy George, Ignacio Marcos and Philipp Radtke, “Jump-Starting Resilient and Reimagined Operations,” McKinsey, May 11, 2020, https://www.mckinsey.com/business-functions/operations/our-insights/jump-starting-resilient-and-reimagined-operations

9 Sath Rao, “The Case of the Missing Insights.”

10 David Uberti, “How BMW Used Pandemic Plant Stoppages to Boost Artificial Intelligence,” The Wall Street Journal, July 28, 2020, https://www.wsj.com/articles/how-bmw-used-pandemic-plant-stoppages-to-boost-artificial-intelligence-11595939400?mod=djemAIPro

11 Rajesh Devnani and Justin Bean, “Health and Safety of Workers,” Hitachi, https://social-innovation.hitachi/en-us/think-ahead/manufacturing/health-and-safety-of-workers/

12 Chris Walton, “3 Ways Starbucks Will Emerge from COVID-19 Stronger Than Before,” Forbes, April 3, 2020, https://www.forbes.com/siteschristopherwalton/2020/04/03/3-ways-starbucks-will-emerge-from-covid-19-stronger-than-before/#1d89d6641844

[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section]

Visions of the Decade to Come

Customized, autonomous, micro-networked, localized, AI-rich, modular, and more sustainable? What will global manufacturing look like in the decade to come? Members of the MLC’s Board of Governors share their unique perspectives on the future of manufacturing in 2030. By Paul Tate

Detlef Zühlke

Executive Director of Europe’s SmartFactory EU network

Dr. Dean Bartles

President and Chief Executive Officer of the U.S.-based Manufacturing Technology Deployment Group

Michele D’Alessandro

Vice President and CIO of Manufacturing IT at Merck

Brad Heath

Chief Executive Officer and Owner of VirTex Enterprises.

Moderator

Paul Tate

MLC’s Co-founding Senior Content Director and Executive Editor

Over the last ten years the manufacturing industry has seen massive changes. Some aspects are almost unrecognizable today – from the way products are designed, to the technologies used to produce them, to the scope and speed of the supply chains that support them, to the demands and expectations of the employees who build them and the customers who use them. As the industry stands on the threshold of the next decade of industrial transformation, what do you think manufacturing will look like in another ten years’ time by the year 2030?>

Detlef Zühlke: I think many of the changes over the next few years will be driven by the increasing individualization of products by the customers themselves. Customers will be able to sit at their computer, click on a product, individualize the parts, order online, have it produced locally, and then get delivery much faster than they can today where it often has to come from a distant part of the world. Speed will be a major part of the future, and I believe speed always beats price. We will also still need extremely high quality, of course.

These changes will mean that production will need to be located much closer to customers in the decade ahead. It’s already happening and is being further driven by the COVID crisis as companies strive to simplify their supply chains to become less complex and vulnerable. I think many factory operations will not be part of those large global supply chains in the next few years but will be much closer to home so they can respond faster to local customer demands and are more secure in the face of growing competitive and political cybersecurity issues around the world. I’m really convinced of this.

Additive manufacturing will also drive real change here. It’s provides completely a new way of producing things where you can design a customized product or part in one location and then produce it anywhere in the world within seconds. That will change the way we think about factories and how they operate. In smaller companies, or perhaps even at home, people will be able to produce even complex parts and products. And that will change the way we work in the future because people may not all need to be in one factory location anymore, they can be distributed across multiple locations. Not only the people working with data or in design, but also the people actually producing or assembling things.

I also think factories themselves will not be the highly individual plant set ups we see today but will be built around more standards-based approaches with modular, plug-and-play paradigms at the core of the operation, which then support more individualized software systems and fully digitized workflows. That will drive much greater awareness of the huge amount of data being created and accelerate the need for technologies like AI to handle and analyze all that data and convert it into knowledge and value. And with so many technological changes ahead, that means we have to start thinking now about the requalification of the people in our factories, or wherever they are, and retrain them to keep track of all of these industry-changing developments.

Autonomous Operations

Dr. Dean Bartles: When I picture 2030, I believe some manufacturing plants will be capable of full, lights-out automation. I’m thinking of an end-to-end computer-controlled system that’s going to be capable of receiving 3D models electronically and, without human intervention, be able to automatically estimate the near-exact cost and time it would take to manufacture the specified quantity for the customer. This platform will take into consideration the capability and availability of each machine the company has on the shop floor. It will be able to pulse the supply chain, real time, for needed raw materials costings and lead times, as well as automatically pulse the subcontractor base and obtain quotes for parts and/or services that the company’s not able to make or perform themselves. It will then be able to roll up all this information and provide a quote to the customer automatically. And it’ll do all this in less than a day.

Then, if the customer accepts the quotation and sends the order to the company, the computer platform will automatically order all required materials, tooling, expendables, et cetera, and automatically schedule each machine internally to do the required work in a logical order of operations, taking into consideration the scheduling of other orders and work, as well as orders expected to come in. The platform will compute the probability of a win for each quotation provided and schedule future work into the production flow based on a certain level of probability and make adjustments as needed if orders are not won.

“When I picture 2030, I believe some manufacturing plants will be capable of full, lights-out automation.” – Dean Bartles

The platform will also direct and oversee a team of robots and autonomous guided vehicles that will retrieve all the necessary raw materials and deliver to each machine as required. The same team of robots and AGVs will move in-process parts from one machine to the next, and eventually to final assembly and pack-out.

During that automated manufacturing process, every step of the operation will be monitored in real time and, if drift occurs on various machines, the platform will automatically send instructions to the subsequent machine to make the necessary adjustments needed to compensate. The platform will also monitor every internal machine and automatically dispatch maintenance robots, when required. It will be capable of performing routine service of machines – tool insert changes, coolant replacement, chip removal, and so on. The only human intervention required will be for major machine maintenance, like ball screw replacement and that type of thing.

And from the day the order is received, the platform will provide daily updates to the customer on the status of the work. These updates will include the status of raw materials, status of subcontracted work, status of production efforts, information on all quality inspections throughout the process, forecasted delivery dates, etc. The customer will know in real time exactly where their parts are on a daily basis, right up until the time they are delivered and the quality of their parts before they’re even packaged for shipment.

As a dream of what the future of manufacturing could be like in 2030, I think it’s entirely realistic that we will have that kind of lights-out control in future plants.

Regional Micro Factories

Brad Heath: I think we’re going to see a significant shrink in the number of really large factories in the next decade to more regionally based micro-factories. Perhaps even small individualized factories within a factory, supporting dedicated work cell types of operation.

That same trend will roll out into the supply chain but in a slightly different way with more regionalization of basic commodity component production to locations like South America and Central America. Right now, the majority of that is done in Asia, but that’s going to diversify to minimize the possibilities of global supply chain disruption. The combination of extensive automation and low-cost labor is going to increase manufacturing in a lot of regions where there are just start-up manufacturing ecosystems today because people aren’t going to put those low-cost, totally commoditized kinds of products into factories in Europe, the US, and Canada, where labor rates are higher and there’s a shortage of workforce.

For higher-range commodity components, like integrated circuits or high-reliability connectors in the electronics sector, for example, I think we’ll see a lot more smaller scale factories spread on a regional basis to help diversify risk, particularly in industries like medical and aerospace and defense which have suffered significant supply chain disruptions in recent months. These micro-factories are not going to produce the super-high-volume products. They are going to be running smaller quantities that are more customized as people choose to customize their products, and there will be less focus on pure cost and more focus on time to market and the overall cost of acquisition. I think there will also be a return to more complete factories in some cases too, supporting the full production cycle, rather than the mass outsourcing of multiple processes, parts, and packaging that we see today simply to drive lower costs.

Within those micro-factories themselves, I think you’ll see a combination of AI and augmented reality, used for both monitoring what happens and training the workforce because there will be a lot of data and dashboards for people to review. With such a large number of smaller factories in the network, it becomes difficult for people to try and track it all on a centralized basis, so a lot of that will be relegated to machines to identify exceptions, early corrections, and best practices. You can then deploy those lessons across the micro factory network with a combination of human training, human analysis, and by using augmented reality to speed up the time to teach the new workforce how to run things by watching someone in another factory, or even a virtualized worker, doing the same work. That will be important because you’re going to have to continually create a skilled workforce where there probably is none right now.

I think those trends are going to happen – smaller factories with higher levels of technology and a continually trained workforce building much smaller lot sizes in a lot more areas of both the country and the world.

“I think we’re going to see a significant shrink in the number of really large factories in the next decade to more regionally based micro-factories.”

– Brad Heath

Augmentation & Integration

Michele D’Alessandro: There are several themes in the process industry that we see will be prevalent by the time we get to 2030, particularly in areas like pharmaceutical manufacturing and others that are heavily regulated.

The first is the advancement of high-definition imagery. When that is combined with the use of AI and machine learning it provides a really different way to visually inspect what’s happening in our production processes and will probably displace, to a large degree, human involvement. Not just efficiency-wise, but also in being able to achieve much higher degrees of quality than we could ever do with humans alone.

Likewise, the advent of IoT that we’ve seen over the past number of years will continue to accelerate. We see completely sensored buildings and workers in the future. What are our buildings doing at any point in time? What is our equipment doing at any point in time? What are our workers doing at any point in time? Do they have the right PPE? Before they access a room, are they authorized? Do they have the right training before they go to touch a machine or perform a certain task? So, we think every piece of equipment and every person will be tracked, monitored, and proactively informed whether they’re allowed to do a task or not.

Augmented reality will be increasingly important for us too. We had a crisis on our hands with COVID where we have needed to use augmented reality to actually do our day-to-day work because we couldn’t send the workers into the plant sites. I think that’ll be the norm in the future and no longer just a response during a crisis.

We will also see blockchain technologies being used extensively to secure our supply chain. It’s an immutable and highly resilient way to share data and have one source of the truth about a product. As we cross borders around the globe, we will be able to ensure that the product has not been tampered with, either maliciously like counterfeiting, or non-maliciously just through environmental factors. We see that to be the standard way to have a digital fingerprint travel along with our product.

I think there will be far greater integration between internal and external nodes in tomorrow’s supply networks too. In the process industries today, sometimes you have the ability to share data easily, but you don’t necessarily see into each other’s production processes. Think of every node in our supply chain now being equally visible and interoperable, whether you’re an internal node at a pharmaceutical company, or a process manufacturer, or you’re the external node that helps them produce through some type of contract manufacturing.

Finally, I have a strong belief that sustainability is going to be the norm by which we are all measured in the future, and not only our own green initiatives, but as an industry. How are we controlling the by-products and the associated waste from what we produce? And that extends to everybody in our supply chain. What do different nations do around the world and what are their sustainability practices like? If we only get certain raw materials from certain places in the globe, how do we ensure that they’re doing what we expect them to do around global standards so that when our products are looked up by the consumer population, they don’t take issue with any aspects of our external supply chain.

“I’m absolutely convinced that we will need more and more creative people over the next ten years to really shape the future much better than we have done in the past.” – Detlef Zühlke

New Workforce Skills

Tate: In such a technology dependent world that you have all envisioned, what role will the human workforce play in the manufacturing industry of the future?

Bartles: You’re going to see a much larger shift towards people that have computer skills because the computer systems are going to control the manufacturing operation. I think more companies that move towards this lights-out manufacturing concept are going to have to have a larger contingent of computer science majors to do all of the programming in order for the computer systems to run all these various machines and the processes associated with them.

Heath: I agree with Dean, to some extent. There’s going to be a lot more need for computer science, whether that’s AI or data scientists doing the overall structure of how the data’s going to flow from the machines. But one of the things I don’t think will happen within the next 10 years is that all machines will be standardized to where there are completely common interfaces. It hasn’t happened in the last 30 years and I don’t see it happening in ten. There will be more standardization, but not everybody’s going to be able to replace all their legacy equipment, so there’s going to be a lot of work to be done by people on how you make those legacy machines communicate on the factory floor and, again, get the data out there.

By the same token, I think the skill level of the jobs that are being done by people are going to have to move up, because they are going to be doing a lot more in-conjunction with computers and fully automated machines, and with a digital thread flowing through the whole operation. For example, how do you present that information from the computer systems, via digital thread, into the work instructions, or into the training? Somebody’s going to have to create all of that data. Down the road, computers can probably do a large portion of that, but initially, it’s going to require industrial engineers, manufacturing engineers to optimize that workflow, monitor the data coming out, and ensure the efficiencies are what people expect. I think the ratio of technical engineering workers to factory floor workers is going to become closer to parity, where it may be three factory workers to the knowledge worker right now.

So, I think there’s a lot of training-the-workforce changes that have to happen and a continuing focus on STEM curriculums and the education of current students to what manufacturing really offers these days. That will be critical to building the supply of students who can go into those increasingly automated shops in 2030.

D’Alessandro: The convergence of classic operations technology and IT is an obvious one. Folks may still be very much equipment-focused but understanding the sophistication of the computers that will run that equipment is going to be a critical skill. Whether you’re retraining the current workforce with new skills or hiring more computer specialists to help run the plant, I think that’s definitely a trend.

But I’d agree with the statement that things will still be non-standardized. There will be bespoke types of technologies and, so, the folks who are responsible for integrating those technologies, whether it’s from a data or system perspective, will definitely be in high demand.

Taking manual work out and replacing that with automation then frees up the workforce to be more knowledge workers. I think we’re going to see more people with a more sophisticated ability to use data to drive their day-to-day work and that is a skill set we need to grow. We’re going to generate even more data than we do today, which means we’re going to be understaffed when it comes to data science and decision science workers. That is a real need in the future.

Zühlke: We have to educate people to be capable of building bridges between IT and OT so they will need to have a more interdisciplinary approach. I’m positive we will have young people coming from our universities with the right profile here. However, we also have to consider the workers who’ve already spent years on the shop floor. We have to encourage them to participate in this transformation too because we need these people to help make it all happen. We don’t have enough young people coming onto the shop floor right now. That is why I believe retraining and requalifying the current workforce will be really important for the next 10 years.

Also, as we get more individualized products, I think we will need human beings in this loop because systems will become more complex and that means the potential for failure will be quite high, so we will need very creative people on the shop floor recognizing what goes wrong and correcting things when they do.

“I don’t think we completely understand yet what sustainability will mean for the future of production.”– Michele D’Alessandro

Harnessing Human Innovation

Tate: How important do you think that creative human role will continue to be in the automated factories of the future? Is this one area where human ingenuity and innovation will still be a vital part of the manufacturing mix?

Bartles: It’s still going to take human imagination and human ingenuity to conceive ideas for new products but, when it comes to the best way to design that product, I think things like generative design are going to play a huge part in the future. We’re already seeing that generative design can come up with better designs than humans can even think of, especially with ad-lib or customized manufacturing continuing to grow stronger. And they’ll probably be greener, cheaper to produce, lighter weight, and higher quality, all because of the advanced manufacturing technologies that are available.

Heath: I’d agree that humans can’t come up with as many ideas or perfect something as well as a machine. But when it comes to understanding a particular problem to solve, that’s still going to come from people. Just because a computer can come up with 40 different possibilities, someone has to be able to look at these and decide which one will work best in the market, not just how to build it effectively. You’re always going to have the human piece in that. I think that’s one of the things that’s kept Western engineering ahead, in a lot of cases, by creating so many innovative new ideas. Machines will come up with ideas after they have been taught certain things and follow a pattern of what’s been learned, but humans are not limited to a specific way of thinking. They have the imagination to be able to think out of the box and will continue to drive new ideas.

Zühlke: I’m absolutely convinced that we will need more and more creative people over the next ten years to really shape the future much better than we have done in the past. This is a basic requirement for success, for me, and is closely linked to a culture of innovation. Innovation is not some sort of a sudden flash event in most cases, but it’s based on knowledge, personal experience, and the information you have available. So, companies must enable people to be able to gather the right information and share it with others to generate the best ideas as part of an innovation culture that encourages the freedom of thinking and is supported by opportunities for people to discuss those ideas in a productive forum. The availability and sharing of the more information in the next few years will certainly help this process to succeed.

More Sustainable Future

Tate: One of the points made earlier in our discussion was around industrial sustainability. As manufacturing enters a new decade, how influential do you think that sustainability trend will be to how manufacturing develops over the next ten years?

Heath: I think a large part of that is going to continue to be driven by our customers and by our shareholders. They see sustainability as a core thing that can’t be compromised. There’s more and more pressure to eliminate waste and leave everything better than we found it. That has to drive the overall corporate culture in the future because that’s what our customers want.

Bartles: The sustainability trend has been with us now for quite some time. I left General Dynamics six years ago and, for the 10 years prior to leaving, there was a huge focus on leaning-out waste. There was a feeling that large blocks of investors buying significant shares of stock were watching corporations to see what they were doing to be greener. I also think that we’re now entering a time where you’re going to begin to see customers paying a premium for products that have a smaller carbon footprint. I always felt that utopia would be to have three buttons on all my machines. One button would be that the customer wanted it as fast as possible, that’s one operation. If the customer wanted it as cheap as possible, that’s a different button you’d push. The third button would be if a customer wanted the product to be as green as possible and use the least amount of energy in manufacturing that part. I think there’s going to be a larger focus on customers willing to pay a premium for greener products in the years ahead.

Zühlke: I think all companies will ultimately be forced by their customers to push that green button. And customers will be prepared to pay a premium as long as they can see that companies are responding and have something greener to offer. There’s a big green energy wave, for example, moving through the industry with more and more companies installing solar panels on factory roofs or reusing thermal energy from their machines to power heating or cooling systems in their plants. But I’m a little disappointed by the production systems industry’s performance in this so far. For example, we’ve talked for a long time about individual controllers, POC’s, machine tools, and other production equipment having some sort of a standby state. Yet most still don’t. Production machines are either left running all the time, or when you switch them off, it then takes 10 minutes to bring them back up again. That’s an obvious and unnecessary waste of energy. If we aim to use more individualized machines in a more modular and agile way in future production lines, this will have to change. We will have to adopt new energy approaches at a very detailed machine level across all parts of our production systems to make them more energy efficient.

D’Alessandro: I think sustainability will be a trend that we will all need to pay more attention to across many parts of the industry over the next decade. Social awareness around sustainability is far under-appreciated right now. People are connecting with each other throughout society quicker, and asking things like, “Why is there plastic in what I’m buying? Why is there chemical in what I’m buying? Why do you use chemicals when you produce what I’m buying?” There’s already amazing demand for greener approaches. And I don’t think it’s only going to come just from shareholders. It’s going to be from consumers at large.

I also don’t think we completely understand yet what that will mean for the future of production. Some of the sustainability and green goals we have today are probably minor in comparison to where that’s headed. Then, if you think of industries who provide food supply, I think it’s going to be even more radical in the future. What will the future food supply chain look like? Where are the products coming from? What will people be demanding about their food? I think it’s fascinating and I think it’s something that will ground us all in the next few years and require us to develop very different ways of producing things in the future. M

1 Sath Rao, “Digital Innovation: Scaling for the Fast and Furious Future,” Manufacturing Leadership Journal, April 2020, https://www.manufacturingleadershipcouncil.com/2020/04/10/digital-innovation-scaling-for-the-fast-and-furious-future/

2 Jared Spataro, “2 Years of Digital Transformation in 2 Months,” Microsoft 365 (blog), April 30, 2020, accessed August 10, 2020, https://www.microsoft.com/en-us/microsoft-365/blog/2020/04/30/2-years-digital-transformation-2-months/

3 Sath Rao, “The Case of the Missing Insights,” Manufacturing Leadership Journal, October 2019, https://www.manufacturingleadershipcouncil.com/2019/10/04/the-case-of-the-missing-insights/

4 Knut Alicke, Richa Gupta and Vera Trautwein, “Resetting Supply Chains for the Next Normal,” McKinsey & Company, July 21, 2020, https://www.mckinsey.com/business-functions/operations/our-insights/resetting-supply-chains-for-the-next-normal

5 Joglekar N., Parker G., and Srai J. S., “Winning the Race for Survival: How Advanced Manufacturing Technologies Are Driving Business-Model Innovation,” https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3604242

6 Sath Rao, “Digital Innovation.”

7 Fleming Shi, “Threat Spotlight: Coronavirus-Related Phishing,” Barracuda, March 20, 2020, https://blog.barracuda.com/2020/03/26/threat-spotlight-coronavirus-related-phishing/

8 Edward Barriball, Katy George, Ignacio Marcos and Philipp Radtke, “Jump-Starting Resilient and Reimagined Operations,” McKinsey, May 11, 2020, https://www.mckinsey.com/business-functions/operations/our-insights/jump-starting-resilient-and-reimagined-operations

9 Sath Rao, “The Case of the Missing Insights.”

10 David Uberti, “How BMW Used Pandemic Plant Stoppages to Boost Artificial Intelligence,” The Wall Street Journal, July 28, 2020, https://www.wsj.com/articles/how-bmw-used-pandemic-plant-stoppages-to-boost-artificial-intelligence-11595939400?mod=djemAIPro

11 Rajesh Devnani and Justin Bean, “Health and Safety of Workers,” Hitachi, https://social-innovation.hitachi/en-us/think-ahead/manufacturing/health-and-safety-of-workers/

12 Chris Walton, “3 Ways Starbucks Will Emerge from COVID-19 Stronger Than Before,” Forbes, April 3, 2020, https://www.forbes.com/siteschristopherwalton/2020/04/03/3-ways-starbucks-will-emerge-from-covid-19-stronger-than-before/#1d89d6641844

[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section]

Connected Customers: The Next Frontier

Consumers have more choice now than ever. Why wouldn’t you use readily available data from today’s increasingly connected customer to anticipate their needs, drive innovation, and earn their loyalty? By John Barcus

While successful manufacturers have always had a strong focus on the customer, increased expectations and new technologies are driving a fundamental shift in how manufacturers and customers engage with each other. A shift away from products to services and experiences is inherent throughout our economy, and manufacturers are no exception. That does not mean that manufacturers will quit manufacturing. They will, however, need to be much more aware of their customer’s ultimate needs and how their products are being consumed, and be prepared to understand and both manage and improve the experience across the entire customer lifecycle. Connecting to the customer will be the next frontier of differentiation for companies, providing a win-win situation where the customer is better served at lower total costs for the manufacturer.

To improve the overall customer experience across the customer lifecycle, we must start with knowing all that we can about the customer. For many of us, the advent of e-commerce and the use of our smartphones have made us the ultimate connected customer. Based on our search history, companies understand our wants and desires while providing us offerings and experiences that match those needs seamlessly between devices, and even at the physical locations we visit. The experience will only improve as we continue to share more and more information about ourselves.

Manufacturers have been slower to adopt the same technologies even though it is estimated that more than 61% of B2B transactions are started online and multichannel customers are significantly more profitable than single-channel customers. Most of us have felt the frustration of having to provide the same information over and over again during a single interaction. Customers now expect a totally seamless experience where nothing is entered twice, that you know what products I have, how I am using them, what I am interested in, and even why I am contacting you. Having a constantly updated 360-degree view of your customer can solve this problem and enables a completely personalized experience regardless of how they interact with you or where you are in the customer journey.

“Enhancing the customer experience has become one of the most effective ways of keeping your current customers happy.”

Using AI and Data to Predict Customer Needs

The concept of a 360-degree view of the customer is not new; however, technologies have recently advanced to the point where an understanding of the customer is significantly enhanced by connecting all aspects of the customer journey through marketing, sales, service, and commerce — from the front office to the back office — to deliver a single and unified experience. Using AI to actually predict behavior and solutions is becoming a much more prevalent trend. AI digital assistants that provide 24/7 coverage are realizing the goal of developing an engaging predictive experience. Bajaj Electricals, a provider of consumer products, which include commercial and home lighting products as well as home appliances, uses an AI-based customer service chatbot to let users report broken appliances, schedule installation appointments, and request demos from service technicians to learn how to use new products. This provides a better customer experience and reduces the workload on their customer call center.

Another differentiated benefit enabled by the connected customer is the ability to innovate the right products and services faster. With the increasing use of connected devices and software-driven innovation, it is now possible to know how your customers are using your products, which features they are using the most, and even identify opportunities for enhancements or new products. Knowing exactly what customers want helps to reduce the costs and time to innovate new products along with ensuring the success of those products.

This data that comes from the customer is invaluable input to your innovation process. Sound United’s Denon and Marantz, producers of high-fidelity sound equipment, were able to use data from their new HEOS line of connected speakers to improve the quality of their products and also innovate an entirely new product. Using information available from customers who chose to share their information, they noticed that many named their speakers “bathroom.” Based on this information, they decided to build and offer a product targeted directly for use in the bathroom. They replaced the felt covering with a metal covering and one of their most successful products was born. Trying to get this same information in the traditional manner could have taken years with no guarantee of success.

“Another differentiated benefit enabled by the connected customer is the ability to innovate the right products and services faster.”

As another example, Oracle now predominately offers software products in the cloud as services that provide them real opportunities for continued and rapid innovation. Oracle monitors anonymously which features are and are not being used across the applications and leverages this information as input to the innovation process. With regular quarterly releases, customers can see functionality enhancements in areas where they have the most need, many times without even asking for the enhancements.

Customer-Driven Innovation

Finally, it is important to recognize the benefits to innovation that the combination of the connected customer, software-enabled features, and over-the-air updates has provided. Upgrading our computers with the latest CD, taking our cars in for the latest software update, or having to live with buggy software have all become problems of the past. Over-the-air fixes of smartphones, vehicles, etc., has made all of our lives much easier and more efficient.

The connected customer is now also seriously enhancing the performance and execution of the supply chain. For as long as products have been made and sold, companies have been hyper-focused on reducing costs and improving the efficiencies of the overall supply chain. In fact, with the events of the last few years, the ability for companies to digitize and differentiate their supply chains has, for many, been the difference between success and failure. Connecting the customer is a logical extension of that supply chain. For many of us, that extension is the result of subscriptions, such as the automated replacement of ink for your printer. A simple reminder text or email asking for approval gets you replacement ink along with service recommendations. It is now almost automatic to schedule an oil change or service on your car exactly when it is required — and it is easier than ever. The evolution from having to call for service to advising us when service is required to now predicting and/or automatically scheduling a replenishment or repair with little effort has made or lives much easier. The logical extension to this is offering products as a service. A 3d printing company now only offers their products as a service, making them solely responsible for ensuring uptime and for servicing the products. Constant monitoring allows them to provide the highest level of satisfaction for their customers.

With ever-increasing competition, it is now easier than ever for customers to search out and find other suppliers. Enhancing the customer experience has become one of the most effective ways of keeping your current customers happy and there is no better way of enhancing their experience across the entire customer lifecycle than getting connected to them. M

1 Sath Rao, “Digital Innovation: Scaling for the Fast and Furious Future,” Manufacturing Leadership Journal, April 2020, https://www.manufacturingleadershipcouncil.com/2020/04/10/digital-innovation-scaling-for-the-fast-and-furious-future/

2 Jared Spataro, “2 Years of Digital Transformation in 2 Months,” Microsoft 365 (blog), April 30, 2020, accessed August 10, 2020, https://www.microsoft.com/en-us/microsoft-365/blog/2020/04/30/2-years-digital-transformation-2-months/

3 Sath Rao, “The Case of the Missing Insights,” Manufacturing Leadership Journal, October 2019, https://www.manufacturingleadershipcouncil.com/2019/10/04/the-case-of-the-missing-insights/

4 Knut Alicke, Richa Gupta and Vera Trautwein, “Resetting Supply Chains for the Next Normal,” McKinsey & Company, July 21, 2020, https://www.mckinsey.com/business-functions/operations/our-insights/resetting-supply-chains-for-the-next-normal

5 Joglekar N., Parker G., and Srai J. S., “Winning the Race for Survival: How Advanced Manufacturing Technologies Are Driving Business-Model Innovation,” https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3604242

6 Sath Rao, “Digital Innovation.”

7 Fleming Shi, “Threat Spotlight: Coronavirus-Related Phishing,” Barracuda, March 20, 2020, https://blog.barracuda.com/2020/03/26/threat-spotlight-coronavirus-related-phishing/

8 Edward Barriball, Katy George, Ignacio Marcos and Philipp Radtke, “Jump-Starting Resilient and Reimagined Operations,” McKinsey, May 11, 2020, https://www.mckinsey.com/business-functions/operations/our-insights/jump-starting-resilient-and-reimagined-operations

9 Sath Rao, “The Case of the Missing Insights.”

10 David Uberti, “How BMW Used Pandemic Plant Stoppages to Boost Artificial Intelligence,” The Wall Street Journal, July 28, 2020, https://www.wsj.com/articles/how-bmw-used-pandemic-plant-stoppages-to-boost-artificial-intelligence-11595939400?mod=djemAIPro

11 Rajesh Devnani and Justin Bean, “Health and Safety of Workers,” Hitachi, https://social-innovation.hitachi/en-us/think-ahead/manufacturing/health-and-safety-of-workers/

12 Chris Walton, “3 Ways Starbucks Will Emerge from COVID-19 Stronger Than Before,” Forbes, April 3, 2020, https://www.forbes.com/siteschristopherwalton/2020/04/03/3-ways-starbucks-will-emerge-from-covid-19-stronger-than-before/#1d89d6641844

Spatial Computing: Digitizing the Future of Work

By 2030, spatial computing applications that precisely locate and map 3D movements to improve operations and maximize the multiple interactions between humans, machines, objects, and working environments will become ubiquitous.

By Steve Dertien & Will Hastings

Spatial computing is the digitization of spatial relationships between machines, people, objects, and environments to identify both their precise location and their movement within a 3D space to enable and optimize their operations and interactions.

It describes a class of applications that most are already familiar with in their personal lives. If you’ve used GPS navigation or activated Tesla’s autopilot mode, you’ve already enjoyed some of the benefits of spatial computing.

Human and Machine Interaction

In today’s world, work increasingly gets done through a combination of human and machine inputs. McKinsey estimates that for 60% of occupations, 30% of the tasks involved are automatable. In the decade ahead, automation and human labor will play increasingly complementary roles.

That can be good, but also has risks; the safeguarding methods used for decades to protect workers are often insufficient for this new environment and could be impediments to the future of human and machine collaboration. What is missing today is how to optimally utilize machines and humans in a clearly defined physical space to get work done. For manufacturers, emerging spatial computing technologies offer unique opportunities to address this challenge and unlock the next step change in productivity.

With the rapid advances in machine learning, computer vision, wireless communication, satellite positioning systems, and other technologies, along with the increasing ubiquity of cloud computing, industry is at a tipping point for the development of spatial computing applications in the decade ahead. In the factory, the warehouse, or out in the field, by 2030 the comprehensive capture of motion and precise location will reveal insights into the way machines, people, and processes work and interact with each other and their surroundings. Future manufacturers will leverage this new understanding to dramatically improve the efficiency and safety of operations by expanding the scope of IIoT initiatives, empowering front-line workers, and optimizing their industrial environments.

“With a shared understanding of the space and happenings around them, the actions of people and machines will be harmonious.”

Expanding the Vision of IIoT

Over the past decade manufacturers have reached new levels of efficiency through Industrial IoT initiatives. These connected operations are already creating and leveraging vast amounts of data to maximize revenue, reduce cost, and improve quality. What IIoT has done for manufacturing cannot be understated, but it is still unable to provide a fully comprehensive view of all operations as it currently lacks important spatial information.

Essentially, traditional IIoT is blind to its surroundings. In choosing what sensors to install and what machines to connect, adopters of IIoT define the boundaries of their own digital perception. These boundaries can result in enormous gaps of knowledge between the digital representation of an operation and its physical execution in a 3D environment.

Companies commonly rely on people to bridge these gaps. It is often the people on the factory floor who identify when a missing bolt is responsible for abnormal vibration data, or when a dropped pallet at one end of the factory impacts the uptime of a line at the other end. Despite their unmatched ability to discover and react to changes in their environment, to rely on people for this role comes with unavoidable challenges. Their perception is limited to their immediate surroundings, their knowledge is difficult to transfer, and their ability to input and retrieve digital information is limited by modern human-machine interfaces. For many people, making connections between seemingly disparate events either happens by chance, or is painstakingly slow.

Spatial computing promises to resolve these challenges by digitizing the discovery process and providing IIoT with “eyes on the ground”. With the discovery process digitized, analytics can be applied to correlate all activities, not just the ones that have been connected. Insights gained from this process can be acted on quickly to improve operations in, or near, real-time. With spatial computing adding motion awareness to the analytical mix, manufacturers in 2030 will be able to augment their IIoT capabilities to move beyond the intermittent optimization of individual processes, to the continuous optimization of entire factories.

Connecting Workers to the Digital Workflow

It may seem that spatial computing threatens the value proposition of the frontline worker, but this couldn’t be further from the truth. Spatial computing is a means to address the challenges faced by frontline workers by digitizing their movement and connecting them as a consumer and provider to the digital ecosystem that surrounds them.

“The adoption of spatial computing in manufacturing will happen much quicker than you might think.”

Motion capture has long been used by clinical medicine to analyze biomechanics for health reasons and by high-performance athletes to perfect their tennis serve or golf drive. With spatial computing entering the industrial setting, the same type of analysis can be applied to workers to examine their motion and synthesize individually tailored best practices. These industrial athletes will be empowered with personalized processes suited to their unique skills and physical attributes and optimized for safety and efficiency. Going one giant step further, companies will be able to leverage augmented reality to deliver the insights gained through spatial computing in time, and in a spatial context, for each worker.

From operators to technicians and floor managers, the incorporation of people’s action and intelligence into the real-time digital workflow of manufacturing operations will be imperative for training and upskilling workers, improving labor performance, increasing safety, and reducing planned and unplanned downtime. The workforce of 2030, digitally native millennials and younger generations, will thrive in this advanced, technology driven environment as it reflects the high expectations of the technologies they will already use in their normal lives.

Improving Collaboration & Optimizing Environments

By 2030, the cutting-edge applications of spatial computing now being adopted today will be components of much broader spatial computing initiatives. With a shared understanding of the space and happenings around them, the actions of people and machines will be harmonious. Operators will use gesture control to direct the motion of machines. Machines will adjust their actions to account for the movements of people and products. Each will be aware of the goals and intent of the other through a shared perception of digital and spatial information.

In this vision, it’s not just the operations that are optimized, but the environment as well. For the first time, industrial engineers will have a complete and persistent view of the interaction of materials, people, and processes. This comprehensive knowledge will provide continuous feedback for the improvement of factory or warehouse layouts to resolve inefficiencies of time, motion, and the use of space. With spatial computing, each industrial environment will be as engineered, monitored, analyzed, and optimized as the processes conducted within it.

More Science than Fiction

The adoption of spatial computing in manufacturing will happen much quicker than you might think. Already spatial computing is permeating our daily lives and will soon play a larger role with the continued advances in autonomous vehicles and the incorporation of spatial sensing (LiDAR) into next generation smartphones. The world is about to witness an explosion in applications, expertise, and opportunity in this domain. In the industrial world, companies with established IIoT and Augmented Reality programs will find the incorporation of spatial computing a logical and transformative next step in their digital transformation journey. M

FOOTNOTES

1 Niall McCarthy,” Rise of the Machines: The Countries with the Highest Density of Robot Workers,” Forbes, Sep 28, 2020, https://www.forbes.com/sites/niallmccarthy/2020/09/28/rise-of-the-machines-the-countries-with-the-highest-density-of-robot-workers-infographic/amp

2 Ibid.

3 Emil Protalinski, “Boston Dynamics CEO talks profitability and the company’s next robots,” Venture Beat, Sep 14, 2020, https://venturebeat.com/2020/09/14/boston-dynamics-ceo-profitability-roadmap-next-robots/

4 Manufacturing Leadership Council, “Vision 2020: The Factory of the Future,” 2017. https://www.mljournal-digital.com/meleadershipjournal/ february_2017? pg=25#pg25

5 Art Markman, “How You Define the Problem Determines Whether You Solve It,” Harvard Business Review, June 6, 2017, https://hbr-org.cdn.ampproject.org/c/s/hbr.org/amp/2017/06/how-you-define-the-problem-determines-whether-you-solve-it

6 Manufacturing Leadership Council, “Vision 2020: The Factory of the Future,” 2017.

7 Niall McCarthy,” Rise of the Machines: The Countries with the Highest Density of Robot Workers,” Forbes, Sep 28, 2020, https://www.forbes.com/sites/niallmccarthy/2020/09/28/rise-of-the-machines-the-countries-with-the-highest-density-of-robot-workers-infographic/amp/[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section]

Disruption Brings Endless Opportunities

The reality is that end-market disruption is only going to increase. If you want to play a pivotal role in shaping the American economy for the next decade, you need to consider how to face that disruption with strengthened innovation and vision.

By Jerry Gootee, Mark Heidenreich, Mitali Sharma, and Addison Lanier

You have just been named CEO of an industrial manufacturing company and your first goal is to hit the ground running. The board and Wall Street are watching, excited for what’s to come but also waiting to see where your vision will lead. With the expectations of shareholders, the board, and your employees in mind, you start to think: Where are we now and where do we need to go?

You recognize key strategic decisions are at hand. Can you continue to compete on quality and cost with new competitors nipping at your heels, or is it time to double down on higher value, more difficult-to-replicate solutions, products and services? You could shift your company beyond its roots in traditional manufacturing and create new digitally enabled products and services. Perhaps you choose to rebrand from a materials manufacturer to an industrial producer, developing products that have multiple applications. Instead of threats to what you’ve always done, you see these situations as opportunities to grow and chart a new course for your business.

The key to capitalizing on these and other new business models is a willingness to change. Shifts in demographics, economics, politics, environment, and technology, along with sector convergence and the increasing importance of sustainability, are transforming global end markets.

The traditional linear value chain is rapidly evolving into a fluid ecosystem of supply networks, requiring manufacturers to make new choices about the most reliable and cost-effective way to manage their supply chains. It hasn’t been an easy transition.

As CEO, you understand that a traditional focus on efficiency has helped you to manage your margins, but often reduced your ability to be flexible when circumstances shift quickly. Thus, when the landscape changes, it’s not just disruptive. It can be paralyzing.

“Look for opportunities for vertical innovation which would require a shift, rather than a dramatic transformation of your business model.”

Here are ways CEOs can be the agent of change to brighten the horizon and create opportunity for years to come.

Get to Know End-Market Disruption

When disruption seems to be everywhere at once, it’s hard to know where to focus your attention. If you’re seeking to serve your customers better, begin by considering how well you know the needs of their customers. As business models in end markets evolve, your customers will need to grow and change to serve them. Keeping up with the pace of business, we can sometimes find ourselves too comfortable in the markets we know best and tell ourselves that now isn’t the right time to take a risk on the unknown. It’s the customers of customers who are often driving innovation as companies search for solutions to support their evolving needs. Understanding the end customer and in turn end market is where the true innovation takes place, allowing us to leverage the insight to build what’s needed for tomorrow.

To understand, you need to listen. If you have systems in place throughout your supply chain and distribution channels that allow you to listen for these insights and share them with the right people in your organization, you’ll be well positioned at all times to create products and services that are in tune with your customers’ needs. Make time to engage in conversations that increase your knowledge, strengthen relationships, and boost awareness of what’s happening in your space. Finally, have a clear and realistic view of yourself and the market in which you operate, and constantly revisit that view for gaps.

Infuse Your R&D Strategy with Market Insights

Innovation is most effective when it’s closely aligned with your company’s priorities. R&D teams, whether centralized or distributed among your company’s business units, need to be an integral part of your communication. Take those conversations you have with your customers and create a forum in which you can build off that dialogue. Look for opportunities for vertical innovation which would require a shift, rather than a dramatic transformation of your business model.

“Success in manufacturing in the 2020s will require leaders who are willing to set aside once tried-and-true strategies in pursuit of a greater reward ”

COVID-19 has spawned numerous examples of vertical innovation. Companies around the world have adapted existing products to serve as essential supplies while other businesses have modified equipment and processes to build urgently needed medical supplies. Manufacturers have shown that, with the right inspiration and drive, no sector boundary or time limit can hold back innovation.

Take a lead role in this process and bring anyone to the table who can help further the conversation. You may need to take a hard look at your team and its capabilities and introduce new voices that enable you to make more informed decisions. The most important thing is to ensure that everyone engaged in this process is working toward the same common goal.

Don’t Let Your Past Disrupt Your Future

There is one cautionary note to consider as we analyze the approaches to innovation. It is possible that an idea from the past may be the answer for the future, and old ideas should be met with a fresh perspective. M4.0 leadership acumen is not necessarily focused on the implementation of digital technology alone. Instead it’s focused on understanding that new technologies, new ideas and innovative approaches will always come your way and understanding your business well enough to know how to incorporate them is key. Approaching ideas, whether new or old, with a fresh lens will allow you to capitalize on the disruption ahead. Be ready to revisit ideas you’ve tried before and be ready to hear from individuals from all facets of the company. The beauty in innovation can be found in the minds that we bring together and the ideas that we embrace from all walks of the organization.

You Don’t Have to Do It Alone

Some problems are simply too big for one company to manage on its own. One response might be to create ecosystems in which companies can partner with other businesses and jointly work on reframing their future to meet market needs. The transition from linear to network-based supply chains will require all ecosystem players to enhance their value contribution to avoid disintermediation. Success in manufacturing in the 2020s will also require leaders who are willing to set aside once tried-and-true strategies in pursuit of a greater reward — the preservation, and ultimately the dynamic growth of an entire industry. M

FOOTNOTES

1 Niall McCarthy,” Rise of the Machines: The Countries with the Highest Density of Robot Workers,” Forbes, Sep 28, 2020, https://www.forbes.com/sites/niallmccarthy/2020/09/28/rise-of-the-machines-the-countries-with-the-highest-density-of-robot-workers-infographic/amp

2 Ibid.

3 Emil Protalinski, “Boston Dynamics CEO talks profitability and the company’s next robots,” Venture Beat, Sep 14, 2020, https://venturebeat.com/2020/09/14/boston-dynamics-ceo-profitability-roadmap-next-robots/

4 Manufacturing Leadership Council, “Vision 2020: The Factory of the Future,” 2017. https://www.mljournal-digital.com/meleadershipjournal/ february_2017? pg=25#pg25

5 Art Markman, “How You Define the Problem Determines Whether You Solve It,” Harvard Business Review, June 6, 2017, https://hbr-org.cdn.ampproject.org/c/s/hbr.org/amp/2017/06/how-you-define-the-problem-determines-whether-you-solve-it

6 Manufacturing Leadership Council, “Vision 2020: The Factory of the Future,” 2017.

7 Niall McCarthy,” Rise of the Machines: The Countries with the Highest Density of Robot Workers,” Forbes, Sep 28, 2020, https://www.forbes.com/sites/niallmccarthy/2020/09/28/rise-of-the-machines-the-countries-with-the-highest-density-of-robot-workers-infographic/amp/[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section]

The Evolving Role of Middle Management

Middle managers have been a part of organizational hierarchy since humans started working together. But that role must change as traditional manufacturing transforms to a data-driven digital engineering model. By Kevin Prouty

Middle management is so engrained in how we operate that few people even consider or question the reason for its existence. For centuries, the owner or executive level of any sizeable organization has relied on managers, supervisors, foremen, or other middle managers to translate executive decisions into realistic tasks for individual workers. That same flow happens in reverse: Information on operational progress traditionally has had to move up the chain to become digestible information for senior managers.

There’s a reason for this historical hierarchy. A person can only handle so much data and information in a short period of time — and they can only make a limited number of effective decisions at the same time. But this middle management-based hierarchy comes with a cost.

For example, it can take days, week, and even months for the information senior decisionmakers need to make its way up through layers of staff, each of whom must collate, analyze, and interpret the data — and each of whom also have biases shaped by personal goals, KPIs, and incentives. Once the data is collated into actionable information, orders or tasks must then make their way down that same middle management layer.

All that up-and-down activity means that, by the time the decision reaches the point of activity, there is a good chance the decision is obsolete.

In addition, middle managers tend to create or reinforce siloes in the organization and unintentionally limit free collaboration.

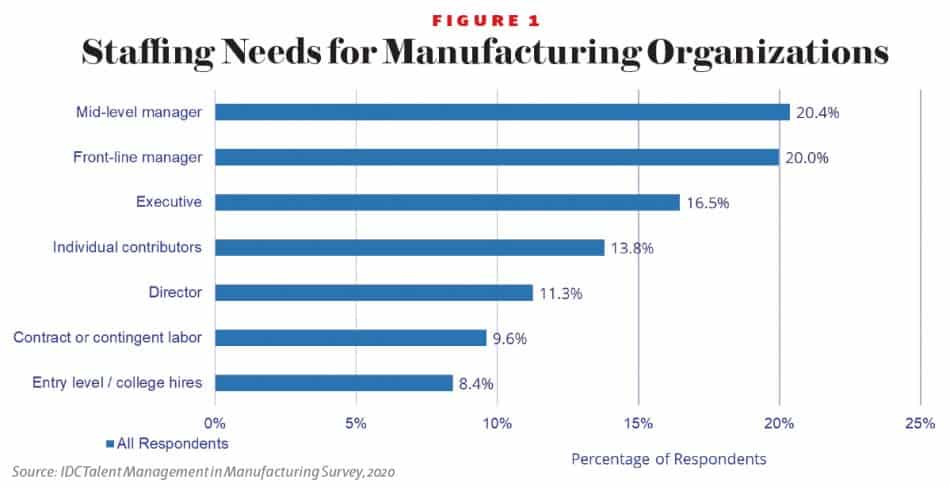

In fact, as Figure 1 shows, one of the biggest concerns manufacturing companies have today from a staffing perspective is not engineers and technical staff driving innovation, its middle managers.

The insatiable need for middle managers is directly attributable to the explosion of data and the increasing demands from senior management for faster decision-making cycles. But effective middle managers must have a unique combination of detailed domain expertise, creativity, charisma, and ambition. These traits are very hard to find in combination, especially for manufacturers, which tend to struggle with a skills gap and is generally viewed as less appealing than other industries by the younger workforce.

The Data Dilemma

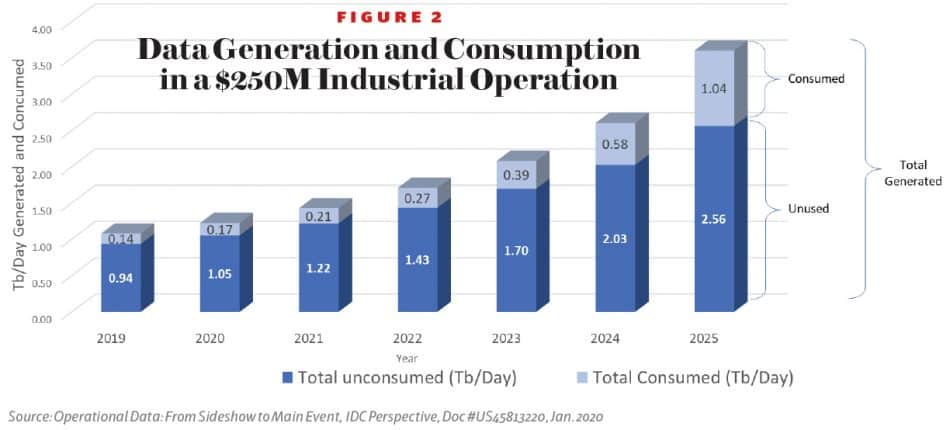

We are at the precipice of revolution in how manufacturing organizations operate. By 2030, we believe that the middle management layer of large manufacturing organizations will begin to compress until it eventually becomes a very thin layer of people who manage a highly structured decision-support system. That system will be based on the massive data flows coming into and out of the operation. As Figure 2 shows, data volumes are only increasing in industrial companies.

The four main areas driving this increase in data are connected operational assets, video as a sensor, supplier information, and connected product information. Manufacturing organizations will very quickly be overwhelmed not just by the data being generated, but by the demand from employees that need to consume it.

The dilemma around data leaves manufacturing companies with only a few options:

- Hire more middle managers in the areas of operations and IT to ingest, collate, and report information (which is already a difficult role to fill).

- Ignore the data and risk insights into operational performance that your competitors will have from their operations.

- Develop a consistent, defined, accessible system that can ingest, analyze, and present decision options to senior management rapidly and effectively — and take decisions back down to the point of activity.

- Employ artificial intelligence (AI) is as the main tool companies will have to manage the data dilemma. However, AI is itself a data monster that requires massive amounts of data to operate effectively.

Modern AI systems are very effective at ingesting large data feeds, rapidly analyzing the data, and prescribing answers or guidance that senior managers can use to make final decisions that impact operations and the company. AI can then take those decisions and rapidly translate them into tasks for staff in the plants. In fact, by 2030, a number of those tasks will be automated themselves.

The main takeaway is that AI represents the largest area of untapped potential to combat this manufacturing data issue: AI-based automation can flip decision making from human-led all the way to machine-controlled.

Digital Engineering: The New Middle Management

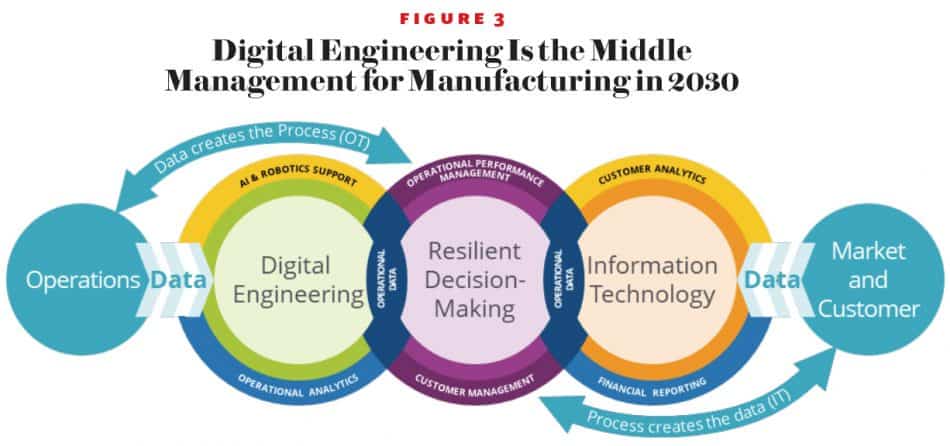

But these new data-centric systems are just one piece of the transformation to what IDC calls the Digital Engineering organization. IDC’s vision of the Future of Operations (IDC Perspective: Digital Engineering and the Future of Operations, April 2020) is for an operation based on resilient decision-making that is driven by customer and market activity. The core of that new organization is senior decisionmakers sitting within an AI-driven decision-making framework fed by business and market information from IT and operational information from Digital Engineering.

The DE organization is the new middle management in operations. This staff has a combination of domain expertise, some IT skills, and digital capabilities — which are some of the skills that middle management was developing anyway. Successful middle managers not only had domain expertise, but they had learned through experience how to work with IT. And they tended to lead the way in digital projects. All the Digital Engineering organization is doing is recognizing the shifting of responsibilities for operational data needs to the DE group staffed from various siloes in the organization.

But that transformation of middle management to DE will encompass completely new responsibilities. Instead of being the collators and interpreters from senior management to point of activity, they will manage the digital systems that do that through operationally focused data ingestion, data governance, cybersecurity collaboration with IT, AI, and analytics model management. Probably one of the biggest changes is that fewer people are needed to support these systems, compared to current human-focused middle management decision support infrastructures. IDC estimates that an AI-driven decision-support system operated by DE will reduce middle management staffing by 40% in 2030, and up to 65% by 2050.

This doesn’t mean that middle management is dead, but it does mean it needs to transform. In the near term companies need to create these support structures to hasten business and reduce bottlenecks. It’s also important to be realistic —at this moment in time I do not believe anyone can automate access to data and decision frameworks to the point where middle managers are literally exiting the workforce. Again, the transformation is that middle managers must become digital engineering staff. In that role they become less movers of data and more owners of a rapid and resilient decision-making framework. M

FOOTNOTES

1 Niall McCarthy,” Rise of the Machines: The Countries with the Highest Density of Robot Workers,” Forbes, Sep 28, 2020, https://www.forbes.com/sites/niallmccarthy/2020/09/28/rise-of-the-machines-the-countries-with-the-highest-density-of-robot-workers-infographic/amp

2 Ibid.

3 Emil Protalinski, “Boston Dynamics CEO talks profitability and the company’s next robots,” Venture Beat, Sep 14, 2020, https://venturebeat.com/2020/09/14/boston-dynamics-ceo-profitability-roadmap-next-robots/