New Ways to Solve Old Problems

Blockchain technology demonstrates significant potential for mitigating uncertainties related to product tracking, quality assurance, and adherence to ethical practices in supply chain management.

TAKEAWAYS:

● The implementation of blockchain-based solutions introduces an unparalleled level of transparency within the realm of supply chain management.

● Leveraging such solutions can cultivate relationships and enhance efficiencies within the supply chain ecosystem by advocating for, and contributing to, a uniform standard.

● Moreover, these solutions unequivocally bolster consumer confidence in the manufacturing process, as Smart Contracts ensure a trustful interaction among manufacturers.

In an increasingly globalized commercial landscape, supply chain transparency has ascended as a paramount issue for both corporations and consumers. The necessity to verify a product’s provenance, authenticity, and ethically-sound sourcing is integral to cultivating trust, endorsing sustainability, and adhering to regulatory compliance mandates. Traditional supply chain systems, however, are frequently plagued by information asymmetry, limited visibility, and compromised trust among participants. These prevalent challenges have catalyzed the pursuit of advanced technologies capable of transforming supply chain transparency. Blockchain technology, in particular, emerges as a potentially revolutionary solution.

Incorporating Transparency into a Beverage Company’s Operations

Blockchain technology stands as an innovative catalyst in the manufacturing industry, providing an unparalleled degree of pellucidity across the supply chain ecosystem. From its ability to authenticate consistent testing procedures and ensure quality control from raw materials to the finished product, to confirming the origin of all subcomponents from approved factories that adhere to fair labor practices – these solutions have the potential to change the way an organization does business. Moreover, it revolutionizes the processes associated with specification enforcement and payment guarantees between purchasers and producers, making transactions more transparent and reliable.

“Anytime a product is produced, stakeholders within the blockchain network verify the data and add to the block.”

Take, for example, the amplified visibility a beverage company could derive from the adoption of blockchain technology. Quality testing, a cornerstone of any manufacturing process, is given an extra dimension with the introduction of blockchain.

Imagine a pallet of 64 oz. orange juice bottles, already filled, that is prepared for final testing and shipping. Traditionally, the manufacturer would scan each bottle for conventional quality data based on factors like production line performance, added vitamin and mineral solution, and ingredient ratios. With blockchain technology however, these organizations can go a step further with the ability to provide verifiable information about every ingredient and packaging item that constitutes the final bottled product, thus ensuring a level of trust and transparency that has been previously unattainable.

The right solution can enable the manufacturer to see the acceptance testing both the cap and bottle went through before being packaged and shipped to the plant for filling – looking as deep as the liner material within the cap which can be viewed as a series of sheets, adhesives, and laminates — all with verified tracking to the film plant they were produced in. The cap and bottle could likewise be traced back to the resins the stock was produced from and the oils, plant material, and other bases that make up the resins.

The organic side of the equation is tracked just the same. While the oranges used may be grown by the company internally, the verification blockchain provides allows the company to prove that ethical practices are used for sustainable farming. Blockchain technology further supplies clarity into the quality and content of the fertilizer used for growing. Local farmers can join the network and contribute to the authentication process of the blockchain and further improve the security of the blockchain network.

These aforementioned capabilities stem from the distinctive architecture of blockchain technology, characterized by its network of nodes, each of which maintains an authenticated copy of the blockchain. Whenever a product is manufactured, stakeholders within the blockchain network validate the associated data before it is added to a new block. This verified block is then propagated across all nodes in the network, which collectively maintain the blockchain’s integrity and robustness. This distributed verification and record-keeping process significantly reduces the likelihood of any single network participant manipulating or fabricating data, thereby strengthening the trust and transparency inherent to the blockchain system.

How Blockchain Can Be Used to Track the Supply Chain

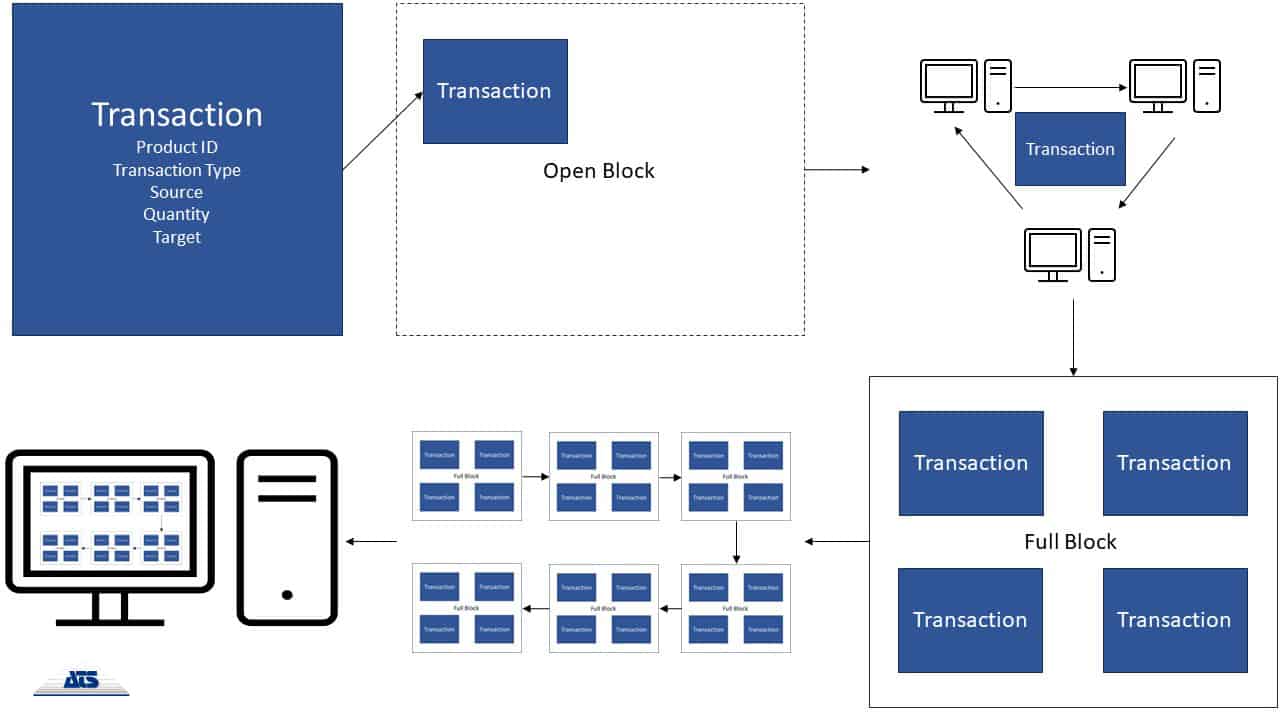

Currently, the most common use of blockchain technology is in the realm of cryptocurrencies. However, to harness the potential of this technology to enhance supply chain management, innovative approaches must be explored, as the priorities in these contexts diverge significantly. A typical procedure for generating a blockchain to monitor the progression of goods and materials through a supply chain could be conceptualized as follows:

1. Generate a transaction that holds the following information:

– Unique product ID (Part Number, Item Code, UPC, Barcode, etc.)

– Type of transaction (Production, Transfer, Sale, etc.)

– Source (Vendor ID, Plant ID, etc.)

– Quantity (Including units)

– Target (Purchaser ID, Plant ID, etc.)

2. Send the transaction to the peer-to-peer network.

3. The transaction is encrypted and sent to the nodes in the network.

4. One or more nodes run a series of equations against the encrypted transaction to verify that it is legitimate.

5. Transactions are collected until a full block can be formed.

Once a block has been added to the blockchain, its contents can be queried and some of its information becomes available to anyone who has access to the blockchain. Exactly which information should be widely available and to which blockchain users is still an open question.

Evaluating the Implications of Blockchain Implementation in Supply Chain Management

Several fundamental challenges arise when adapting blockchain technology to meet the unique demands of today’s supply chain. At its core, the structural design of most existing blockchains often conflicts with the requisites of supply chain applications. Despite our ability to innovatively repurpose this technology to facilitate effective supply chain operations, doing so successfully necessitates navigating a complex landscape of constraints and opportunities.

A pivotal consideration in implementing blockchain in supply chains is the degree of information transparency and accessibility within the network. One approach is for individual companies to maintain proprietary blockchains, with access granted to vendors, customers, and third parties on a need basis. Ideally, these independent blockchains could be interconnected, allowing a transaction to seamlessly transition from one blockchain to another. Alternatively, industry-wide shared blockchains could be established to enhance traceability, enabling end-to-end tracking of materials and components across the entire supply chain. Such a system would, for instance, enable precise identification and recall of products linked to a contaminated farm, in the event of an E. coli outbreak.

Understanding that most manufacturers have numerous internal systems already in place to track pertinent operational information, an additional consideration to ensure is not overlooked, is the solutions’ ability to integrate seamlessly with the diverse technology stacks that make up the inner workings of most manufacturing environments. Blockchain itself, however, is not a data collection solution; instead, it’s designed to disseminate previously collected data and communicate changes in data collected by other systems. The implementation of this innovative technology could prospectively bring added cost, effort, and complexity to the day-to-day operations that decrease the maintainability of the systems by local operators and engineers.

Conversely, one of the primary advantages of employing blockchain technology in supply chain management is the simplified compliance with diverse regulations across multiple jurisdictions. Given the rapid and frequent changes these regulations can undergo, the degree of flexibility associated blockchain solutions provide its ability to adjust the definition of a transaction and the tracked data accordingly.

If we look back at the juice example for instance, while monitoring a basic quality rating for orange juice may be sufficient today, future needs might demand tracking additional factors, such as viscosity or pulp content.

Industries with the Greatest Potential

Blockchain technology has the capacity to deliver both traceability and security to a broad array of manufacturing sectors. With ever increasing competition and dilemmas to solve, it is sure to have multiple applications. Wherever transparency can improve relationships between supplier and consumer, or two parties can benefit from guaranteed payment upon completion of contractual terms, blockchain can help.

Industries reliant on extensive assembly processes — including but not limited to automobile production, small machinery manufacturing, and computer assembly — stand to reap substantial long-term benefits at a manageable initial cost by incorporating blockchain technology. The competitive edge for these companies hinges on the quality of their own manufactured parts as well as the reliability of the supplied sub-components. Given the existing adoption of systems such as PLC networks in many factories, the foundational infrastructure for blockchain technology integration is already in place. Capitalizing on the understanding of these pre-existing networks, the introduction of blockchain technology could provide digital traceability, aid in regulation adherence through smart contracts, and affirm the genuineness of OEM-produced parts.

“The ability to determine whether a supplier is in compliance or if ethical harvesting practices are being used may make the difference between foods and medicines of the highest quality.”

Further, other sectors such as the food service, agricultural, and pharmaceutical industries could vastly benefit from the transparency brought by blockchain in relation to the sourcing of foods, fertilizers, and chemicals. The ability to ascertain supplier compliance or to validate the ethical practices used in harvesting could be pivotal in ensuring the output of top-tier food products and medicines. While the adoption of blockchain technology might pose challenges in some instances, its promise as a secure, reliable solution to the need for farm-to-table visibility and guarantee of medicinal authenticity cannot be understated in today’s manufacturing landscape.

Practical Applications of Blockchain in Supply Chain Management

Numerous applications of blockchain technology within supply chain management already exist, effectively addressing a wide variety of challenges through its familiar technological framework.

IBM Food Trust uses a network of resellers, growers, processors, shippers, and others involved in the growth, development, delivery, and sale of food. The security that blockchain provides, facilitated by the network IBM has created, allows for assurances around the quality of the food being delivered and traceability from farm to table for products worldwide. The goal of Food Trust is to provide healthier food options for communities and strengthen the relationship between buyers and sellers. By enhancing traceability of products, consumers can verify the quality of the food being purchased. This improves the reputation of the contributors within the supply chain and improves business prospects for all.

Other companies like FedEx and Walmart have already begun utilizing blockchain to improve product tracking. FedEx uses blockchain technology to improve delivery tracking and reduce customer disputes with delivery issues. Similarly, Walmart utilizes blockchain in their process for product tracking at both point of sale and point of purchase to aid in efforts like product recall, while simultaneously helping leadership determine needs for supplier changes.

The Path Ahead: An Increasingly Interconnected Future

The integration of blockchain-oriented solutions presents significant potential for enhancing supply chain transparency and overcoming the difficulties typically associated with conventional supply chain systems. While an array of alternative technologies and strategies exist to fulfill these objectives, the relevance of blockchain as a substantial contender cannot be discounted. Irrespective of the technology employed, the assertion holds that firms capable of capitalizing on the benefits of a more transparent supply chain could uncover a unique competitive edge, and perhaps more critically, a novel value proposition for their end-users. M

About the author:

Travis Goertz, VP, Americas at ATS Applied Tech Systems.