How Manufacturing 4.0 Got Its Name—and Why It Matters

Flashback to 2015: “Hamilton” debuted on Broadway, millennials surpassed baby boomers as the largest U.S. generation and the term “Industry 4.0” was gaining traction in manufacturing circles. It was also when the Manufacturing Leadership Council created a conceptual framework called “Manufacturing 4.0.”

So what is the difference between Industry 4.0 and Manufacturing 4.0? While the terms may not sound all that distinct from each other, Manufacturing 4.0 represents the MLC’s commitment to a far-sighted, holistic approach to manufacturing’s tech-enabled metamorphosis—one that has served it well in over the past eight years.

The background: The 4.0 movement started in Germany in 2011 when the German ministries for education, research, economic affairs and energy developed a strategic initiative that would push forward the digital transformation of industrial manufacturing.

- They named this initiative Industrie 4.0. It featured an action plan that combined policy initiatives, public–private funding, strategies for technology implementation and the identification of business drivers and barriers.

The difference: For the MLC and its members, Manufacturing 4.0 is made up of transformations in three different arenas: technology, organization and leadership.

- Contrast this with Industry 4.0, which covers only technology topics—specifically nine pillars of technological innovation, which include autonomous robots, big data, cloud computing, IoT, cybersecurity, systems integration, simulation, AR/VR and additive manufacturing.

- “MLC, of course, covers all of these technologies, but, importantly, adds the dimensions of organizational and leadership change as part of its perspective on manufacturing’s digital transformation,” says David R. Brousell, the MLC’s founder, vice president and executive director.

MLC in action: While the MLC does provide member resources that focus on specific technologies and their uses in manufacturing operations, it also covers topics such as how leaders can prepare their workforce for digital transformation, how organizations should be structured to make business decisions based on manufacturing data and how leaders can ensure they set their teams up for digital success.

- Additionally, the annual Manufacturing Leadership Awards recognize not only high-performing digital manufacturing projects but also outstanding individuals who demonstrate both technological understanding and strong personal leadership.

M4.0’s continued evolution: Today, the MLC continues to use Manufacturing 4.0 as the overarching framework for its member companies’ activities.

- Its influence is apparent in the MLC’s annual Critical Issues Agenda, a member-created list of key business drivers and enablers of digital manufacturing.

- The agenda covers technological advances like smart factories and data analytics, alongside the organizational ecosystems that put such advances into operation—from the leaders who direct them to the cultures that make them succeed.

The Future of M4.0: As the MLC gets ready to set its 2023–2024 Critical Issues Agenda, it will continue to take a holistic approach to the technological changes sweeping the industry by recognizing the importance of people in making those transformations happen.

Go deeper: You can learn more about Manufacturing 4.0 by downloading the MLC’s white paper, Manufacturing in 2030: The Next Phase of Digital Evolution; reading a recent report, The Future of Industrial AI in Manufacturing; or attending its Aug. 30 virtual Executive Interview, Shifting from Disruption to Growth.

Extrapolating from the results of NTT DATA’s recent research report, Innovation Index: Shifting from Disruption to Growth, John Petrusick, Managing Director, Manufacturing — Data and Analytics Practice, offers insights into the future of data in the latest in MLC’s Manufacturing in 2030: Crystal Ball series.

Data-Driven Transformation and the Future of Human-Centric Innovation by 2030

By 2030, I envision a significant change where data flows freely from sources including the shop floor, enterprise resource planning systems and third-party external providers. Manufacturers will centralize, harmonize and analyze data to enable real-time action. This encompasses all actions, including automated actions, to maximize business efficiency. Doing so will impact aspects of the business ranging from daily production operations on the plant floor, to engaging customers in selling activities, to the development and testing of new products.

With respect to sales, products and services, manufacturers will create seamless customer experiences in which customers can purchase goods using their preferred interface. Infusing data into a design thinking-led approach will also improve overall experiences once the product is in use. From an operational data perspective, employees on the shop floor or within the business will see performance data in real time and act instantly.

Highly commoditized or repetitious manufacturing environments might function as a largely ‘headless’ or ‘dark’ operating environment. Such environments rely on processes that are highly routine, reproducible and repeatable. They will, therefore, be able to leverage physical robots in the ecosystem to take the place of today’s manual interventions. These environments will have a significant advantage in productivity and efficiency while improving safety. They may use technologies including robotic process automation for monitoring and control, generative AI for requests from outside observers, and physical robots to take actions when physical interventions are required. Nevertheless, I do not foresee a near-term scenario in which manufacturing is 100% automated with no human involvement. Through 2030 there will continue to be entire plants, production lines and core processes where the need for creativity will keep humans integral.

Empowering Manufacturing through Data-Driven Insights

Data’s role will evolve naturally, and part of the role will entail solving problems. But the primary function data will serve is to enable insights that guide the actions of individuals, software or machinery so that they deliver increasing business value.

Currently, the data sphere focuses on providing high-quality, reliable data to manufacturing business actors — humans, software, physical robots and so on. These actors need specific analytics or insights in forms such as real-time or near-real-time Key Performance Indicators from a production line on quality to make value-adding decisions. When such data indicates deteriorating quality, we may need to halt the line and perform a root cause analysis to remediate the issue to re-gain performance with thresholds.

In a preventive maintenance scenario, telemetry data from machinery might show that a machine will fail within two hours. A worker would then receive an alert prompting them to reallocate capacity from that line to others, if possible, to allow for necessary maintenance. Alternatively, in a product development scenario, we might be able to design and test a product virtually. This will help manufacturers create the right product to the correct specifications the first time around, thereby reducing time to market.

As the right analytics become available in 2030 and beyond, manufacturers will gain the real-time insights to deploy end-to-end automation using autonomous tooling. Automation may extend even to the point of delivery, potentially with no human intervention. This data-driven automation will create additional value through improved efficiency and shorter time to revenue generation.

Unlocking Future Manufacturing Success for Enhanced Plant Operations

Currently, we are observing advantages in various aspects of plant operations such as preventive maintenance and quality improvement. For example, vision robotics is already providing assessment data at all stages of manufacturing, from raw materials to finished products. Moving toward 2030, we see manufacturers that start or continue to follow data and analytics best practices gaining significant benefits. These benefits will be in part due to the advantages of an expanded role for AI and the benefits it can provide, enabled by continuously improving data quality. In combination with the Internet of Things (IoT), AI will have the potential to help manufacturers build factories that are more agile, transform their workforce, make significant progress against sustainability objectives, improve security and compliance, and more. Again, this is contingent on establishing the right data standards and practices.

Building Technology Ecosystems that Unleash Data’s Power

Realizing the potential of data as we are discussing it here will not require any singular technology, but rather an ecosystem of solutions working in concert.

Even today, when we consider the data stack, we emphasize cloud-native data solutions that shift away from monolithic platforms towards an ecosystem of best-in-breed, loosely coupled and high-use technologies and tools.

Data in 2030 will similarly require an array of elements. These range from IoT sensors on machines — many of our clients already have such systems in place or are testing them — to the ability to centralize this data and provide global visibility to it. To cite just one example, manufacturers will increasingly implement machine vision, which involves converting video into data for analysis across a wide variety of use cases from quality inspection to safety compliance.

Finding Future Success by Navigating Data’s Complexities to Overcoming Storage, Reliability, and Analytics Challenges

Data storage and reliability challenges I alluded earlier to the need for data centralization. Many of our clients have already conducted pilot projects or have implemented some of the technologies previously discussed in various plants. But most have yet to successfully centralize their data for global visibility. At the heart of this issue will be the need for investment as, historically speaking, manufacturers have not made the significant investments in their data ecosystem needed to resolve this key dependency.

On the flip side, despite the importance of data centralization, there are cases where manufacturers will need to balance their need for centralization versus a need for rapid analysis and action. In such cases, the challenge will be how to embed intelligence into a local system and thereby enable machine-learning-based decision-making at the edge.

Both challenges will be pervasive. Consider a global manufacturer or a multi-site operator aiming to achieve visibility across all their operations. They may have plants that are almost entirely automated with minimal human intervention and others that have a larger human presence. Both environments present the need for clear visibility into each plant’s operations via data, so the different plants might all require a sort of “control room” view. The first step to enabling that view is to store the data on which to base the view. The data may reside in a centralized location or at defined edge locations.

The next step is to ensure the data’s reliability, whether the data is in storage or in transit. This phase involves a data management component that underpins everything before proceeding to the analytical stage.

Data analytics challenges

After overcoming data storage and reliability challenges, manufacturers can shift to the challenge of data analytics. For most manufacturers, the data management in place today is not at a level where they can trust the data without question.

At the same time, there are potential solutions to these challenges from which two separate elements come to mind. First, from a data management perspective, manufacturers could use machine learning algorithms to conduct quality checks and make recommendations on how to master the data. This process is crucial to effective analytics.

The second element pertains to both the techniques of analysis and the human factor involved. Often, achieving success with analytics depends on clearly defining the question we are trying to answer and the action we aim to take. When discussing data and analytics, our shop floor personnel may say they lack the needed technical knowledge. But the reality is, they do not need to understand all the complexities of data. Instead, as data professionals or leaders, we should focus on the actions they take and the decisions they must make in their roles, and develop analytics capabilities accordingly.

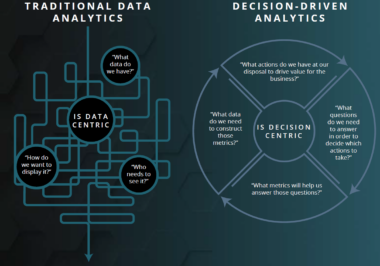

Traditional data analytics versus decision-based analytics

Anticipating the evolved and central role the workforce will play in manufacturing in 2030, decision-driven analytics is about determining the necessary actions the workforce must take to create value in a business. First, we need to ask the right questions to guide these actions. We then identify metrics or measures to establish decision points and gauge results. Lastly, we must determine the type of data needed to create those metrics and measures.

The decision-driven approach to analytics can be simplified to four elements: actions, questions, metrics and data. The goal is to understand the actions that create value in a business, then enable these with data strategies and analytics that also yield value.

Fostering Data Literacy and Collaboration to Bridge the Gap Between IT and Business for Action-Oriented Analytics

From a technologist’s perspective, it is essential to understand what is happening in the business and what actions or decisions we are informing or enabling with the technologies we are deploying. As such, IT organizations must enhance their engagement with the business. Simultaneously, business actors might need to upskill their data comprehension.

This does not mean that all business actors must learn to write SQL queries and Python scripts or be up to speed on the latest data science modeling techniques. Rather, it means they must have the requisite level of data literacy to understand the actions they take in their business and how data could help them make better decisions. Approaching it from this angle will help manufacturers find success, in part because business teams and IT organizations are thinking similarly and working towards achieving specific business outcomes.

Infographic. Aspirent, an NTT DATA Company.

To bridge the gap between IT and business teams, we have found success using a structured Decision Architecture framework focused on the following critical topics:

- What actions do we have at our disposal to drive value for the business?

- What questions do we need to answer in order to decide which actions to take?

- What metrics will help us answer those questions?

- What data do we need to construct those metrics?

This decision-driven framework offers manufacturers a more targeted, action-oriented approach to data and analytics that enables the creation of specific business cases and a clear path to unlocking their data’s potential.

Empowering Manufacturing Excellence by Navigating Data-Driven Insights for Collaborative Success and Outcomes

Ultimately, data analysis and subsequent actions depend on the workforce. It is essential to ensure that we provide data in a format that the workforce can use effectively. Similarly, the speed and effectiveness with which currently top-of-mind technologies can grow is constrained by the need for data that is accurate, complete, reliable, relevant and timely. Data and analytics reside at the core of high-value business outcomes — whether driven by the workforce, AI or combinations thereof. Potential outcomes range from creating more resilient supply chains to accelerating innovation and delivering new services to engaging customers in new ways.

In short, although we have covered a lot of ground here, my single most important piece of advice is to create and maintain a focus on driving collaboration at the intersection of IT and business teams with a focus on the business context and outcomes of data usage. By doing so, manufacturers will be able to increase the business value that data solutions create and avoid complications preventing the realization of that value.

If this data discussion has sparked your interest, we invite you to check out our infographic “Innovate Confidently with Data-Driven Decisions.” It features relevant data from the 2023 NTT DATA Innovation Index.

About the Author

About the Author

John Petrusick is a Data and Analytics Managing Director at NTT DATA, serving as the Manufacturing Industry Lead. In his role he advises manufacturers on how best to leverage their data to create business value-driven, actionable, and analytic insights to increase efficiency, sustainability, and competitiveness. He is passionate about helping clients solve their data challenges, specifically in data governance, architecture, engineering and integration, advanced analytics and business intelligence, and intelligent automation, as well as helping them implement strategies to drive digital transformation.

Six Key Takeaways: Be ‘Predictive’ to Be ‘Preventive’

A recent MLC Master Class focused on how manufacturers are using condition monitoring and predictive maintenance to avoid downtime, maximize productivity, and enhance operational efficiency. Micah Statler, Director of Industrial Technologies at Advanced Technology Services (ATS) shared his experiences and expertise in an engaging conversation with MLC’s Senior Content Director, Penelope Brown.

Here are six key takeaways from their discussion:

1. Transforming data charts into prescriptive actions

According to Statler, no matter how mature a maintenance organization is, any change is difficult and change management techniques are important because there are outside influences and new tools involved. But transforming data from a squiggly line on a chart into action is paramount.

“The biggest challenge facing any manufacturers out there today is not necessarily the collection of data, but the interpretation of that data to gain a level of insight that allows them to be successful in taking action and recognizing a return,” Statler said.

Figure 1 – maintenance maturity levels

He identified four maturity levels for overall equipment effectiveness (OEE) and uptime reliability: reactive, preventative, predictive, and precision. To find where an organization falls on this maintenance maturity scale, Statler provided a few assessment questions:

- Are you planning your work?

- Are you able to put a plan forward and able to execute that without a lot of schedule breakers?

- Are you able hit your production targets?

2. Eating the condition monitoring elephant one bite at a time

For companies looking to implement best practices for condition monitoring, don’t try to boil the ocean. Instead look to where you’re seeing the most impactful downtime and eat the elephant one bite at a time. Some areas to look at first include where you are spending the most on MRO parts and repairs, what problems cause your most expensive maintenance labor, and what assets experience issues regularly.

Statler also recommended avoiding a single firefighter to look at these issues.

“We have an opportunity to do it in a much more efficient way, and also in a way that doesn’t mean it is an individual contributor, and therefore your progress – if you’re not dependent on an individual – can’t backslide from it. It’s more ingrained in your culture and it just becomes how you do business,” he said.

3. Combatting alert fatigue with collaboration

“Cross-functional teams are critical. It’s not just about the data collection,” Statler said. “We have to do something with that data, and we have to really align on what the ultimate outcome is.”

Further, to avoid what Statler called “alert fatigue,” there must be trust and the right level of communication between the factory floor and those asking them to take an action from the data. Change management comes into play here, and the collaborative team – including data scientists, developers, technology departments and the maintenance team – needs to be realistic about how mature a company’s maintenance program is.

4. The beautiful circle: AI and data analytics

Analytics and statistical process control has been around for a long time, but newer technologies like artificial intelligence (AI) help manufacturers see broader trends and take findings from one measure to another.

To illustrate this, Statler mentioned the core four traditional predictive maintenance analysis: oil, vibration, ultrasonic, and thermographic.

“What we’re able to do with the tools that we have today is, say there’s something else that I want to measure, we can apply a lot of the same models to that,” he said. “We’re getting a lot better at being able to not only say there’s a problem, there’s a change in that trend, but being able to predict what is the remaining useful life of that component that’s being monitored.”

“Ultimately,” he said, “we don’t want to get to a position where, when we notice a change in trend, we make a component change. We want to be at a point where we’re able to make minor but precision adjustments to anything that’s being measured.”

This is where AI and advanced analytics come into play.

“The better we can deliver the service, the better we can train the model, the better we can deliver the service. It’s a beautiful circle,” Statler concluded.

5. Avoiding “service on a stick” partners

For those looking to partner with a technology provider to achieve better predictive maintenance, it’s as important to look at what a company does now as it is to look at the company’s vision for the future.

“You want to pick a partner that is going to grow long-term with you and be able to work within the platforms and the tools and the data sets that you have today and in the future,” said Statler.

He also recommended looking at the service offering, itself: is it an end-to-end solution that not only collects the data and monitors the equipment but also helps you interpret the data in real time?

Statler cautioned against providers who offer one-size-fits-all solutions, and likened them to getting a plain corn dog at the fair.

“There are an infinite number of options out there for you to buy hardware, tons of platforms available, and a lot of them have coupled those together,” he said. “Internally, we call that ‘service on a stick.’”

6. A fully digital future for condition monitoring and predictive maintenance

Condition monitoring and predictive maintenance are primed for a future full of innovation.

“The technology will be accelerating so quickly and be so ingrained that we’re not even going to notice that the industry has transformed. It will be fully digital,” he said.

In fact, he pointed to technologies that we’re already seeing today. In particular, smart hands or augmented reality tools will transform the business, and people will view dashboards through heads-up displays in proximity of specific assets.

Beyond the technology itself, Statler expects to see a shift in the technical capabilities of on-site staff as well.

“There’s going to be a real integration of vendors with technology vendors and equipment vendors being able to, real-time, see what maintenance technicians see – and that’s where the smart hands come into play,” Statler said.

MLC members may access the full recording under Master Class in the Resource Center of the Member Dashboard.

More information about the Master Class Series is available online.

Balancing Resiliency and Efficiency

Supply chain executives face a new optimization problem: becoming more resilient while minimizing costs. Here’s how to strike the right balance.

TAKEAWAYS:

● Disruptions over the past few years have exposed vulnerabilities in manufacturers’ existing supply chains.

● As a result, conventional approaches may no longer be enough to achieve the desired level of supply chain assurance.

● This article highlights a range of new approaches and tools manufacturers are deploying as disruption becomes the norm.

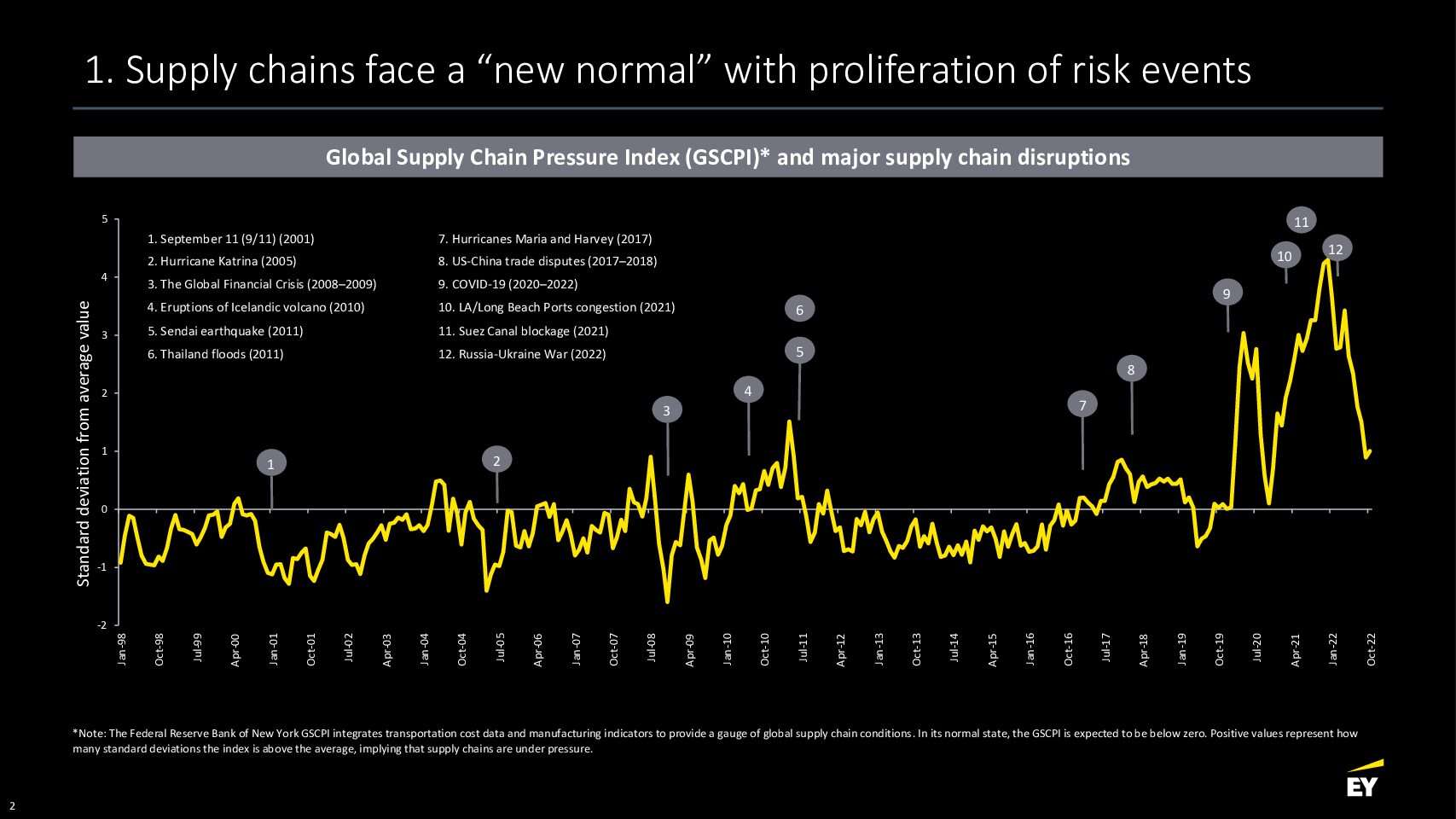

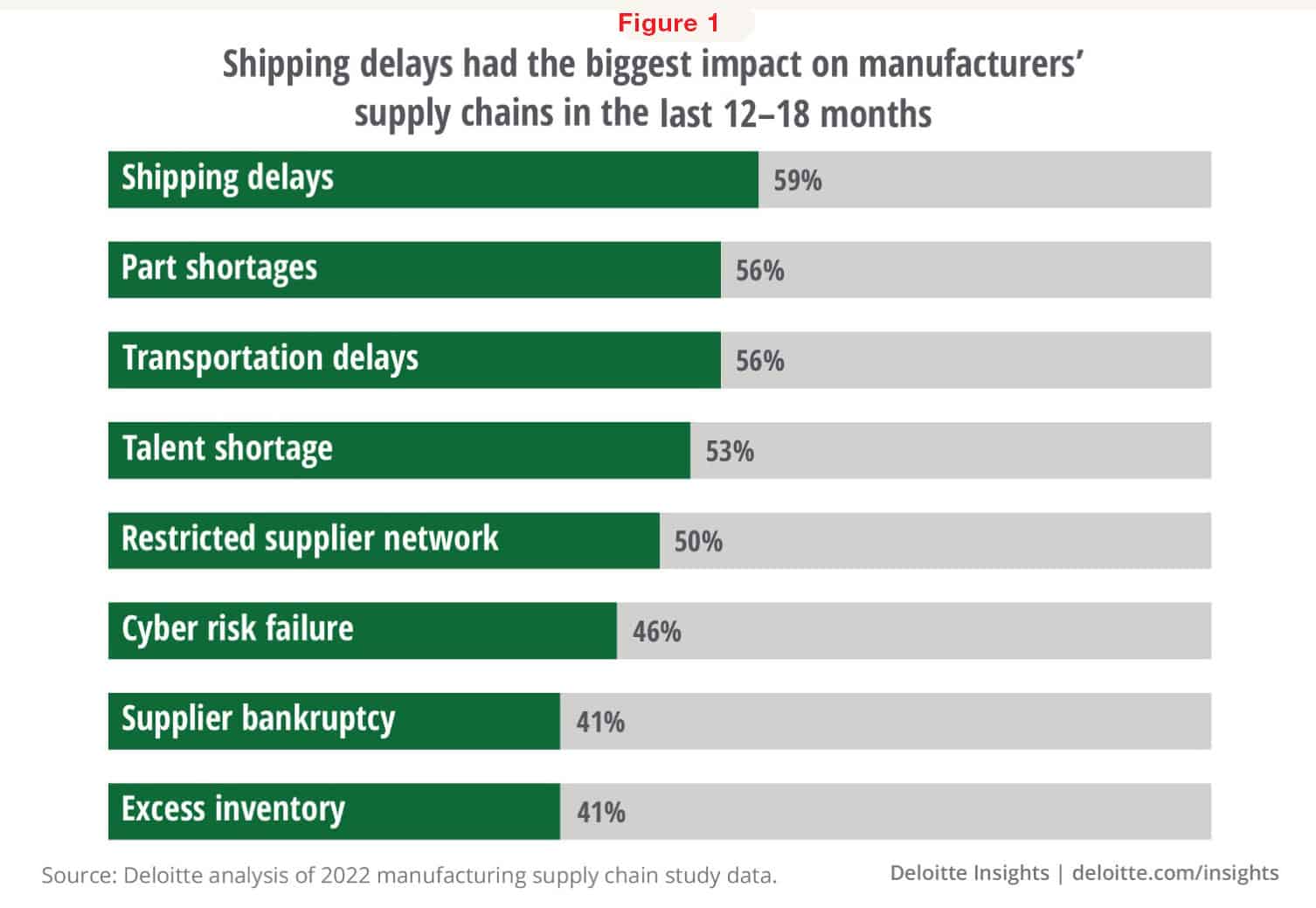

Shipping delays, parts shortages, and transportation delays due to truck driver shortages and congested ports had the greatest impact on manufacturing companies in the past 12–18 months, according to survey respondents (figure 1). Production and profits are the two key areas where this impact has been felt, and a majority of respondents report a negative impact to profits of up to 13%.

These factors suggest that supply chain executives are working to solve a new optimization problem with more stringent constraints: Costs still need to be minimized, yet resilience and redundancy should be built in to assure supply. This calculation is ever more challenging given the rising costs of energy and materials and labor, current workforce shortages, and ongoing logistics challenges resulting from two years of pandemic disruptions.1

The exigencies of the current environment are bringing a new focus on time-tested skill sets. Several supply chain executives surveyed emphasized that in volatile environments, the familiar skill of supplier relationship management can become even more important to avoid disruption. However, junior employees may need to be taught these skills as most are used to working in a demand-driven environment. The sudden shift to a supply-constrained business model meant not all employees were armed with the needed relationship management skills to work closely with suppliers as partners to manage forecasts, lead times, inventory strategies, and costs.

In many cases, this partnership has developed as quarterly supplier reviews turned into daily calls between senior supply chain executives and the CEOs or CFOs of their suppliers, sharing information and helping each other navigate the business environment (figure 2). For example, one company worked through its supplier as a partner to find an alternate source of chips during the chip shortage, thereby achieving greater flexibility and visibility. Another company worked closely with suppliers as shipping options from Asia were reduced and freight was moved to air cargo, which incurred higher costs.2

Proactively Managing Multiple Tiers

Supply chain executives have been drawn into management not just of their primary suppliers, but increasingly of secondary and tertiary suppliers as well. Several executives interviewed noted that previously they did not get involved beyond Tier 1, but the dynamics of the current environment drove a need to increase visibility. For example, if Tier 3 suppliers were unable to give firm dates for shipping, often this potential weak point wasn’t visible to primary suppliers or to the company itself, and potential delays were not flagged early enough. To address this risk, one company interviewed has begun working closely with its own suppliers to apply transparent decision-making based on metrics and benchmarking to that supplier’s suppliers. This can provide the company more visibility and clarity in terms of the companies with whom its suppliers are contracting.

The semiconductor shortage, which has affected industries from automotive to handheld electronics, raises the question of how to achieve resilience when the market is highly concentrated. In the semiconductor supply chain, some suppliers are unique—for example, worldwide, there’s only one epoxy supplier and two suppliers of cutting-edge chips.3 Moreover, the global semiconductor industry has been running at over 95% utilization since December 2020, which is well over the 80% utilization rate normally considered full capacity, suggesting additional production capacity is needed.4

“Supply chain executives have been drawn into management not just of their primary suppliers, but also secondary and tertiary suppliers.”

The passage of the CHIPS Act in 2022 has helped jump start investment in additional production capacity in the United States. For example, a semiconductor manufacturer is considering building four semiconductor chip fabrication plants (fabs) at a cost totaling nearly US$30 billion. Intel announced plans for an initial investment of more than US$20 billion to construct two new fabs in Ohio, a new region for chip-making.5 And it isn’t just US-based companies considering adding capacity in the country: South Korea’s Samsung has proposed a US$17 billion fab in Taylor, Texas, and has also recently submitted an application with the Texas comptroller outlining a long-term plan to build up to 11 chip-making plants in Texas, an investment that would be worth more than US$192 billion in the coming decade. Arizona is also poised to receive investment for chip manufacturing.

Supplier Risk Considerations

As supply chains elongate and supply bases increase with new sources created, procurement teams are becoming more central to enterprise risk management. Procurement and supplier risk management functions should work more closely with suppliers and their compliance and risk management departments. Executives interviewed for the study are engaging more often and earlier with third-party risk management protocols. The historic approach of a point-in-time assessment, even if done annually, may no longer be sufficient for organizational risk management objectives. Companies must sense, monitor, and be ready to take action as needed.

Sensing: Leading companies are beginning to use intelligent sensing of data, including social media, in combination with assessments and investigations, to enhance the effectiveness of their suppliers in managing third-party risk.

Monitoring: As companies identify their critical risk domains, from financial health to geopolitics to cybersecurity, they can develop technology-enabled processes to proactively monitor their third-party ecosystem and identify the early warning signs that could trigger action.

Taking action: For quick action, such as switching to a new supplier, having a preapproved response plan can be critical. One company requested all its vendors participate in response planning, outlining COVID-19 contingencies, such as if parts weren’t received and trucks stopped delivering. Similarly, additional suppliers need to be “prequalified,” such that the contracting work could be done already, shortening lead times.

Scenario planning: Management teams can also identify potential scenarios in advance, along with sub criteria that help indicate the best response plan in a given situation. Executives should decide in advance who has decision-making power in each scenario and how to, for example, reduce downtime and address breach of contract incidents.

Moving Away from JIT Approaches

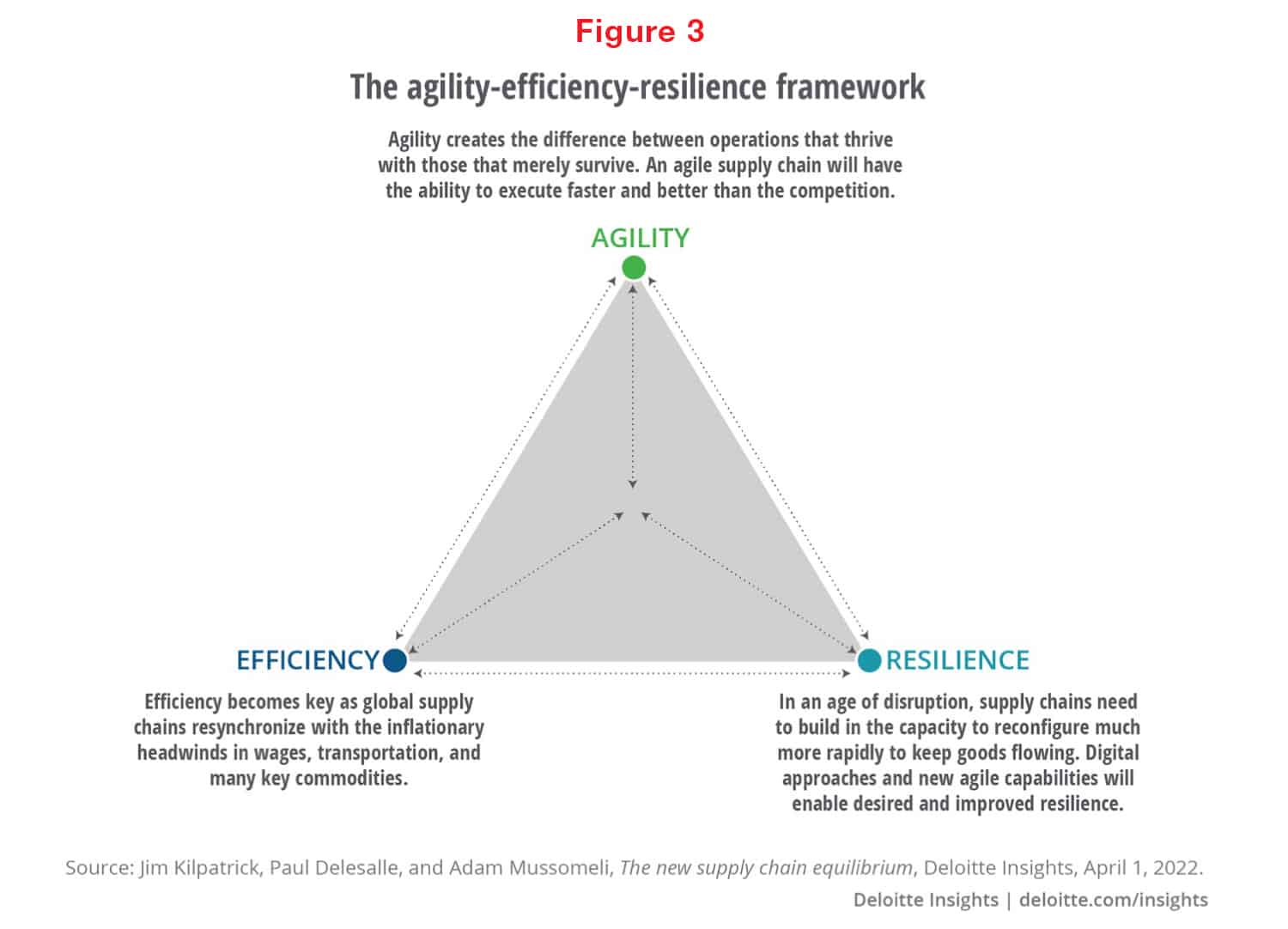

Manufacturers seem to be drifting away—maybe only temporarily—from just-in-time approaches to help manage the constraints of higher labor and materials costs, logistics bottlenecks, and labor shortages. One executive explained that in early 2021 his team decided they needed to move away from the focus on cost and orient increasingly on business continuity and customer satisfaction. Executives draw a distinction between operational challenges, which can be solved through improved supplier relationships and visibility, and logistics and external challenges, which are out of the supplier’s or company’s control. However, to manage external challenges, supply chain leaders need to be well-equipped and strike the right balance between agility, resilience, and efficiency (figure 3).6

Building out agile processes: agility and flexibility are potential game changers. Flexibility of design could be used to standardize product-specific parts, allowing a standardized part to be used across products that would require minimal customization. For example, Tesla uses a number of chips in its vehicles for various control and infotainment systems, and its self-driving software. During the ongoing semiconductor shortage, Tesla swiftly changed to new microcontrollers, while simultaneously developing firmware for new chips produced by new suppliers.7

Mitigating transportation challenges: the persistent labor shortage in manufacturing, which has been exacerbated by the pandemic, has contributed to port delays, slower warehouse processing, and a truck driver shortage. As one executive explained, no matter how reliable your supplier, a labor shortage at a port can still cause a shipping delay. To address this disruption, building redundancy or resilience is needed. One company shared that it is looking at diversifying supply routes on the West Coast, possibly adding a Canadian port.

Developing resiliency: to build resiliency, in some cases manufacturers are actively partnering with other manufacturers or are investing in their suppliers to support building more production capacity. Executives interviewed described a continuum of collaboration ranging from buying capacity in advance from suppliers to actually taking equity stakes in certain critical suppliers. There have been several examples in which industrial manufacturers are expanding their activities into adjacent areas. Our study highlights that Tier 1/Tier 2 suppliers are likely to coinvest or partner with other Tier 1/Tier 2 suppliers in emerging technologies to develop new capabilities and advance through logistics and transportation challenges.

“Manufacturers seem to be drifting away – maybe only temporarily – from Just-in-Time supply chain approaches.”

In one example, an industrial technology company made an acquisition to expand its presence through existing distribution channels, and also to expand in the aftermarket filtration space. In other cases, investment is focused on fostering more competition in a given market, ultimately to build more choice among existing producers. These additional investments could clearly have an impact on the industry’s cost structure, but that reduction in margin could be worth the resilience ultimately provided through developing a deeper market with more producers.

Getting to Resiliency

As manufacturing executives solve the current supply chain optimization problem, they are leveraging familiar mitigation strategies to balance resilience with efficiency. But they are also wielding new skill sets and tools to manage the tougher constraints of rising costs, labor shortages, and logistics bottlenecks to achieve agility.

Here are three sets of recommendation to boost resiliency:

Strengthen existing supplier relationships to increase resilience:

● Work closely with suppliers to help them apply metrics to their Tier 2, 3, 4 suppliers

● Agree on mutually beneficial KPIs so that all parties know what to expect from one another

● Help suppliers maintain data on their suppliers’ throughput to boost transparency and assurance

● Train newer employees on relationship management

Engage with multiple suppliers to balance efficiency and resilience:

● Correctly calculate the benefits of engaging multiple suppliers with the costs of lower margins and reduced control

● Use dual sourcing to achieve some cost control where possible, evaluating investing in development of additional suppliers in a niche market

● Have scenarios in place and alternative suppliers preapproved, conducting practice drills to make contingency plans more effective

● Locate additional production or alternate suppliers close to markets to reduce transportation costs and exposure to shipping delays

Employ digital solutions to boost efficiency and resilience:

● Implement warehouse automation in response to workforce shortages

● Move to digital solutions that increase visibility beyond Tier 2 suppliers

● Boost collaboration by initiating high-level information-sharing between all parties with the help of easy to-use technologies

● Track potential sources of logistical disruption such as restricted routes and workforce shortages

Manufacturing executives are acutely aware of causes for both internal and external disruption and are taking steps to build redundancy into supply chains to assure business continuity. Though these efforts may lower margins, they can increase agility, reflecting the new balance that manufacturers are achieving between efficiency and resilience. N

Endnotes

1. Stanley Porter and Kate Hardin, “Energy and commodities outlook: Disruptions from the Russian invasion of Ukraine,” Wall Street Journal, June 3, 2022.

2. Insights gleaned from manufacturing executives’ interviews conducted in July 2022.

3. Deloitte, Anchor of global semiconductor: Asia Pacific takes off, 2021, p. 9.

4. Semiconductor Industry Association, Increasing chip production: Industry shouldering in to addressing shortages, 2022, p. 1.

5. Intel Corporation, “Intel announces initial investment of over €33 billion for R&D and manufacturing in EU,” news release, March 15, 2022.

6. Jim Kilpatrick, Paul Delesalle, and Adam Mussomeli, The new supply chain equilibrium, Deloitte Insights, April 1, 2022.

7. Lambert, “How Tesla pivoted to avoid the global chip shortage that could last years,” Electrek, May 3, 2021.

About the authors:

Paul Wellener is a Principal within the US Industrial Products & Construction practice with Deloitte Consulting LLP. He has more than three decades of experience in the industrial products and automotive sectors and has focused on helping organizations address major transformations.

Stephen Laaper is a principal at Deloitte Consulting LLP and a manufacturing strategy and smart operations leader in Deloitte’s Supply Chain & Network Operations practice. He helped build Deloitte’s Digital Supply Networks (DSN) methodology that uses existing and “next gen” technologies to drive efficiencies in operations and across the supply chain.

Kate Hardin, executive director of Deloitte’s Research Center for Energy and Industrials, has worked in the energy industry for 25 years. She leads Deloitte’s research team covering the implications of the energy transition for the industrial, oil, gas, and power sectors.

Aaron Parrott is a managing director with Deloitte Consulting LLP. With more than 20 years of experience in supply chain and network operations, Parrott’s focus is helping clients complete large- scale transformation in the supply network, developing analytic solutions to address difficult business issues, and implementing digital solutions to manage complex supply networks.

This article contains general information only, does not constitute professional advice or services, and should not be used as a basis for any decision or action that may affect your business. The authors shall not be responsible for any loss sustained by any person who relies on this article.

Resilience Is Key for Today’s Supply Ecosystems

With disruption and change being the new norm, manufacturers need to ensure their supply networks and ecosystems can adapt to changing needs.

TAKEAWAYS:

● Recent disruptions have highlighted the need for supply networks and ecosystems that can manage the physical movement of goods and the financial side of the supply network.

● Key aspects of a resilient supply chain and ecosystem include redundancy, flexibility, collaboration, information sharing, technology, and data-driven insights.

● It’s important to align with strategic partners that can provide real-time end-to-end visibility, enhanced communication, data-driven decision making, automation and efficiency, traceability within the supply chain, and collaborative Innovation.

In an increasingly interconnected and globalised world, the importance of resilient supply networks and ecosystems cannot be overstated. Supply networks encompass the complex web of suppliers, manufacturers, distributors, and customers that facilitate the flow of goods and services. Meanwhile, ecosystems represent the interdependent relationships and interactions between organisations, industries, governments, and communities. By cultivating resilience within these networks and ecosystems, businesses can better withstand disruptions, adapt to changing circumstances, and ultimately thrive in today’s dynamic and uncertain landscape.

In recent years, there has been a growing awareness of the vulnerabilities present in traditional supply chains, emphasizing the necessity for adopting a more resilient approach. The risks linked to dependence on single-source suppliers, restricted transportation routes, and fragile coordination mechanisms have been underscored by events such as the COVID-19 pandemic, natural disasters, trade disputes, and geopolitical tensions. As a result, both businesses and policymakers are increasingly acknowledging the pressing requirement for resilient supply networks and ecosystems that can both manage the physical movement of goods and the financial side of the supply network. For example:

- More than 80% of the global merchandise trade is transported over sea,1 making it difficult and complex to coordinate between organisations, suppliers, and customers.

- Over the past three years, average container shipping costs have fluctuated from around $2,000 in February 2020, to above $20,000 in September 2021, to now back down to around $2,000.2 This fluctuation makes it complex to make important financial decisions.

Elements of a Resilient Ecosystem

To develop a resilient supply network and ecosystem, organisations need to implement multiple strategies, including:

- Redundancy and Flexibility: Building redundancy by diversifying suppliers, manufacturing locations, and distribution channels can help mitigate the risk of disruptions. By maintaining flexible production capabilities and adaptable logistics systems, businesses can quickly adjust to changing circumstances and minimize downtime.

- Collaboration and Information Sharing: Open lines of communication and collaboration between all stakeholders within the supply network and ecosystem are essential for effective risk assessment, contingency planning, and problem-solving. Sharing information on potential risks, inventory levels, shipment delays, and production issues enables proactive decision-making and faster response times.

- Technology and Data-Driven Insights: Leveraging advanced technologies, such as artificial intelligence (AI), blockchain, and Internet of Things (IoT), can enhance supply network visibility, traceability, and efficiency. The utilization of real-time data collection and analytics empowers proactive risk management, predictive maintenance, and issue resolution, thereby optimizing operations throughout the entire network.

“Building redundancy by diversifying suppliers, manufacturing locations, and distribution channels can help mitigate the risk of disruptions.”

By incorporating redundancy, flexibility, collaboration, information sharing, technology, and data-driven insights, organizations can experience multiple benefits, including:

- Risk Mitigation: Resilient networks can anticipate and withstand disruptions, reducing the financial and reputational costs associated with supply chain disruptions. By proactively identifying vulnerabilities and implementing mitigation strategies, businesses can safeguard their operations and maintain customer satisfaction.

- Adaptability and Innovation: Resilient networks encourage agility and foster a culture of innovation. The ability to quickly adapt to market changes, emerging technologies, and customer demands provides a competitive advantage. Moreover, collaboration within ecosystems often sparks cross-industry innovation and the development of new business models.

- Long-term Sustainability: Resilient networks support sustainable growth by promoting responsible sourcing, ethical practices, and environmental stewardship. By embracing circular economy principles and reducing waste, organizations can contribute to the well-being of communities and minimize their environmental footprint.

Implementing a Resilient Ecosystem

Investing in resiliency is not only a strategic imperative, but also a responsibility to stakeholders and broader society. Organisations that prioritize resiliency will be better positioned to thrive in the face of uncertainty and forge a path towards a more profitable and sustainable future. By leveraging digital technologies and establishing a network that connects all partners involved, organizations can enhance collaboration, communication, and information sharing, leading to increased agility and resiliency.

So how does an organisation implement a resilient supply network and ecosystem? Organizations need to seek out strategic partners who possess a wide range of digital capabilities and can enable:

- Real-Time End-to-End Visibility: [BN1] [SF2] Visibility across the supply chain provides internal stakeholders with a comprehensive view of inventory levels, production processes, and logistics. This visibility helps identify bottlenecks, anticipate disruptions, and make informed decisions in real time.

- Enhanced Communication: Seamless communication and information exchange among all participants within the ecosystem is essential to a resilient supply network and ecosystem. This enables quick response times, efficient issue resolution, and collaborative decision-making, even across geographically dispersed teams.

- Data-Driven Decision Making: Digitisation enables the collection, analysis, and utilization of vast amounts of data from various sources. Advanced analytics and machine-learning algorithms help identify patterns, trends, and potential risks, enabling proactive decision-making to mitigate disruptions and optimize operations.

- Automation and Efficiency: Automation can help replace manual and repetitive tasks, streamlining operations and reducing errors, to increase efficiency. Robotic process automation (RPA), IoT devices, and AI technologies can enhance operational efficiency, allowing organizations to respond quickly to changing demands.

- Traceability within the Supply Chain: Digital technologies, such as blockchain, enable end-to-end traceability and transparency within the supply chain. This helps ensure product authenticity, reduce counterfeiting, and improve adherence to regulations and ethical standards.

- Collaborative Innovation: Large digital networks and ecosystems foster collaboration and innovation by connecting partners, suppliers, and customers. This enables the sharing of ideas, best practices, and insights, leading to the development of new products, services, and business models.

Overall, a resilient supply network and ecosystem is no longer a nice-to-have in today’s business environment; it is a must-have. While implementation may present challenges, the benefits, both in the short and long term, surpass the obstacles, particularly when supported by a strategic partner possessing diverse digital capabilities. M

About the author:

James Bailey, Director, Infor Nexus™. He has spent 20+ years travelling the world, working with brand owners, factories and LSPs to help them work better together, improve processes to ensure all parties are working towards the same end goal.

References

1. Why ports matter for the global economy, World Bank Blogs

2. Global shipping costs are returning to pre-pandemic levels, The Economist

Building Resilience Is a CEO Imperative

Manufacturing companies can future proof their supply chains using digitization, Lean and Agile methodologies, and other industry 4.0 technologies.

TAKEAWAYS:

● CEOs must build resilience to navigate shocks and disruptions and exploit emerging opportunities.

● Using Manufacturing 4.0 technologies, companies can make their supply chains more resilient and agile and unlock up to $1.5 trillion in value.

● Digitization can improve transparency and give companies unprecedented access to valuable information.

Trends around volatility and the need for productivity and resilience create tough operational questions for the CEOs of manufacturing companies. These are some of the most pressing questions: Can we meet customer demand, both today and tomorrow? Should we boost capacity to prepare for a prolonged period of rapid growth or reduce it to prepare for the threat of stagflation? Where will we get the skilled, digitally savvy workforce we will need in the coming years? How do we decarbonize, minimize regulatory risk, and still stay in business?

Too often, the answers reveal that a company’s operations are not fit for purpose in today’s complex, uncertain, and fast-changing environment. Modern global supply chains and Lean production systems were designed to deliver high-quality products and services at the lowest possible cost. They work best when supply and demand behavior are well understood and when every participant in the value chain is performing as expected. Today, that design is proving to be costly. Modeling by the McKinsey Global Institute suggests that, over a decade, the average company in the S&P 500 can expect that supply chain disruptions will cause losses equivalent to approximately 42 percent of one year’s earnings.

Slowdowns in productivity have compounded these volatility effects. According to the Bureau of Labor Statistics, manufacturing labor productivity fell 2.5 percent in Q1 2023, the sixth time in the past seven quarters. With disruptions expected to become more frequent as turbulence from political and environmental events continues to impact economies, this does not bode well for manufacturers looking to be more agile, productive, and sustainable—with less. There is a clear imperative for CEOs to look to their operations leaders to run the business today while planning for tomorrow; indeed, resilience is about getting many things right, at the same time.

Three Business-Operations Imperatives for the CEO

Companies now need both the resilience to ride out shocks and disruptions and the agility to exploit emerging opportunities. They will also need to master fast, effective, coordinated, and large-scale change. These attributes can’t be bolted on to slow-moving, inflexible operating models. Instead, companies need to build them into their organizational structures and processes and train up their staff.

The CEO is the catalyst for such transformation, supporting the COO and engaging the entire senior-leadership team. CEOs can set their organizations on the right path by focusing on three critical starting points:

- Setting up resilient, risk-tolerant supply chain structures that abandon outdated ideas about centralization and scale;

- Doubling down on digitization with bold investments designed to achieve a truly end-to-end vision of what the future promises; and

- Achieving real agility throughout the organization via better real-time visibility and systematic response to external developments.

Rethink Supply Chains

Companies have a once-in-a-generation opportunity to future proof their supply chains. CEOs who recognize the need for supply chain leadership in the C-suite will prosper. The ground-level view supply chain leaders have gives them the clearest and furthest-reaching vision. The processes that they work every day to perfect are the key to an organization’s stability and sustainability. And the resilience they aim to build into the system is the biggest kind of thinking there is, because it is resilience that will safeguard business against an ever more disruptive future.

Supply chains are a priority because disruption is unpredictable yet inevitable—a known, manageable risk. Consider Toyota. After the Tohoku earthquake in Japan in 2011, Toyota’s production in the region was down for six months. To avoid this sort of disruption in the future, the carmaker regionalized its supply chains and addressed supplier vulnerabilities. When another earthquake hit in 2016, Toyota lost production for just two weeks—that is resilience in action.

Rethinking supply chains, the way Toyota did, is difficult. Finding and qualifying alternative suppliers is also difficult. Logistics networks and flows are tricky to set up, integrate, and optimize. Building new plants, or closing old ones, is a complex, costly exercise. As a result, many organizations’ supply chain structures tend to be set up to meet yesterday’s requirements rather than tomorrow’s.

“Manufacturing 4.0 has the potential to unlock up to $1.5+ trillion in value, while bolstering supply chain agility and resilience.”

To close that gap, companies should empower their supply chain leaders to assess their networks and structures. Some of the paradigms that have long driven footprint-design decisions are now ripe for reconsideration. McKinsey research in the automotive sector, for example, found that midsize supplier plants with 1,000 to 1,500 direct employees were almost twice as likely as their smaller or larger counterparts to achieve top-quartile productivity. Manufacturers that split production over several medium-size plants rather than one mega factory may also benefit from closer proximity to customers and reduced location risks, such as weather-induced shutdowns and energy price spikes.

Prioritize Digitization

Manufacturing 4.0, the next phase of operational excellence in manufacturing, is here. These technologies have the potential to unlock up to $1.5+ trillion in value, while bolstering supply chain agility and resilience. While this goal should be well within reach, in fact, more than 70 percent of digital transformations fail to deliver, and companies struggle with issues of data fragmentation, variable IT and OT systems, unsupported legacy systems, and the increasing pressures of the talent market.

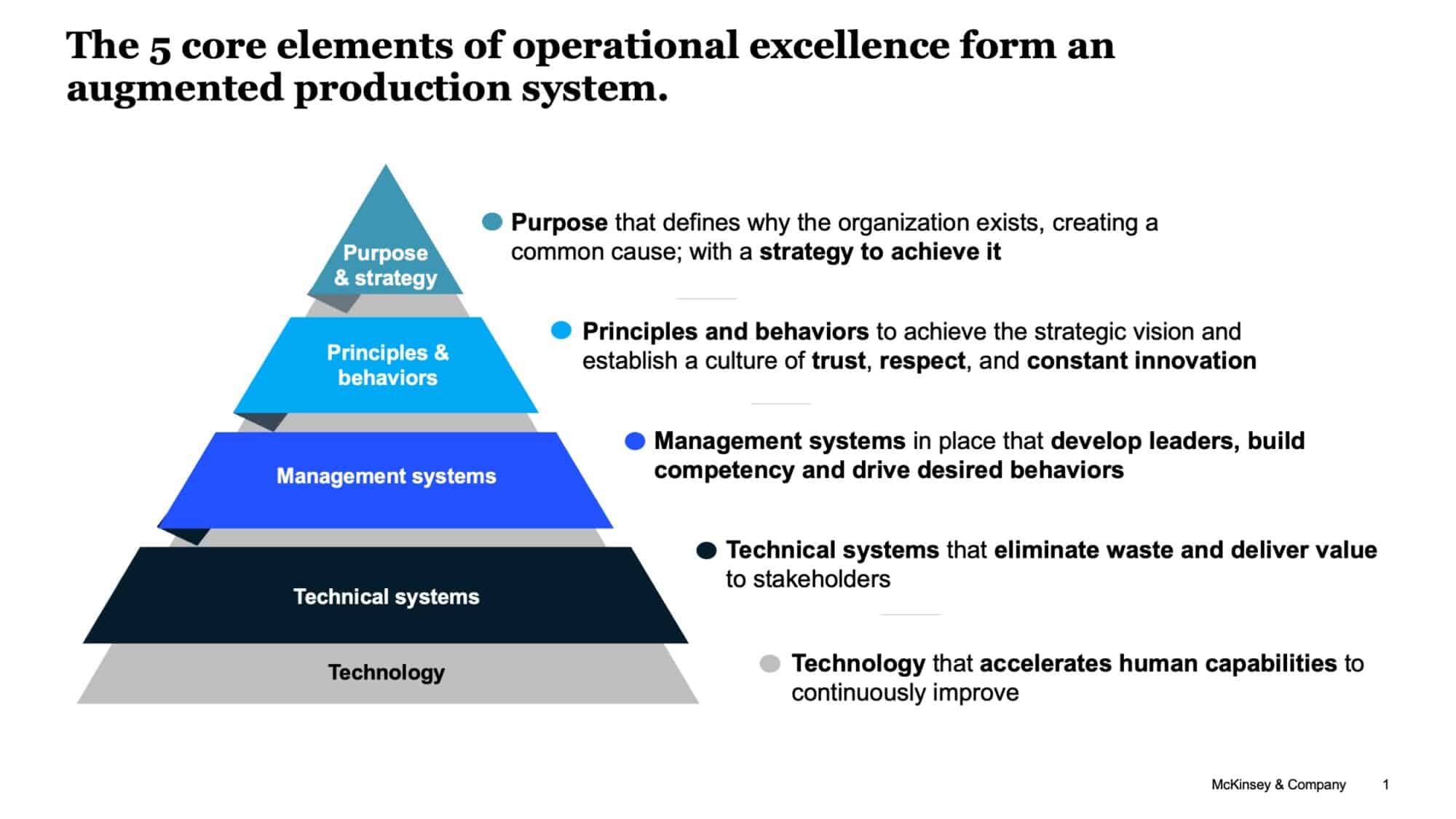

A handful of companies have found a new way to operate that is revolutionizing how they create value in operations. The combination of Lean and technology is allowing these companies to create new augmented production systems that sustainably capture the full value of digital at scale, with a holistic approach built on strong organizational foundations. The benefits include year-on-year improvements in productivity, environmental protection, safety, employee engagement, and customer satisfaction.

Figure 1: Five core elements of operational excellence

The most successful initiatives share a handful of characteristics:

- Ownership through robust understanding and conviction: Across all levels of the organization, leaders and frontline operators ought to understand and fully support the use of technology in their day-to-day decision-making processes. The leaders of one large mining company, for example, built understanding and conviction through a bottom-up process. They organized technical workshops to define a shared vision for the future functioning of their operations, so that the entire organization could see how the effort would improve its work.

- Updated organization and management systems for optimal decision-making: High-performing organizations structure teams in working cells linked to value streams (such as end-to-end operations, reliability, or planning), rather than the value chain’s individual process components (such as mine operations, plant operations, and technical services). At another mining company, this structure empowered one product owner to make decisions across the entire value chain, therefore aligning objectives and performance metrics with bottom-line business results.

- Evolved roles and capabilities to empower and engage the front line: Companies that have succeeded in using technology to achieve operational excellence, adapt roles and capabilities to suit the new ways of working required to sustain, and continuously improve technology solutions. Product owners are empowered and accountable. Data scientists and engineers use data collected throughout the process to build optimization models that assist in decision-making. “Translators”—that is, staff who work in the Transformation Office and have deep domain knowledge and technical fluency—serve as a communication bridge between processing experts and the digital team. Finally, frontline leaders are supported by everyday insights from AI tools, with more scope to improve operations, pilot new ideas, and collaborate with their colleagues upstream and downstream.

Create Agility, Visibility, and Systematic Response

Too many companies still run their operations blindfolded. Limited information sharing and collaboration among functions, sites, and business units make optimal decision-making slow and unwieldy—or impossible. Internal coordination is only a fraction of the challenge. Companies’ knowledge of the situation at their direct suppliers is usually patchy at best. Their picture of the deeper tier-n supply chain is practically nonexistent—many lack the systems and structures necessary to mount an effective and timely response.

Instead of lurching from operational crisis to operational crisis, CEOs naturally want to be able to navigate complexity and uncertainty. Digitization can partially solve the transparency problem. New and emerging digital solutions are giving companies unprecedented access to external information that could affect their business operations, from logistics disruptions to environmental, social, and governance risks and prospective changes to legislation. Leading organizations are already building operational control towers that act as central hubs for a wide range of operationally relevant data.

“Limited information sharing and collaboration among functions, sites, and business units make optimal decision-making slow and unwieldy—or impossible.”

The value of that data is limited by the organization’s ability to analyze and act upon it, however. In recent years in response to the global challenges they face, many companies have shifted from manual short-term solutions to longer-term solutions for transparency and planning that incorporate advanced technologies. Such technologies are not limited to monolithic architectures and are often the result of advanced planning systems (APSs) that combine bespoke advanced-analytics (AA) models for increased functionality.

Building advanced planning capabilities requires transformation. In a recent survey, McKinsey found that nearly 90 percent of global supply chain leaders have started or expect to soon overhaul their current planning IT. The same survey also found that 60 percent of these transformations take more time or money than expected or don’t achieve anticipated business outcomes.

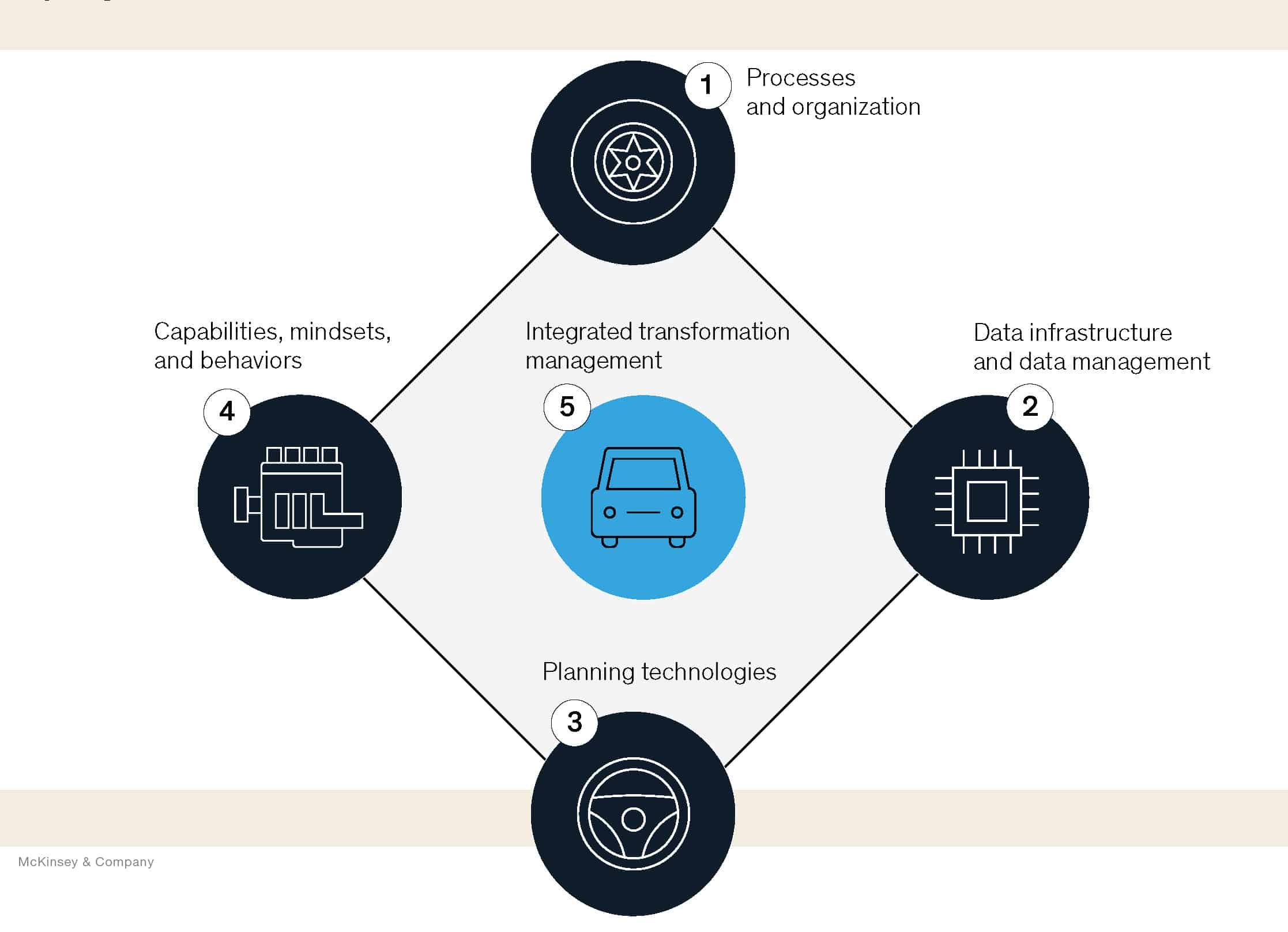

The winning recipe for a successful transformation requires integrating five ingredients to deliver at-scale impact.

- Processes and organization: A cross-functional approach beyond IT highlights opportunities for optimization, including offering value-added services to customers or driving profitability through the coordination of sales and operations.

- Data infrastructure and data management: Digital planning requires four system layers to integrate seamlessly: a system of innovation, APS as a core planning software, a data consolidation layer, and a system of record for ERP data.

- Planning technologies: Companies should select suppliers through an assessment of capability to build a two-level architecture that combines APS technology with AA solutions, such as advanced prediction and optimization algorithms.

- Capabilities, mindset, and behaviors: To develop talent with more-complex skill profiles, companies can create two new types of capabilities: one with a combination of functional, technical, and leadership competencies to drive performance; and another with technical competencies to build, maintain and develop core AA-model archetypes.

- Integrated transformation management: Leaders can focus on value-led transformations by implementing guardianship around three distinct, equally important, and mutually reinforcing pillars of responsibility: design, delivery, and value.

Linking these five ingredients will require fundamental shifts in the ways of working for organizations undergoing APS transformations. Making these shifts can help organizations achieve their business goals on time and under budget.

Figure 2: Five ingredients to integrate APS transformations

Integrated advanced planning systems transformations require five key ingredients.

The COVID-19 crisis, the war in Ukraine, and consumer and regulatory requirements to improve sustainability, and continuing volatility in global markets have lifted operations-related issues to the top of the senior-leadership agenda. There’s good reason for them to stay there. The transition to the constantly evolving global economy is already testing the resilience of business-operations functions in multiple industries. The transition to a low-carbon economy is set to test them even further. All this turbulence is continually opening new value pools for companies with the agility to seize them. The challenge for today’s CEOs and other senior leaders is to get their organizations onto the front foot, building the supply chains, digital skills and capabilities, and organizational capabilities needed to thrive in an economy that promises to be anything but normal. M

About the author:

Dan Swan is the Co-leader of McKinsey’s Operations Practice

Using Digitized Supply Chains to Improve Planning and Predictability

Manufacturers that integrate digital capabilities can reap benefits on the shop floor, in SIOP planning, and in third-party relationships.

TAKEAWAYS:

● Digitally enabled supply chains can save manufacturers time and money by reducing guesswork about what changes to make on the shop floor.

● Companies can also make better decisions about which suppliers to choose or the best ways to distribute and deliver their products.

● Especially when it comes to inventory planning, digitally enabled supply chains and a data-driven approach to decision-making are key.

The benefits of digitally enabled supply chains go well beyond boosting production and efficiency; manufacturers that intentionally harness advanced technologies can make their planning more accurate, demand forecasting more precise, and operations overall more predictable.

Improved predictability is especially critical at this time. As of May 2023, RSM US LLP’s chief economist put the chance of a U.S. recession at 75 percent over the following 12 months. Elevated inventory levels among industrial companies add another element of stress and potential financial risk, as RSM wrote in this June article. In this environment, supply chain visibility is of utmost importance for planning and fundamental to making more informed decisions in areas such as procurement, order allocation, expedited shipping, and avoiding costly on time in full (OTIF) penalties and accessorial fees such as demurrage and detention.

Manufacturers that integrate more digital capabilities into their supply chains can reap significant benefits on the shop floor and at other facilities, in their sales, inventory, and operations planning (SIOP), and in their relationships with third parties along those supply chains.

On-the-ground Enhancements

Industrial Internet of Things devices, digital twins, artificial intelligence (AI), and predictive data analytics are some of the technologies that manufacturers are implementing to achieve better visibility into their supply chains. That clearer picture of supply and demand will enable businesses to adjust their orders and production as needed and ultimately improve their planning and forecasting abilities, in addition to enabling customer service to better interface with transaction-level inquiries.

“Industrial Internet of Things devices, digital twins, artificial intelligence, and predictive data analytics are some of the technologies that manufacturers are implementing to achieve better visibility into their supply chains.”

Here are some examples of use cases for a handful of advanced technologies:

- Integrating smart devices such as sensors into manufacturing operations can give companies real-time awareness of product quality, the rate of production, downtime issues, necessary machine maintenance, and potential errors. That real-time information allows teams to communicate better with customers about expectations for delivery and make more informed decisions about inventory management, whether in terms of manufacturing or purchasing.

- Using digital twins enables companies to run virtual simulations of various supply chain scenarios and get a clearer picture of their supply and demand impacts. Virtual simulations can help manufacturers save time and money by cutting down on guesswork about what changes to make on the shop floor.

- Employing AI-based software can help manufacturers continually scan high-risk suppliers for potential disruptions, enabling management to pivot to alternative options.

- Using predictive data analytics, in conjunction with the other technologies described above, should include both internal company data and external economic data to improve forecasts and guide inventory, budgeting and resource decisions.

“Companies will continue to prioritize flexible, resilient supply chains, but that flexibility brings a higher cost in the form of increased inventory, more suppliers and higher input costs,” we wrote in this April article. “In thinking about what supply chains will look like in 2030, we expect AI will play a larger role in helping manufacturers manage such costs strategically, as will proximity to end markets and the increased presence of digitalization and automation. Global middle market manufacturers will need to invest in their supply chain capabilities with these factors in mind.”

With a better understanding of supply disruptions and demand changes, manufacturers can make better decisions about whether to choose an alternative supplier or the best ways to distribute and deliver their products. At a global level, this improved supply chain visibility allows businesses to hone their strategy for the next several years, adapt their operating model, and determine whether they may need to diversify their sourcing or nearshore aspects of operations.

Sales, Inventory, and Operations Planning

Beyond the shop floor, these advanced technologies and the data generated from them can enhance an existing SIOP process or serve as a foundation to implement such a process for the first time. Perhaps most critically, these technologies can improve communication among the various functions involved in that process: the sales side, supply side, inventory team, and finance team.

“With a better understanding of supply disruptions and demand changes, manufacturers can make better decisions about whether to choose an alternative supplier or the best ways to distribute and deliver their products.”

Especially when it comes to inventory planning, digitally enabled supply chains and a data-driven approach to decision-making are key. Here are four of the most critical areas of focus for businesses that want to adopt or improve their data-driven approaches to inventory management:

- Technology: Implement or optimize inventory management software and leverage data analytics and supply chain management systems to support data-driven decision-making. Predictive analytics should include both the company’s internal data and external macroeconomic real-time data.

- Collaboration: Build partnerships with suppliers, distributors, and customers to gain insights into market trends and forecast demand accurately. Optimizing shared data among third parties is ideal; but if it is unworkable, then businesses need to collaborate with suppliers more often.

- Processes: Form governance policies based on statistical analysis for key areas like reorder points, target levels, and costs by inventory segment on an ongoing basis.

- Training and change management: Technology is only a useful tool if organizations adopt a continuous improvement approach and well-trained managers monitor and measure the results. Invest in training and budget for it as part of the program cost.1

Many manufacturers struggle to figure out where to start or what to do first when it comes to integrating technologies into their SIOP process. Working with an advisor can help companies determine where they exist along the broader supply chain maturity model relative to other organizations. This analysis sheds light on how digital tools and improved processes can help manufacturers manage margins and increase predictability.

A Comprehensive View

Collaboration with external partners is a crucial element of success when implementing digitally enabled supply chains. But it’s often challenging for manufacturers to determine which digital tools will allow their trading partners to have the best supply chain visibility while not requiring burdensome technological adoption or being overly intrusive.

The key is to find ways to frequently share only the critical data that provides a holistic view of inter-party trading. This holistic view is essential on both the supply side and the demand side. For the former, digitally enabled supply chains can help track and manage supplier performance and variability of the supply itself. For the latter, advanced technologies help manufacturers better predict sales demand across various products, geographies, and channels.

Especially given economic expectations for the rest of 2023 and into next year, manufacturers should zero in on how digitally enabled supply chains can enhance predictability and boost efficiency through more precise planning capabilities. M

1 The content in the four bullets was originally published in an RSM article titled “Elevated inventory: A data-driven approach is necessary to mitigate risk.”

About the authors:

Casey Chapman is a principal at RSM US LLP.

Matt Dollard is a principal and industrials senior analyst at RSM US LLP.

Resilient Supply Chains: Manufacturing 4.0 Solutions

How resilient supply networks enable supply chain leaders to predict, manage, and respond to constant disruption.

TAKEAWAYS:

● Resilient supply networks and collaborative ecosystems, supported by Manufacturing 4.0 technologies, enable supply chain leaders to predict and resolve disruption effectively.

● Companies are using Manufacturing 4.0 technologies to improve visibility, planning, and information management; creating platforms to identify key events and coordinate effective responses, as exemplified by Unilever’s use of predictive AI during the COVID-19 pandemic.

● Building resilient supply chains involves proactive risk identification, communicating and collaborating with suppliers and partners, and pursuing leading supply chain best practices.

In recent years, supply chain disruption has been the main catalyst for evolution in the manufacturing industry. And with supply chain disruption, we have seen a shift towards resilience rather than the typical focus on cost and service. What was previously thought of as “once in a lifetime” crises have become the norm as the frequency and costs of each disruptive event have increased.

To succeed in this environment, resilient supply networks and collaborative ecosystems are needed to communicate and plan across suppliers, partners, and customers. These networks are increasingly supported by Manufacturing 4.0 technologies, including digital solutions to improve visibility, planning, predictability, and the rapid response to disruption, all working in tandem to enable greater resiliency across the supply chain.

Resiliency starts with proactive risk identification and assessment, identifying sources of risk and associated probabilities. While adaptability to unforeseen challenges is often seen as the hallmark of resilience, predicting and preparing for issues before they present themselves ensures the best outcomes. With this, companies are looking to digitally support business planning, risk management, and organizational preparedness for future disruptions.

The evolution of supply chain thinking

As disruptions increasingly serve as a catalyst for change, the way leaders manage and think about supply chains is changing, too. The COVID-19 pandemic served as a watershed moment, reshaping entire industries as supplies of protective equipment and health and hygiene products were stretched beyond historic constraints. Other products experienced dramatic peaks and valleys in their demand curves – causing manufacturing and supply shortages – followed by increased inventories, and eventually a need to scale back production dramatically.

“Resiliency starts with proactive risk identification and assessment, identifying sources of risk and associated probabilities.”

But the pandemic is far from the only disruption in recent history. Climate change is wreaking havoc as natural disasters and dangerous weather conditions are now a constant concern across the world. Just recently, wildfires burning across Canada led to unsafe air quality spreading as far as the southern United States. Global political unrest, economic instability, and cybersecurity concerns have further led to an environment marked by insecurity and vulnerability.

By embracing Manufacturing 4.0 technology for improved visibility into the current state of operations, as well as predicting how different actions will impact outcomes, leaders can better support scenario planning, risk management, and overall organizational preparedness.

Technology to predict and manage supply chain disruption

Unilever is a great example of a brand using Manufacturing 4.0 technology to predict and manage the effects of external threats. During the pandemic, we worked with Unilever to support their people while securing their supply chain to continue delivering products to their 2.5 billion customers worldwide. Together, we rolled out a predictive artificial intelligence tool: COVID-19 Awareness and Situational Intelligence (CASI) technology.

The CASI tool monitored and predicted global COVID-19 trends, providing a regional analysis relating to individual Unilever sites worldwide. With up to 80 percent accuracy, the dashboard enabled leaders to predict workforce trends and take action to keep employees safe during high-risk times while ensuring that its locations across the world were well-equipped to keep up with supply chain demands.

Diversification to weather times of uncertainty

Other ways to boost resilience include diversification of and collaboration with suppliers and partners. When companies rely on one key supplier, their entire supply chain can become derailed if that supplier encounters trouble, the infamous “single point of failure.” Trade tariffs, material issues, and worker shortages are all valid concerns. Widening the net and finding trade partners in a variety of regions can ensure that if one supplier is unable to deliver, fall-back options are available to keep lines moving. Furthermore, digital tools are providing companies with greater visibility deeper within their supply chains to see where critical supply, geographic market, and operations constraints may exist. This higher level of visibility improves mitigation planning, and with it, greater agility, and resiliency.

A supplier ecosystem that reflects consumers

Diversity in the supply chain goes beyond product offerings and individual companies – it all comes down to people. As brands commit to responsible supply chains that work towards the betterment of the world, those that prioritize people tend to come out on top. Procter & Gamble (P&G) is just one example of a major brand that focuses on the diversity of suppliers to create a supply chain that is representative of its consumer base. This includes working with businesses that are owned by ethnic minorities, women, members of the LGBTQ+ community, people with disabilities, and U.S. veterans.

“Digital tools are providing companies with greater visibility deeper within their supply chains to see where critical supply, geographic market, and operations constraints may exist.”

P&G also makes it a point to source materials and products responsibly, considering factors such as human rights and environmental risk across its supply chain. By monitoring and minimizing harm wherever possible, the brand safeguards the future for those living in areas where the company does business, as well as the planet at large.

While many companies today are working towards environmental, social, and governance (ESG) goals, P&G is one example of a company that not only pursues these goals on its own but empowers suppliers that are making strides to improve as well.

Overcoming obstacles to build resilient supply chains

While many leaders understand the importance of resilience, overhauling processes and getting the entire organization on board can be difficult. Resistance to change, ignorance of the risks of continuing business as usual, budget limitations, and other concerns are common issues limiting progress.

To overcome these challenges, it is vital to instil a culture of resilience and show organizational commitment from the start. This includes getting buy-in from other leaders across the firm and establishing cross-functional teams to assess what needs to change, who needs to be involved, what the process looks like, and the desired outcomes. It also requires leaders to maintain a strategic focus on building resiliency for the long term, while they may be addressing current issues in the short term. Many companies have ignored addressing their supply chain challenges because they are focused on immediate relief of areas such as order backlog, but this does not address the root causes of the backlog in the first place.

“To overcome challenges, it is vital to instil a culture of resilience and show organizational commitment from the start.”

Collaboration is key. Working with other partners across the supply chain ecosystem opens the door to new ideas and implementation strategies. They may even have access to data analytics that can be used for risk assessment and decision-making. The better partners can monitor, prepare for, and manage crises, the more secure the overall supply chain will be for all players.