Smart Factories: Finding Greater Value in the Ecosystem

To ensure adaptability, a smart factory should be part of a broader digital transformation strategy for a manufacturer.

The smart factory, with its digital production model, is gaining momentum, driven by a combination of forces that includes global disruptions and instabilities, supply chain disruptions, and heightened customer demands for digital-first experiences. Usually, when organizations think of their objectives for digital transformation, they tend to lean toward production optimization or cost reductions. However, the success of real factory transformation comes from transforming the way companies capture and provide value to their customers.

Organizations embarked on a smart factory journey that has scaled beyond the pilot phase have experienced unprecedented increases in operational efficiency as a result of greater agility in their operations. However, most companies appear to be stuck in “pilot purgatory.” There may be several reasons for this, ranging from lack of leadership, cultural aspects, workforce readiness, and legacy and disparate systems, to a lack of process standardization as well as cybersecurity risks.

Many manufacturers are already leveraging components of a smart factory in areas such as gaining visibility in production operations using Manufacturing Execution Systems (MES), planning and scheduling using real-time production and inventory data, and leveraging augmented reality for maintenance. But a true smart factory is a more holistic endeavor, moving beyond the shop floor toward influencing the enterprise and the broader ecosystem. The smart factory should be an integral part of a broader digital transformation strategy for an organization. That strategy should have multiple elements that manufacturers can leverage to adapt to the changing marketplace more effectively.

The strategic importance of the smart factory is undeniable as early adopters have reported greater agility in their operations, serving their customers better, and driving more to the bottom line. NTT DATA and Oxford Economics surveyed 528 business and IT executives recently. We found that manufacturing organizations of all kinds are prioritizing revenue growth, cost reduction, increased resiliency, and innovation for the three years ahead. In this article, we will discuss the following aspects of the smart factory:

- Key considerations for smart factories and enablers

- Maturity models, assessments, and framework; how to start, scale, and transform

- Use cases

- Conclusion

Key Considerations for Smart Factories and Enablers

1. Data Mastery and Analytics – A foundational pivot for smart factories is data mastery. Data mastery involves the use of data and analytics to find insights that help organizations become more efficient and pursue new business opportunities effectively. Data mastery is about more than building data lakes or empowering senior leaders to make better decisions. It is also about structured and unstructured data flowing through organizational processes to enable decisions at the edges of an enterprise.

In today’s manufacturing environment, accessing, aggregating, and analyzing data remain primary challenges. Manufacturing data come in many different formats (both structured and unstructured) and from many different sources: smart sensors, PLCs, DCSs, HMIs, MESs, motion control systems, vision systems, historians, completed work records, operator and maintenance logs, quality records, automation protocols, batch reports, energy meters, spreadsheets, databases, and a host of other sources. To meet these challenges, a well-orchestrated common data framework that is designed to ingest, aggregate, and condition the entire variety of data from the factory floor and then channel it to the company’s AI Data Pipeline for analysis is critical.

What’s essential to meet this critical need is a mechanism to manage data coming from the manufacturing shop floor. First, the data must be contextualized automatically using artificial intelligence, including an expert system, machine learning (ML) classifiers, and highly sophisticated ML algorithms. Next, a factory/plant digital twin must be generated and configured to mirror the actual manufacturing production lines. The digital twin, a dynamic, empirical mirror of the factory production systems, machines, equipment, and processes, produces a real-time semantic context for all product, production, and process data. Analytics can be performed on real-time data streaming from sensors, machines, and production systems to determine state condition and support best practices based on quality reporting, engineering diagnostics, and KPIs for asset performance Using analytics, users can design new reports and dashboards that address predictive maintenance, process optimization, root cause analysis, statistical process control, KPIs, and process deviation, among other data points. The analyzed data can be visualized as real-time, actionable information for every machine, line, and plant across an enterprise in contextualized dashboards that are designed to present the right information to the right people.

Cybersecurity – As more IoT devices are connected to networks, potential attack surfaces can increase, along with risk from compromised devices. These attack surfaces may not be exploitable or vulnerable today but may be easily exploited in months or years to come. Thus, leaving devices unpatched and connected to the network is not likely feasible. The responsibility of securing these devices should not lie solely with those who deploy the connected device; instead, the responsibility should be shared with the device manufacturers, who may be best positioned to implement the most effective security. Historically, OT networks have typically been implemented quickly without proper precautions being taken to electronically safeguard the industrial control assets they contain. Consequently, they are inherently full of risks, which are often not assessed, categorized, or even known and understood. Gartner reported that typical cybersecurity incident losses range from under $50K to over $100M with an average cost of roughly $3M and reported payments for ransomware incidents ranged from under $100K to more than $2M, with an average cost of roughly $520K. Additionally, organizations took an average of 170 days to detect an incident and an average of 66 days to investigate an incident. The time to remediate was on average about 80 days.

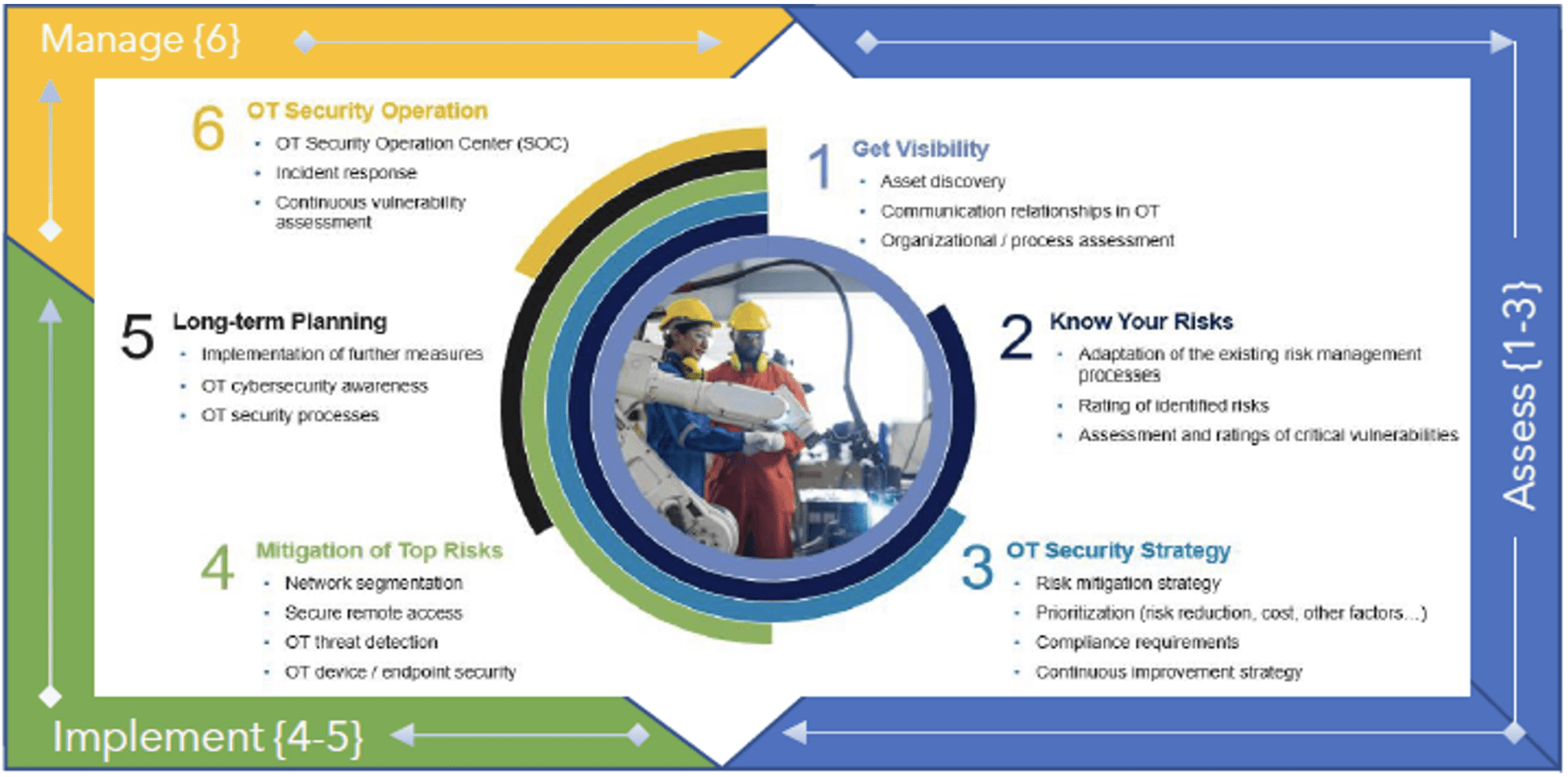

To mitigate the risk of cybersecurity, organizations must adopt a holistic approach across lifecycle assessment, implementation, and management.

Figure 1. Cybersecurity methodology

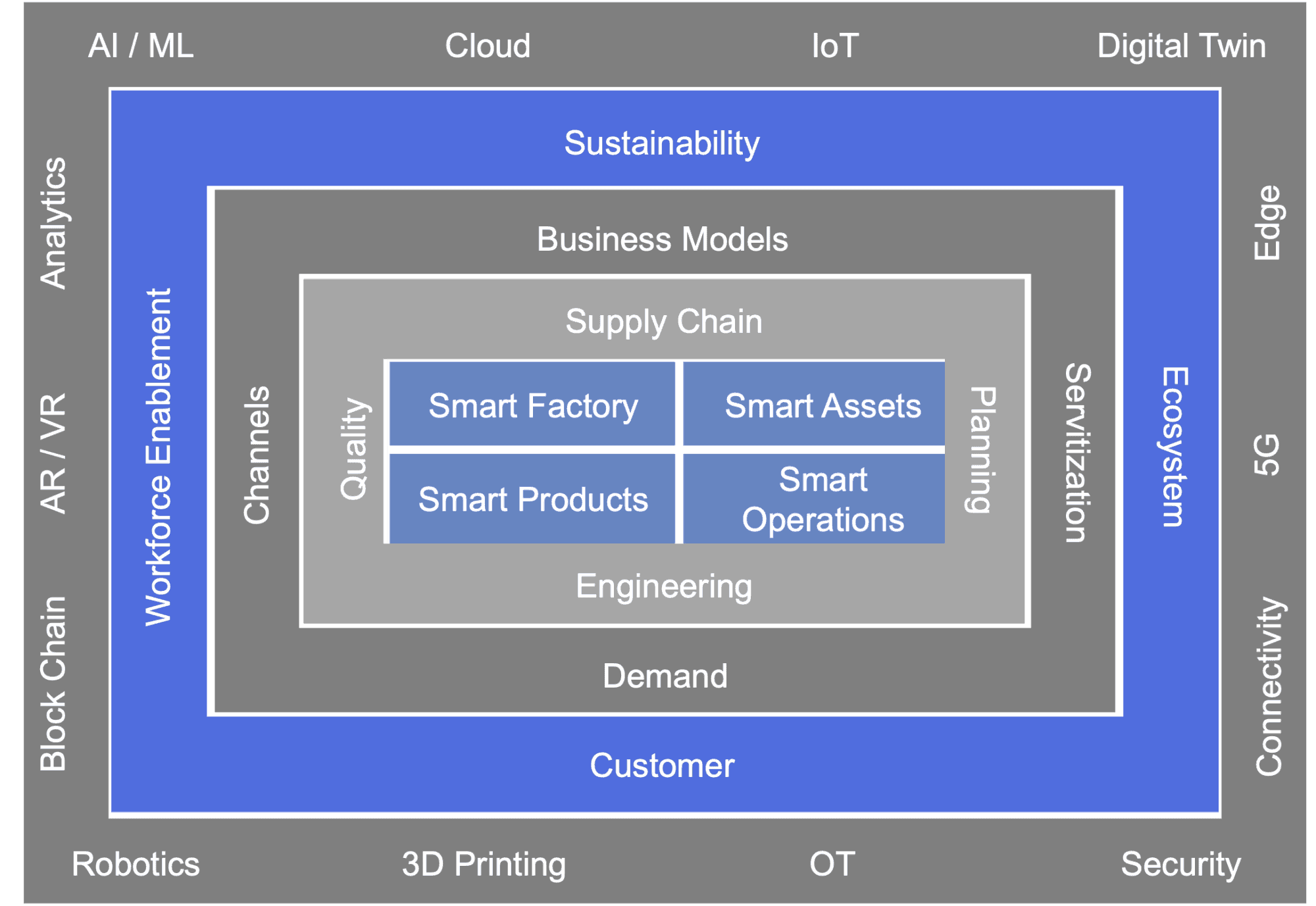

2 Digital Technologies – Smart factories typically integrate functions beyond the factory floor. While the Smart Factory focus mostly spans across operations, quality, sustainability, safety compliance and technology risk mitigation, it also integrates with the ERP, CRM, PLM, and other value chain applications. Ecosystem and sustainability are beginning to play a very prominent role in the evolving smart manufacturing priorities.

Figure 2. A variety of digital technologies are being leveraged to enable transformation in these functions:

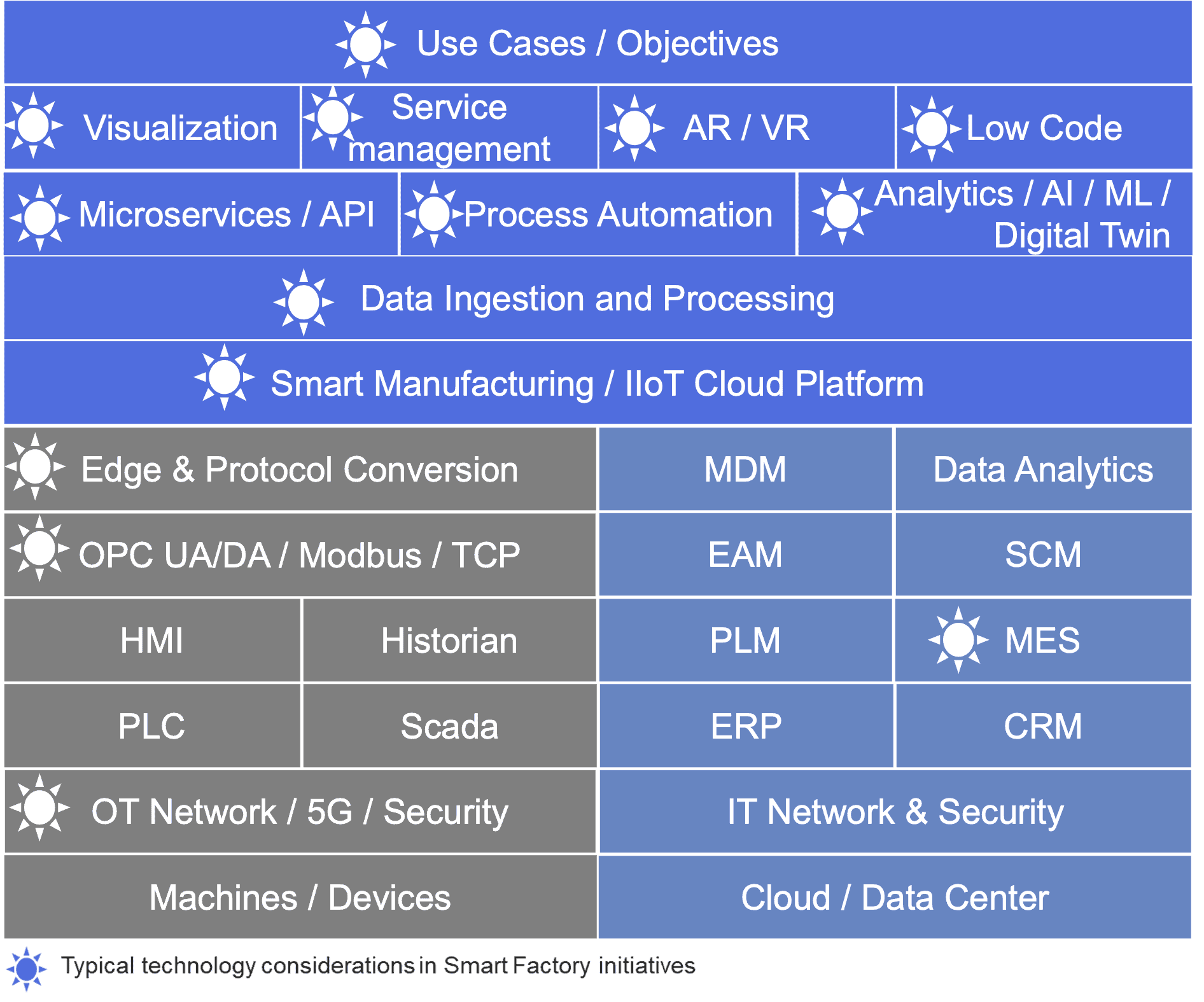

Some of the technology considerations and capabilities to address smart factories from an IT and digital perspective are listed below.

Figure 3. Typical stack and technology considerations to keep in mind.

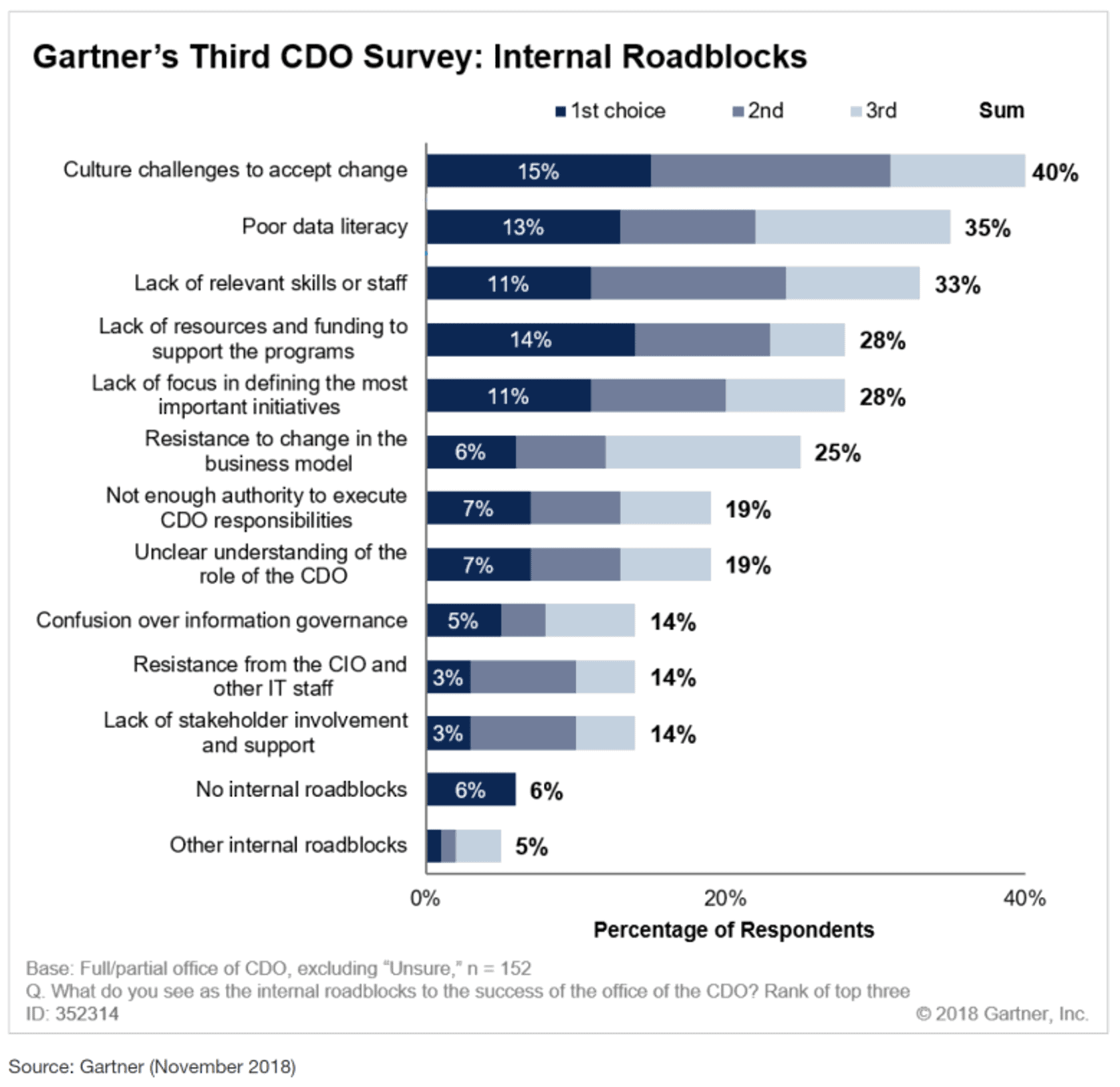

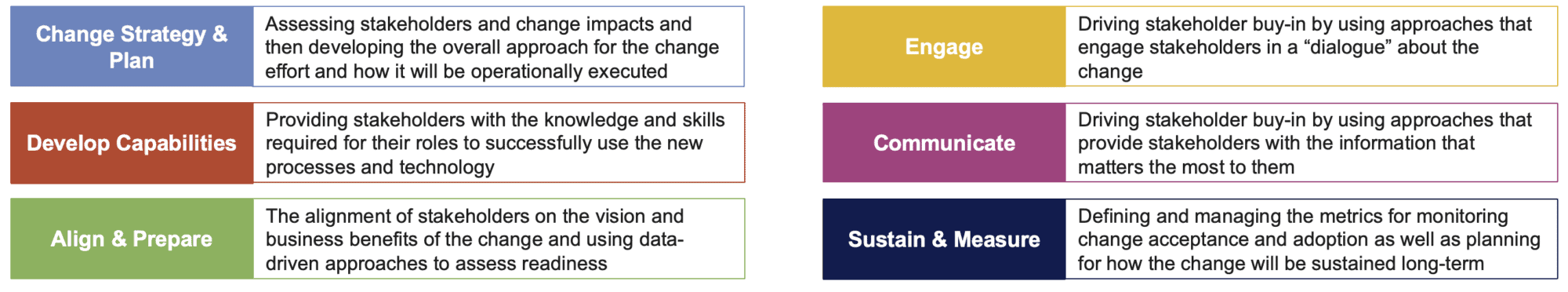

3 Leadership, Organization, Culture and People – Factory Initiatives need a higher level of engagement to manage change. When a factory becomes smart, and front line and management decisions are more data driven, product lines are getting smarter, the traditional corporate silos are being broken down and replaced with flatter, more collaborative organizational structures and monolithic entities are being replaced by more federalized, distributed, and agile value-chain ecosystems, it requires both a top down and bottom-up approach to manage change, culture, training, and communication across the enterprise.

Figure 4. Gartner found that the top three challenges for Chief Data Officers all had to do with concerns about the required culture and skills to achieve their goals.

Prioritize support at a leadership level as well as on the ground to gain organizational buy-in and ensure adoption. It also requires diverse teams with a broad variety of skill sets. The leadership or the chief digital officer must identify and deploy skill sets required to support the initiative such as engineering, master data management, analytics, edge, and data science to ensure the value extends beyond the four walls of an enterprise. Another key point to consider is upskilling resources, reskilling of employees, and ongoing support and learning. It requires development and assessment of skills required for the long term to ensure ongoing success as the smart factory evolves.

Building skills can pay major dividends such as driving acceptance and adoption of solutions and providing support for employees as they adapt and creating a culture of continuous learning. As smart factories leverage advanced digital technologies, roles within the factory will call for new and different skills than had been needed previously, making it challenging to upskill and train. Organizations should also look at some of the non-conventional models to deploy alternate talent models, collaborate with universities to build a pipeline of talent, and leverage the ecosystem of partners. This will also help attract and motivate young people starting their career in manufacturing.

Figure 5. A six-step approach to managing change.

Maturity Models, Assessments and Frameworks:

A Think Big, Start Small, and Scale Fast Approach

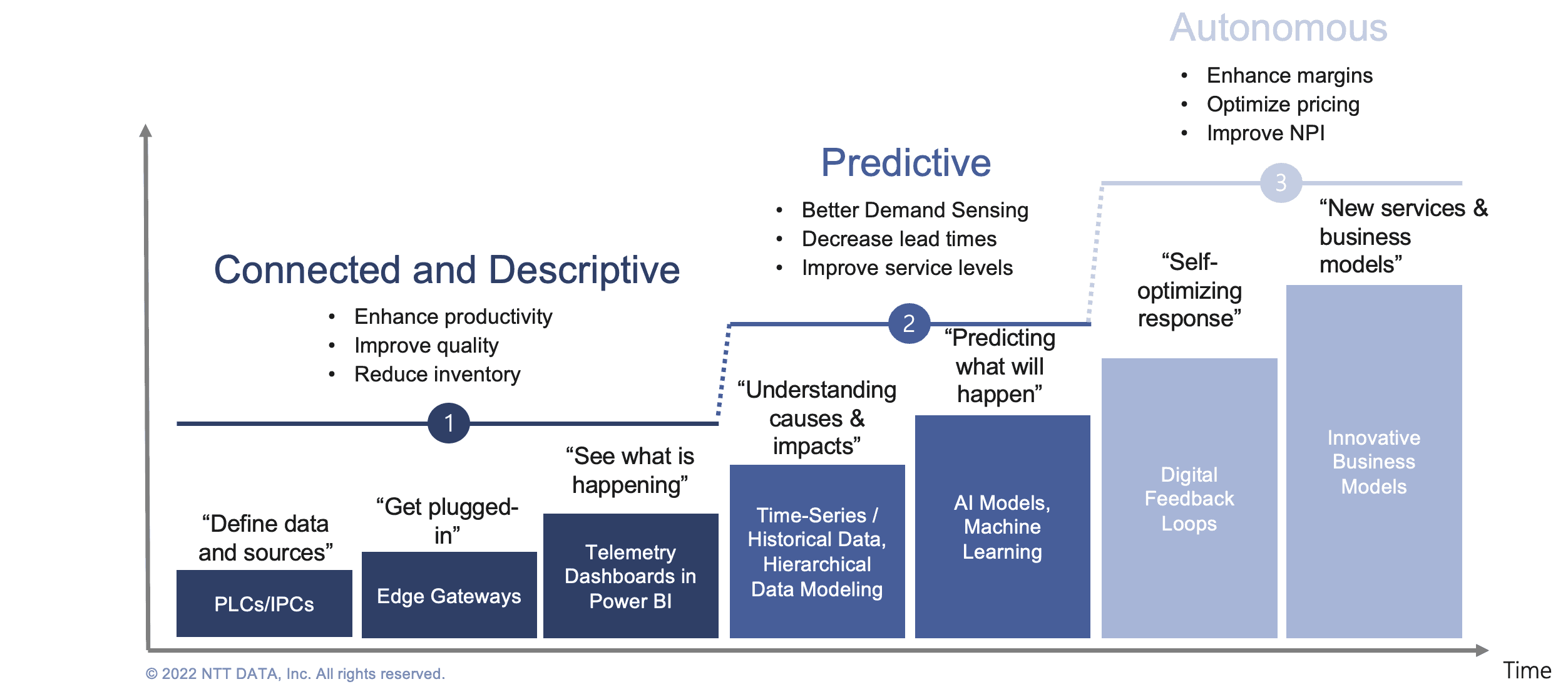

Smart factory investments often start with a focus on specific opportunities. It will be effective to start small, test out concepts in a manageable environment, and then scale once lessons have been learned. Once a “win” is achieved, the solution can scale to additional assets, production lines, and factories, thus creating a potentially exponential value creation opportunity. Moreover, achieving the ultimate true “Lights Out” operation requires a crawl, walk, and run approach as illustrated below. A company’s manufacturing strategy and environment will determine which specific issues to address and the way to unlock value through smart factory solutions. Customizing the approach to each scenario and situation can help ensure the resulting smart factory meets the needs of the organization.

Figure 6. A three-horizon approach to achieving smart factories.

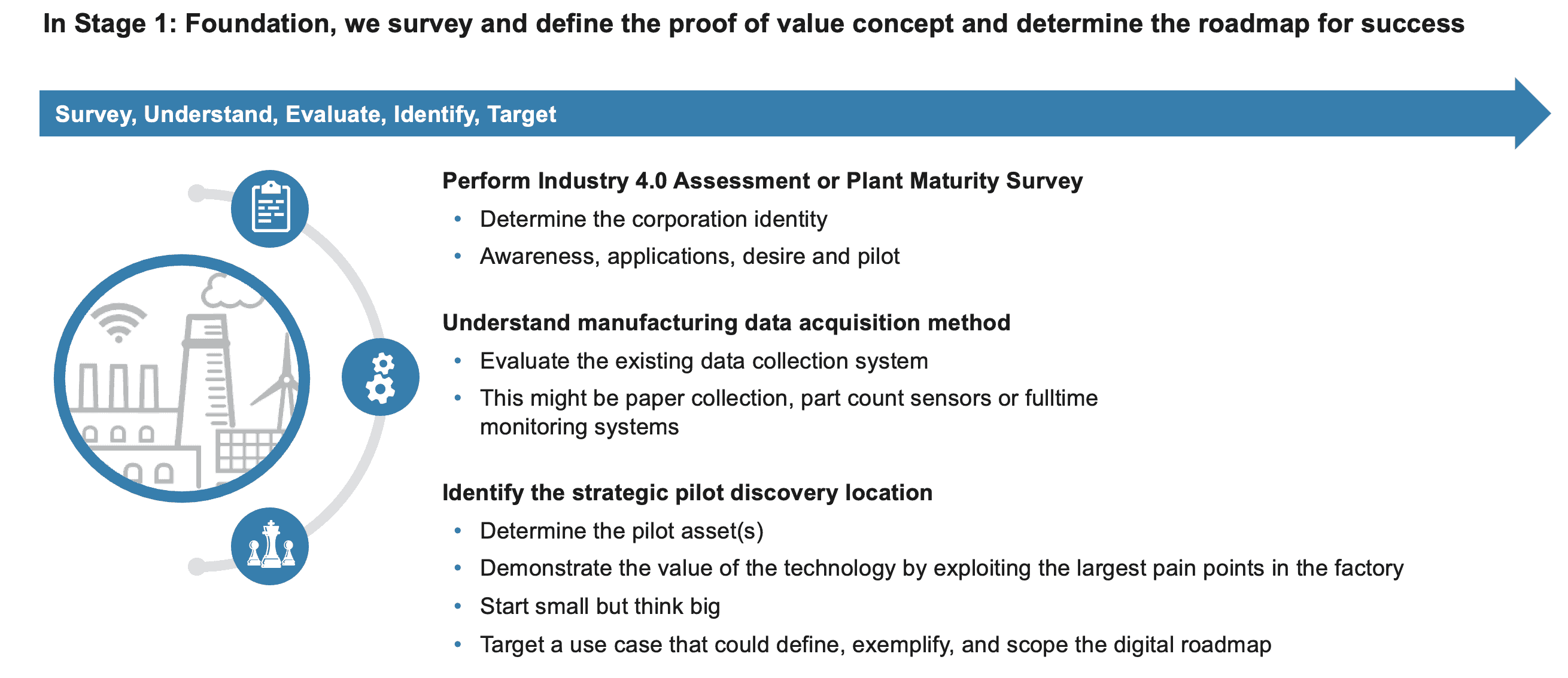

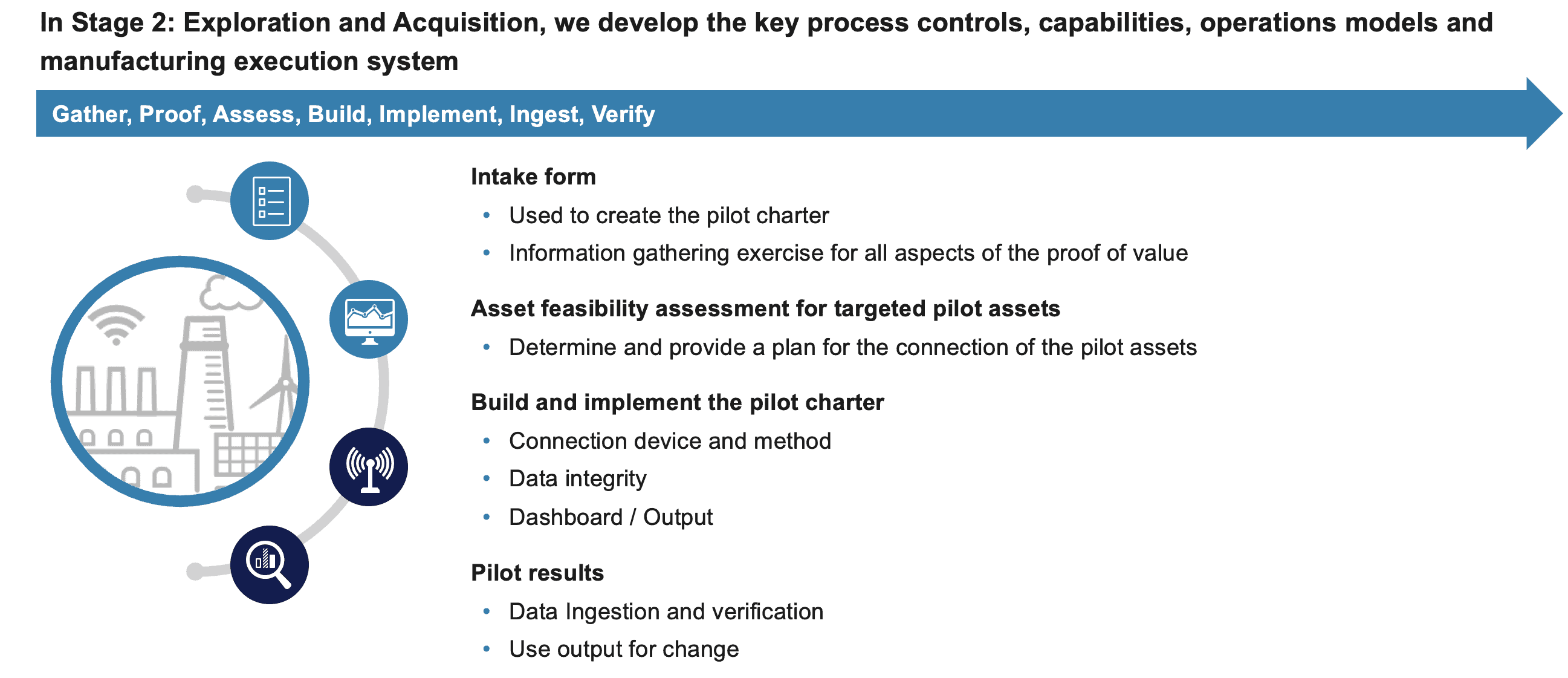

Execution Approach – Pilot Site

Plant Maturity Assessment and Transformation Framework

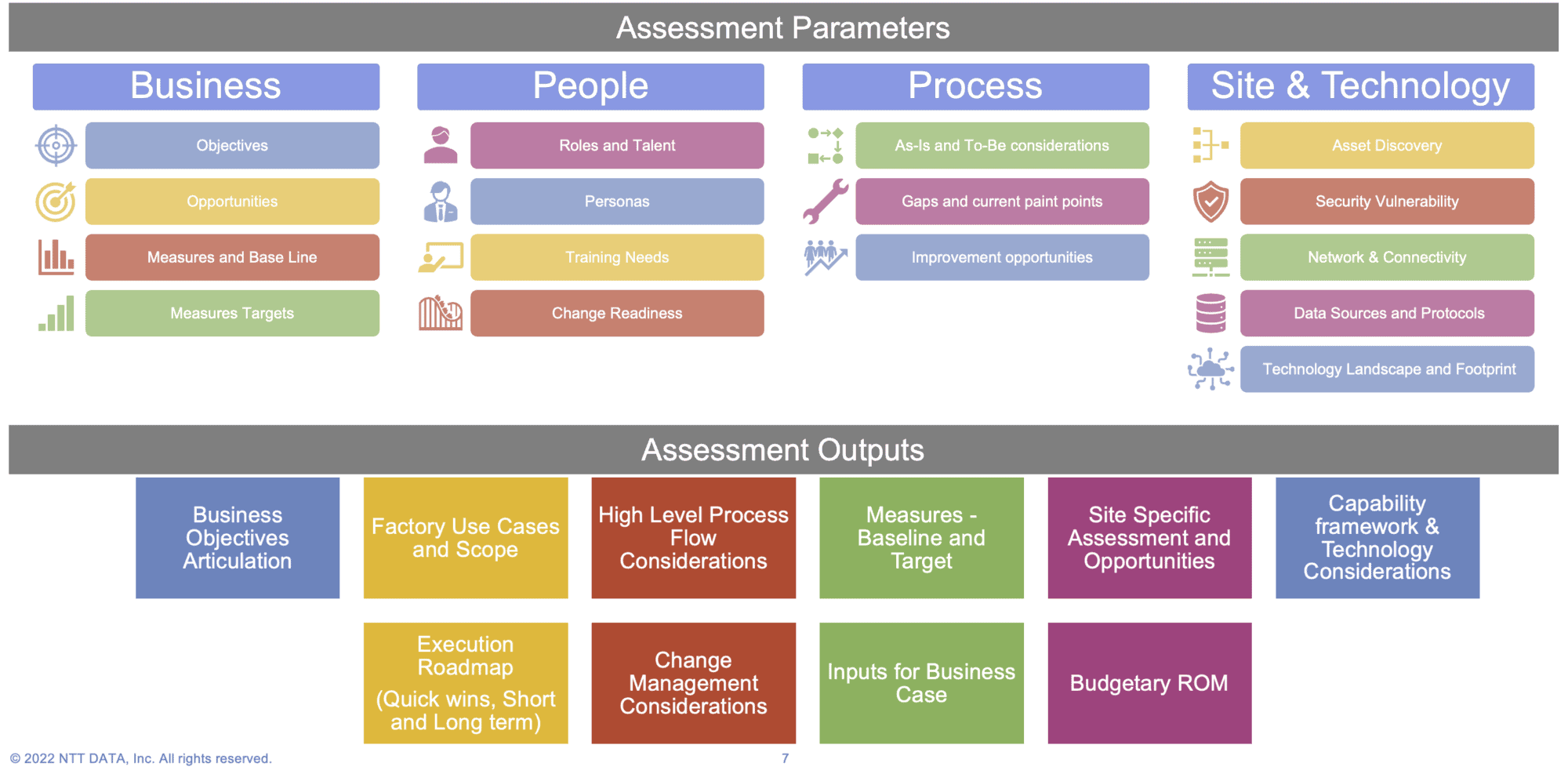

Before an organization embarks on a transformation, it is important to assess and understand the maturity levels of people, process, and technology. While there is no globally accepted maturity assessment framework for smart factories, the World Economic Forum has taken a leadership role in shaping the future of global manufacturing. A vital component of this initiative is the Smart Industry Readiness Index (SIRI). SIRI is a suite of frameworks and tools that help manufacturers start, scale, and sustain their manufacturing transformation journeys. The assessment findings depend heavily on sharing relevant organizational practices and self-reflection on areas of improvement.

Figure 7. Smart Factory Maturity Assessment

The report should have a comprehensive roadmap that depicts current maturity across process groups and people; a readiness index and levers to improve; capabilities required to implement; the next logical step; and recommendations to start the transformation.

Use Cases

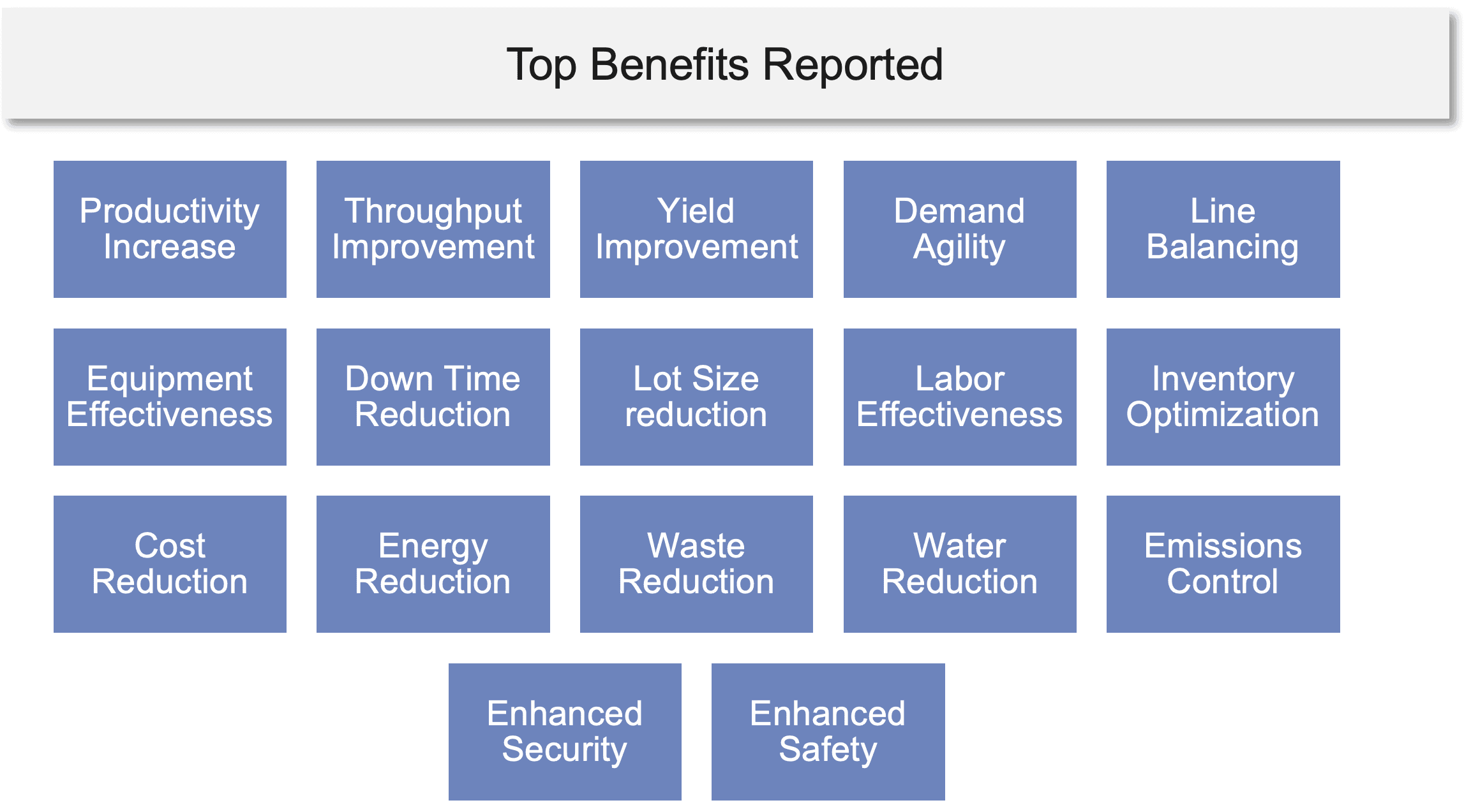

Smart factories encompass operations, quality, sustainability, safety compliance and technology risk mitigation. Use cases and process groups vary depending on specific customer and factory needs. Typically, smart factory use case benefits are focused on productivity increases, cost reductions, improved energy efficiency, inventory reduction, lead time reduction, and improved throughput.

The World Economic Forum has reported some of the top use cases implemented by the Global Lighthouse network companies.

Figure 8. Typical process groups and representative use cases in smart factories.

Key Value Realized by Organizations Implementing Smart Factories

Lighthouses are demonstrating how digitally infused operations go beyond productivity improvements to create sustainable, profitable growth. To be sure, the productivity gains are there, resulting from digital machines and management applications driving output increases at the factory level. Looking past productivity, two ways to drive growth stand out: by adopting new business models and unlocking capacity in the people and production processes. The results are encouraging. These measures optimize resources and infrastructure while enabling workers to realize their potential equipped with powerful digital applications – all without massive capital investment or negative environmental impact.

Figure. 9 Value realized

Conclusion

Though there are many different approaches to smart factory deployment, lessons can be learned from each approach that can lead to significant value creation. These range from people-centric experiences such as change management, putting humans at the center of capabilities, and managing skill diversity to broader operational and technological considerations. If leaders take just one lesson away, however, it is the importance of moving forward. All our recent surveys and research show that organizations broadly agree that the future of manufacturing is smart. The empirical results in global lighthouse factories reported by WEF demonstrate the value of the smart model. While it seems daunting, by starting small with specific program objectives that can produce tangible value, companies can get themselves started on driving sustainable value. For those who are in the journey, it is about accelerating and scaling the benefits. For those just contemplating how to start, now is the moment to begin — or risk being left behind. M

About the author:

Baskar Radhakrishnan is Strategic Advisor, Manufacturing Industry Solutions at NTT DATA