Supply Chain Evolution: From Disruption to Resiliency

The need to integrate manufacturing and engineering into supply chain planning and the five evolution levels companies need to consider.

TAKEAWAYS:

● True supply chain innovation and transformation come from integrating all key stakeholders and requires a platform approach.

● Invest in people and processes to reach new levels of efficiency and leverage technology to help provide the structure and tools to enable them.

● It is a long journey. Define your end-vision and map out the evolution to achieve incremental benefits to help fund the transformation at each stage.

Introduction

Most companies now consider disruption to be a constant rather than an exception in business operations. This drives increasing challenges for companies in today’s ever-changing business environment. To overcome them, companies have a bewildering array of technologies available, but they should also integrate more stakeholders into the planning process to develop holistic and feasible strategies.

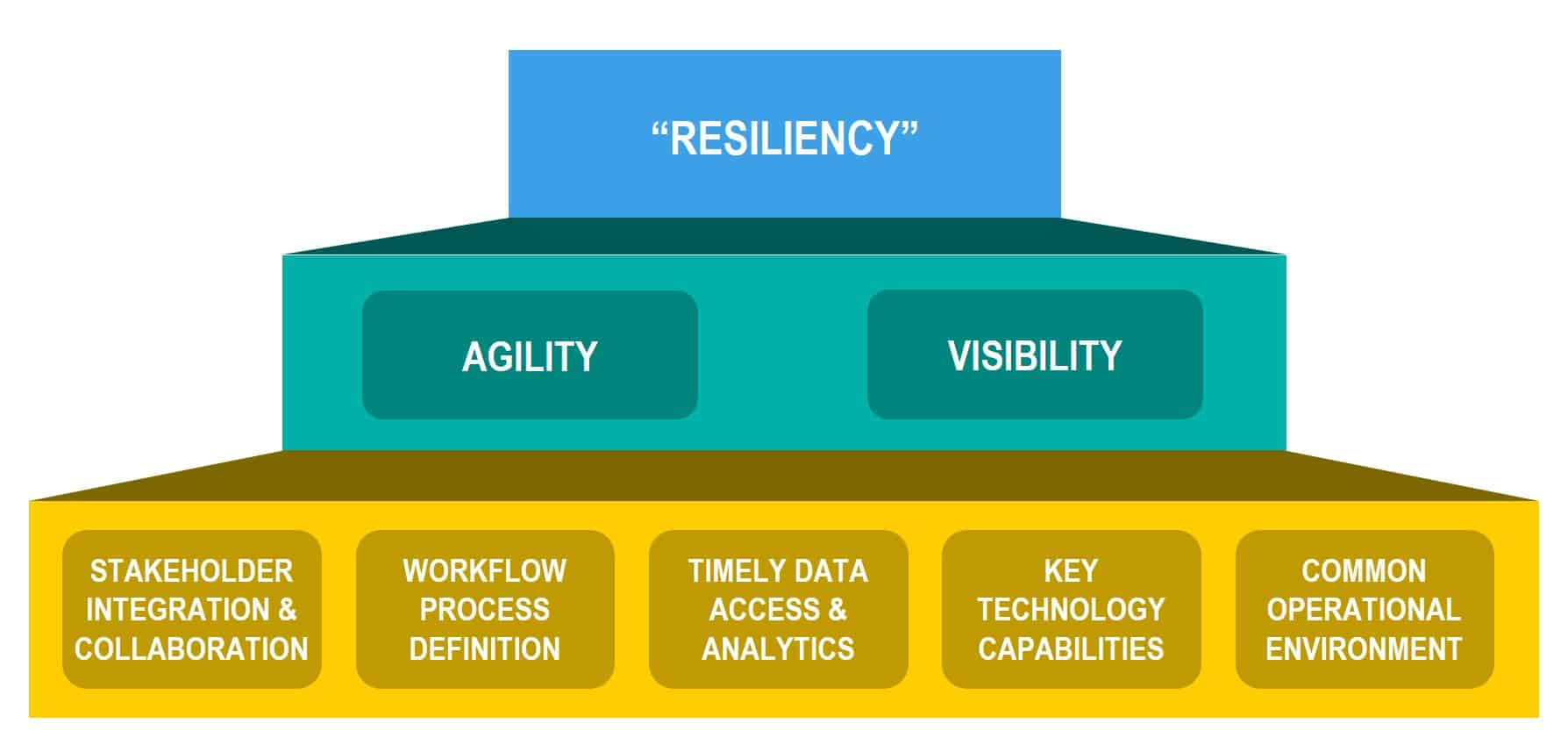

Companies will need to adapt and evolve in order to be resilient against future disruptions. However, adapting to this can be challenging, as there are many philosophies, solutions, and processes available to effect change. Initially, companies should understand some of the fundamentals needed to reach supply chain agility, visibility, and resiliency, and then ask what is needed to meet requirements such as stakeholder integration, defined workflows for managing supply chain risks, access to data, key technology capabilities, and a common operational framework.

Figure1: Fundamental building blocks for Supply Chain Resiliency

Five Stages of Supply Chain Evolution

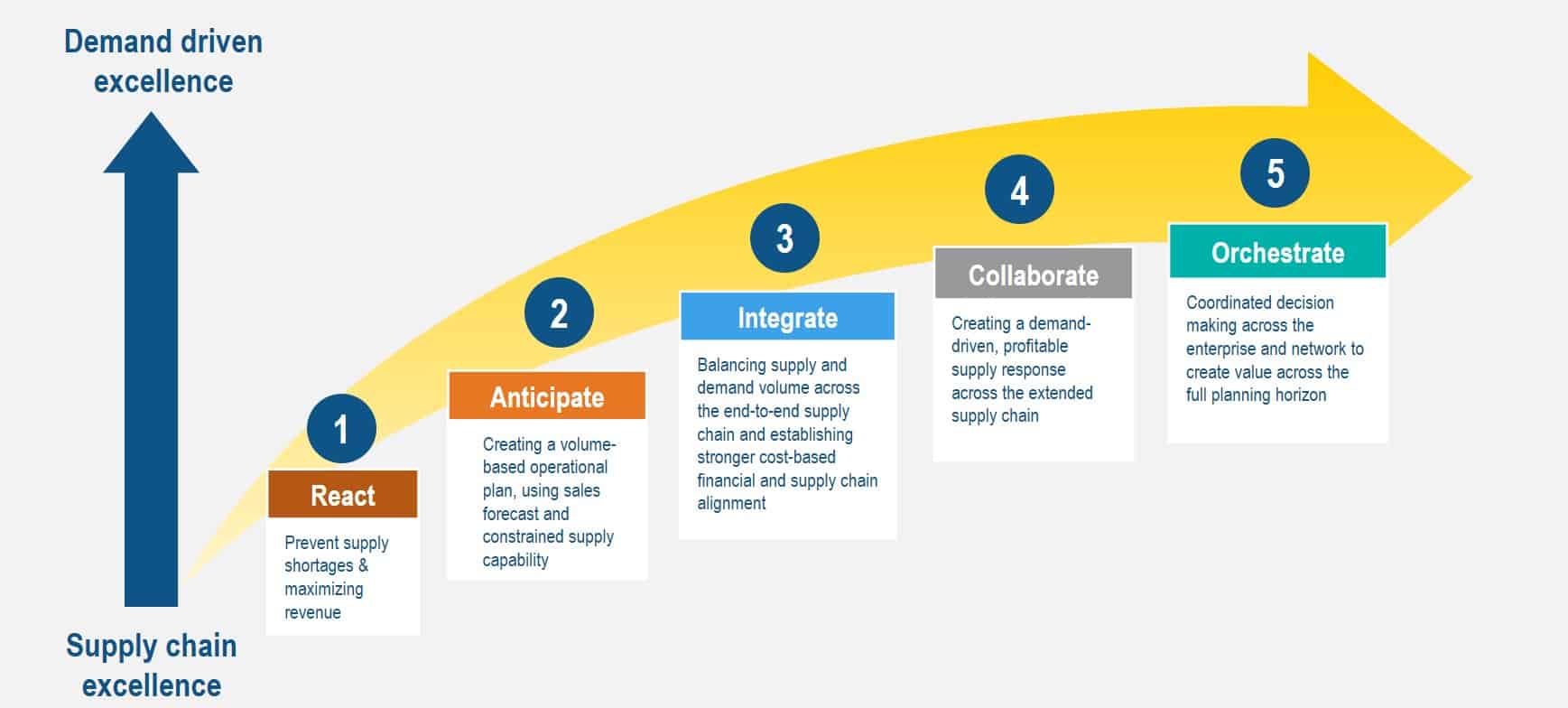

Achieving supply chain resiliency is not a short-term endeavor. For most, it will be a journey of progressive evolution, capabilities and results. This evolution can be broken down into key milestone stages that help define important steps and how to focus on process and technology changes.

Figure:2 Key stages of supply chain evolution

Early Stage Evolution (Stages 1-2)

Companies in the early stages probably still rely on manual processes, spreadsheets, or homegrown applications, and their focus is usually entirely on internal operations. The opportunities at this stage are to enable new levels of automation and more robust processes. This will help stakeholders manage the data and workflows needed to stop reacting and start making more proactive and collaborative decisions. There are also opportunities to introduce the first levels of optimization to help develop better forecasting and planning of operational models.

Mid-Stage Evolution (Stage 3: The Tipping Point)

The fundamental change in focus at the mid-stage is to stop thinking of the supply chain as an isolated and internal operation. Most supply chains are heavily dependent on additional stakeholders inside the organization.

- Operational divisions support the business model, so additional stakeholders need to be included in the decision-making process. Finance is an especially important role to include in the process as they represent the fundamental business metrics and goals for success.

- Supply chain planning is generally strategic in nature, but tactical execution can influence performance and long-term goals. For manufacturers, production operations can both present opportunities in developing strategic plans and disrupt plans already in place. Including manufacturing execution and scheduling as part of the planning process can help achieve strategic goals.

There are many challenges related to collaboration and the management of new types of data and information, but achieving this level of maturity means companies have developed a robust Sales & Operations Planning (S&OP) process and have started to enable the first elements of Integrated Business Planning (IBP).

Late Stage Evolution (Stages 4-5)

Previous stages enabled a maturity level of all internal processes and planning. However, since supply chain operations are often outsourced or dependent on third parties, it is important to consider external stakeholders as part of the collaborative process too. In addition, the growing scope and complexity of the planning process requires new levels of automation beyond just facilitating workflow and data management.

- External stakeholders: Whether it is alternative supply sources, contract manufacturers or logistics partners, it is impossible to make confident supply chain decisions without being able to model the details of the extended value network.

- Autonomous supply chains: It is likely that the workforce managing the supply chain process is becoming busier and/or more constrained. With the explosion of the volume of data and variables now being considered, optimization should now be applied to resolve supply and demand changes automatically wherever possible (e.g., within certain thresholds of acceptable outcomes). This way, supply chain professionals can manage “by exception” and spend their time on value-added activities.

In addition to including external stakeholders, supply chain organizations need to recognize the critical dependencies of other internal divisions on overall success. Some of the greatest opportunities (or risk mitigation) come from considering manufacturing and product design and engineering as critical stakeholders in the planning process.

Integrating Manufacturing & Engineering

Design, engineering and manufacturing processes have a significant impact on overall supply chain efficiency and effectiveness. For example, a design change can lead to better supply chain planning by reducing the number of components or materials, which can lower costs and improve delivery times. Similarly, changes in manufacturing plans can lead to better supply chain planning by increasing production efficiency and reducing inventory levels.

“Companies have a bewildering array of technologies available, but they should also integrate more stakeholders to develop holistic and feasible strategies”

In reverse, supply chain strategies can also affect engineering and production planning. A company may decide to outsource certain manufacturing processes to reduce costs and improve delivery times, which may in turn influence the product design.

Many supply chain problems have root causes in the disconnection between these important stakeholder divisions. Similarly, companies are missing innovation opportunities by not planning holistically across all enterprise stakeholders simultaneously. To achieve true supply chain resiliency, it is now imperative to develop a strategy that integrates manufacturing and engineering into the planning process.

Value Network Orchestration

Adding internal and external stakeholders and data to the process increases the complexity of developing consensus planning. Really, the process becomes more of a need to orchestrate all the numerous elements and possible scenarios to ensure alignment. Two critical technology solutions that can help this orchestration are digital twins and collaborative platforms.

Digital Twins

Already proven for product and facility process modeling, digital twins represent the ideal solution to enable companies to innovate and rapidly experiment with real world challenges without risk or excessive cost. Supply chain planning can benefit from the same philosophy. The supply chain digital twin models the extended value network and uses real-time data to update the status and allow planners to simulate unlimited what-if scenarios to plan for the future.

Additionally, since many companies have already invested in digital twins of their products and resources, connecting the digital twins enables the necessary integration between operations, engineering and manufacturing processes.

Collaborative Platforms

While connected digital twins allow the sharing of data and models, humans are still required to help orchestrate the process. This is where a collaborative platform becomes essential. Just as supply chain evolution moves companies from spreadsheets to automated S&OP, achieving true orchestration means stakeholders should collaborate and communicate as seamlessly as possible.

The collaborative platform provides a common structure for visualizing data, posing questions, publishing scenarios and making confident decisions. As each stakeholder and department may have separate goals and objectives, the key to success is to provide timely information and transparency as they collaborate cohesively on models of the enterprise and plans.

Industry Applications

Every organization has unique factors and challenges but achieving supply chain resilience requires evolution regardless of industry.

Discrete manufacturing industries such as automotive, aerospace, and industrial equipment have already invested in digital twin technologies from design and engineering to process simulation and digital manufacturing. It now becomes a natural extension for their operations teams to leverage the existing digital models during supply chain planning. This makes designing for supply chain a strategic advantage in new product innovation and enables extreme agility and visibility to supply chain challenges throughout the enterprise.

“To achieve true supply chain resiliency, it is now imperative to develop a strategy that integrates manufacturing and engineering into the planning process”

Process manufacturing industries such as consumer packaged goods, energy, and metals are also users of process simulation, but they are also increasingly investing in the digital modeling of their products. Instead of discrete parts, virtual models represent formulations, recipes and ingredient mixes. In the same manner, these industries can inform their supply chain decisions with a more holistic view of product potential and manufacturing dependencies.

Delivering Sustainable Supply Chains

More effective planning helps optimize supply chain and logistic flows to reduce emissions, energy consumption, and waste across the value network. Matching supply and demand with optimized S&OP also means a more efficient use of resources, raw materials and energy.

However, connecting the supply chain to engineering and production operations also provides unparalleled new opportunities to drive sustainability initiatives:

- Digital twin technology allows integration of product design with supply chain planning to design an efficient production system built for scalability and removing excess material waste.

- Efficient product design and engineering as well as considering reverse logistics and disassembly keeps valuable and scarce materials in the supply chain — enabling a circular production system.

- Connecting supply chain planning to downstream operations and consumer feedback allows for innovation in the design of green products, with opportunities to reduce the overall production footprint.

- Connecting a broad range of stakeholders enables more productive continuous improvement collaboration and ideation in areas of efficiency and sustainability.

Value

Each supply chain evolution can bring substantial value and benefits. Simple automation and optimization can greatly increase planner efficiency and accuracy. This efficiency continues to scale as maturity levels increase to include more stakeholders and capabilities, freeing up additional time for key staff to engage in value-added activities.

Efficient planning benefits then become tangible improvements in key company metrics as seen by companies in different industries:

- 10-40% improvement in production throughput

- 15-200% increase in on-time deliveries

- 12.5% savings on operational costs

- 15% reduction in logistics mileage

Additional impact areas include inventory reductions and sourcing costs, but the real value lies in developing a key competitive advantage in the marketplace – to develop the agility to weather disruption and capture new revenue streams at high profit margins.

Summary

Supply chain resiliency is a realistically achievable goal. The evolution that makes this possible is not trivial, but the benefits of gaining this level of agility and visibility is well worth the investment.

Most companies are thinking about the journey that they need to take – what their end-vision needs to look like to make the transformation worthwhile. Some key elements to consider in the thought process are:

- Think broader than just supply chain. True innovation and transformation come from integrating all key stakeholders, especially manufacturing and product engineering.

- Effective integration of stakeholders and technology requires a platform approach. The complexity of working with point solutions or legacy systems prevents efficient collaboration and optimization.

- Becoming resilient is not just about technology. Invest in people and processes to reach new levels of efficiency and leverage technology to help provide the structure and tools to enable them.

- It is a long journey. Get help defining what your end-vision should or could be and map out the evolution to achieve incremental benefits to help fund the transformation at each stage.

The call to action for resilient supply chains is to determine what critical metrics are important to your organization, identify the key stakeholders that influence those metrics (wherever they sit in the organization), and then engage with trusted partners to develop an execution plan. M

About the authors:

Adrian Wood is Directory of Strategy & Marketing at Dassault Systèmes