Rethink 2022: Supply Chain Through a New Lens

Greater visibility and an engaged workforce are key to overcoming long-lasting supply chain disruption

Lots of heads were nodding when Cynthia Farrer kicked off her opening comment of a fireside chat during the MLC’s Rethink 2022 Summit by noting that supply chain is something that everyone in the room is dealing with and it is top of mind.

Farrer, Senior Vice President of Global Operations and Integrated Supply Chain for Allegion, was joined by Ken Engel, Senior Vice President, Global Supply Chain North America for Schneider Electric, USA for the chat moderated by Paul Tate, MLC’s Co-Founding Executive Editor and Senior Content Director.

Throughout the discussion, Engel and Farrer shared how they’ve adapted to challenges and where they see improvement opportunities for supply chain management. To mitigate future disruption, they shared that it is important to gain visibility throughout the supply chain and line of sight into the entire ecosystem. At Schneider, for example, they have created an upstream supplier readiness plan that Engel referred to as “a plan for every part.”

Meanwhile, for those companies with limited resources or with a significant number of parts, Farrer recommends that companies identify the most important component parts and focus on gaining visibility and redundancy for those parts.

Ultimately, to create calmer supply chains and operations, Engel emphasized the need to partner closely with suppliers and acknowledge the important role employees play. People must be empowered to be agile as they navigate personal and business disruptions, according to Engel. In fact, Schneider Electric has found that by providing digital training to its workforce, there is greater engagement and excitement around the work.

Photo by David Bohrer / National Assoc. of Manufacturers

Rethink 2022: What’s the Real Value of M4.0?

Mastering data will help manufacturers unlock value they hadn’t thought of before.

“Today, we are still only scratching the surface of the M4.0 value proposition,” noted David R. Brousell, Co-founder of the Manufacturing Leadership Council during his opening speech this morning at the MLC’s Rethink 2022 Summit in Marco Island, Florida. “But I am convinced” he added, “that a powerful case can now be made that the already significant value that has been realized with M4.0 will be significantly surpassed in the days ahead.”

Speaking to a packed auditorium of 500 senior level manufacturers, industry experts, innovators, and academics at the MLC’s 18th Summit event, Brousell predicted that the manufacturing industry is now poised to cross a chasm with M4.0 – making the transition from initial visionaries and early adopters, to the next dimension of value from M4.0 through grounded pragmatism, focused application, and enterprise-wide deployment.

“The value that we will be able to generate from the digital model – whether that value is expressed in time, productivity, customer satisfaction, speed, or hard dollars – will be determined by our ability to master data, not only to improve what exists, but also to identify what might not yet exist – but could,” said Brousell.

“The value that we will be able to generate from the digital model – whether that value is expressed in time, productivity, customer satisfaction, speed, or hard dollars – will be determined by our ability to master data, not only to improve what exists, but also to identify what might not yet exist – but could,” said Brousell.

Mastering data, he believes, will deliver positive change in many areas – changing the jobs people do and how they execute those jobs; changing the processes by which manufacturers make things, assure their quality, and delight customers – driving greater efficiencies, speed, cost effectiveness, and productivity; and it will change product and service portfolios, leading to the creation of new revenue streams and new customers.

In the years ahead, he continued, it will also allow companies, and the industry at large, to reimagine the art of the possible, unleashing imagination, creativity, and innovation, and ultimately, enhancing manufacturing competitiveness on the global stage.

“So set your expectations high,” concluded Brousell. “Think big about the next phase of M4.0. and embrace something that Michelangelo once said. “The greater danger for most of us lies not in setting our aim too high and failing short, but in setting our aim too low, and achieving our mark.”

Manufacturing Tops Industrial Ransomware Hit List in 2021

Manufacturers are increasingly targeted for attack as cyber criminals refine their ransomware and adopt new business models to fund their operations.

Last year ransomware gangs turned up the heat against all industrial sectors, but manufacturers have the most to worry about amid this distressing rash of cyber extortion. The statistics show that in 2021 adversaries targeted manufacturing with industrial ransomware nearly twice as often as all the other industrial sectors combined.

It’s a trend that shows no sign of slowing down as adversaries increasingly recognize manufacturers as extremely profitable targets for ransomware schemes that encrypt and disable operational technology (OT) systems on the factory floor and beyond, requiring victims to pay for the keys to decrypt their files and restore functionality to their systems. Savvy ransomware groups recognize the value of uptime in the manufacturing industry and they’re ruthlessly profiting on the fact that manufacturers are often the least mature in their OT defenses compared to other industrial verticals.

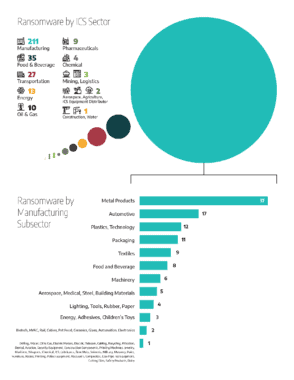

Manufacturing Ransomware Statistics

Dragos identified the intensification of manufacturing ransomware through data compiled for its 2021 ICS/OT Cybersecurity Year in Review (YiR) report, an annual compendium of OT security statistics and observations.

YiR findings showed 2021 as a pivotal year for ransomware groups targeting OT systems, with ransomware becoming the number one driver for compromises in industrial environments. Weak boundaries and poorly understood interactions between OT and IT systems, coupled with the rise in remote access—especially as more organizations rely on their work-from-home staff—contributed to industrial ransomware’s rising trend lines.

Broken down by industrial sector, manufacturing accounted for 65% of all the industrial ransomware incidents last year. Manufacturers suffered six times as many industrial ransomware incidents as the second leading sector, food and beverage, which suffered about 11% of last year’s attacks. Transportation came in third, accounting for about 8% of industrial ransomware attacks in 2021.

Digging deeper into the category of manufacturing ransomware incidents, the top three most common subsectors impacted by these attacks were Metal Components (17%), Automotive (8%), and Plastics/Technology (6%).

Rise in Ransomware Attacks

While ransomware still mainly targets enterprise IT systems, Dragos intelligence shows there are growing instances of these attacks that impact OT directly and in integrated IT and OT environments. Often ransomware adversaries indirectly attack OT systems as targets of opportunity after gaining initial access in adjacent and integrated IT systems. They use the compromise of critical enterprise IT systems to move laterally into OT. Some ransomware groups specifically target OT systems.

For example, EKANS is a specific ICS targeted ransomware that has gone after companies across electric, oil and gas, medical and pharmaceutical manufacturing, and automotive sectors. Dragos analyzed multiple variants of EKANS malware and discovered that the EKANS variant has the ability to stop ICS-related Windows processes before initiating encryption.

In 2021 the most prolific ransomware groups to attack OT systems were Conti and Lockbit 2.0, which caused 51 percent of total ransomware attacks, with 70 percent of their malicious activity targeting manufacturing. A lot of the success that groups like these have achieved in cyber extortion can be attributed to malicious business models like ransomware-as-a-service (RaaS) and sophisticated underground marketplaces where ransomware developers outsource operations to affiliates who execute the attacks. Affiliates do not require high-level technical expertise because the ransomware software has been developed and they can purchase access to systems and hackers for hire, which significantly lowers barriers to entry.

The DarkSide gang (now rebranded as REvil) offered customer service with real-time chat support andbrought in at least $60 million before it announced it was closing its operations. Investing in their business, ransomware groups are also funding research and development, which is fueling their industry as their extortion methods become more extreme. These are criminals, but they’re also savvy businesspeople, so manufacturers should expect them to continue to knock over vulnerable factory systems if they stand to make a handsome profit through ransoms readily paid by manufacturers who can’t afford to have their production ground to a halt.

What to Expect in 2022

Unfortunately, many manufacturers are still ill prepared to buffet these ransomware attacks before the adversaries have already stopped production. Dragos YiR analysis based on professional services engagements last year shows that 90% of manufacturers have limited visibility into their OT systems and the same percentage have set up poor network perimeters. Meantime, 80% of manufacturers have external connectivity exposed in OT systems and 60% utilize shared credentials that can easily be leveraged by ransomware groups to compromise systems.

Ransomware trends are likely to continue shifting as groups reform, reprioritize, and as law enforcement pursues them and takes them offline. As this evolution continues to evolve, Dragos analysts believe with a high degree of certainty that ransomware will continue to disrupt all industrial operations and OT environments through 2022, in manufacturing and beyond. Manufacturers should prepare now because ransomware actors’ extortion techniques will continue to grow in severity and intensity as adversaries deploy any means available to maximize their ransom profits.

To read more on OT cybersecurity trends, see the full Year in Review (YiR) report: https://www.dragos.com/year-in-review/

————————————————————————————————————

Peter Vescuso is Vice President of Marketing at industrial cybersecurity provider Dragos and a member of the Manufacturing Leadership Council.

Peter Vescuso is Vice President of Marketing at industrial cybersecurity provider Dragos and a member of the Manufacturing Leadership Council.

5G Will Help Unlock M4.0’s Potential

5G networks vastly increase the speed and scope of data transmission and capture. Could it open the door to the factory of the future?

Transformative technologies can take years to develop, and widespread adoption, especially among manufacturers accustomed to hardwired factories, can take even longer. Think artificial intelligence. Introduced as a concept in the mid-1950s, AI underwent a growth spurt in the 1980s, but still is in a relatively early stage of adoption by manufacturers 40 years later, though it is gaining ground rapidly.

Cellular communications technology is following a similar path, said David R. Brousell, Co-Founder, Vice President and Executive Director of the MLC, a division of the National Association of Manufacturers, in a recent Master Class Series session titled “Transforming the Factories of the Future: 5G and Data”. After first surfacing about 50 years ago, cellular technology has undergone multiple generations of development and maturity. These range from 2G in 1991, which brought digital voice text messaging and dial-up capabilities, to 3G-supported email photos and web applications, to 4G, which began supporting streaming video in 2009.

And now we have 5G. According to the MLC’s latest Transformative Technologies survey, results of which were published in October of last year, 26% of respondents had already invested in the technology. But more than half expect to either invest or are considering investing in the technology over the next two years to take advantage of 5G’s speed and capacity advantages. 5G networks can send data round trip in milliseconds, and they can capture data from hundreds of thousands of sensors per square mile.

5G and the Digital-First Revolution

Research from IDC’s Manufacturing Insights Group explored some of the drivers behind this push toward 5G adoption in the industry. The constant disruptions caused by the COVID-19 pandemic have helped to accelerate change. But the need for greater operational resiliency to meet increasing customer expectations for more personalized products and services was clear even before the pandemic, said Reid Paquin, Research Director, Manufacturing Insights, IDC.

“It’s clear that the importance of having a digital-first strategy is now being embraced across the industry,” he said.

Manufacturers know that data is essential to becoming more efficient, resilient, and competitive. While IDC research shows that AI tops the list of current technology investment priorities over the next five years, manufacturers’ two main areas of focus now are connectivity, leading to investments in IoT, edge computing, and wireless, and maximizing the value of data, which means investing in analytics-related technology such as AI and machine learning.

But while creating, gathering, and analyzing critical data throughout operations can improve the decision-making process, the explosion in the amount of data now available makes turning data into actionable insights more challenging than ever.

That’s where 5G comes in, because to remain competitive, manufactures need the bandwidth speed and low latency 5G offers to fully realize the benefits of new technology such as IoT. “That’s why you see so many manufacturers realize that the wireless connectivity piece is so critical to achieving the operational excellence and resiliency (needed to future-proof the factory of the future),” said Paquin.

According to one of IDG’s IoT studies,16% said they have already started to use 5G, while 35% said they are considering it. Among the top considerations for adoption is 5G’s ability to enable new use cases, as well as maximize current use cases for mobile robotics, augmented reality, and other applications that place a high demand on manufacturing networks, Paquin said.

However, a manufacturer’s goals for adopting 5G differ depending on the type of manufacturer. For example, discrete manufacturers such as automobile makers tend to concentrate on how 5G can help enable new capabilities for products and for customers. Discrete manufacturers’ goals for 5G tend more toward enabling new capabilities for the organization itself, complying with regulations, and replacing older 2G to 4G technology.

For all types of manufacturers, it’s important to remember that 5G is not simply a technical upgrade from 4G, said Sameer Joshi, Senior Director, Manufacturing, Industry Solutions and Strategy, NTT DATA, one of the webinar’s panelists. “5G represents a massive leap forward.”

What’s Driving 5G Adoption?

“Businesses need to focus on how to monetize 5G as a technology that is now available on the market,” said panelist Anisha Biggers, Managing Director, Intelligent Automation Advisory, NTT DATA. The main business drivers she identified were leveraging 5G to grow revenue, optimize the cost of doing business, and reduce stresses in the system. “We can’t simply identify random 5G use cases and implement point solutions without thinking through how that impacts the business strategy and objectives. We need to start with understanding: why do we need to invest in 5G? What is the value we will get out of it?”

Some priorities where 5G can play a part include:

- Automation. While automation has been a focus in manufacturing for a long time, 5G can help provide faster data transmission, allowing for better optimization of production and operations.

- Visual-based inspection. This area is seeing a sharp increase in interest from a use case standpoint when it comes to improving product quality and scrap waste rework.

- Robotics/AGVs/Cobots. Is 5G essential in realizing the potential for investments manufacturers are already making in these technologies? It’s important to set a goal first, then align the technology investments needed to achieve that goal. 5G enables manufacturers to offload data to the cloud and network edge. And as the complexity of tasks that robots can do increases, it will allow manufacturers to increase their use of cobots and AGVs.

- Remote monitoring/diagnostics of assets and processes. “Asset monitoring and maintenance are clearly the low-hanging fruits that show the ROI and production efficiencies” that can be gained by using 5G technology, Joshi said.

- Workplace safety and lone worker protection. This is another low-hanging-fruit area of clear ROI that’s ripe for picking, the panelists said.

- Talent recruitment and retention. COVID accelerated an already significant challenge in recruiting and retaining staff. 5G is one of the technologies that younger workers are already accustomed to in daily life and could be important to attracting qualified applicants. “The younger workforce is more comfortable with changes in technology because they are born into a world where technology is changing all the time,” said Biggers.

Keep in mind that while there are benefits to adopting 5G technology, it is still emerging, as are ancillary technologies such as AI, augmented reality, edge computing, and robotics. Some may wonder if they should hold off on investing in a rapidly evolving technology — will it become obsolete before they reap the benefits of their investment? And if they do decide to invest now, will it create a sufficient value to prove a significant ROI? To answer those questions, manufacturers should determine how they can incorporate 5G in specific use cases that show it can drive tangible outcomes.

Also, as the technology continues to mature it will become more plug-and-play. However, there still will be the need for more bespoke 5G deployments for niche areas that require additional customization or configuration. And while 5G promises a high level of reliability, the open connectivity to cloud can cause significant security concerns. Manufacturers — and their vendors and service providers — will have to undergo a cybersecurity paradigm shift along with the paradigm shift that 5G represents, the panelists said.

Because manufacturers tend to be risk averse — as NTT DATA’s Joshi said, “they would prefer to be fast followers rather than leaders when it comes to adopting a lot of this new technology” —it’s important to balance the short- and long-term benefits by developing use cases that can deliver value now, while also building out longer-term use cases that identify opportunities for this technology that manufacturers may not yet have.

But they are getting there. While autonomous operations, where the decision-making process is intensely data-driven, may not be realized yet in many factories, this is where the industry is headed. 5G technology could very well be one of the transformative keys to help make the M4.0 vision a reality.

Disrupt the Disruption in Manufacturing Supply Chains

Track and trace can improve resiliency and response

The past two years will get plenty of blame for supply chain disruption, but disruption — from human and technology error to weather and other crises — has always been a challenge. Manufacturers are using dashboards to visualize performance measurements and gain deeper diagnostics for uses like preventative maintenance and process optimization. But while they are a critical starting point, supply chain dashboards are not enough. Today’s manufacturers need a way to move from data collection through the supply chain to decision support and actionable insights.

In his supply chain management research, MIT Professor Yossi Sheffi noted that those companies that thrive and survive amid supply chain disruption bring people together in control centers creating a “plan B” for when disruption occurs, and a centralized area of focus for data and insights. Track and trace solutions build on the control tower concept to bring manufacturers the insights needed to improve responsiveness and build supply chain resilience.

The goal is to evolve beyond what typical control towers offer, delivering the ability to autonomously alert or trigger workflows and provide decision support. Tracking and tracing key components and products all through the supply chain provides the core data for eventual autonomous management and control from supplier to the factory and the factory to the customer. In larger factories there is a growing need to apply the same level of tracking and tracing.

Track and Trace in Manufacturing

In a nutshell, a proven track and trace approach will allow you to use the same infrastructure to track multiple sources: materials, products in production, assets, and people. Specifically, the track and trace solution the technology you’re looking for can:

Track and trace the order through the plant by mounting tags and dynamically associating the work order with the tags. This approach supports seamless tracking throughout production, even when the material moves into a different zone or is transferred to a different holding device or tag, or the source of data changes (RFID to GPS to BLE).

Manage events in the zone by monitoring how the movable assets go in and out of areas of production and shipping and sending alerts to managers as needed. For example, an alert is generated if an operator moves a specially calibrated tool from one zone to another, where it might disrupt the production process.

Make assets easy to configure and visualize. Typically, when managers and operators encounter a problem, they don’t want to get bogged down creating or waiting for code. They just want to fix it. A successful track and trace solution will operate via an intuitive administrative interface. For example, it may allow upload of JPG or PNG images of technical factory drawings to provide the image needed to designate zones (production line, workspace, machine) and associate appropriate tracker readers (RFID, BLE and QR).

Use cases for track and trace range from in-production and location or work-in-progress tracking to finished goods and in-transit tracking: The solution will produce alerts if your materials are in the wrong location, inadequate or haven’t reached assembly station. It will report the absence of qualified people at specific station, receipt, and placement of a shipment, and how much of your product is on hand and ready to ship, as well as on the journey from factory to warehouse.

A caveat to the track and trace solution proposition is that your people must be ready for it. As you put the solution together it is important to involve your people in the journey so that they are ready for change.

The value proposition for the control tower with track and trace technologies is the extensiveness of the solution. Going beyond just visualization of the activity in your supply chain, track and trace enables the complex analytics involving materials, people, and assets, that produce actionable insights. It brings autonomous capabilities to tracking, identifying deviations, and predicting where issues may occur — disrupting any disruption in your manufacturing supply chain.

Owen Keates is Industry Executive Asia-Pacific Manufacturing Practice for Hitachi Vantara.

Digital Transformation: The Necessity for ‘Unified Leadership Alignment’

Company manufacturing leaders need to get on the same page with digital transformation projects if they are going to succeed

As any company that has undertaken a digital transformation knows from sometimes painful experience, transitioning to the digital model of manufacturing includes overcoming many obstacles. Over the last several years, MLC research has revealed that dealing with legacy systems, keeping abreast of new technologies, and developing return-on-investment models for digital manufacturing expenditures are among the most important challenges manufacturers say they face in their Manufacturing 4.0 journeys.

There are several cultural and organizational issues that manufacturers must sort through as well. After all, digital transformation should not be thought of as just another technology project; it is an undertaking the entirety of the organization must be involved with since it will inevitably change nearly every aspect of how work is conducted, how products are built, and, perhaps most importantly, how power and authority flows in a company.

This aspect of an M4.0 journey – the internal organizational dynamics – was highlighted in a recent MLC Master Class Executive Interview program with NTT DATA, an MLC member company. The program centered on a new survey called “The Road to Industry 4.0” produced by NTT DATA and Oxford Economics. In a question-and-answer session I had with Baskar Radhakrishnan, NTT DATA’s Strategic Advisor for Manufacturing, I asked Mr. Radhakrishnan what he thought were the most important challenges faced by manufacturers as they attempt to get underway with M4.0. He didn’t hesitate: “A lack of unified leadership alignment.”

Why is it so difficult sometimes to get key stakeholders on the same page regarding a strategic move like a digital transformation? In some companies, I think it simply could be that not everyone clearly understands the goals and benefits of such an undertaking. But I also think part of the answer can be found in the words of that question. Digital transformations, by their nature, can indeed be strategic, meaning that they could involve a fundamental or major change in the direction of a company. And the word transform – which means “to change in condition, nature, or character” – clearly signals that what came before may not continue ahead.

As we all know and may have experienced in our own business lives, change can be hard and even frightening when patterns of work or even job roles change. And at the executive level, the often-unmentioned additional elements of power and prestige can come into play. One can role-play typical questions: ‘How will a digital transformation affect my area of expertise and control and my career path?’ ‘I have many years in manufacturing, but do I have enough understanding of digital to continue to contribute or will I become obsolete?’ ‘How can I be sure that the company will continue to be successful after a digital transformation?’

Add into this mix the still relatively early stage the industry is in with regards to codifying the payback and benefits of digital transformation and it is not hard to understand why some executives, including those long in place in their careers and jobs, may still have questions or even hesitancy about a strategy that transforms.

Nevertheless, the unified leadership alignment cited by Mr. Radhakrishnan not only needs to be done but can be done if manufacturing leadership takes the right steps and follows through. My interpretation of this is that leadership needs to work hard to clearly formulate and articulate the vision, goals, and objectives of a digital transformation to everyone in the organization, especially the leadership team which will ultimately be charged with carrying the message and developing the strategy and planning needed to see a transformation through to a successful conclusion. This involves a whole gamut of work, from envisioning a new and better business end state enabled by digital transformation to how a transformation can benefit the individual employee. And leadership needs to be open and transparent about the challenges along the way even as those challenges are being defined as the journey proceeds.

Obviously, this is quite an undertaking for leadership, requiring great reservoirs of stamina and persistence. After all, digital transformation isn’t an option anymore. It’s a business necessity if a company wants to not only survive but thrive in the years ahead. And that may be all the motivation a manufacturer needs to press head.

For an additional resource and further insights, access to the recent NTT DATA and Oxford Research study can be found here:

https://us.nttdata.com/en/engage/the-road-to-industry-4-0.

Blockchain in the Semiconductor Industry: 5 Innovative Use Cases

Blockchain technology is set to empower the semiconductor industry to expand its business horizons.

According to Reportlinker research, the semiconductor silicon wafer market stood at $9.85 billion in 2019 and will reach $13.64 billion by 2025, with a CAGR of 6.18% between 2020 to 2025. Such growth rates accentuate the need for semiconductor companies to integrate business processes with the blockchain to enhance security, transparency, and encryption. While blockchain technology is still in the early stages of development, it is now poised to aid semiconductor manufacturers in decreasing costs & counterfeits and enhance visibility into the value chain.

Embracing Blockchain

With semiconductors evolving as the building block in multiple hi-tech products – from smartphones, to electric vehicles, to household appliances – industry innovation and advancements directly impact a broad range of market segments. As the demand grows multifold, so will the complexities across manufacturing & supply networks.

Enter blockchain, which has the potential to help ease many semiconductor manufacturing pain points. Blockchain’s distributed functionality, bundled security measures, and inherent features such as smart contracts, assist manufacturers in tracing goods, regulatory compliance, managing records transparently, and automating supply chain processes & payments. It also enhances collaboration among suppliers, manufacturers, and customers. In addition, it helps protect IP and reduces counterfeiting, while integrating blockchain with IoT and AI/ML technologies, helps to improve their predictive maintenance capabilities, reduce batch-based updates, and increase transparency & harmony in the value chain.

Blockchain Use Cases

#1 Blockchain for Supply Chain Visibility

Both COVID and recent semiconductor shortages have underscored the need for deep insights into both the immediate supply chain and the supplier’s supply chain down to the source. Blockchain does just that, bringing all the stakeholders under one unified platform and enhancing transparency. The threat of disruption can be eliminated when there is clear visibility through multiple levels, from manufacturers to distributors and repair shops. As a result, the global blockchain supply chain market is slated to grow from US$253 million in 2020 to US$3,272 million by 2026, at a CAGR of 53.2% during the forecast period, according to the Markets & Markets report.

Implementing blockchain solutions help semiconductor companies to record price, date, location, quality, certification, and other relevant information to manage their supply chains effectively. The availability of this information within blockchain increases traceability of the material supply chain, lowers losses from the counterfeit and gray market, improves visibility & compliance over outsourced contract manufacturing, and potentially enhances a semiconductor company’s brand equity in the market.

Moreover, combining blockchain technology with Radio Frequency Identification (RFID) tag equipment enhances the visibility of wafer electronics along the supply chain. It helps verify the sources of raw material origins from the supplier, track & trace materials with unique data ID, and detect any counterfeits.

Data is written onto an RFID tag, which can be encrypted and published through blockchain technology. Merging the blockchain technology with RFID tag equipment lets the manufacturers, suppliers, distributors, transporters, and customers create a single source of trusted information mechanism in the supply chain.

#2 Blockchain for Enterprise Collaboration

Businesses have started leveraging blockchain’s intrinsic traits into their operations, such as security, integrity, and transparency. The versatile nature of blockchain permits companies to collaborate safely with business partners in a shielded environment. Blockchain solutions synchronize data between business partners, creating a shared and immutable record of data and transactions.

Acting effectively as a ‘middleware’ enables confidential and complex collaboration between enterprises without leaving any sensitive data on-chain. Blockchains build relationships and drive collaboration while letting enterprises stay in control of their sensitive information. The blockchain network safeguards the privacy of all of the parties involved and strengthens the security and credibility of the transaction.

Offering stakeholders access to the same information in real-time, blockchain develops a trusted environment among the partners by sharing verified information on a shared ledger. This creates newer opportunities for semiconductor enterprises as well as their suppliers and assists them in navigating new value for many years to come.

#3 Blockchain for Business Process Transformation

Blockchain technology contains a record of all transactions happening in a peer-to-peer network. With each occurrence of a new transaction, data transferred through blockchain gets encrypted, making the entire ledger highly secure. Always looking for new opportunities, many businesses have already started using blockchain as part of their business process transformation strategy. One of the biggest use cases in this journey has been blockchain-based tracking of raw materials & finished products, providing detailed tracking information to all stakeholders within the supply chain.

Another blockchain feature that businesses are fast exploring is the smart contract. Smart contracts get automatically executed when predetermined conditions and terms are met satisfactorily. According to Gartner, the business value of blockchain will exceed $3.1 trillion by 2030, and this augurs well for the early adopter semiconductor industry to integrate enterprise-wide secure blockchain networks into their existing technology platforms and scale their businesses rapidly.

#4 Blockchain for Data Monetization

There is no central data repository controlled by only one organization due to the distributed record system in the blockchain network. As no single central data store is open to external attacks, security is far stronger. Once data gets embedded onto the chain, it cannot be changed. Blockchain integrates best-of-breed cryptographic mechanisms which guarantee the network participants’ digital identity and secures the stored data’s privacy to enable role-based data access. Additionally, smart contracts – embedded business logic – can be added to a blockchain, which enables the automation of many processes and secures the handling of contracts. The application of smart contracts automatically structures that data into a digestible format, eliminating manual re-organization. Offering all the stakeholders in the value chain greater visibility into the data, the distributed ledger enhances transparency, data distribution timeliness, information sharing, and data access.

#5 Blockchain for Counterfeit Equipment and Material Identification

Companies have been combating counterfeiters for years, investing significant time and resources to guard against the risk of defective and fake parts entering the production system and to prevent clever look-alikes and reverse-engineered goods from stealing sales.

According to a BCG study, counterfeit parts cost component manufacturers about $100 billion annually in the electronics industry. The Semiconductor Industry Association estimates that semiconductor manufacturers lose $7.5 billion in revenue to counterfeiting each year. A further study by OECD stated that counterfeit & pirated goods accounted for $461 billion in worldwide trade. That’s about 2.5% of global GDP, which doesn’t include untold additional costs from the threats counterfeits may pose to the recipients’ health, safety, and security.

The use of smart tags and blockchain allows supply chain partners to verify a product’s authenticity quickly. Even if a smart tag can be copied, the information on the blockchain will remain unchanged. A scan of the item will exhibit the exact location of manufacturing and sale, exposing the duplicate item as a fake. Advances in blockchain-with-IoT counterfeit detection provide visibility in tracing and recording of provenance data from source to sale.

New Horizons

Blockchain provides an immutable, permanent digital record of materials, parts, and products, augmenting end-to-end visibility to all the stakeholders in the semiconductor value chain. Reducing costs & time by eliminating the need for third parties that manage ledgers and transparent transactions ultimately improves the profitability of semiconductor companies.

The ability to support smart contracts, such as on the Hyperledger Fabric and Ethereum platforms, is opening possibilities for speeding commerce and reducing costs. As edge computing and blockchains advance in capability and become integrated or interoperable, semiconductor companies would achieve peak efficiency and flexibility. In short, blockchain is set to empower the semiconductor industry to expand its business horizons.

Harnessing Next-Generation Warehouse Robotics

Advances in robotics and AI are driving innovation in warehouse automation.

A radical shift in consumer behavior accelerated by the COVID-19 pandemic has exponentially expanded the wide-scale adoption of e-commerce and online purchasing. As consumers increasingly make online purchases for standard items like groceries and household supplies, this shift is likely to become permanent ― creating a significant impact on warehouse operations and creating new opportunities for innovation.

Early winners so far in this business environment have been the technology-embracing early adopters such as Amazon and Ocado, who have innovated with robotics and software to create more efficient, durable supply chains. However, there’s room in this space for all players who are prepared to adopt warehouse automation and robotics. It’s likely that those who don’t participate in this disruptive innovation risk being left behind.

Adapting to Warehouse Challenges

Traditionally, robotics has been applied in repeatable, fixtured applications such as those on automotive assembly lines. Now, artificial intelligence (AI) and the Internet of Things (IoT) are enabling breakthroughs in robotic perception and complex decision-making in real time. This allows robotic technologies to operate effectively in more complicated, unstructured environments such as the warehouse and distribution networks.

Due to the inherent modularity and scalability of robotics systems for picking, sorting, and palletizing, organizations of all sizes can reap the benefits of these innovations while making warehouse operations more efficient, cost-effective and safe. The ability to add solutions with a high return ROI, intermixed with manual processes, make them ideal candidates for investment in existing manual facilities.

Due to the inherent modularity and scalability of robotics systems for picking, sorting, and palletizing, organizations of all sizes can reap the benefits of these innovations while making warehouse operations more efficient, cost-effective and safe. The ability to add solutions with a high return ROI, intermixed with manual processes, make them ideal candidates for investment in existing manual facilities.

The Robotics Opportunity

The rise of e-commerce has stressed existing parcel and distribution networks to their limits. Faced with a huge need for the efficiencies and increased capacity that warehouse automation can fill, a new breed of intelligent robotics solutions has started to go mainstream. The scalability of these solutions makes them a good fit for an industry that is still mostly manual, and they are a logical next step. For many enterprises, warehouse automation adoption is lagging significantly or absent altogether. According to DHL research, 80% of warehouses remain manually operated. Another recent survey indicates that the greatest investments to date are in conveyance (63%), while robotic palletizing and picking are still very low (15% and 8%, respectively).

Major e-commerce companies know that nimble, automated supply chains are key to meeting demand and staying ahead of the competition. To keep up with these major players, smaller and emerging e-commerce companies must take the right steps to automate their warehouse supply chains too.

Every Season is Peak Season

Prior to the pandemic, e-commerce and logistics were geared toward the peak season (early November through January). Distribution networks would ramp up for peak, then struggle with underutilized capacity for the remaining nine months. In 2020, the peak began in mid-March and hasn’t slowed. The challenge now for many smaller enterprises is how to innovate and grow within a peak environment that never subsides. Enterprises no longer have the luxury of a downtime during which to upgrade facilities to increase capacity and integrate new technology.

The e-commerce giants have an easier time integrating new technology organically because their technology stacks are already built. Smaller enterprises must work to bridge this chasm. One of the advantages of advanced robotics is that it can be integrated into operations without taking down a system or facility. Robotics can be added little by little, in a modular fashion, without major disruptions.

The Holistic Approach

There is now a significant need among both types of businesses to explore the best ways to develop, productize, and scale solutions across their entire distribution networks. By adopting a customized holistic solution that addresses key challenges and provides insights across their IT and warehousing infrastructures, companies now have an opportunity to drive continuous improvements and create flexible, robust supply chains that can keep up with increasing customer demands.

M2030: The Shape of Things to Come

What will the shape of manufacturing look like in ten years’ time?

“We are here to put our shoulders to the wheel of progress,” MLC Co-founder David R. Brousell told the hundreds of live and virtual attendees in his opening remarks at the MLC’s new Manufacturing in 2030 event, which opened in New Orleans earlier today.

“We can’t be certain about what tomorrow will bring, let alone what might be in 2030,” he continued. However, “we can project or extrapolate based on current trends and conditions, with a reasonable amount of probability, what the shape of manufacturing will look like in 10 years’ time.”

Well before the pandemic, noted Brousell, manufacturing companies were altering their organizational structures, in part due to the influence of technologies that were increasingly empowering more people with information, shifting from hierarchical, command-and-control models to flatter, more collaborative ways of organizing people and processes. As a result, manufacturing is now harnessing its intellectual capital much more effectively than ever before.

“All around us, conventional notions of what can be accomplished in production as we understand the potential of new technologies, how we arrange work and processes based on new organizational forms, and how we leverage the creativity of our people, are being reimagined,” he said.

There will continue to be challenges ahead, of course, from continued global disruptions, to redefining the relationship between humans and machines, to the increasing urgency of combatting climate change and how to create more sustainable, digitally enabled, circular business models. “Competitive advantage will flow to the companies that master these challenges,” he added.

But there will also be massive opportunities too. In the decade ahead and beyond, Brousell believes that factories and plants will be distinguished by a now evolving set of technological, organizational, and leadership characteristics that will set them apart from facilities of the past. “The extent and depth of change ahead of us will be profound”, he predicted.

That’s why events such as Manufacturing in 2030, and the MLC’s upcoming year long M2030 Project during 2022, is so vitally important to help manufacturers explore, understand, and plan for, the shape of things to come for the manufacturing industry over the next decade.

That’s why events such as Manufacturing in 2030, and the MLC’s upcoming year long M2030 Project during 2022, is so vitally important to help manufacturers explore, understand, and plan for, the shape of things to come for the manufacturing industry over the next decade.

“If we do things right in the next 10 years,” stressed Brousell, “we have the opportunity to create the greatest engine of manufacturing production humankind has ever seen.”

Analytics for Aerospace: Creating One Powerful Cell

Manufacturing cells that incorporate automation and analytics can boost both efficiency and sustainability for the aerospace industry.

Aircraft manufacturing demands the highest-quality materials, highly trained experts, rigorous quality control, and precision processes that remain largely manual. These demands make it an ideal candidate for a digital reinvention.

By combining major leaps in operating technology (OT) with integrated IT for a fully optimized environment, aircraft manufacturers can take advantage of recent advances in automation and analytics to improve manufacturing speed and accuracy and reduce waste, making manufacturing cells both more efficient and sustainable.

Challenges abound

A single-aisle commercial aircraft contains tens of thousands of nutplates. The manual installation of each one takes three to four minutes.

This process is repeated thousands of times over the life of the craft as plates are removed and reinstalled for routine maintenance. Until now, nutplate installation has been done manually, exposing manufacturers to risks including:

- Human error: Over the course of tens of thousands of manual actions, mistakes are inevitable. The potential for error is compounded by the small size of nutplate components, which make them difficult to handle and increase the potential for mistakes.

- Rising costs: Beyond the sheer labor cost of time on the job, the associated errors of manual installation lead to increased costs through scrapped materials, poor inventory management and time-intensive quality control.

- Inefficiency: Manual installation often requires down time for changing tools and changing shifts. It also limits visibility across the manufacturing environment, which means that resources are sometimes unavailable or poorly optimized.

To meet today’s demands to become more sustainable and socially accountable, manufacturers must also find ways to reduce the waste and inefficiencies inherent in their legacy processes, and the aerospace industry is no exception.

To meet today’s demands to become more sustainable and socially accountable, manufacturers must also find ways to reduce the waste and inefficiencies inherent in their legacy processes, and the aerospace industry is no exception.

Tremendous Potential

To address these multiple challenges, automated manufacturing and robotics technology provider, JR Automation, has deployed Hitachi Vantara’s Lumada Manufacturing Insights in its SmartAttach™ manufacturing cell as a way to merge the huge advances in automation at the operational level with superior insights at the informational level to help drive a comprehensive shift toward smarter aerospace manufacturing for the future.