Connected Business Ecosystems Can Boost Supply Chain Resiliency

In a time of unending disruption, the old model of linear supply chains optimized for cost efficiency must be rethought for resiliency and agility.

TAKEAWAYS:

● In a networked ecosystem, rivals can end up being partners in their supply chains, a development that was potentially unthinkable years ago.

● The levels of supply chain disruption repeatedly surged to record levels since 2020, highlighting the need for new strategies.

● Effective networked ecosystems are underpinned by reimagined architectures, greater end-to-end visibility, and technologies that enable faster decision-making and agility.

In the past decade, supply chains went from a back-office concern to front-page news, from enablers of strategies optimized for cost efficiency to potential sources of disruption that demand resiliency. Many organizations are slowly realizing that their supply chains are structured around market dynamics and operating models that are no longer relevant, and the solution requires efforts oriented outward — in networked ecosystems of supply — and not just inward.

To determine the way forward, it helps to reflect on what happened that took us to this point. The COVID-19 pandemic was a rupture with clear before and after points in our lives, yet it is only one part of a broader narrative that’s still unfolding: evolving technology enablers, geopolitical risks, and sector convergence are also complicating a landscape in which hardened borders and conflicts between governments are undermining globalization.

Against this backdrop, yesterday’s supply chain operations are ill-suited for today’s world — and grow more obsolescent in a business landscape that never returns to normal. When you pinpoint the forces affecting your organization, you clarify how best to build your roadmap to the future, and the partners to involve along the way.

Why Back to Normal Never Arrives

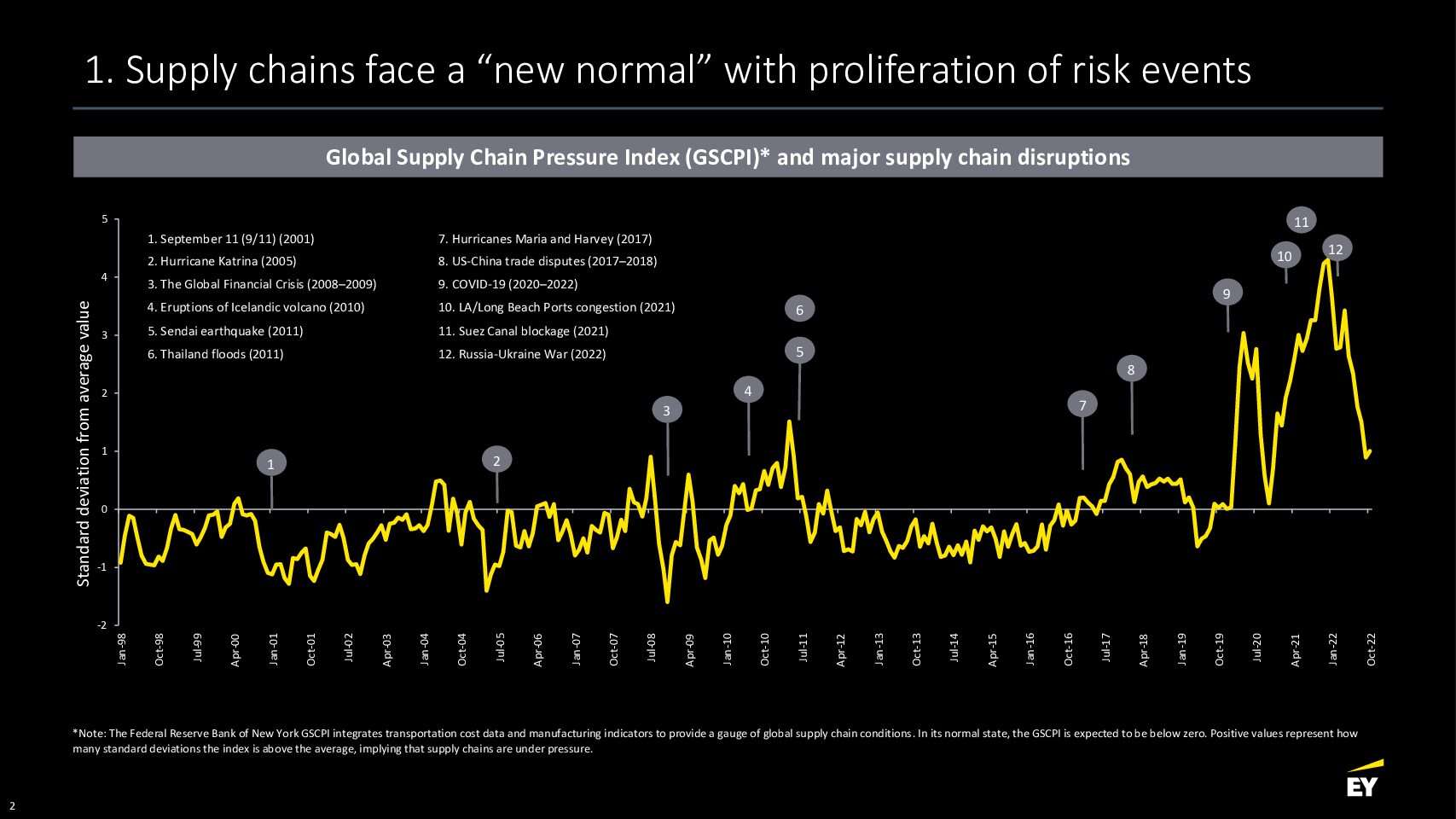

The past few years have felt like an endurance test of unprecedented chaos. Through its Global Supply Chain Pressure Index, the Federal Reserve Bank of New York backs up those feelings with hard evidence: since 1997, the beginning of the index, the levels of disruption repeatedly surged to record levels since 2020. The one-two punch of Japan’s Sendai earthquake and tsunami and Thailand’s catastrophic monsoon flooding in 2011 marked the high point of supply chain concerns before the COVID, but reflected just about a third of the standard deviation from the norm than what companies expected in 2021 and 2022.

This chart also illustrates how, until fairly recently, the major substantive supply chain disruptions were almost exclusively natural disasters, events that, while serious, but do not reflect persistent foundational challenges to business as usual. It’s feasible to recover from a natural disaster and return to normal in, say, three months. But a number of foundational challenges have made supply chains leaders feel like they’re always recovering, with normal further away than ever.

Around 2017, many companies experienced new headaches stemming from geopolitics, as the US and China, a key point in supply chains for many big multinationals, became embroiled in trade disputes. Today, the world is still grappling with the fallout of Russia’s war with Ukraine, which scrambled the markets for energy, certain precious metals, agriculture, and more. These events are representative of how the promise of globalization, forged after the collapse of the Soviet Union, has taken a turn into greater nationalism and populism.

More leaders globally have made tighter restrictions on the movement of goods and people across borders a defining principle of how they govern. Many trade blocs and agreements have been rewritten or discarded entirely, such as when then-President Donald Trump took the US out of the Trans-Pacific Partnership. Power blocs oriented around China, or more involving neutral nations like India and Brazil, have formed under “Globalization 2.0,” and as a result, many multinationals are left with supply chains that reflect a prior era of cooperation, exposing them to risk in today’s era of fragmentation.

“AI and data analytics can drive resiliency by identifying patterns in changing customer demands.”

At the same time, many governments have been implementing new regimens around tax rates, permanent establishment, and nonfinancial reporting that are challenging the equation for where companies do business. And technologies such as AI, Internet of Things connectivity, and digital twins have rewritten how companies compete and what they can achieve. In this environment, traditional sector boundaries are being blurred, and new business models are driving greater mergers and acquisitions for vertical integration or market/portfolio expansion, as well as regional strategies.

All these factors converge on supply chains — where they’re located, how they operate, and what implications and risks they have for the broader business. Linear supply chains with single sources, optimized for cost-efficiency and scale, must be rethought for resiliency and agility — as part of a networked ecosystem.

Building an Ecosystem

Amid so much disruption, rivals can end up being partners. Products in various stages of completion do not necessarily move in a straight line any longer; most companies rely on networks that might include hundreds or thousands of suppliers to create overly complex products such as consumer electronics or automobiles. For example, in the auto sector, one consumer electronics player will rely on another for the battery in the electric vehicle it is designing, even as they both fight for market share against each other in TVs.

This is an example of what we call a networked ecosystem, which enables the flexibility that multinationals need to thrive in today’s environment. Here are some tactics for managing and gaining oversight across your ecosystem — and making it pay off.

1. Redesign your strategic architecture and secure alternate sources of supply

Moving from a linear operating model to one that is agile requires a hard look at your global trade flows, global tax models, and network footprint. Beyond examining whether you have warehouses and manufacturing sites in the appropriate locations, scrutinize whether you have alternate sources of supply established, without heavy concentration from one vendor or geography. Single sources of supply are the symptoms of failures in today’s disruptive age, and by adding more redundancy to reduce bottlenecks and risk, you’re expanding your ecosystem. Also, pinpoint when to rely on third parties instead of enhancing in-house capabilities, and when to localize and/or diversify. Consider future-back planning: determine what results you want, then work from there to determine the foundational priorities and partners to enable them.

2. Embed end-to-end visibility within your ecosystem

An expanded ecosystem brings more variance in what you can achieve and optimize. Therefore, tools and connections that enable visibility are imperative. But too many supply chains run on disconnected systems, manual processes, and unstructured data. Suppliers and other players across manufacturing, logistics, and distribution typically have their own IT systems that may be connected within their own four walls, but not across the full supply chain, greatly reducing its impact. But in a true networked ecosystem, all the data can be stored in the cloud, and all entities can see and respond to events at the same time, instead of linearly. You have the opportunity to evaluate and develop multi-tier supplier visibility and to enhance inventory accuracy and visibility across all nodes.

“Using a digital twin to create a replicate of a supply chain can help in identifying contingencies. ”

3. Use data to enable supply and demand sensing and risk monitoring

This level of connectedness can drive companies move toward predictive, prescriptive, and autonomous decision-making, away from the reactive approaches that are ineffective or unsustainable. A bigger network benefits from optimal tools to drive performance; for instance, AI and data analytics can be used to identify patterns in changing customer demands, market conditions, and risks, driving increased resiliency and flexibility. This information can help you rapidly adjust production and implement predeveloped plans, such as acquiring more components from other suppliers in your networked ecosystem if a disruption surfaces.

4. Enable simulations to create contingencies

This data can also underpin a digital twin, a virtual replica of your supply chain used in simulations. What’s the impact of a loss of one supplier, or a new protectionist policy from a government, or a natural disaster in a key logistics hub, or another blockage in the Suez Canal? All these possibilities — whether a potential failure or source of optimization — can be tested in a digital twin to explore contingencies and hone strategies for events with a cascading impact across functions. By wargaming out scenarios, companies can capture advantages that their more sluggish rivals cannot. For example, Ukraine has positioned itself as a major supplier of car parts to Europe, including wire harnesses, a crucial foundational component in the assembly of vehicles. Russia is also a crucial provider of titanium for the aerospace and defense industry. Capabilities such as a digital twin would prove invaluable as war between the two nations went from rumor to reality.

The bad news is that disruptions are likely to continue to intensify and become more prevalent. But the good news is that the world is making strides to build more useful redundancy in supply, and enabling technologies are advancing and becoming easier to implement. Seen through the right lens, today’s challenges can be tomorrow’s opportunities, and normal isn’t worth pining for.

The opinions expressed in this article are those of the authors and do not necessarily reflect those of the EY global organization or its member firms. M

About the authors:

Aaron Pernat is a Managing Director at EY with experience leading large, multi-national supply chain organizations along with proven success driving business performance improvement.

Sven Dharmani is a Partner/Principal in Supply Chain & Operations at EY with a proven track record of driving process improvement, business transformation and turnaround in the automotive industry.