Extrapolating from the results of NTT DATA’s recent research report, Innovation Index: Shifting from Disruption to Growth, John Petrusick, Managing Director, Manufacturing — Data and Analytics Practice, offers insights into the future of data in the latest in MLC’s Manufacturing in 2030: Crystal Ball series.

Data-Driven Transformation and the Future of Human-Centric Innovation by 2030

By 2030, I envision a significant change where data flows freely from sources including the shop floor, enterprise resource planning systems and third-party external providers. Manufacturers will centralize, harmonize and analyze data to enable real-time action. This encompasses all actions, including automated actions, to maximize business efficiency. Doing so will impact aspects of the business ranging from daily production operations on the plant floor, to engaging customers in selling activities, to the development and testing of new products.

With respect to sales, products and services, manufacturers will create seamless customer experiences in which customers can purchase goods using their preferred interface. Infusing data into a design thinking-led approach will also improve overall experiences once the product is in use. From an operational data perspective, employees on the shop floor or within the business will see performance data in real time and act instantly.

Highly commoditized or repetitious manufacturing environments might function as a largely ‘headless’ or ‘dark’ operating environment. Such environments rely on processes that are highly routine, reproducible and repeatable. They will, therefore, be able to leverage physical robots in the ecosystem to take the place of today’s manual interventions. These environments will have a significant advantage in productivity and efficiency while improving safety. They may use technologies including robotic process automation for monitoring and control, generative AI for requests from outside observers, and physical robots to take actions when physical interventions are required. Nevertheless, I do not foresee a near-term scenario in which manufacturing is 100% automated with no human involvement. Through 2030 there will continue to be entire plants, production lines and core processes where the need for creativity will keep humans integral.

Empowering Manufacturing through Data-Driven Insights

Data’s role will evolve naturally, and part of the role will entail solving problems. But the primary function data will serve is to enable insights that guide the actions of individuals, software or machinery so that they deliver increasing business value.

Currently, the data sphere focuses on providing high-quality, reliable data to manufacturing business actors — humans, software, physical robots and so on. These actors need specific analytics or insights in forms such as real-time or near-real-time Key Performance Indicators from a production line on quality to make value-adding decisions. When such data indicates deteriorating quality, we may need to halt the line and perform a root cause analysis to remediate the issue to re-gain performance with thresholds.

In a preventive maintenance scenario, telemetry data from machinery might show that a machine will fail within two hours. A worker would then receive an alert prompting them to reallocate capacity from that line to others, if possible, to allow for necessary maintenance. Alternatively, in a product development scenario, we might be able to design and test a product virtually. This will help manufacturers create the right product to the correct specifications the first time around, thereby reducing time to market.

As the right analytics become available in 2030 and beyond, manufacturers will gain the real-time insights to deploy end-to-end automation using autonomous tooling. Automation may extend even to the point of delivery, potentially with no human intervention. This data-driven automation will create additional value through improved efficiency and shorter time to revenue generation.

Unlocking Future Manufacturing Success for Enhanced Plant Operations

Currently, we are observing advantages in various aspects of plant operations such as preventive maintenance and quality improvement. For example, vision robotics is already providing assessment data at all stages of manufacturing, from raw materials to finished products. Moving toward 2030, we see manufacturers that start or continue to follow data and analytics best practices gaining significant benefits. These benefits will be in part due to the advantages of an expanded role for AI and the benefits it can provide, enabled by continuously improving data quality. In combination with the Internet of Things (IoT), AI will have the potential to help manufacturers build factories that are more agile, transform their workforce, make significant progress against sustainability objectives, improve security and compliance, and more. Again, this is contingent on establishing the right data standards and practices.

Building Technology Ecosystems that Unleash Data’s Power

Realizing the potential of data as we are discussing it here will not require any singular technology, but rather an ecosystem of solutions working in concert.

Even today, when we consider the data stack, we emphasize cloud-native data solutions that shift away from monolithic platforms towards an ecosystem of best-in-breed, loosely coupled and high-use technologies and tools.

Data in 2030 will similarly require an array of elements. These range from IoT sensors on machines — many of our clients already have such systems in place or are testing them — to the ability to centralize this data and provide global visibility to it. To cite just one example, manufacturers will increasingly implement machine vision, which involves converting video into data for analysis across a wide variety of use cases from quality inspection to safety compliance.

Finding Future Success by Navigating Data’s Complexities to Overcoming Storage, Reliability, and Analytics Challenges

Data storage and reliability challenges I alluded earlier to the need for data centralization. Many of our clients have already conducted pilot projects or have implemented some of the technologies previously discussed in various plants. But most have yet to successfully centralize their data for global visibility. At the heart of this issue will be the need for investment as, historically speaking, manufacturers have not made the significant investments in their data ecosystem needed to resolve this key dependency.

On the flip side, despite the importance of data centralization, there are cases where manufacturers will need to balance their need for centralization versus a need for rapid analysis and action. In such cases, the challenge will be how to embed intelligence into a local system and thereby enable machine-learning-based decision-making at the edge.

Both challenges will be pervasive. Consider a global manufacturer or a multi-site operator aiming to achieve visibility across all their operations. They may have plants that are almost entirely automated with minimal human intervention and others that have a larger human presence. Both environments present the need for clear visibility into each plant’s operations via data, so the different plants might all require a sort of “control room” view. The first step to enabling that view is to store the data on which to base the view. The data may reside in a centralized location or at defined edge locations.

The next step is to ensure the data’s reliability, whether the data is in storage or in transit. This phase involves a data management component that underpins everything before proceeding to the analytical stage.

Data analytics challenges

After overcoming data storage and reliability challenges, manufacturers can shift to the challenge of data analytics. For most manufacturers, the data management in place today is not at a level where they can trust the data without question.

At the same time, there are potential solutions to these challenges from which two separate elements come to mind. First, from a data management perspective, manufacturers could use machine learning algorithms to conduct quality checks and make recommendations on how to master the data. This process is crucial to effective analytics.

The second element pertains to both the techniques of analysis and the human factor involved. Often, achieving success with analytics depends on clearly defining the question we are trying to answer and the action we aim to take. When discussing data and analytics, our shop floor personnel may say they lack the needed technical knowledge. But the reality is, they do not need to understand all the complexities of data. Instead, as data professionals or leaders, we should focus on the actions they take and the decisions they must make in their roles, and develop analytics capabilities accordingly.

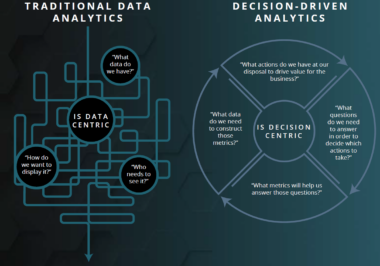

Traditional data analytics versus decision-based analytics

Anticipating the evolved and central role the workforce will play in manufacturing in 2030, decision-driven analytics is about determining the necessary actions the workforce must take to create value in a business. First, we need to ask the right questions to guide these actions. We then identify metrics or measures to establish decision points and gauge results. Lastly, we must determine the type of data needed to create those metrics and measures.

The decision-driven approach to analytics can be simplified to four elements: actions, questions, metrics and data. The goal is to understand the actions that create value in a business, then enable these with data strategies and analytics that also yield value.

Fostering Data Literacy and Collaboration to Bridge the Gap Between IT and Business for Action-Oriented Analytics

From a technologist’s perspective, it is essential to understand what is happening in the business and what actions or decisions we are informing or enabling with the technologies we are deploying. As such, IT organizations must enhance their engagement with the business. Simultaneously, business actors might need to upskill their data comprehension.

This does not mean that all business actors must learn to write SQL queries and Python scripts or be up to speed on the latest data science modeling techniques. Rather, it means they must have the requisite level of data literacy to understand the actions they take in their business and how data could help them make better decisions. Approaching it from this angle will help manufacturers find success, in part because business teams and IT organizations are thinking similarly and working towards achieving specific business outcomes.

Infographic. Aspirent, an NTT DATA Company.

To bridge the gap between IT and business teams, we have found success using a structured Decision Architecture framework focused on the following critical topics:

- What actions do we have at our disposal to drive value for the business?

- What questions do we need to answer in order to decide which actions to take?

- What metrics will help us answer those questions?

- What data do we need to construct those metrics?

This decision-driven framework offers manufacturers a more targeted, action-oriented approach to data and analytics that enables the creation of specific business cases and a clear path to unlocking their data’s potential.

Empowering Manufacturing Excellence by Navigating Data-Driven Insights for Collaborative Success and Outcomes

Ultimately, data analysis and subsequent actions depend on the workforce. It is essential to ensure that we provide data in a format that the workforce can use effectively. Similarly, the speed and effectiveness with which currently top-of-mind technologies can grow is constrained by the need for data that is accurate, complete, reliable, relevant and timely. Data and analytics reside at the core of high-value business outcomes — whether driven by the workforce, AI or combinations thereof. Potential outcomes range from creating more resilient supply chains to accelerating innovation and delivering new services to engaging customers in new ways.

In short, although we have covered a lot of ground here, my single most important piece of advice is to create and maintain a focus on driving collaboration at the intersection of IT and business teams with a focus on the business context and outcomes of data usage. By doing so, manufacturers will be able to increase the business value that data solutions create and avoid complications preventing the realization of that value.

If this data discussion has sparked your interest, we invite you to check out our infographic “Innovate Confidently with Data-Driven Decisions.” It features relevant data from the 2023 NTT DATA Innovation Index.

About the Author

About the Author

John Petrusick is a Data and Analytics Managing Director at NTT DATA, serving as the Manufacturing Industry Lead. In his role he advises manufacturers on how best to leverage their data to create business value-driven, actionable, and analytic insights to increase efficiency, sustainability, and competitiveness. He is passionate about helping clients solve their data challenges, specifically in data governance, architecture, engineering and integration, advanced analytics and business intelligence, and intelligent automation, as well as helping them implement strategies to drive digital transformation.