DIALOGUE: AB InBev’s Award-Winning Dream

Multiple ML award winner AB InBev is harnessing the power of technology to create a future with more cheers, says Global VP Marcelo Ribeiro.

“Manufacturing needs to create an ecosystem for the future where we can all learn from each other.”

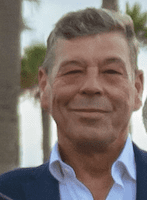

Marcelo Ribeiro, Global Vice President, Engineering and Operations, AB InBev.

Anheuser Busch InBev (AB InBev), the world’s leading brewer, swept the boards at the recent 2022 Manufacturing Leadership Awards Gala with three individual Project awards, three High Achiever awards, and the ultimate accolade of the 2022 Manufacturer of the Year-Large Enterprise award.

AB InBev was formed in 2008 by the merger of Belgian/Brazilian brewing company InBev and US-based Anheuser-Busch, later adding South African company SABMiller in 2016. It now produces around 500+ local beer brands available worldwide, with revenues of more than $54 billion in 2021, and is supported by 169,000 employees in over 50 countries.

In our latest Dialogue with a manufacturing industry thought leader, AB InBev’s Global Vice President of Engineering and Operations, Marcelo Ribeiro, talks to Manufacturing Leadership Council Executive Editor Paul Tate about harnessing advanced digital tools to empower front line teams, making data accessible to help solve key business problems and drive new ideas, and creating an industrial ecosystem to drive resiliency and sustainability in the years ahead.

Q: What’s the scope of your role as Global Vice President at AB InBev?

A: It’s really a dual role. One is to define our strategy, including Manufacturing 4.0 priorities, in both operations and engineering so we have a unified approach across all our regions – from glass bottles and cans, to labels, malt, and beers. The other is to identify best practices and what works best, and then to make sure that we incorporate those best practices into the overall management system with ensuring they are successfully shared across all our markets.

“Our goal is to bring all of our operations to a level of world class performance and achieve operational excellence by addressing both the challenges of today, and to prepare ourselves for the future.”

Our goal is to bring all of our operations to a level of world class performance and achieve operational excellence by addressing both the challenges of today, and to prepare ourselves for the future. And that future is coming at us more rapidly than it used to, so we need to harness the potential of those new 4.0 technologies through continuous improvement and try to bring that future into the present. The key focus there is to ensure we have the skills and the empowered autonomous front-line teams to do that, because it’s those front-line teams who will ultimately drive the success of the company into the future with sustainable and reliable operations.

Q: What are the key trends driving AB InBev’s business transformation today?

A: We have a dream at ABI which is “to create a future with more cheers”. Within that dream we have a clear strategy to lead and grow the category, to digitize and monetize our ecosystem, and to optimize our business. This means we are developing and delivering products that reach consumers on more occasions. That requires flexibility, and not only operational excellence, but also innovative thinking to develop new products at the pace that consumers want. So, we are digitizing our sales more and more – today, 55% of our revenues are now made through digital platforms. We have built quite a considerable amount of data about changing consumer behavior and preferences and the varieties of products people want so we are using those insights to prepare our supply chain to deliver on those changing needs.

The COVID-19 is an example of a very rapid mix of changes. On-premise outlets, like restaurants and bars, were closed and consumption moved to the home, which required very different approaches to packaging and delivery. E-commerce became much more prevalent as well, so we had to make sure the supply chain could adapt quickly and find new ways of increasing capacity without compromising safety, quality, and sustainability for the company.

So today, as we continue to optimize the business and focus more on organic growth, we have learned a lot about optimizing the interjection point between superior operational performance and leveraging digital transformation. In many ways, it’s the consumer that drives that transformation because the supply chain and operations need new tools and solutions to be able to adapt quickly and be prepared to fulfil that changing demand.

Q: What does winning these prestigious 2022 Manufacturing Leadership Awards mean to you and AB InBev?

A: It is huge. We are very honored and proud of all the people who contributed to these award-winning projects. These tools are now in use in all of our operating markets. It’s an important recognition of all the teams involved and their hard work in using technology to solve customer and consumer problems, to make our products better, our environment safer, and improve our operational performance. What we’re really interested in, of course, are the kinds of benefits we have seen in all three projects and what those benefits will be in the years to come. Their achievements are all likely to be important to the future of AB InBev. So, these awards are one more incentive for us to continue to work on transforming the business by collaborating with each other – with vendors, with suppliers, and among ourselves inside the company – to continue to drive our dream to deliver world class performance in every single operation we have.

“We have a clear strategy to lead and grow the category, to digitize and monetize our ecosystem, and to optimize our business.”

Q: Can you explain a little more about the three main projects involved?

A: The first one is in the AI and Machine Learning category. This is the SORBA project designed to reduce fuel waste in overused assets like air compressors and boilers. We wanted to incrementally improve energy consumption using real-time AI industrial optimization techniques and to develop a platform that could be shareable between breweries. We started a pilot a few years back but decided to find a partner who could develop an AI and machine learning solution that was more agnostic. We had tried several solutions but found them hard to scale with the same success from one site, to two, or three sites. So, we were looking for a platform to use with an algorithm that was more independent of the specific environment that we were working on, like the type of data we had or the installation on different machines and so on. That’s what we found with SORBA. It’s easy to use and could be tailored to the business need.

Today it is more than an individual energy solution. Initially we were focusing on steam, heat, and energy, but now the same platform is being leveraged in other parts of the business for things like quality purposes and the consumption of water. We’re also testing it for efficiency, like OEE validation. And it is already driving a massive benefit in terms of energy fluids. But we’re only just getting started as we are looking to extend it to more sites. And our teams who are using it are now coming up with new business cases because it’s easy to use and not so complex to set up the model, so we don’t have to tailor and customize a complete solution every time.

Q: The second award winning project is AODS in the Digital Networks and Connectivity Category. How is that helping the company?

A: This tool really allows us to compare our maintenance plans and activities across all of our operations. It’s a centralized downtime tracking and monitoring tool for brewing, packaging, and utilities operations and it can identify critical machines and connect equipment performance with a set of indicators to prescribe necessary actions and improve both line and performance results.

The goal is 100% reliability and optimized operations for all equipment and processes at all of our global facilities. This tool allows us to leverage the information we have in our Standard Operating Procedure (SOP), plus operational performance data that we have in other systems. Now we are we adding more operational data into the tool as well, more maintenance information, even spare parts, and so on. So, it’s becoming a great collaborative tool to help us benchmark and find best practices across our operations, especially when you have similar machines or similar conditions.

“We have defined three key aspects of digital technology that we are working on. One is the democratization of data to make sure it is easily available to the front line.”

We are now expanding this to other areas of the company and I’m confident the more data we put in, the more we can leverage the analytics to give us additional value and multiply the benefits we are seeing today.

Q: And the third project, using the ACADIA and DeepHow tools in the Operational Excellence category?

A: These are tools to help empower front-line teams. Acadia automates our SOP in a digital way, replacing paper and PDFs with a more modern experience with short videos. We combined this with the AI powered DeepHow tool which makes it much easier create and edit those videos and also has the capability to add subtitles and voice translation in multiple languages, so you can easily switch from Chinese to Portuguese, for example. This is important with multiple sites around the world and a global workforce.

What we are building here is another shareable knowledge platform across the company. It solves many problems on the training side, helps people learn faster, and accelerates the pace of sharing across the globe to accelerate our performance gains. And although it began with SOPs, we are now adding best practices and other kinds of training so every time we find a good solution, we can update the procedures. It’s a great enabler to help empower the front-line teams and improve decision making across all our production sites

Q: When you look back at these projects, what have you learned about digital transformation along the way?

A: Clearly, the technology does not define the solution. If you have a problem, then you can leverage technology to find the right solution. But it’s not about doing technology for technology’s sake and then trying to find a problem to solve. All three projects were either solving a business issue or helping us seize a business opportunity. And all of them have delivered clear tangible benefits for the company, whether it’s in financial performance or the number of people they reach. I believe the participation of the frontline teams in their development was key to making them successful. Those teams become part of the solution, identify with it, and have a strong sense of ownership. Finally, you need to have good metrics to help you know when to scale. Not everything you try to explore is going to be a success, but if you have good metrics and goals from the beginning it helps you to identify whether a pilot is a success or not, or whether you could improve the new tools more to bring more value at scale.

“We also need to be more modular, more flexible, with systems that can be more easily tailored to the needs of specific businesses so we can be more agile in the future.”

Q: These are challenging times, though. What challenges still keep you awake at night?

A: We’re not short of challenges today with today’s dynamic operating environment. The safety of our people is always our priority. Despite the challenges, we remain focused on creatively using technology to find solutions that can help us to continue to grow, to continue to invest, and to continue to drive towards world class performance. And we want to do so while advancing our sustainability goals and our purpose to create a future with more cheers.

Q: Looking ahead, what would you highlight as the greatest business challenges and opportunities for the manufacturing industry over the next five years?

A: One thing we have learned in recent years is that the future is becoming less predictable. We need to prepare for that, so we have to build a more resilient supply chain, and a more flexible supply chain. I think that’s the biggest business challenge for the industry going forward and using technology as an enabler to help solve new problems. So, we need to increase collaboration with everyone across the ecosystem – suppliers, partners, vendors, universities, associations like the MLC, and so on – to achieve that resiliency and sustainability. We used to have a very transactional relationship with vendors and suppliers and we are now changing that to be more partners, sharing more, and opening our doors.

For example, to meet our sustainability goals, and for every company’s sustainability goals, we have to look at Scope 1, 2, and 3 requirements which means the scope goes beyond out operations and across the entire supply chain. We recognise that we need to collaborate with our suppliers and distributors along that chain, to be able to meet our ambition to achieve net zero by 2040 across our value chain. We need to work together and share more good solutions. We need to use systems that talk to each other end-to-end across the supply chain, so we have more visibility on supplier operations, and we give them more visibility on our front-line operations, production planning, and so on. Manufacturing needs to create an ecosystem in the future where we can learn from each other. And we have to actually enable that to happen as becoming more resilient will require building a collaborative ecosystem.

Q: What are the priorities for your own digital strategy to meet those future challenges?

A: We have defined three key aspects of digital technology that we are working on. One is the making the data more accessible and easily available to the front line. That may sound like an easy thing, but in a large company like ours, with a very diverse footprint, with different operations and different ages of equipment, it’s not a simple thing to do. So, we need to standardize that data from anywhere in the world, whether it is coming from China or Brazil, so we can see all that information in the same way.

“All three projects were either solving a business issue or helping us seize a business opportunity.”

That will allow us to use a more modular execution system. We used to have a very monolithic system, which was hard to adapt and implement. Now we need to be more modular, more flexible, with systems that can be more easily tailored to the needs of specific businesses so we can be more agile in the future.

The third layer is advanced analytics. So, we want to be able to use all the data we have from the first level, contextualize it in a more modular execution system, then apply all the different levels of analytics tools we have, from BI to AI and machine learning to digital twins.

Those are the three aspects that we believe will help make a real difference in the future.

Q: What new leadership skills do you feel that senior industry executives now need to successfully drive that continuing digital transformation?

A: It is critical to empower the front line. Leaders should be focused on providing the resources to allow people to do the work and achieve excellence themselves. Leaders also have to be mindful of a culture of collaboration and inclusive environment that stretches both inside and outside the company. They should also have active listening and communicating skills to understand and help resolve challenges.

In the end, people are key for any business transformation. They are the ones who make the technology work, who adopt the new digital tools, and who find the right problems to address. People make or break digital transformation programs. To move from a traditional, operational approach to more people-empowered collaborative decision making we need more knowledge, more information, and we need to put that knowledge into people’s hands so they can apply it to create a better decision-making process. Today, knowledge is more important than ever. We have to have the knowledge and the skilled people who can use it to drive our transformation. Technology is also evolving very fast and nothing can be taken for granted. So, that requires new leadership skills where leaders must be able to really listen to their teams and understand the potential or limitations of different technologies so we can find the right ways to succeed with any implementation.

Q: Finally, if you had to focus on one thing as a watchword or catchphrase for the future of manufacturing, what would that be?

A: I’ll use our company purpose: “The dream big to create a future with more cheers”. When we have a more collaborative ecosystem that shares learnings and best practices, and when we have more inclusive, sustainable environments across the industry, then we really will have a brighter future for everyone, our employees, our customers, our suppliers, our shareholders, and so on. And technology plays an important role in helping us to get there. M

FACT FILE: Anheuser-Busch InBev

HQ: Leuven, Belgium

Industry Sector: Consumer Goods

Revenues: $54.30 Billion (2021)

Net Earnings: $13.82 Billion (2021)

Employees: 169,000 Employees

Presence: Operations in 50 Countries

Production Sites: 200 Breweries + 40 Vertical Facilities

Website: www.ab-inbev.com

EXECUTIVE PROFILE: Marcelo Ribeiro

Title: Global Vice President, Engineering and Operations, Anheuser-Busch InBev

Nationality: Brazilian

Education: BSc Mechanical Engineering, Universidade de São Paulo, Brazil; MBA, Universidade Luterana do

Brasil-Canoas RS, Brazil; Accelerated Leadership, INSEAD, Paris, France.

Languages: Portuguese, English, German, Spanish

Previous Roles Include:

– Global Vice President, Engineering, Anheuser-Busch InBev

– Zone Brewery Support, North America Region, Anheuser-Busch InBev

– Global Packaging Director, Anheuser-Busch InBev

– APAC Zone Brewery Support, Anheuser-Busch InBev

– People Supply Director – Canada, Anheuser-Busch InBev

– VPO Implementation Manager, Montreal & London, Anheuser-Busch InBev

– Plant Manager – AmBev

– Corporate Manager, Manufacturing Projects Leader, AmBev,

– Project Manager, Fichtner Consulting Engineers

Other Industry Roles/Awards/Board Memberships

– 2022 Manufacturer of the Year – Large Enterprise, Manufacturing Leadership Awards MLC/NAM

About the author:

Paul Tate is Co-founding Executive Editor and Senior Content Director of the NAM’s. Manufacturing Leadership Council.