M2030 Perspective: FOMO Can Spark Next Digital Revolution

What the past tells us about an AI and ML enriched future

TAKEAWAYS:

● Manufacturers can leverage AI/ML strategies to overcome the prohibitive cost related to data-driven decision-making.

● AI and ML are business investments not technology investments.

● In the future, AI will drive people, process and technology changes that deliver manufacturing ROI.

Past is prologue when it comes to AI

More than two and a half decades ago the world was in a state of panic and desperation over technology. The situation was simple: business solutions that ran supply chain, financial, and payroll systems – to name a few – could have a basic flaw in how dates were stored, and on January 1, 2000, they could simply stop working and business would stop working. The Y2K problem led to a massive investment in IT spending, turbo charging the technology capabilities that brought about the recent advancements in artificial intelligence and machine learning (AI/ML).

Then as it is now, we have a disruptive concept that threatens to upend business as usual, and executives can no longer avoid the hard discussions on how to prioritize technology investments. Then as it is now, we have a juxtaposition of business and technology interests intersecting a common goal of relevance and sustainability. The difference is that with artificial intelligence the fear of missing out is driven by excitement and opportunity.

“The difference between artificial intelligence and the Y2K problem is that with AI the fear of missing out is driven by excitement and opportunity”

The concept of data-driven decision-making, which is the basis of leveraging AI/ML in manufacturing, is not new but it has been relatively unattainable due to costs. Manufacturing is a people-driven enterprise that needs to maximize efficiencies to keep costs down and react to customer demands. The challenge is how to balance business operations with the disruption in leveraging new systems and process, balancing the potential skill gaps in using automated systems, and driving towards measurable business outcomes. As we move toward the year 2030, AI/ML can be the unifier of all those goals if manufacturers can map executive goals and business outcomes to people, process, and technology.

People power to drive top-down transformation

With the popularity of topics around generative AI and ability to access technology infrastructure for various back-office automation tasks there is urgency to innovate to stay ahead. The change that occurred since last year is driven by awareness, access, and actionable insights in the manufacturing space driving pragmatic business innovations. Executives have greater awareness of how to leverage AI/ML in business operations and are empowering their teams to invest in digital strategies around automation and efficiency. IT and business leaders within organizations are finding common cause in terms of goals for improving supply chains, understanding customer behavior, improving product quality, and investing in sustainable practices. The general concerns and narrative that AI may replace people is shifting to how AI is helping teach the workforce and automate complex production processes. While common misconceptions around AI sophistication and the practicality of certain use cases still exist, the urgency of change is overcoming the stagnant comfort of the predictable. As we move towards 2030, we will see more broad adoption of these technologies to work side-by-side and seamlessly in performing business actions severely reducing manual repetitive tasks.

Pragmatic solutions to drive maximum ROI

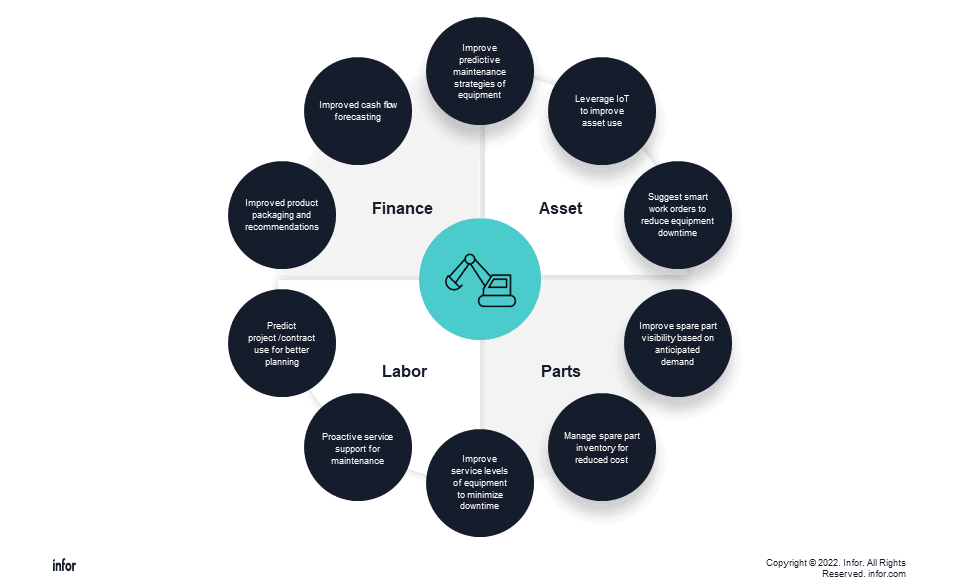

Concepts like Industry 4.0 drive business goals towards automated dark factories heavily leveraging IoT sensors that constantly improving plant output. Looking beyond factory operations, AI/ML solutions can optimize entire value chains as illustrated in a sample view of an equipment as a service manufacturer/distributer.

Figure 1: Leverage AI/ML solutions to drive enterprise value in manufacturing and after-market service.

The benefits earned from leveraging AI/ML solutions to track asset management and performance, labor, and financial planning are an example of data-driven decision-making and leveraging “one version of the truth” in business operations with clear ROI.

Considering these use cases can be setup very quickly and incrementally, they can drive manufacturers’ changes and urgency to adopt measurable business innovations.

Investment in business versus technology

Manufactures, like other businesses, are loathe to spend money on IT for the sake of re-platforming the business. Perception of IT spending as a costly task changes significantly with AI/ML-powered solutions.

The target goals for these solutions are business productivity, plant scrap reduction, financial visibility, and improved revenue, which are markedly more impactful than purchasing a new business application. Other tangible business applications are better customer and employee experience driven by personalized and contextual actions. The implicit benefits of cloud-based architecture and improved cyber security are attractive but not as much compared to improved margins and responsive business operations. Focusing on technology as a means for better business results is a big difference in driving future investments in the next several years. Manufacturers will invest in approaches that drive better, transparent, explainable, and faster time to value that provide seamless decisions between different business systems with more emphasis on action versus interaction. Focus will be on how automated decision-making results in improved productivity versus the current focus on user experience and complex manual tasks.

Bringing digital revolution 2.0 into focus

As manufacturers begin adopting data-driven decision-making tools, the current AI/ML strategies will change to adapt to more complex ecosystems. While we already have focus on sustainability and automated decision-making, the future will bring more emphasis on circular economy value chains involving leveraging data across different companies across the product lifecycle and responding proactively to customer needs. By 2030, this will open up an avenue to track products, customer use, recycling, and maintenance, which will expand business opportunities for new product development and new manufacturing processes. This will ultimately and hopefully lead to digital revolution 2.0! M

About the author:

Sandeep Anand is Senior Director of Decision Analytics and Science Platform at Infor. He has over 15 years of experience building and delivering AI/ML solutions. Experience includes solutions around yield/scrap, supply chain improvements, and smart asset management strategies. He leads the AI/ML practice at Infor, a leading enterprise cloud solutions provider.