2022 Speakers

Cindy Farrer

Senior Vice President of Global Operations and Integrated Supply Chain, Allegion

Mike Tomasco

Senior Vice President and Chief Information Officer, FUJIFILM Biotechnologies

Can’t make it to Marco Island? You can still participate in Rethink as a virtual attendee. Virtual registration includes:

Note: Virtual registration closes at 11:59 pm on Monday, June 27. There will be no registration available during the event.

Devoted to digital manufacturing, Rethink is the world’s premier event for senior operational executives and their teams as they continue to navigate disruption.

Find out how the world’s leading manufacturers are tackling digital transformation for operations. Rethink offers three days of best practices, real-world concepts, and strategic insights for senior operational executives and their teams.

Rethink examines digital manufacturing as it intersects with technology, organizations, and leadership. Come away with a better understanding of what’s needed to compete, succeed, and thrive on the journey to Manufacturing 4.0.

Engage and learn through keynotes, breakout sessions, 1-on-1 meetings, and networking events.

Need we say more? Spend several days building relationships and connecting with like-minded executives both in and out of the event sessions.

Need we say more? Spend several days building relationships and connecting with like-minded executives both in and out of the event sessions.

Hear from industry experts with curated content throughout the event, including real-world case studies, panel discussions, research insights, executive interviews and more!

Hear from industry experts with curated content throughout the event, including real-world case studies, panel discussions, research insights, executive interviews and more!

Participate in our personal 1-on-1 meetings to understand how different solutions can help you overcome your current business challenges.

Participate in our personal 1-on-1 meetings to understand how different solutions can help you overcome your current business challenges.

Collaborate, engage, share and learn with your peers in our interactive Think Tank sessions. With a dozen topics to choose from, you are certain to walk away with new insights and ideas.

Collaborate, engage, share and learn with your peers in our interactive Think Tank sessions. With a dozen topics to choose from, you are certain to walk away with new insights and ideas.

No matter where you are in your digital transformation journey, Rethink will help you understand how technologies can accelerate your journey, provide real-world insights and access to the manufacturing organizations leading the way.

No matter where you are in your digital transformation journey, Rethink will help you understand how technologies can accelerate your journey, provide real-world insights and access to the manufacturing organizations leading the way.

A Rethink exclusive! Hear the highlights from each of our event partners during the Rethink custom VIP tour. In two minutes or less, you’ll gain quick insights and know where you’d like to take the opportunity to understand more.

A Rethink exclusive! Hear the highlights from each of our event partners during the Rethink custom VIP tour. In two minutes or less, you’ll gain quick insights and know where you’d like to take the opportunity to understand more.

Join small group table discussions during lunch to discuss specific industry topics around some of the biggest challenges facing manufacturers today.

Join small group table discussions during lunch to discuss specific industry topics around some of the biggest challenges facing manufacturers today.

Connect with some of the top Manufacturing Leadership Award project winners and gain firsthand insights into their award-winning projects during our lightning round sessions and meet n’ greet tables.

Connect with some of the top Manufacturing Leadership Award project winners and gain firsthand insights into their award-winning projects during our lightning round sessions and meet n’ greet tables.

Located along the tranquil waters of the Gulf of Mexico on a white sand beach, the JW Marriott Marco Island Beach Resort offers a luxurious setting for our first in-person Rethink since 2019!

Located along the tranquil waters of the Gulf of Mexico on a white sand beach, the JW Marriott Marco Island Beach Resort offers a luxurious setting for our first in-person Rethink since 2019!

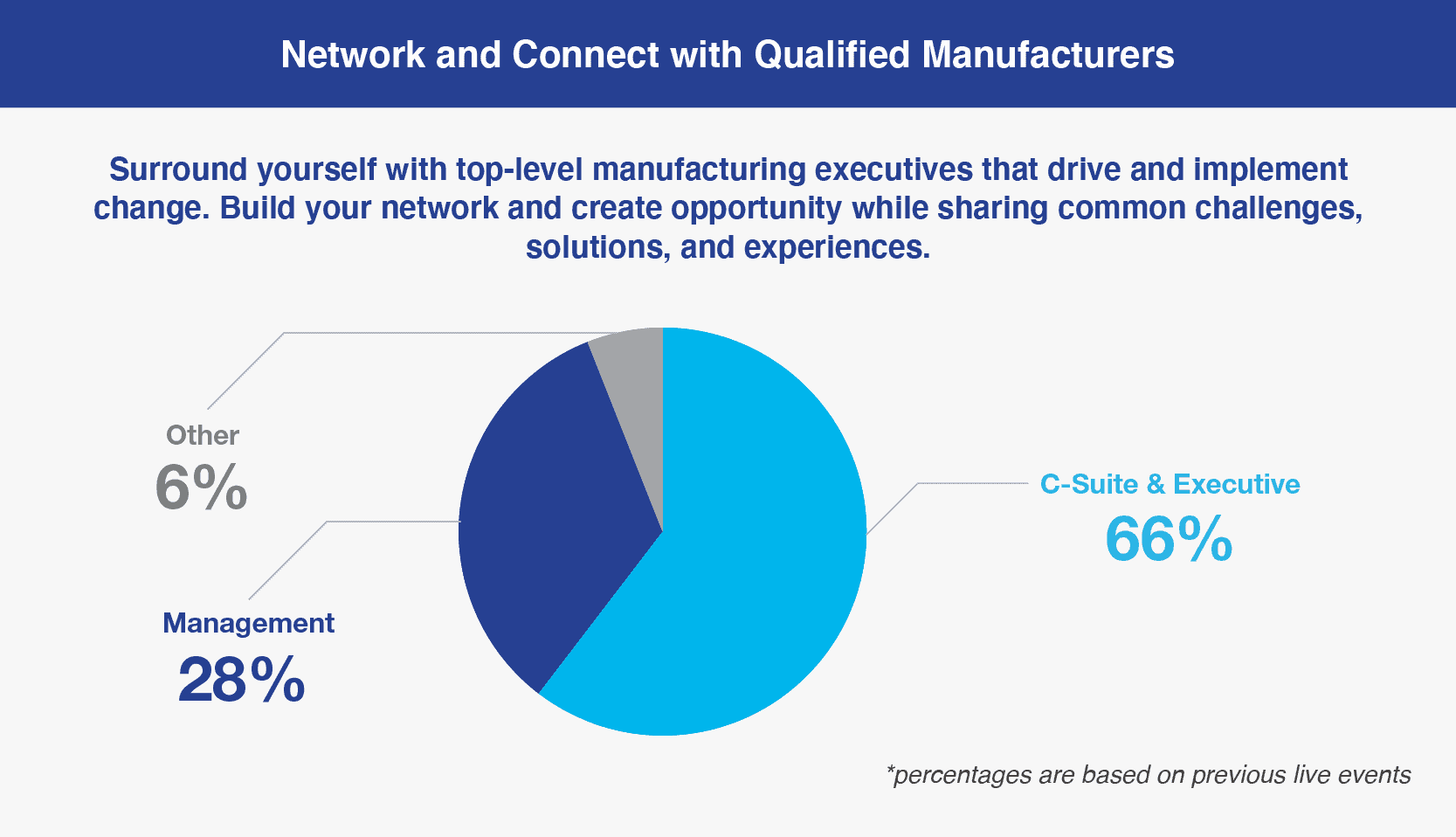

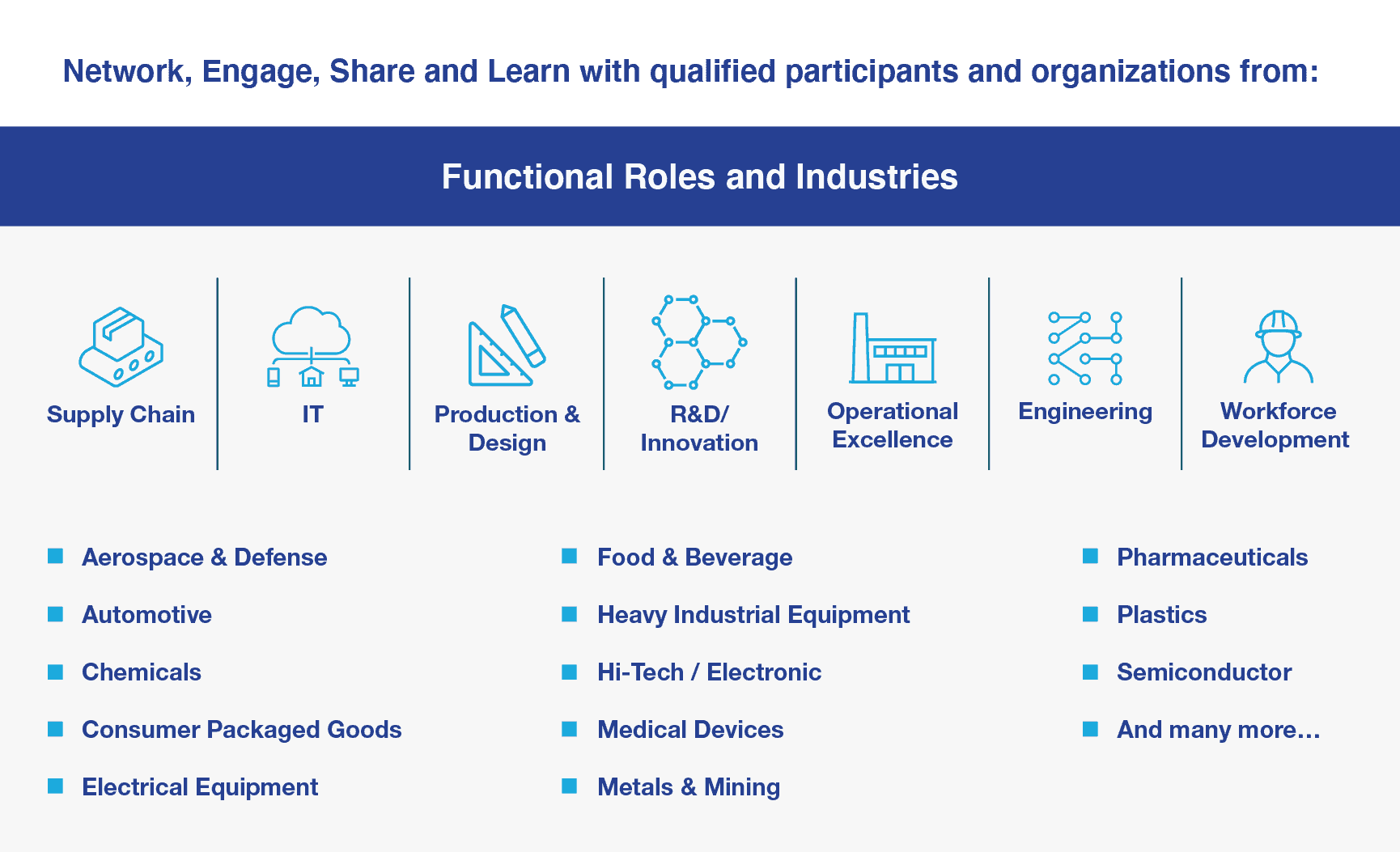

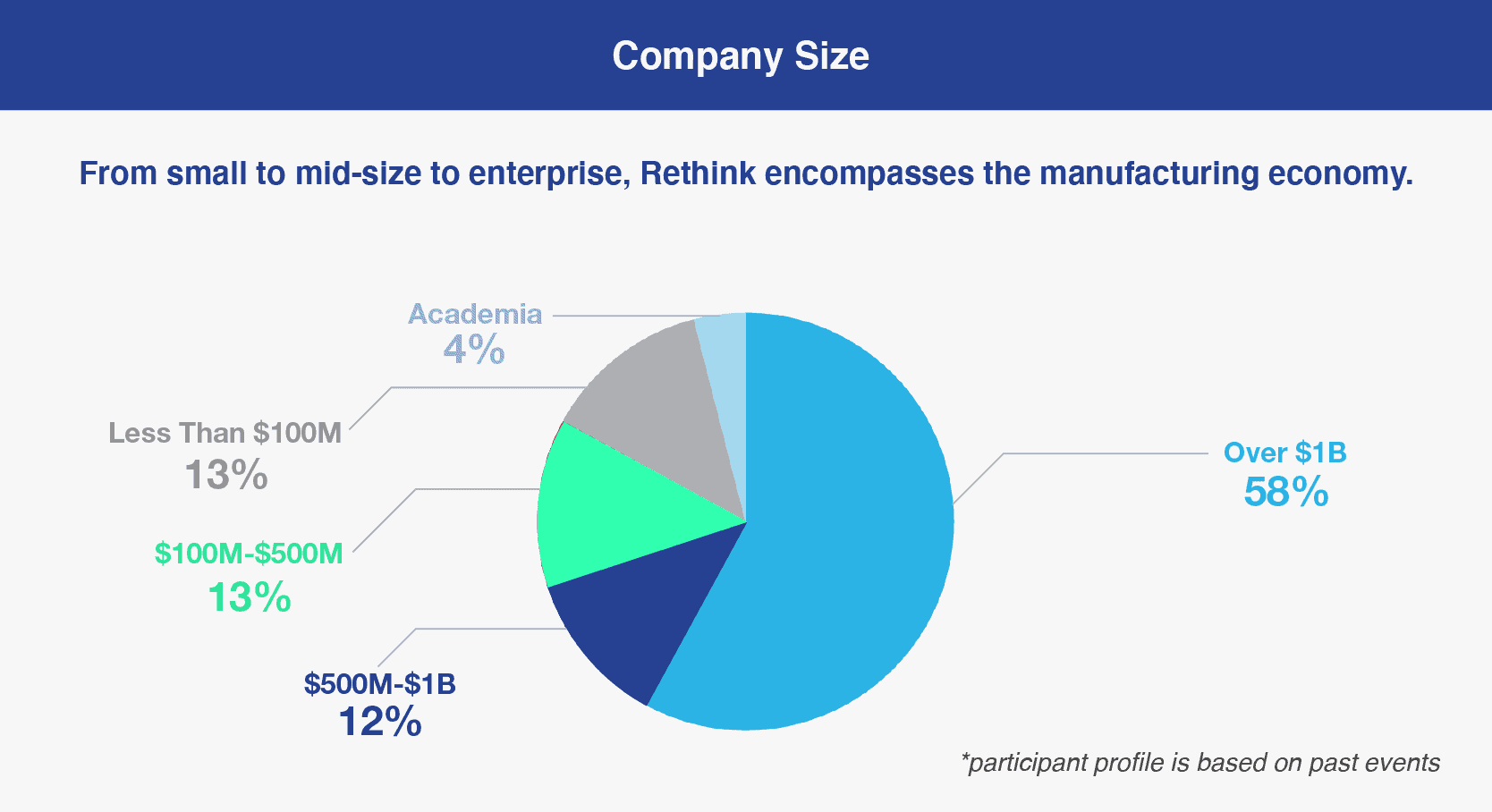

With over 300+ top-level manufacturing executives and their teams, you’ll have access to real conversations, revealing real insights and providing real results.

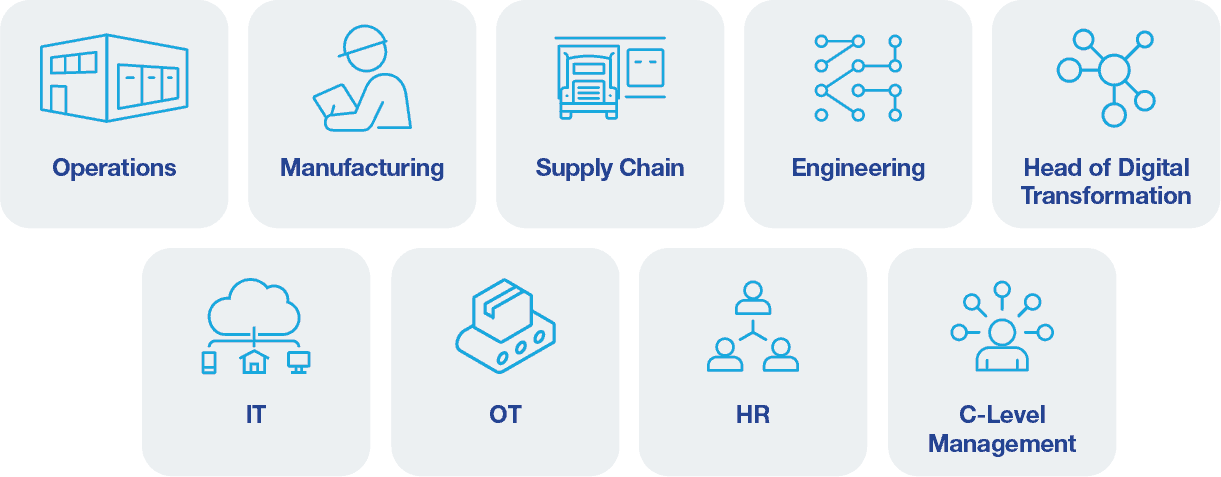

Manufacturing 4.0 requires support from cross-functional teams within multiple divisions to integrate technologies, advance the adoption of M4.0 and keep your organization ahead of the curve.

Rethink is designed to support all areas and provides content that covers technology, organization, culture, leadership, workforce and more.

This event is built for you and your team, including, but not limited to:

With multiple concurrent interactive sessions, more than two dozen live sessions, and access to content pre and post-event as well as main stage session recordings, the best value will come from providing your team access to Rethink 2022. With multiple participants, you’ll be able to divide and conquer to collaborate and bring new ideas back to your company!

Agriculture is nearly as old as humankind itself but keeping up with today’s global food demand requires modern innovations. Corteva Agriscience, the winner of the 2020 Manufacturing Leadership Awards Large Enterprise Manufacturer of the Year, is utilizing machine learning data science techniques and advanced analytics to create more sustainable and efficient means of farming and food production. By developing capabilities in agile team management, data engineering, and AI implementation, Corteva is moving forward in its digital journey and improving its ability to pivot along with continuously changing business needs. This transformation is also helping Corteva reduce emissions, increase use of sustainable packaging, reduce waste, and other sustainability advances.

In conversation with: Paul Tate, Co-Founding Executive Editor and Senior Content Director, Manufacturing Leadership Council

As a result of the pandemic, many manufacturing companies are rethinking their supply chain strategies, shifting to a much greater emphasis on supplier risk management and supply chain resiliency. The goal: enabling greater supply chain continuity. Learn how Allegion and Schneider Electric are developing their new strategies in a time of protracted disruption.

As manufacturers proceed with their M4.0 journeys, clearly understanding the challenges with identifying and measuring business value, partnering with vendors, extracting insights from data, and having the right talent are key factors for success. This session will reveal the 10 most important lessons for a successful M4.0 journey.

In the era of Manufacturing 4.0, many companies have taken on a data modernization (and data monetization) exercise to reach the next level of business and process efficiencies.

But it is not easy to achieve those end goals without having a deep and contextualized look at what the data is telling you. Data is most powerful when viewed through the right lens – i.e., when analyzed and filtered for a company’s unique business needs, then advanced toward actionable insights. This discussion will examine recent findings, best practices, and real-world success stories for data contextualization, including practical and relevant IT+OT data integration along with the what, why, and how for creating the right M4.0 data strategy.

In conversation with: Penelope Brown, Senior Content Director, Manufacturing Leadership Council

The pandemic has up-ended supply chains around the world, forcing manufacturers to rethink their strategies to ensure greater resilience. This session will explore best practices on the deployment of digital tools and ecosystems to help empower companies to create more agile and resilient supply chains that provide the end-to-end visibility and flexibility needed by all supply network partners.

Co-Facilitators:

MLC Moderator:

As IT and OT technologies converge at the hands of operators and management responsible for progress on the front line of operations, new digitally connected processes have emerged with powerful insights that can not only enrich equipment performance monitoring but also unlock breakthrough improvements in overall factory efficiency and quality. This case study will look at how leveraging plant floor IT and OT data can be mastered to achieve breakthroughs in bottom-line performance, with speed and at scale.

Facilitator:

MLC Moderator:

Digital transformation demands a responsive and data-empowered business culture. Traditional hierarchical management and siloed teams are less attractive to a younger, more digitally savvy workforce and struggle with the agility required to respond quickly, missing out on opportunities for collaboration, better performance, and improved competitiveness. This expert panel will examine how to create business cultural transformation and the benefits of undertaking this necessary change.

Panelists:

MLC Moderator:

Complex optimization problems make up a large part of the manufacturing problem space across every part of the value chain, such as materials procurement, robotics, plant maintenance, route optimization, pricing, staffing, scheduling, and more. In a recent research study, over half of the manufacturers surveyed already had a program to explore how quantum systems could be applied to their business problems. This session will provide an overview of some of the most promising quantum use cases in logistics, introduce the concept of classical-quantum hybrid computing and provide guidance on assessing the suitability of quantum for different types of applications.

Facilitator:

MLC Moderator:

As the Colonial Pipeline case in 2021 clearly demonstrated, cyber-attacks have serious consequences not only to the companies targeted but for society at large. This Think Tank will look at best practices companies can adopt to reduce their vulnerability, manage cyber risks effectively, secure their data assets, and better protect their IP.

Facilitator:

MLC Moderator:

MLC research indicates that 80% of manufacturers have already invested in IIoT or will do so in the immediate future. How can they get the most from those networks? The right ecosystem is essential to collecting the right data and leveraging streaming analytics that can have the most business impact. This expert panel will examine considerations for building a robust network that can deliver effective results.

Panelists:

MLC Moderator:

What role will artificial intelligence play in the many enterprise applications – ERP, PLM, SCM, Quality, MRO –that run today’s factories and plants? Will AI help manufacturers using these applications make better decisions faster? Will AI automate basic routines, freeing up users to engage in higher level analytics? This session will focus on the benefits and challenges of AI-powered enterprise applications and what their use in manufacturing might mean in the years ahead.

In conversation with: Paul Tate, Co-Founding Executive Editor and Senior Content Director, Manufacturing Leadership Council

One of the foundational requirements for successful digital transformation is the ability to manage and analyze data from all aspects of operations and use it effectively to improve decision-making processes. But cultural issues often constrain manufacturing organizations from achieving this goal. Now, the emerging discipline of data literacy offers a way to overcome cultural hurdles.

In this session, we will:

Moderator: David R. Brousell, Co-Founder, Manufacturing Leadership Council

Panelists:

Digital transformation can mean very different things for manufacturing companies of different sizes. For smaller companies, expertise and resources can be issues. For larger companies, complexity and inertia can be constraints. But for the industry to succeed with M4.0, all companies need to be able to take advantage of the digital opportunity. Representatives from small, mid-size and large manufacturing companies will share their perspectives on how the industry can avoid a digital divide.

BTE Technologies, a supplier of physical rehabilitation equipment and services, is undertaking its digital journey using lean disciplines as a foundation. This session will explain BTE’s vision for the future, what it hopes to achieve with M4.0, and the challenges it sees along the way.

Pfizer, the $81 billion pharmaceutical and biotechnology company, will share the journey of Pfizer Global Supply’s transition from a digitally-siloed operation to a world-class, digitally-enabled operation. This journey involved experimentation, failure, a transition to scaled agile ways of working, and, ultimately, the transition from pilot purgatory to large-scale global transformation.

Moderator: Penelope Brown, Senior Content Director, Manufacturing Leadership Council

Panelists:

If the adage holds true – “turbulent times make skilled sailors” – then today’s up-and-coming manufacturing leaders are developing a remarkable skill set. Disruption has become the new expectation and there are no comprehensive training manuals for today’s version of on-the-job learning. In this panel discussion, some of manufacturing’s leaders of tomorrow will share what companies should prioritize now to get in position for a better future, what are the most important leadership skills to have in times of change, and what lessons they’ll bring with them for the rest of their career.

Corning, the $14 billion manufacturer of glass, ceramics, and materials, has undertaken a comprehensive digital transformation strategy. The manufacturing digital strategy includes the company’s new M4.0 Framework, designed to establish a common set of factory digital solutions throughout Corning. The Framework allows Corning to articulate the digital applications, IOT and essential infrastructure capabilities that all plants need to deliver their business strategies. This session will explain how Corning defines the concept of a digital factory, what “good” looks like, and how the strategy provides a playbook for legacy upgrades and greenfield investments.

In conversation with: David R. Brousell, Co-Founder, Manufacturing Leadership Council

A data-driven manufacturer delivers value through seamless integration of reliable digital platforms and services connecting people, processes, and information. This entails increasing visibility of data from the shop floor and leveraging digital capabilities to automate processes, improve operational KPIs, and deliver business results. In this session, learn how Ingredion Incorporated, a $6 billion global manufacturer of ingredients such as sweeteners, starches, and biomaterials, has embraced smart manufacturing and digitization. The company’s Digital Plant initiative has focused on replacing manual or paper-based processes with digital and mobile-enabled solutions as well as decreasing reactive maintenance, unplanned downtime, and planned maintenance costs. The program’s benefits, challenges and future goals will be discussed.

5G networks can enable a high-powered, high-speed manufacturing environment with lower latency and the ability to connect more sensors and equipment than on previous generations of wired and wireless networks. This session will explore current use cases for 5G on the plant floor and considerations for its deployment.

Facilitator:

MLC Moderator:

This session will examine how digital technologies are transforming traditional innovation and ideation processes in manufacturing to help inspire exponential thinking in new product and service design, revolutionize production operations, embrace more sustainable practices, and empower individual employee creativity.

Panelists:

MLC Moderator:

Additive manufacturing has proven to be competitive for low-volume production and mass customization of industrial-grade parts. Manufacturers are using it to develop custom tooling and assembly aids at factories for example. This case study will look at how additive systems are being used to make parts, what advantages have resulted, and what future applications may be in the wings.

Facilitator:

MLC Moderator:

Machine learning, a subset of artificial intelligence, enables machines to learn from past data or experiences without being explicitly programmed. The benefits of doing so have become clear to manufacturers: nearly half of respondents to an MLC survey late last year said they have invested in the technology. This session will explore how manufacturers can get the most from the ML systems.

Co-Facilitators:

MLC Moderator:

To win in manufacturing today you need to design, iterate, and deliver the best products faster than everyone else. And you’ve got to do it with a diverse and distributed workforce, operating in a globally dispersed ecosystem, against a backdrop of generational change and high employee turnover. How effectively your teams, stakeholders, and customers collaborate and interact will define your success – which makes adoption of new communication technologies not just a journey of discovery, but a competitive necessity.

Co-Facilitators:

MLC Moderator:

A deep dive look into one company’s advanced deployment of augmented and virtual reality technologies to help transform operational activities and empower front-line workers with access to the data and visual tools they need to continually improve performance and create innovative new insights.

Co-Facilitators:

MLC Moderator:

Get a deeper look at some of this year’s top projects from the Manufacturing Leadership Awards. Featuring presentations from:

Our high-caliber speaker lineup will bring you the insight and inspiration you need for moving your business forward. Check back as more speakers are added to this list.

For information on becoming and/or nominating a speaker, please contact [email protected].

Marco Island, Florida

Please note that due to increased demand at this year’s Rethink, the group block at the JW Marriott Marco Island and Hilton Marco Island are sold out over the program dates. Below are other nearby hotels with availability. They are within a 10-minute drive of the JW Marriott Marco Island

Hilton Marco Island Beach Resort and Spa – some rooms outside of the group block rate are available starting at $650 per night.

To make reservations online, click here.

To make reservations by phone, call (239) 642-2103 and mention the National Association of Manufacturers.

Olde Marco Island Inn & Suites

To make reservations online, click here.

To make reservations by phone, call (239) 394-3131.

Marco Island Lakeside Inn

To make reservations online, click here.

To make reservations by phone, call (800) 729-0216.

Southwest Florida International Airport (50 miles)

Fort Lauderdale-Hollywood International Airport (120 miles)

Sponsorship investments at Rethink provide you the opportunity to connect with top manufacturing executives and are proven to deliver results.

With multiple opportunities to educate buyers about your products and services, discuss challenges and solutions, showcase thought leadership, connect with attendees, build relationships, and generate opportunities with the executive audience, you are guaranteed to see results.

Partnering with NAM’s Manufacturing Leadership Council as a sponsor at Rethink, you’ll have the opportunity to:

Sponsorships are limited and available in a range of levels. Please contact us today to discuss a customized solution for your organization.

Hitachi drives Social Innovation Business, creating a sustainable society with data and technology. We will solve customers’ and society’s challenges with Lumada solutions leveraging IT, OT (Operational Technology) and products, under the business structure of Digital Systems & Services, Green Energy & Mobility, Connective Industries and Automotive Systems. Driven by green, digital, and innovation, we aim for growth through collaboration with our customers.

Infor is a global leader in business cloud software specialized by industry. We develop complete solutions for our focus industries, including industrial manufacturing, distribution, healthcare, food & beverage, automotive, aerospace & defense, and high tech. Infor’s mission-critical enterprise applications and services are designed to deliver sustainable operational advantages with security and faster time to value. We are obsessed with delivering successful business outcomes for customers. Over 65,000 organizations in more than 175 countries rely on Infor’s 17,000 employees to help achieve their business goals. As a Koch company, our financial strength, ownership structure, and long-term view empower us to foster enduring, mutually beneficial relationships with our customers.

Infor Website | LinkedIn | Twitter | YouTube | Facebook

NTT DATA – part of NTT Group – is a trusted global innovator of IT and business services headquartered in Tokyo. We partner with manufacturers to deliver innovative approaches to IT, OT and business challenges. Our experts provide deep industry expertise with applied innovations in digital, cloud and automation across a comprehensive portfolio of consulting, industry solutions, business process services, IT modernization and managed services. We enable clients, and society, to move confidently into the digital future and are committed to our clients’ long-term success.

Maximize productivity by streamlining your purchasing experience. With the value and convenience of Amazon, plus innovative tools and features, procurement leaders in the industrial sector are reducing costs, saving time, and scaling operations while delivering an elevated user experience.

Arch Systems is the leading machine data and analytics provider for electronics and discrete manufacturing with more than 5,000 machines in over 15 countries- powering real time and predictive analytics, improving key metrics such as capacity utilization, quality, and maintenance. Arch has built the largest collaboration of industry domain experts and data scientists, mapping new signals in manufacturing data- changing how manufacturers tackle their most complex problems and allowing them to simplify and align actions both on the shop floor and the top floor.

Technology is complex, and transformation is fast. But when it comes to connectivity and communication, AT&T Business has you covered. We combine our leading portfolio with continuous innovation and investment in our networks to give you what you need to move your business forward. With experience across industries, we understand your business demands, and deliver the right insights, guidance, and highly secure solutions for you. From 5G to fiber, edge to cloud, we help you tackle todays’ challenges and seize tomorrow’s opportunities.

AT&T Business Website |LinkedIn | Twitter | Facebook | AT&T Business Virtual Manufacturing Tour

Advanced Technology Services, Inc. (ATS), is a leading industrial services provider with over three decades of proven experience in technology-driven industrial maintenance and MRO asset management. Through a technically skilled workforce, best-in-class processes, and Industry 4.0 technologies we deliver asset health and productivity to many leading process and discrete manufacturers. ATS is headquartered in Illinois with regional offices located throughout the U.S., Mexico and U.K.

Advanced Technology Services, Inc. (ATS), is a leading industrial services provider with over three decades of proven experience in technology-driven industrial maintenance and MRO asset management. Through a technically skilled workforce, best-in-class processes, and Industry 4.0 technologies we deliver asset health and productivity to many leading process and discrete manufacturers. ATS is headquartered in Illinois with regional offices located throughout the U.S., Mexico and U.K.

Canvas GFX provides collaborative software to power your shift to interactive 3D documentation. The Canvas Envision platform provides a single environment which empowers your teams and stakeholders create, collaborate on, and access interactive 3D content, wherever they are. Replace flat, text-heavy documentation with digital visual experiences that let your audience manipulate 3D models to drive faster, more complete knowledge transfer. Developed to power collaborative design review, digital step instructions, maintenance manuals and more, Canvas software is trusted by the world’s biggest manufacturing brands.

An integral part of the Dassault Systèmes 3DEXPERIENCE platform is the connection between the virtual and real worlds.

DELMIA, powered by the 3DEXPERIENCE platform, helps industries and service providers connect the virtual and real worlds of value networks to collaborate, model, optimize and perform. Operational excellence requires harmony across the value network. DELMIA provides solutions to leverage the virtual world of modeling and simulation with the real world of operations to provide a complete solution to value network stakeholders: From suppliers, to manufacturers, to logistics and transportation providers, to service operators and workforces.

DELMIA disciplines: • Collaborative Operations • Industrial Engineering • Planning & Optimization

• Manufacturing & Operations

Dassault Systèmes Website | LinkedIn | Twitter | YouTube | Facebook

D-Wave is the leader in the development and delivery of quantum computing systems, software and services. Our mission is to unlock the power of quantum computing for the world. We do this by delivering customer value with practical quantum applications for problems as diverse as logistics, artificial intelligence, materials sciences, drug discovery, scheduling, cybersecurity, fault detection, and financial modeling.

D-Wave Website | LinkedIn | Twitter | YouTube | Facebook

Your machines are trying to talk to you – are you listening?

FORCAM delivers an award-winning platform that combines the connectivity of IIoT, the functionality of MES (Manufacturing Execution Systems) and the transparency of real-time data flows to improve the productivity, agility and profitability of manufacturing operations. With the product suite FORCAM FORCE™, customers including automotive, aerospace and defense and discrete manufacturers get the right information at the right time to everyone “from the shop floor to the top floor” for precise and actionable intelligence in a solution that’s fast to deploy and flexible to use.

FORCAM Website | LinkedIn | Twitter | YouTube

IoTco is the Internet of Things Company. IoTco provides Industry 4.0 solutions to realize Zero-Downtime, Zero-Defects manufacturing, with an ROI mindset.

We offer the Predictronics PDX platform, an end-to-end Machine Learning and AI-driven Predictive Analytics solution. PDX monitors critical assets by collecting and analyzing data, with the goal of reducing unplanned downtime, and improving product quality. Our manufacturing clients have been receiving the NAM A.I. Leadership Awards since 2019, including Maxion Wheels, Bocar, MacLean-Fogg, and most recently HINO Motors Toyota, and AO Smith.

IoTco also offers the IoT Academy for digital transformation assessments and training, in addition to our IoT Practice for Connectivity and MES/MOM system integration.

IoTco Website | LinkedIn | Twitter | YouTube

JLL is a global professional services firm specializing in real estate. We proudly serve many NAM members around the world. As a partner to our manufacturing clients, we are uniquely positioned to provide a range of services, from strategy through implementation, to optimize their operations and real estate portfolios.

Key services include:

JLL Website | LinkedIn | Twitter | YouTube | Facebook | Instagram

L2L’s Smart Manufacturing Platform helps factories achieve world-class performance by driving data-based continuous improvement across production and plant management. A different kind of solution for the real-world needs of discrete manufacturers, L2L includes 3 modules that eliminate plant floor disruptions and improve throughput: L2L CloudDISPATCH, L2L Maintenance, and L2L Production. 100% cloud-based and mobile-ready, L2L’s no-code deployment process is completed within 50 days on average, for unmatched speed to value.

L2L Website | LinkedIn | Twitter | YouTube | Facebook

Palo Alto Networks, the global cybersecurity leader, is shaping the cloud-centric future with technology that is transforming the way people and organizations operate. Our mission is to be the cybersecurity partner of choice, protecting our digital way of life. We help address the world’s greatest security challenges with continuous innovation that seizes the latest breakthroughs in artificial intelligence, analytics, automation, and orchestration. By delivering an integrated platform and empowering a growing ecosystem of partners, we are at the forefront of protecting tens of thousands of organizations across clouds, networks, and mobile devices. Our vision is a world where each day is safer and more secure than the one before.

Palo Alto Networks Website | LinkedIn | Twitter | YouTube | Facebook

The world is changing around us. Industrial enterprises need a technology partner that can help them survive—and thrive—wherever the situation, whatever the disruption. That’s where PTC shines.

Our unique portfolio of CAD, PLM, IoT, and AR technologies—delivered on-prem, hybrid, and SaaS—creates a closed loop between the digital and physical worlds to transform how everything around us is engineered, manufactured, and serviced. This digital thread enables continuity of data across departments and fosters collaboration across functions, empowering the people who are involved at every step.

PTC’s best-in-class technology enables industrial customers, from industrial equipment, high-tech, automotive, aerospace and defense, and medical devices, to improve efficiency, maximize revenue growth, and reduce operational costs.

PTC Website | LinkedIn | Twitter | YouTube | Facebook | Blog

Unity is the world’s leading platform for creating and operating interactive, real-time 3D (RT3D) content. Creators, ranging from game developers and architects to automotive designers, filmmakers and more, use Unity to make their creations come to life. Unity’s platform provides a comprehensive set of software solutions to create, run and monetize interactive, real-time 2D and 3D content for mobile phones, tablets, PCs, consoles, and augmented and virtual reality devices.

Varis is consumer-like procurement technology with a marketplace of trusted suppliers, driving hard cost savings & employee productivity.

Varis creates your own private marketplace using pre-negotiated agreements with our trusted suppliers along with your manufacturing suppliers, offering everything you need to operate. Find the right parts and products fast and compare pricing across suppliers with a single search. Plus, leverage analytics to optimize and automate your manual processes.

West Monroe is a digital consulting firm that was born in technology but built for business—partnering with companies in transformative industries to deliver quantifiable financial value. We believe that digital is a mindset—not a project, a team, or a destination—and it’s something companies become, not something they do. That’s why we work in diverse, multidisciplinary teams that blend industry expertise with deep operational and technology capabilities—moving clients from traditional to digital operating models and creating products and experiences that transcend the digital and physical worlds. Our 2,000 employees have the opportunity to own a stake in the company, so when you partner with us you know we are committed—because your success is our success. Our undeniably different approach breeds undeniable results.

West Monroe Website | Twitter | YouTube | Facebook | Instagram

If you have any questions on registration or would like more information, please contact [email protected].

By registering with the 1-to-1 Meetings Package, you are registering for participation in up to eight (8) 15-minute 1-to-1 meetings with leading and emerging sponsors of your choice to receive this discounted registration price*. These meetings are tailored to address your business challenges, gain valuable insights, and potentially find solutions. They take place during designated time periods in the agenda on Tuesday, 6/28 and Wednesday, 6/29, with no other sessions running concurrently, so you’re not missing out on any other content.

*Selections subject to availability. Limited to up to 3 team members to qualify for the discounted rate. A member of the Manufacturing Leadership Council | NAM team will reach out to you approximately 4-8 weeks prior to the event to make your selections and schedule your meetings. All meeting selections must be chosen by June 20, 2022 or the discount will no longer apply and the difference in price will be charged. For each unselected meeting pre-event or unattended meeting on-site, you will be charged.

The Manufacturing Leadership Awards Gala caps off Rethink with a celebration of the industry’s most innovative and forward-thinking companies and their achievements in Manufacturing 4.0. This fun and exciting black-tie event includes a cocktail reception, sit-down dinner, and recognition of the 2022 Manufacturing Leadership Award winners. High Achievers, Manufacturing Leader of the Year, and the Manufacturers of the Year will be announced on stage. Join us for the celebration!

The Manufacturing Leadership Awards Gala caps off Rethink with a celebration of the industry’s most innovative and forward-thinking companies and their achievements in Manufacturing 4.0. This fun and exciting black-tie event includes a cocktail reception, sit-down dinner, and recognition of the 2022 Manufacturing Leadership Award winners. High Achievers, Manufacturing Leader of the Year, and the Manufacturers of the Year will be announced on stage. Join us for the celebration!

The Manufacturing Leadership Awards recognize accomplishments and operational transformation in digital manufacturing, including high-performing projects and outstanding operations leaders. Winners are selected in nine project categories and two individual categories.

The Gala is held at 6:30 p.m. ET on Wednesday, June 29, after the conclusion of Rethink.

Gala admission is included in most Rethink registration packages; you simply need to confirm your attendance at the time of registration. Winners receive two complimentary gala passes per winning project. Other admission fees are listed below:

We have partnered with Men’s Wearhouse for tuxedo rentals. By renting though this partnership, you will receive a discounted rental rate and the tuxedo will be delivered directly to the JW Marriott Marco Island.

*You can secure your tuxedo rental by:

OR

2. Calling 1-866-211-0831 with your measurements and tuxedo selection and provide our group number #11992382

*If you are not a U.S. Resident, please contact Alyssa Dixon at [email protected] for instructions to order your tuxedo.

There will be local Men’s Wearhouse representatives at the JW Marriott for the receptions on the evenings of Monday, June 27, and Tuesday, June 28, to assist with anyone who may need to adjust any sizing/items.

If you or your guest would like to rent a formal gown for the evening, we recommend taking advantage of the formal apparel available on Rent the Runway.

To learn about sponsorship opportunities, contact Lauren Bisset at [email protected].

As the United States moves in the direction of more normal business operations and vaccine availability becomes widespread, the NAM is embracing a cautious approach to reinitiating in-person meetings. Current CDC and local health guidelines will be followed and enforced, and the NAM reserves the right to update health measures and attendance policies based on evolving health threats and guidance from Federal health agencies and local authorities. While we intend for the event to go forward as planned, the event may be impacted by future guidance from Federal and local authorities and protocols will be adjusted as warranted.

By attending this event, you agree to abide by and engage in certain mandatory health and safety conduct while attending the event.

Full vaccination is required to attend Rethink: The Manufacturing Leadership Council Summit and Awards Gala. All MLC | NAM staff onsite are fully vaccinated. Proof of vaccination through a third party will be required and instructions will be sent to all registrants before the event.

Individuals are considered fully vaccinated 2 weeks after the second dose in a 2-dose series, such as the Pfizer or Moderna vaccines, or 2 weeks after a single-dose vaccine, such as Johnson & Johnson’s Janssen vaccine.