Survey: Smarter Factories Are on the Way

Manufacturing Leadership Journal content and MLC resources are exclusively available to MLC members. Please sign up for an account or log in to view this content.

Survey: Sustainability Momentum Surges Dramatically

Manufacturing Leadership Journal content and MLC resources are exclusively available to MLC members. Please sign up for an account or log in to view this content.

Survey: More Expect M4.0 Tech Adoption to Increase

Manufacturing Leadership Journal content and MLC resources are exclusively available to MLC members. Please sign up for an account or log in to view this content.

SURVEY: Manufacturers Get Tough on Cybersecurity

More companies are taking a disciplined approach to dealing with the growing threat of cyber attacks, a new MLC survey finds.

The message has been received.

After years of mounting warnings about the risks of being hacked or worse and now faced with a sharply rising number of cyber attacks in the industry, manufacturers have taken concrete steps to fortify their defenses and protect themselves against what is widely assumed will be an even larger threat in the years ahead.

More manufacturers than ever before have put in place formal cybersecurity plans in their companies to deal with threats and attacks. They are significantly increasing their levels of confidence that they have the internal expertise in place to deal with cybersecurity issues. And a majority of companies now have dedicated cybersecurity budgets, including provisions for cyber insurance, and are providing cyber awareness and technical training to their employees.

These are some of the most important findings of the Manufacturing Leadership Council’s new survey on cybersecurity. More than 160 companies expressed their views on cybersecurity strategy in their organizations, whether they have been attacked and what the nature of those attacks were, what measures they have adopted to defend themselves, and how the growing problem of cybersecurity may be affecting their adoption of Manufacturing 4.0 and their transition to the digital model of manufacturing.

Formal Planning Takes Off

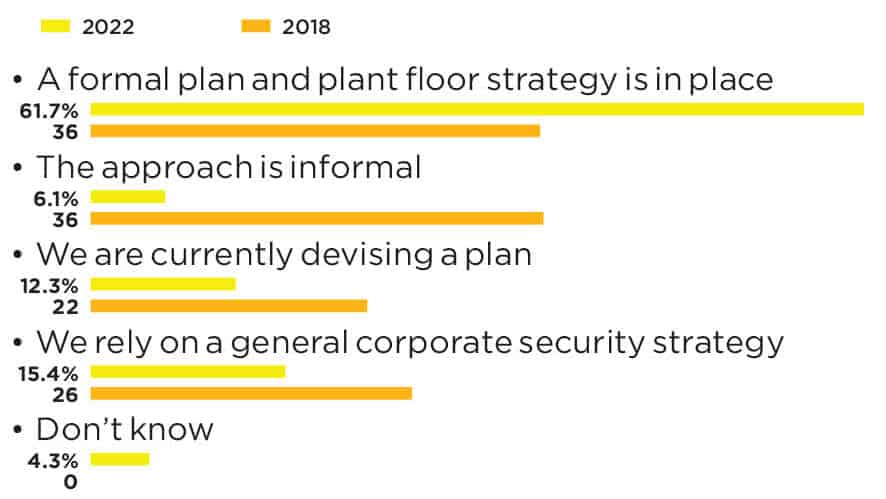

A sea change in how seriously manufacturers consider the cyber threat has occurred at the strategy level. Just four years ago, according to MLC’s 2018 cyber survey, barely one-third of manufacturers had devised and adopted formal cybersecurity plans that encompassed their plant floors. Today, the new MLC survey shows that nearly 62% have put such plans in place (Chart 1).

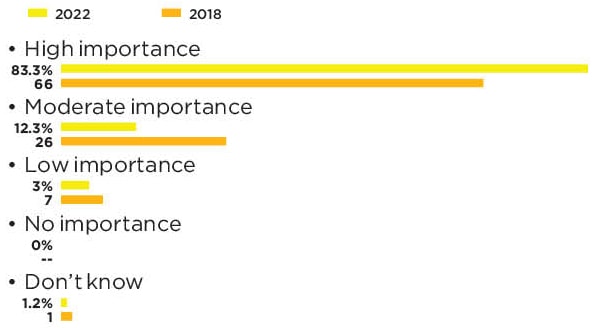

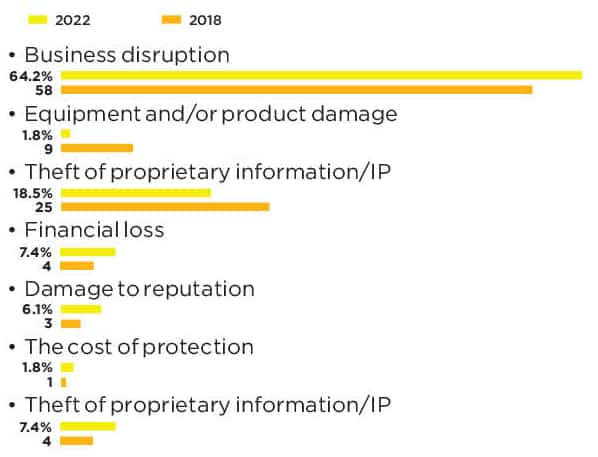

The more serious attitude is directly related to the perceived consequences of cyber attacks. When asked how important cybersecurity is as a business issue, 83% of survey respondents said it is of high importance, compared with 66% saying so in 2018. Moreover, 64% said this year that business disruption is the most significant cybersecurity-related risk to their companies, compared with 58% in 2018. Interestingly, very few fear equipment or product damage from cyber attacks and only 18% this year are worried about the theft of proprietary information (Charts 2,3).

The advent of connected business ecosystems will test current cyber strategies.

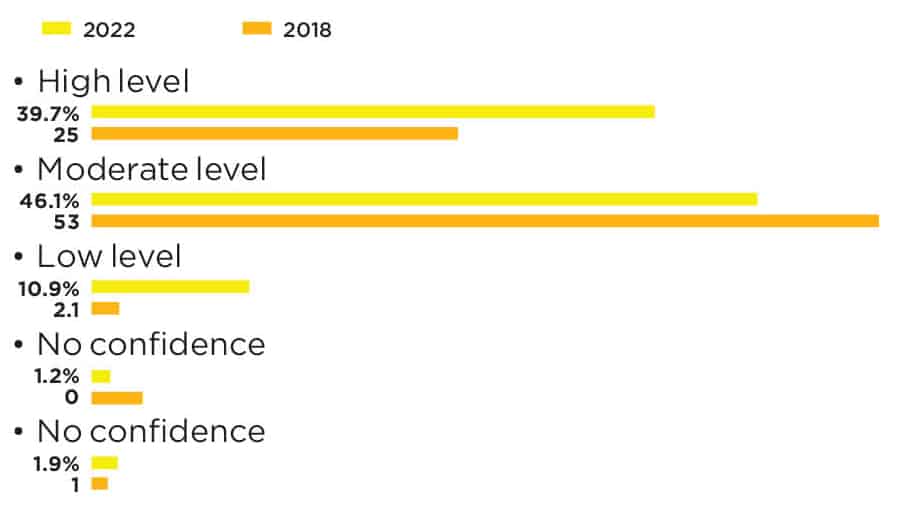

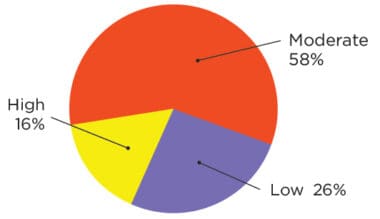

Bolstered by the greater focus on formal planning and now regular awareness and technical training for employees on cybersecurity, a growing number of manufacturers feel confident that they have the internal expertise to deal with manufacturing-related cyber issues. This year, nearly 40% of survey respondents said they had a high level of confidence about their internal expertise, compared with 25% saying so in 2018. Another 46% assessed their confidence levels as moderate this year (Chart 4).

More Attacks Expected

Even as better cybersecurity strategies are put in place and confidence in internal capabilities to deal with threats and attacks grows, an overwhelmingly large number of manufacturers expect more attacks in the year ahead, a perception that is no doubt driving much of the greater emphasis on defensive measures.

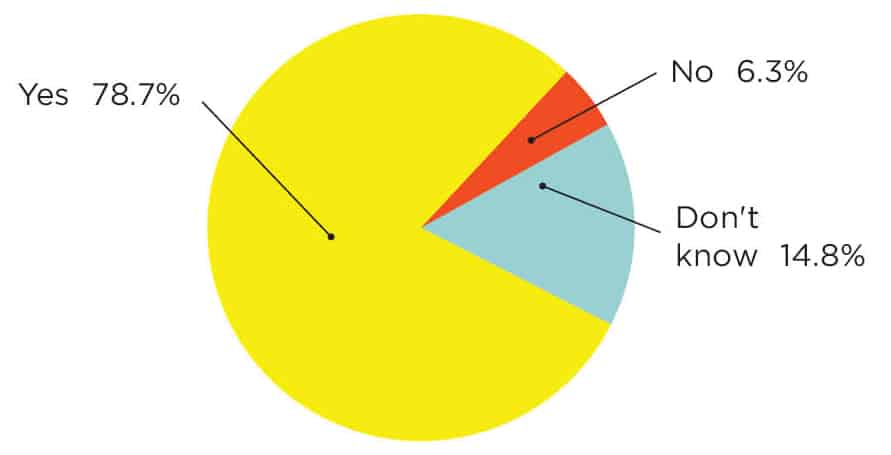

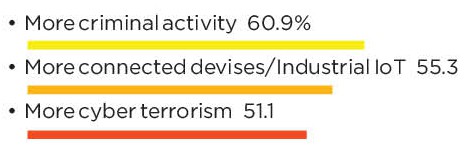

This year, nearly 79% of survey respondents said they expected more attacks in the next year, compared with 64% expressing that feeling in 2018 about 2019 (Chart 8). The three most cited reasons for this expectation are more criminal activity; greater connectivity in their operations, particularly with Internet of Things technologies; and more cyber terrorism (Chart 9). Of least concern: insider- or supply chain-originated attacks. Phishing, malware, and ransomware are the most prevalent methods of cyber attack cited by respondents overall.

When asked to assess the cyber battlefield and its most important points of vulnerability, survey respondents painted an interesting picture of where conflict is most likely to play out.

Mobile devices, e-mail servers, and laptop computers were cited by respondents as having the highest level of cyber vulnerability – not plant floor equipment or plant floor control systems. Looked at from a business function or activity perspective, a similar dynamic – vulnerabilities caused by external connections – was revealed in the survey data. Social media networks, partner and distribution networks, and supply chain networks were the most cited points of vulnerability – not plant floor networks, design and innovation networks, or field service operations. In addition, respondents said their best protected systems are their ERP and MES systems.

More manufacturers than ever have adopted formal cybersecurity plans.

What these findings suggest is that, as manufacturers go about forging so-called business ecosystems of partners, suppliers, and customers that are increasingly digitally connected, they will have to extend existing cyber strategies and tactics or even create new ones to protect these networks in the future. This is perhaps the next frontier in cybersecurity.

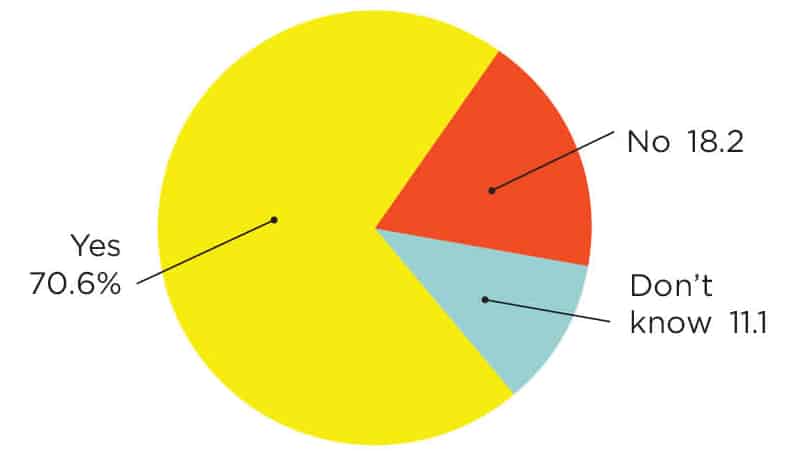

Manufacturers are starting to decode these signals. When asked in this year’s survey whether they have introduced or changed cybersecurity requirements for external partners and vendors with which they share data, 48% said that they had. In addition, 70% said the increase in remote working spurred by the pandemic has caused them to make adjustments to their cyber policies.

The Effects on M4.0

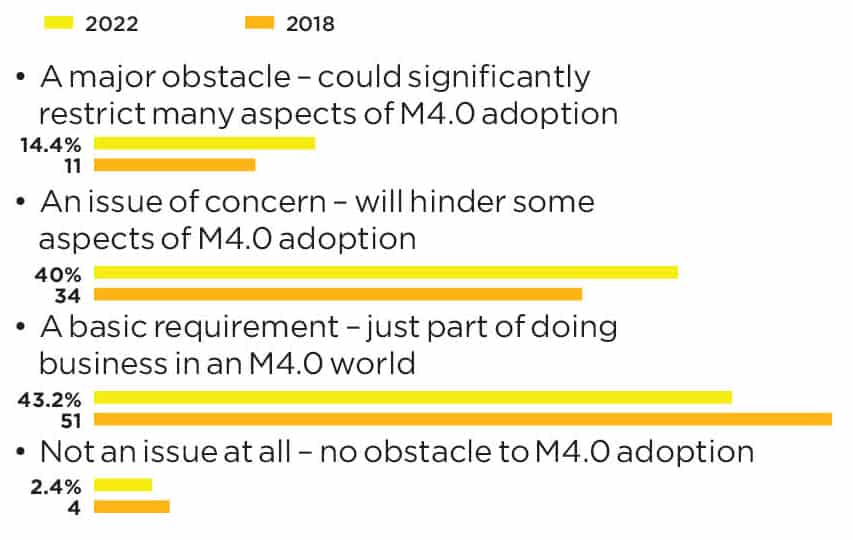

Based on their perception that cyber attacks will increase in the years ahead, more than half of survey respondents expressed concern that cybersecurity issues could affect the speed and scope of adoption of Manufacturing 4.0. Fourteen percent said cyber could be a major obstacle in the next five years, with another 40% describing it as “an issue of concern”. A significant percentage, 43%, consider cyber to be just part of doing business in an M4.0 world (Chart 13).

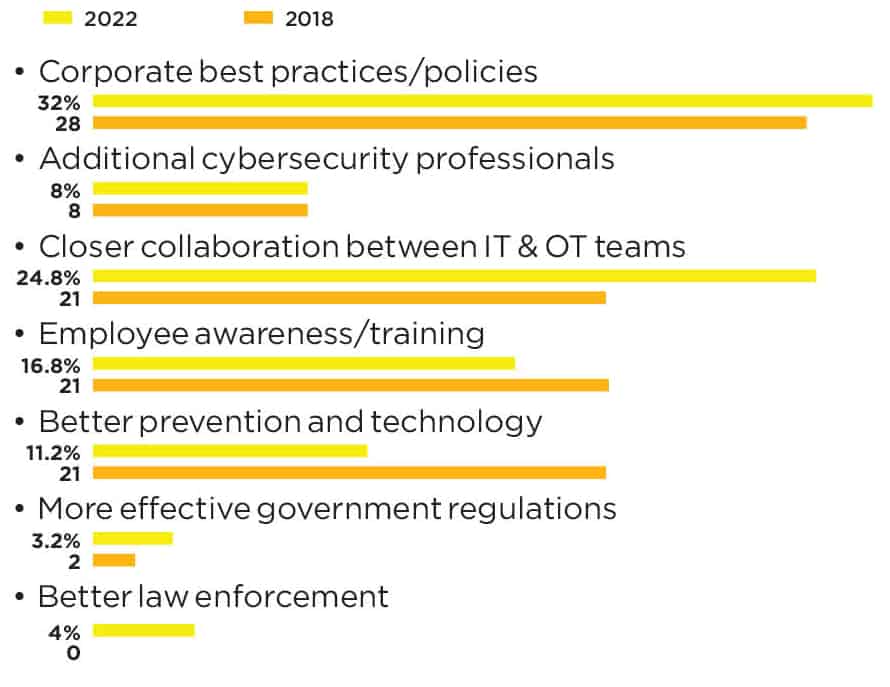

As they devise their defenses, manufacturers are relying more on internal mechanisms, such as corporate best practices and policies and closer collaboration between IT and OT teams, rather than law enforcement or government regulations (Chart 10).

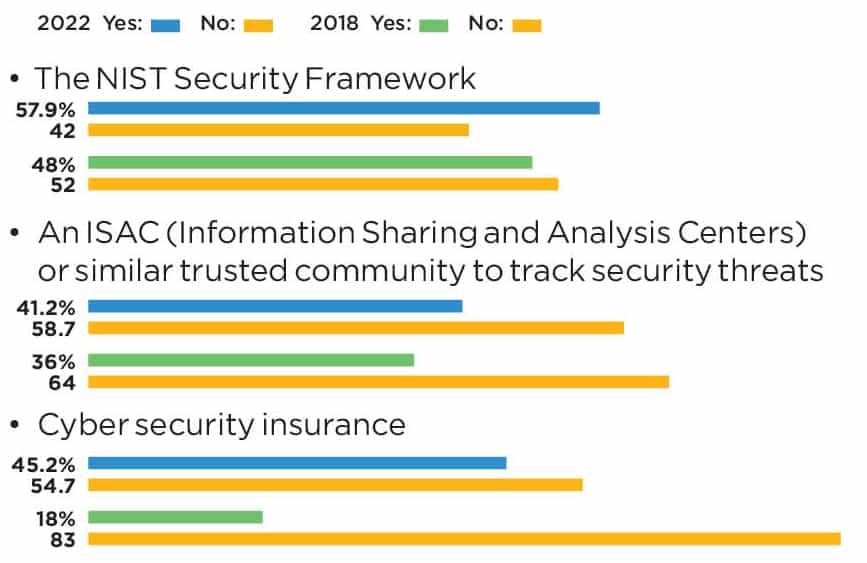

Moreover, more are taking advantage of publicly available approaches, such as the NIST Security Framework, to underpin their strategies. This year, almost 58% of survey respondents said they have adopted the NIST framework, up from 48% in 2018. In addition, there has been a sharp rise in those subscribing to cyber insurance – 45% today, compared with only 18% in 2018 (Chart 12).

All in all, manufacturers have been moving on multiple fronts to combat the growing cyber problem. The challenge for industrial companies going forward will be to try to stay one step ahead as the number and sophistication of attacks increase even as they expand their digital networks outside the four walls of their business. M

Part 1: CYBERSECURITY STRATEGY AND ORGANIZATION

1. Strong Majority Now Have Formal Cyber Strategies

Q: How would you characterize your company’s approach to dealing with manufacturing cybersecurity?

2 Business Issue Concerns Rise

Q: How important is cybersecurity as a business issue to your company, in terms of securely interconnecting systems or exchanging operating data within, or across, your manufacturing sites and partner companies?

3 Business Disruption Still Leads Cyber Risks

Q: What is the most significant cybersecurity-related risk to your company’s manufacturing operations?

4 Internal Expertise Confidence Rises Sharply

Q: What level of confidence do you have that your company has the internal expertise to deal with manufacturing-related cybersecurity issues?

Part 2: MANUFACTURING CYBER ATTACKS AND EVALUATION

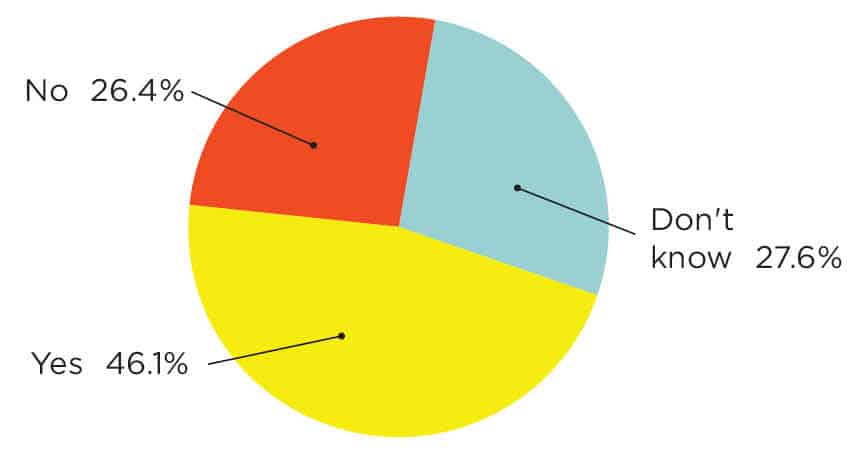

5 Nearly Half Have Suffered Cyber Attacks

Q: Have your company’s manufacturing sites ever been a target or a victim of a cyberattack?

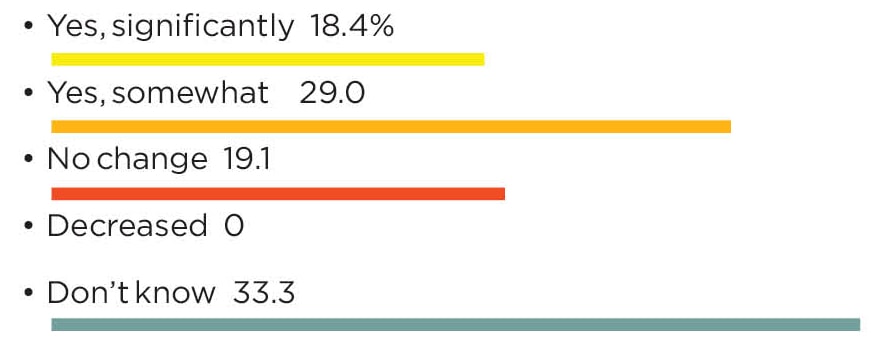

6 Nearly Half Also Say that Attacks Have Increased in the Last Year

Q: Have attacks directed at your company’s plant systems and networks increased over the past year?

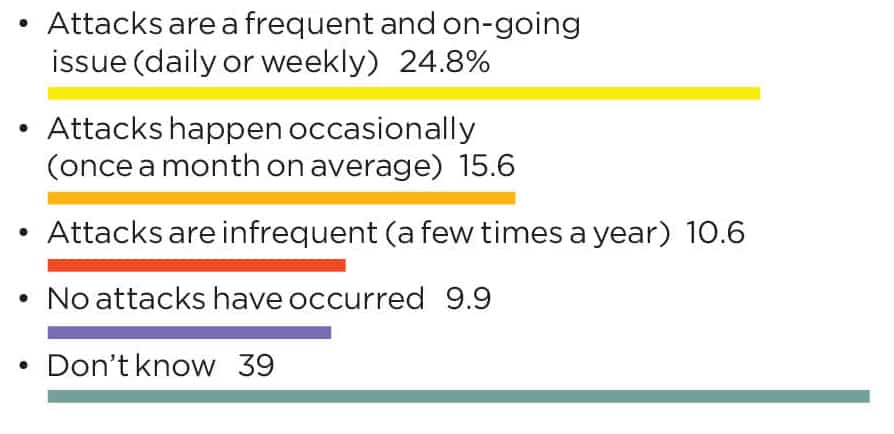

7 Frequency of Attacks is Significant

Q: How would you characterize the frequency of attacks?

8 More than Three-Quarters Expect More Attacks Ahead

Q: Do you expect your company to experience more attacks in the year ahead than in the past year?

9 Criminal Activity Cited as Top Reason for More Attacks

Q: If yes, what’s driving the increase?

Part 3: POLICIES TO DEAL WITH CYBER ATTACKS

10 Corporate Polices Seen as Best Defense

Q: What do you think will help the most in improving manufacturing cybersecurity in an M4.0 world?

11 Remote Work Has Forced Cyber Policy Changes

Q: Has an increase in remote work required any new changes or adjustments to your cyber policies?

12 NIST Framework is More Widely Adopted

Q: Are you engaged in, or have adopted, any of the following approaches as a way to better protect your company or mitigate cyber risks?

Part 4: THE FUTURE ORGANIZATION

13 Concerns Rise on Effect of Cyber on M4.0

Q: Over the next 5 years, how much of an obstacle will cybersecurity issues be to the speed and scope of adoption of Manufacturing 4.0 technologies and approaches?

About the author:

David R. Brousell is the Co-Founder, Vice President & Executive Director of the Manufacturing Leadership Council.

Survey development was led by David R. Brousell, with input from the MLC editorial team and the MLC’s Board of Governors.

SURVEY: Digital Leadership Playbook Still Work in Progress

Manufacturing Leadership Journal content and MLC resources are exclusively available to MLC members. Please sign up for an account or log in to view this content.

SURVEY: Manufacturing Supply Disruptions to Last Well Into 2023

Manufacturing Leadership Journal content and MLC resources are exclusively available to MLC members. Please sign up for an account or log in to view this content.

SURVEY: Future Outlook: Hazy

Manufacturing Leadership Journal content and MLC resources are exclusively available to MLC members. Please sign up for an account or log in to view this content.

Manufacturing’s Sustainability Challenge: The Race is On

Manufacturing Leadership Journal content and MLC resources are exclusively available to MLC members. Please sign up for an account or log in to view this content.

Pedal to the Metal

Manufacturing Leadership Journal content and MLC resources are exclusively available to MLC members. Please sign up for an account or log in to view this content.

Growing Pains

Manufacturers see data’s massive potential to improve operations, predict disruptions, and bring about new revenue streams, but realizing that promise continues to be a work in progress.

Data could be described as the lifeblood that enables the digital enterprise. In the 18-plus months that the COVID-19 pandemic has been roiling supply chains, forcing once-live interactions to go virtual, and necessitating remote work and collaboration, manufacturers have seen the immense value of using data to keep operations going and make better-informed decisions. It isn’t hard to imagine a far worse scenario if this once-in-a-generation disruption had happened in a time of less (or no) digital maturity.

But while former IBM CEO Ginni Rometty once said that big data is the new oil, a more apt comparison might be that data is like sunlight – in infinite supply, unyielding, quite often blinding. But it can also be illuminating, shedding light on former dark spots by improving transparency and visibility, enabling businesses to grow and thrive.

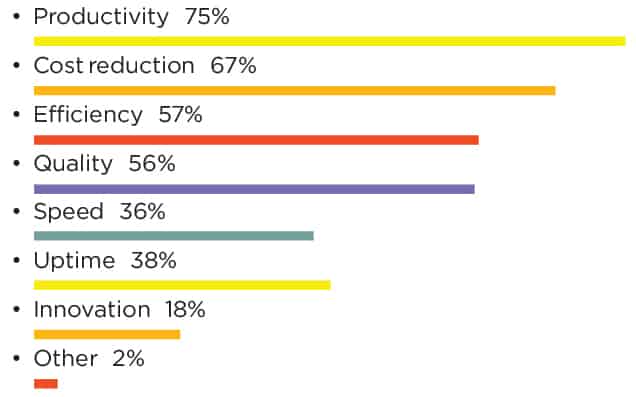

Manufacturing data mastery is in its tween years for most enterprises – certainly past its infancy, but still awkward and gawky and not quite fully formed. It is often unclear who is responsible for data strategy, what the data strategy is, or what data is actually worth to an organization. But manufacturers also say data has helped them to grow their productivity, lower their costs, boost efficiency, and improve quality.

These findings and others from the MLC’s new M4.0 Data Mastery Survey provide insights on where manufacturers are on their journey to harness the power of data and its revolutionary promise.

Where Improvement is Needed

Most manufacturers rate themselves as just average at their organizational data skills, and they struggle not only to collect the right data but also to interpret it. Fifty-eight percent said that their company had just a moderate ability to collect data that is meaningful and impactful for their business needs (Chart 11). More than a quarter ranked themselves as low in this area.

It is often unclear who is responsible for data strategy, what that strategy is, or what organizational data is actually worth.

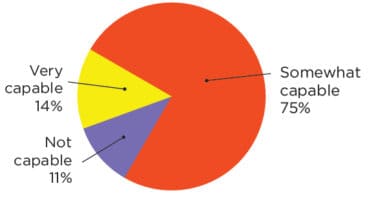

But data collection is not the greatest struggle. Even more respondents said they had room for improvement in terms of finding insights from that data, with 75% ranking their organizations as only somewhat capable in their ability to analyze their manufacturing operations data (Chart 12). In this area, 11% of respondents said their organizations were not capable of this type of analysis.

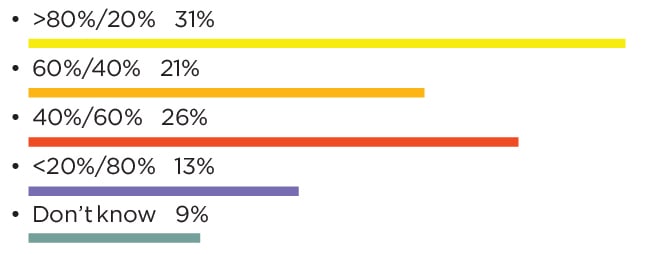

Furthermore, a gap remains between the effort to collect and sort data and the effort to apply insights and create value from that data. Almost a third said they expend greater than 80% effort in gathering and organizing data vs. the effort expended to analyze and apply insights from the data (Chart 8).

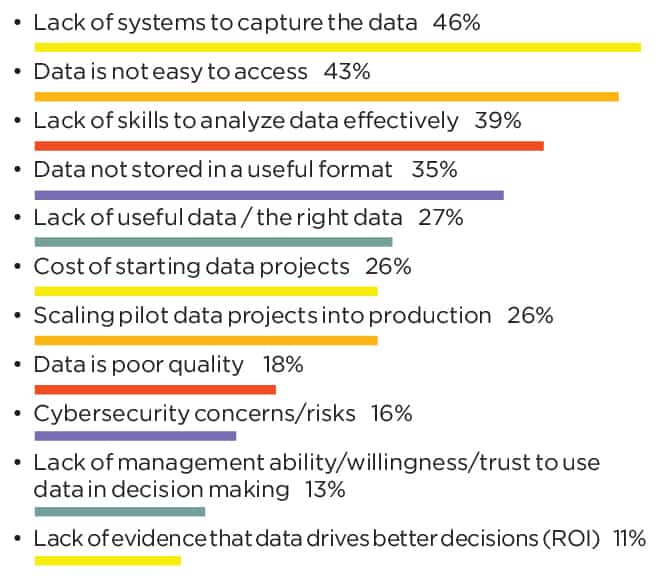

Other stumbling blocks to utilizing data to a greater extent speak to the unwieldy tangle that manufacturers often find when undertaking data projects. This includes a lack of systems to capture the data (46%), followed by data inaccessibility (43%) and a lack of skills to effectively analyze data (39%) (Chart 16).

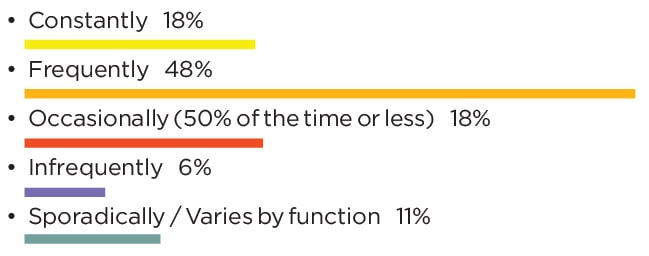

However, for what they are able to collect and analyze, more often than not organizations are leveraging that data to make informed decisions. Forty-eight percent say that their organization makes data-driven decisions frequently, while 18% say that they make data-driven decisions constantly (Chart 13).

Tools of Collection and Analysis

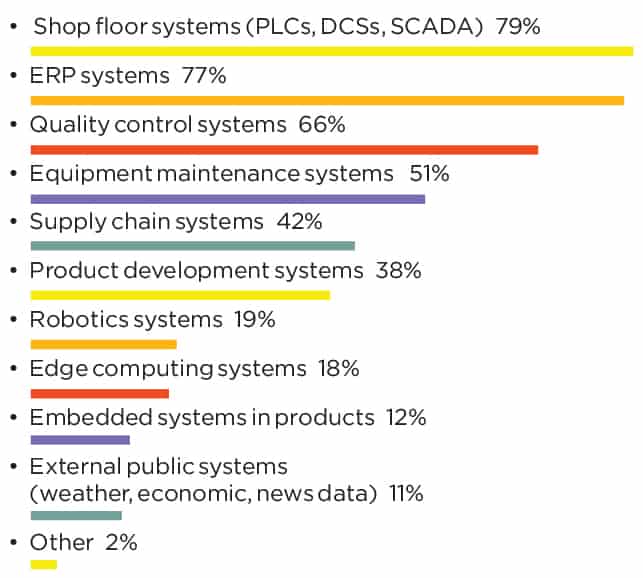

Digging a bit deeper into organizational data tactics, 79% said their shop floor systems are the primary source of manufacturing data, followed closely by ERP systems at 77% (Chart 6). This may not be surprising given the near-ubiquitous nature of those technologies within many manufacturing facilities.

What could be a trend to watch, though, is the growing use of edge computing systems (18%) and even embedded systems in products (12%). The former shows that manufacturers are taking advantage of faster networking technologies to process and store data closer to where it is produced and consumed, while the latter could hold promise for monitoring product lifecycle and performance, in addition to sustainability by making products more efficient and reducing materials usage and waste.

“Manufacturing organizations have serious governance issues to address, such as having a formal plan and somebody ultimately in charge of data management.

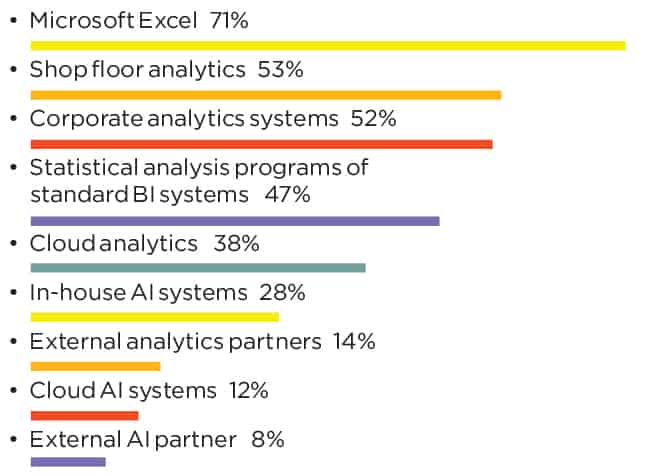

But among those emerging technologies lie some old faithful ones. CPA favorite Microsoft Excel is still the leader as the manufacturing data analysis tool of choice 34 years after its initial release, with 71% of respondents saying they use it (Chart 9). Meanwhile, AI is making inroads in its use for analysis, with nearly a third saying they are using in-house AI systems (28%), and others using cloud AI systems (12%) or an external AI partner (8%).

The Fundamental Flaws

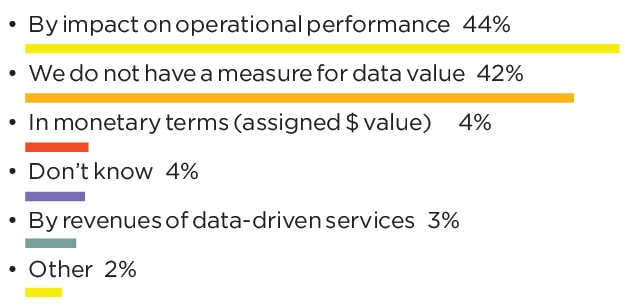

Assigning value to data is an elusive undertaking for many manufacturers. Of those who do, most measure it by impact on operational performance (44%), as it is likely the easiest way to see the results of manufacturing data projects (Chart 1). But nearly as many admitted that their organization has no measure for data value (42%), a somewhat troublesome finding given the time, resources, and effort that go into data collection and analysis.

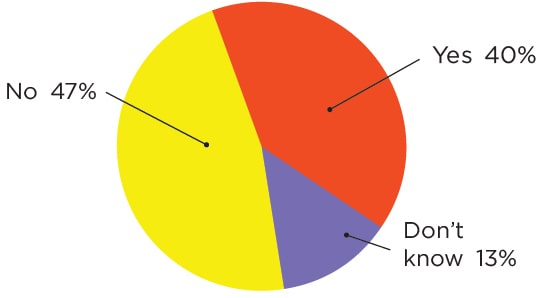

It’s difficult to determine if this is merely an oversight, or if reliable models just haven’t yet been developed to assess ROI, but this will be an important and necessary undertaking for manufacturers to make impactful data-led decisions. The good news is, though, that executives appear motivated to take on this pursuit, as 40% of respondents said data collection, management, and analysis were included as part of annual objectives for company executives (Chart 3).

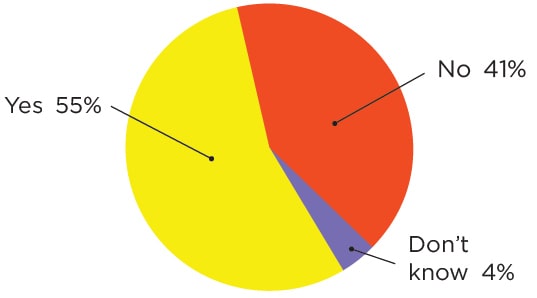

But manufacturing organizations have other serious governance issues that also must be addressed, such as having no formal plan for data management or having nobody ultimately in charge. Four out of 10 respondents said that their company had no corporate plan, strategy, or formal guidelines for how data is collected and organized across the enterprise (Chart 2), an almost-astonishing number at a time when manufacturers are making significant investments in digital technologies to build connected operations.

“In today’s algorithm-driven world, manufacturers must pay heed to data accuracy, quality, and fidelity.

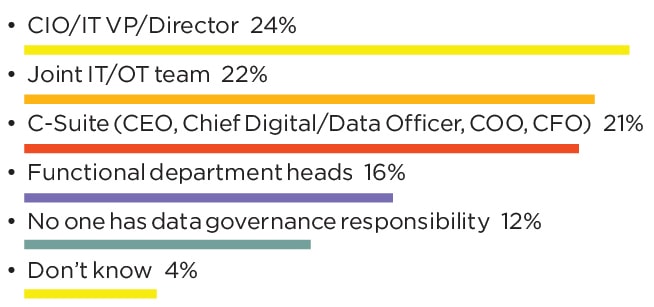

Manufacturers continue to take a scattered approach to governance and control over data, though many have a head of IT or combined IT/OT team ultimately in charge of data governance and strategy (Chart 4). However, 12% said that no one has data governance responsibility at their organization, a glaring issue that must be addressed at any company that wants to stay competitive in the long run.

Trusting the Data

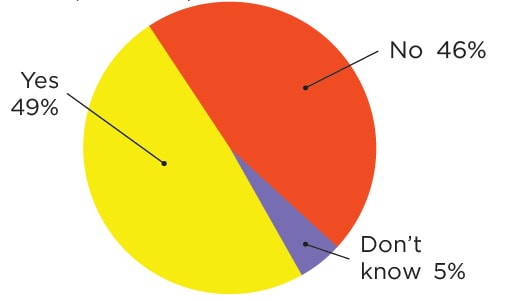

One of the oldest idioms in computer science lexicon is garbage in, garbage out, meaning that flawed input data will result in flawed output data. In today’s algorithm-driven world, manufacturers must pay heed to the accuracy, quality, and fidelity of the data they are using for all-important business decisions. But it’s nearly an even split between manufacturers who check for that accuracy – 49% saying they do vs. 46% saying they complete no such checks (Chart 10).

Whatever leads those manufacturers to believe they can trust their data, there is no question that data is driving much-improved decisions – 94% said the use of data has helped their company make better decisions, though just 35% say it has helped them to make faster decisions (Chart 15).

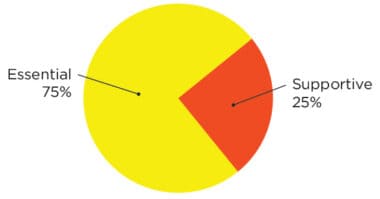

To underscore the views that manufacturers have on data’s value for competitiveness, there is little room for debate that most see it as a requirement. Seventy-five percent said that data mastery will be essential for future competitiveness, with 25% saying it will be supportive for competitiveness – and not one single respondent saying that it will have no impact at all (Chart 17).

There is little question that manufacturers see the immense value that data can bring to their businesses. As organizations grow their data competency, they will seek to move past simply monitoring and collecting data to unlocking the insights and predictive ability that will be essential to future competitiveness. But until those organizations address the fundamentals of data mastery, they are likely to feel more growing pains along the road to that promising tomorrow. M

Part 1: CORPORATE DATA GOVERNANCE & ORGANIZATION

1. Many Organizations Have No Measure for Data Value

Q: How do you measure the value of the data in your organization? (Select one)

2. Many Organizations Lack Formal Data Collection Guidelines

Q: Does your company have a corporate-wide plan, strategy, or formal guidelines for how data is collected and organized across the enterprise, including manufacturing operations? (Select one)

3. For Many, Data Mastery is an Executive Objective

Q: Is data collection / management / analysis included in some way as part of the annual objectives for company executives? (Select one)

4. CIOs, IT Teams Largely Responsible for Data Governance

Q: Who is responsible for data governance and strategy in your organization? (Select one)

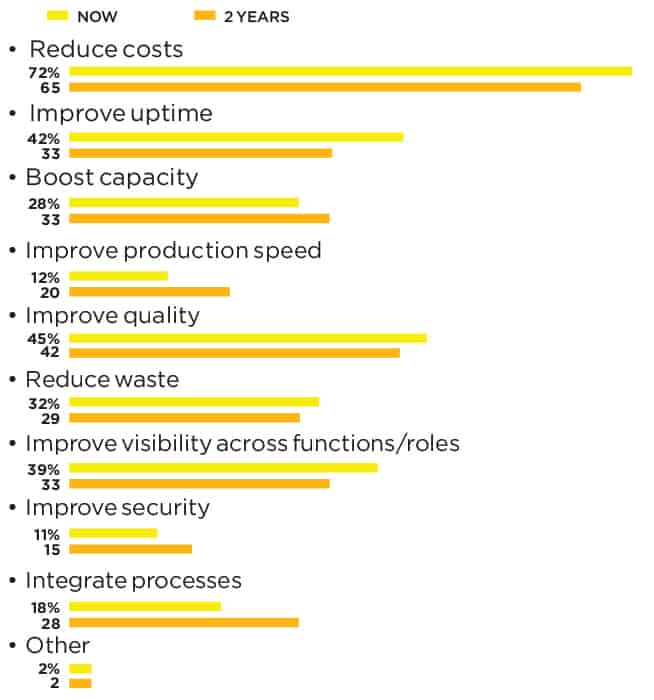

5. Cost Savings, Quality Top List of Business Objectives

Q: What are your key business outcome objectives for embarking on manufacturing data projects today and what do you expect your primary objectives to be in 2 years’ time? (Check top three for Now and top three in 2 years)

Part 2: DATA COLLECTION & ANALYSIS TACTICS

6. Shop Floor Systems, ERPs are Primary Data Sources

Q: What are the primary sources of your manufacturing data today? (Check all that apply)

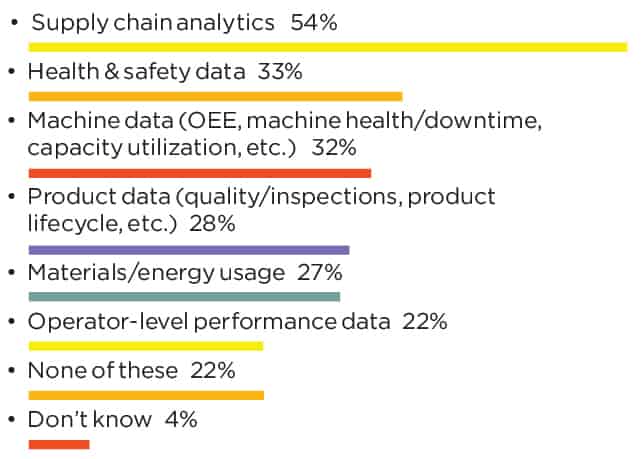

7. Pandemic Makes Supply Chain Analytics a Priority

Q: Has capturing and analyzing certain types of data become more important to your organization in the wake of the COVID-19 pandemic? (Check all that apply)

8. Gap Lies Between Data Collection and Application

Q: What is your estimate of percent effort to gather and organize data relative to the percent effort to analyze, derive insights, and apply those insights to creating value from that data? (Select one)

9. MS Excel Still Leads as Data Analysis Tool

Q: What systems do you use to analyze the manufacturing data you collect? (Check all that apply)

10. Checking Up on Data Accuracy, Quality

Q: Does your company have a process to verify the

accuracy and/or quality of the raw data before decisions are made on it? (Select one)

Part 3: ORGANIZATIONAL DATA MASTERY

11. Matching Data Collection to Business Needs

Q: How would you rank your company’s ability to collect the right data the business needs from your manufacturing operations?

12. Data Analysis Sees Room for Improvement

Q: How would you rank your company’s ability to analyze the data from your manufacturing operations?

13. Data Leads More Decisions, More Often

Q:How often would you say your organization makes data-driven decisions? (Select one)

Part 2: DATA-DRIVEN OUTCOMES & CHALLENGES

14. Data Boosts Productivity, Lowers Costs

Q: How has the increase in manufacturing data

helped you to improve your manufacturing organization? (Check all that apply)

15. Quality, Speed of Decision-Making Improves

Q: How has the use of data affected your

company’s decision-making? (Check all that apply)

16. Data Capture, AccessRemains an Obstacle

Q: What are the most important challenges or obstacles hindering your organization from making more data driven decisions? (Check top three)

17. Most See Data Mastery as Essential to Competitiveness

Q: Looking forward, how important do you think mastering manufacturing data will become to your competitiveness as a future business? (Select one)

Survey development was led by Penelope Brown, with input from the MLC editorial team and the MLC’s Board of Governors.