The Hammer Versus Nails Strategy for Data Analytics

Taking a pragmatic approach to data analytics by focusing on business goals rather than technology allows companies to deliver incremental value.

TAKEAWAYS:

● Many developments in AI/ML for manufacturing can be leveraged now.

● The challenge is driven by people, technology, and process.

● An agile and pragmatic business centric approach can allow for tangible benefits without the high upfront investment.

Manufactures continue to exist in a complex juxtaposition of needing to significantly invest in technology to improve business operations, while still navigating difficult supply chain issues that require keeping costs down and focusing on retaining talent. Given a choice, the natural tendency is to pick the path of known and least resistance. But if the choice requires a difficult decision, sometimes no choice at all is the most likely outcome.

The use of data to drive better and faster business decisions is a necessary component of any executive strategy. Data is the next elixir in the quest to improve operational margins in the same way that cloud infrastructures allowed businesses to grow and transform over the last decade.

The use of machine learning to examine and augment the decision-making process is a similar and exciting extension of data driven decisioning. For example, on the shop floor AI is used to reduce scrap by identifying defective products as well as providing recommended changes to machine and process settings to prevent future issues. AI is also becoming heavily integrated in asset-intensive facilities to analyze sensor data and prevent downtime by alerting operators on potential issues. Beyond asset performance management, companies can also leverage shift and production information to improve workforce planning and management. With all the challenges in supply chains, having visibility into future issues also allows for improved spare parts management of operations.

“It is important to remember that the explosion of data use requires an ever-increasing focus on governance strategies as well as security.”

The benefits of better understanding the business from the prism of data is not constrained to factories alone. Think of how important it is to manage a successful organization by having visibility into cashflow or being able to forecast sales orders and expected product production needs. Beyond the internal business, external customers are also increasingly requesting more transparency into supply chains. The expectation is that product passports will be the next great investment in infrastructure.

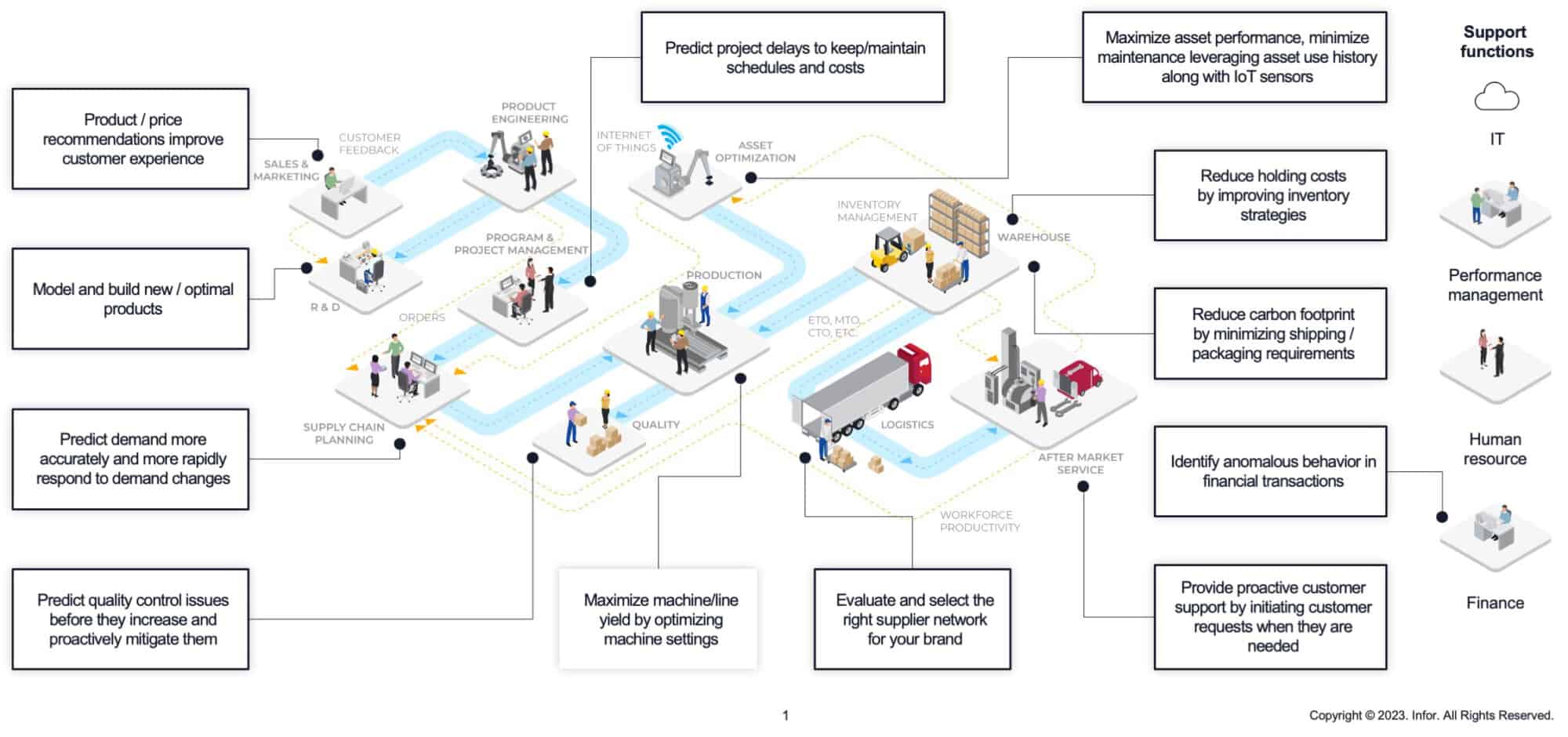

The illustration in Fig. 1 highlights the importance of thinking about data analytics across multiple operations as a way to drive the business forward.

Fig. 1: Data Analytics Opportunities in Manufacturing

It is important to remember that the explosion of data use requires an ever-increasing focus on governance strategies as well as security. Data needs to be protected and carefully curated for safe and effective business purposes. Most companies have multiple business solutions in a variety of cloud and non-cloud systems and the investment in managing, consolidating, and reporting for those systems will only increase. At any given time, there are also ongoing IT projects to move, change, update, or replace existing systems in many organizations. The impact on business operations can be significant, especially as the workforce must continue learning and adapting to changing technology and business conditions, combined with talent retention challenges as new employees struggle to adjust to old systems.

It is perhaps no surprise that this can be overwhelming combination of factors for manufacturers to cope with.

The Hammer Approach

The best-case scenario is to be able to plan out your business operations as a digital blueprint and track the materials to goods to customer order (and their use) so that you can leverage all the latest innovations to drive quick and proactive decision making.

This is a significant effort and best done in the initial stages of a digital transformation when there are fewer moving pieces. The company can then focus on automating more of its manufacturing systems. Once a company has a digital twin of its key systems, it is easier to make process and technology decisions in harmony with business priorities. Investing in IoT sensors and vision systems to augment your software and infrastructure setup then helps prepare the way for future innovation capabilities.

It is recommended that while building data models companies also consider the different personas who will need access to the systems, their data access rights, as well as what kind of decision or action data needs to be captured to improve the intelligence of the entire business operation.

Other considerations would be around how to manage a data mesh of interconnected systems so there is reduced data duplication and retention. It is certainly more effective to invest in the right analytics when you start from a cleaner slate.

It is easy to get caught up in technology and forget business objectives.

“Once a company has a digital twin of its key systems, it is easier to make process and technology decisions in harmony with business priorities.”

The famous quote by Abraham Maslow: “If the only tool you have is a hammer, you tend to see every problem as a nail,” best describes problems with the hammer approach if you have an over reliance on technology versus solutions.

If the focus on IT infrastructure and software drives strategy and investment, organizations feel the burden of trying to rationalize the investment by looking for very specialized and potentially time consuming and expensive challenges. They end up investing in internet of things (IoT) sensors and storage infrastructure for this information without a clear plan on how to maximize their use. They can also resort to streaming analytic dashboards as way to visualize the information without a clear business driver. There is a great temptation to invest in additional hardware and streaming devices like cameras to leverage the data architecture use. The hammer approach is normally common in organizations that are understaffed or have limited experience with data driving decisions.

The hammer approach is a technology first and only approach to data analytics.

The Nails Decision Strategy

The “nails” are business challenges or goals. All organizations have them and expect them to change as often as needed. Nails are shared focus areas which executives want to move forward as part of a plan to improve their business incrementally.

To be thoughtful and organized is important, and to think of innovation as a “fail forward” approach. Due to the complexity of modern supply chains and plethora of operations systems there is a need to have a top-down executive alignment on an agile business benefit driven transformation plan. Change management is easier if there are quick wins with tangible benefits. Often priorities change faster than the time it takes some IT projects to complete, so it is best to focus on quick time to value.

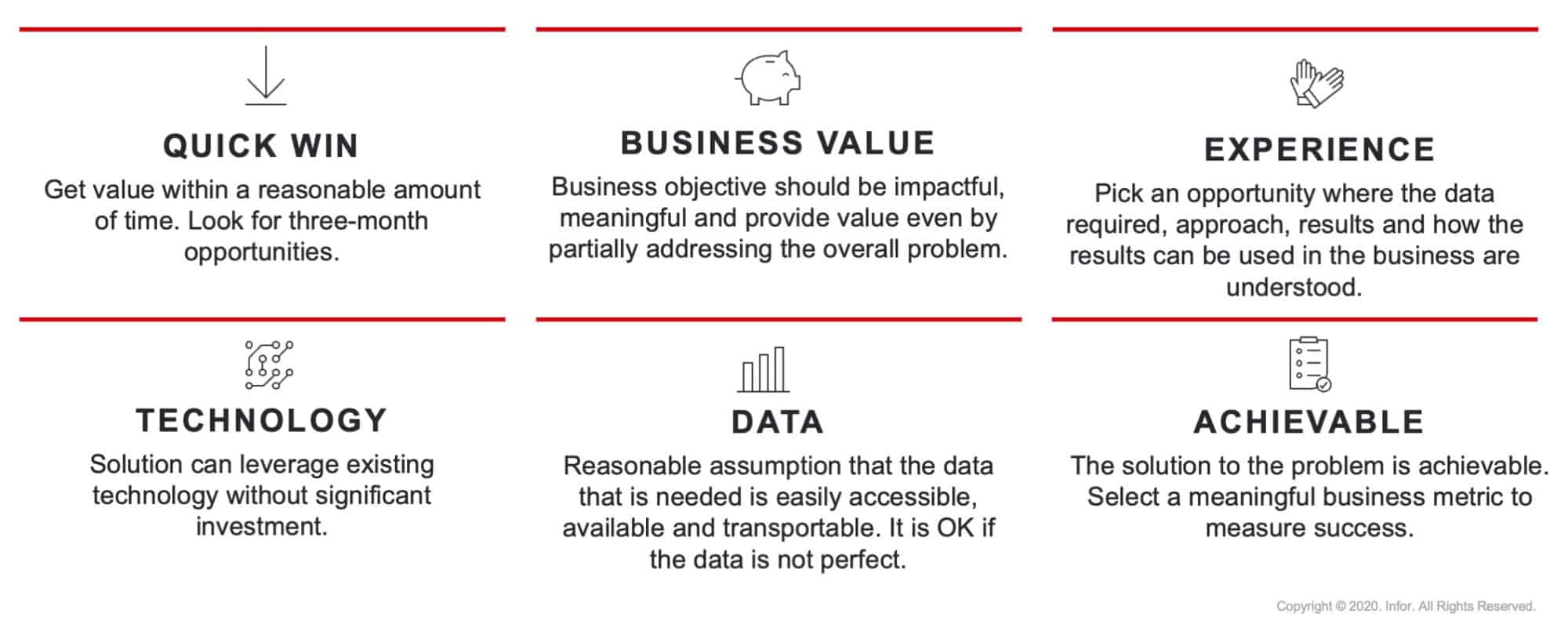

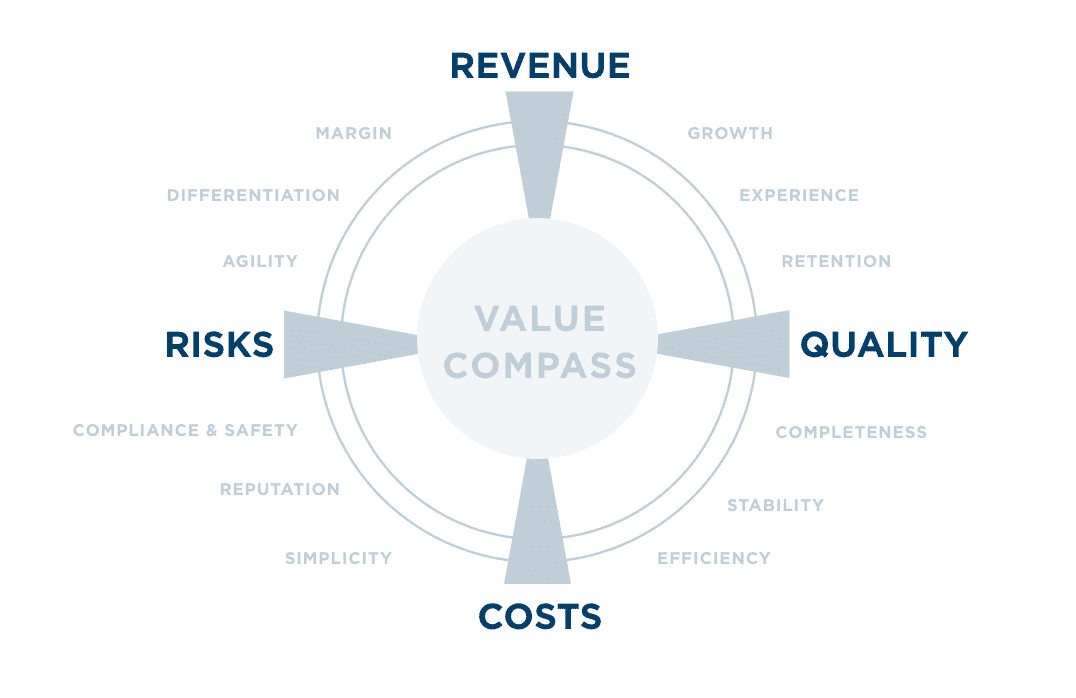

The six pillars are important guiding principles in employing innovation in manufacturing. Companies can apply them to drive analytic decision making when picking their business goal “nails”.

Fig 2: Six Pillars of Analytics Decision Making

For machine learning driven analytics the availability of data is essential but since it is challenging and almost impossible to get perfect or complete data, the best approach is to reverse engineer the goals to be based on pragmatic business outcomes. A successful approach is to compartmentalize the type of data used in decision making. Evaluate and identify useful data that drives expected business outcomes versus where it does not, and then leverage it where it applies, versus a big bang approach.

While manufacturers have invested in sensors to track equipment performance, there are also pragmatic models that can use asset maintenance history to improve insights into maintenance scheduling versus simple time-based maintenance plans. Applying gradual data enrichment processes allows companies to gently bring in new and additional information where there is sufficient business benefit.

Engaging experienced plant supervisors and operators in leveraging any analytics so there is a way to improve work automation and process is an important tenant in maximizing the use of these tools.

A Pragmatic Approach

With this challenging environment most companies rightfully hesitate to invest significantly in changing their mental approach to leveraging data for business decisioning. The approach each business takes will depend on their culture and priorities, but approaching individual challenges and analytics requirements is an easier and faster way to fully realize priorities. The quick wins can engage all the departments of the business in a more collaborative manner and the investment decisions then tend to be less burdensome.

There is a need to prioritize data management strategies to leverage new analytics innovations in manufacturing and supply chains. How companies go about it does not need to overwhelm their focus.

Focusing on concise business goals (nails) and investing in quick wins is a better approach than building a technology first (hammer) solution. M

About the author:

About the author:

Sandeep Anand is Senior Director of Decision Analytics and Science Platform at Infor. He has over 15 years of experience building and delivering AI/ML solutions. Experience includes solutions around yield/scrap , supply chain improvements and smart asset management strategies. He leads the AI/ML practice at Infor, a leading enterprise cloud solutions provider.

Leaning Into the Future

Manufacturing Leadership Journal content and MLC resources are exclusively available to MLC members. Please sign up for an account or log in to view this content.

The Data Monetization Wave Picks Up Speed

The generative AI tool ChatGPT has raised the competitive stakes, requiring manufacturers to embrace the discipline with greater urgency.

TAKEAWAYS:

● The myths and realities of data monetization.

● A framework for identifying and measuring the potential value of direct and indirect data monetization opportunities.

● How generative AI is a game changer for data analysis, valuation, and monetization.

In the Manufacturing Leadership Council’s recent research, Manufacturing in 2030 Survey: A Lens on the Future, 84% of respondents said they expect the pace of digital transformation to accelerate. That means data—more of it and more opportunity to create value from it.

Extracting value from manufacturing data has been rising up the industry agenda in recent years—fueled by success stories from leaders such as Navistar Internal Corporation, which used to rely on miles traveled or time since the last service appointment to develop vehicle maintenance schedules. By introducing new capabilities to analyze sensor data from 375,000 connected vehicles, Navistar has helped vehicle owners reduce maintenance costs by up to 40%.

The industry’s mushrooming volume of data is reason alone to be thinking about data monetization. Then ChatGPT entered the conversation in late 2022—raising the stakes. With generative AI, a user can now formulate a question and feed it into the model, which queries multiple data sources—potentially even integrated data, such as that from a CMMS system. The output provides an explanation of what the problem could be, the tools/parts needed, and a step-by-step explanation of how to fix the problem. This saves significant time and costly trial and error, becoming a source of value. The very human nature of the interaction addresses one of the big challenges with which manufacturing has been grappling: how to equip its workforce with skills to use data in a digital world.

“The time when generative AI will be able to fully ingest and use a company’s data as well as what it scrapes from the web isn’t far off.”

Competition among Microsoft, Google, and others will only accelerate generative AI capabilities as well as business interest in using them. We can expect to soon see it embedded in workplace technologies, enterprise resource planning systems, and other business applications. That means it’s not a question of if, but when generative AI will be able to fully ingest and use a company’s own data and what it scrapes from the web. While AI communities are eagerly anticipating this, so should data-rich manufacturers because it significantly increases the potential for turning data into value.

This is, of course, just one facet of data monetization. But it underscores the vast potential and pace at which things are changing. If your organization isn’t yet in the game, it’s time. We’ll cover some basic principles to shape discussions about data monetization and some ideas for jump starting or reenergizing your organization’s efforts.

What Data Monetization Is and Isn’t

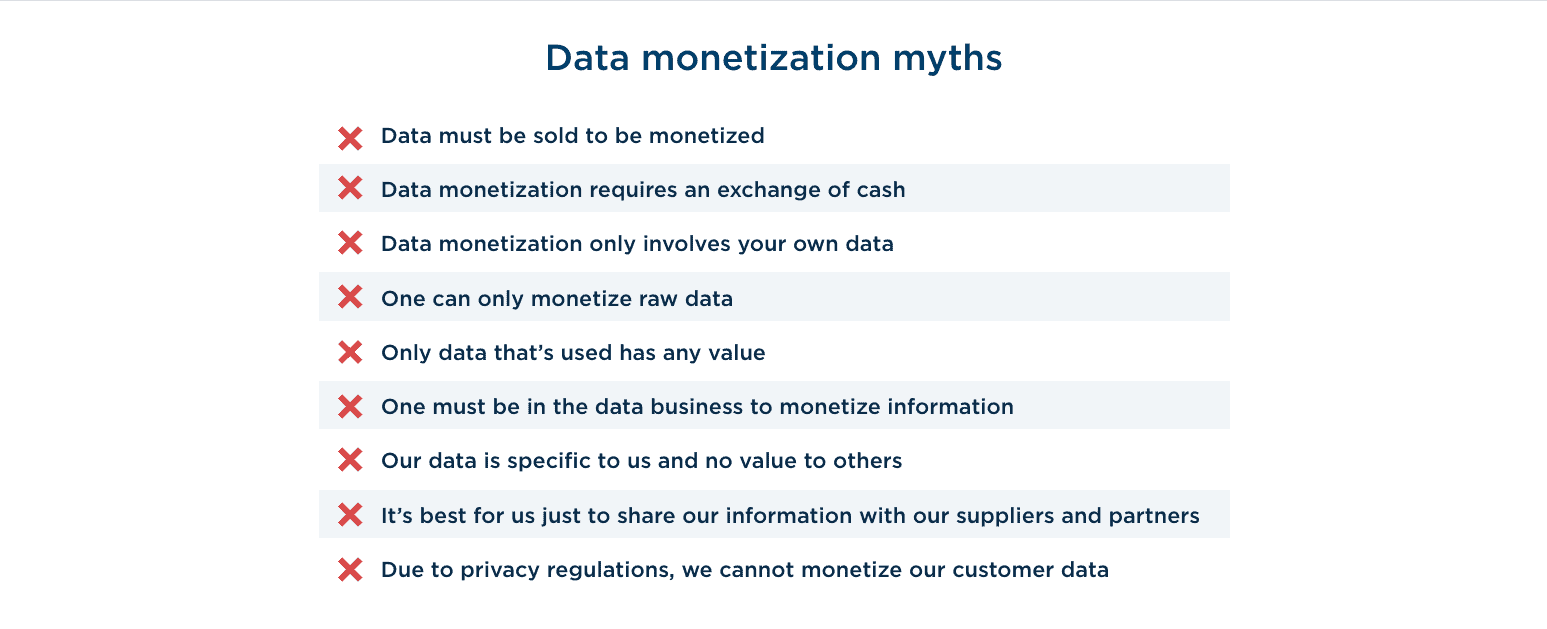

There are a lot of myths regarding data monetization. It is important to understand that these are, in fact, misconceptions.

We’ll touch on a few of these, but the first one is key. From our point of view, data monetization is not just about selling data; it’s about using data internally or externally to generate new value streams.

West Monroe defines data monetization as the process of generating new and innovative measurable value streams from available data assets.

There are several key words in that definition. First, data monetization is a process, not a one-time activity. Applying a product mindset—one that focuses on delivering value rather than milestones—is important. A value stream is about generating measurable benefits. If you aren’t connecting the dots from business value to the data used, then you can’t really claim that you’re monetizing the data. Finally, available data assets is not just about the data inside your four walls. It also includes social media data, partner/supplier data, customer data, and open data sources, among others. Data monetization is about harvesting content to enrich and enhance your own data and make it that much more marketable and usable.

Two Types of Data Monetization

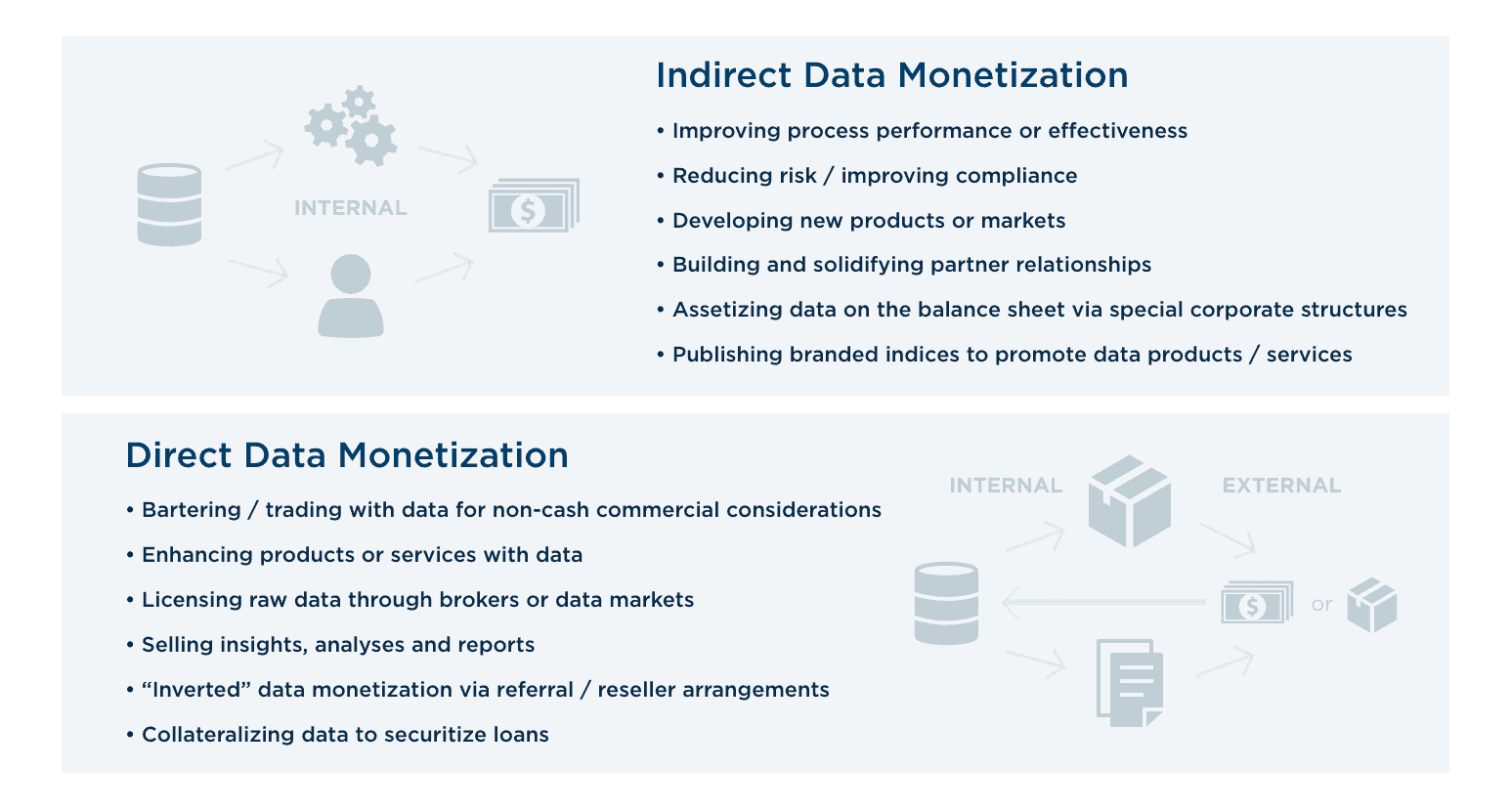

We’ve identified about a dozen data monetization patterns. These generally fall into two categories—indirect and direct. Indirect data monetization focuses on internal business processes that generate measurable returns. Direct data monetization involves externalizing data in return for some type of commercial consideration.

Most manufacturers that have pursued data monetization focus on indirect opportunities. Some have made good progress; for example, with AI/ML models that can predict an outcome (will the machine go down?) or aid decision-making (should we replace or repair?). With new capabilities to analyze data, Harley-Davidson was able to predict machine failures with a very high degree of accuracy, thus reducing unplanned downtime and increasing production capacity 8-10%.

The emergence of generative AI creates bigger and better opportunities for indirect monetization and for direct monetization due to the breadth of data now valuable outside the company. As manufacturers consider new use cases, the need for third-party data will increase, making data (both volume and variety) more valuable on data exchanges.

Naturally, this also raises new questions about data ownership, including who owns the data scraped by the model and whether/how they should be compensated? Consider, for example, the data produced and captured by manufacturing equipment used in a factory: Is that the equipment OEM’s data or the manufacturer’s data?

“Data monetization isn’t just about selling data; it’s about using data internally or externally to generate new value streams.”

In any event, keep in mind that it is not the generative AI model that has value. The value is in the data itself and the productivity of using it more effectively to produce insights, content, or other commercial benefit. And that brings us to packaging.

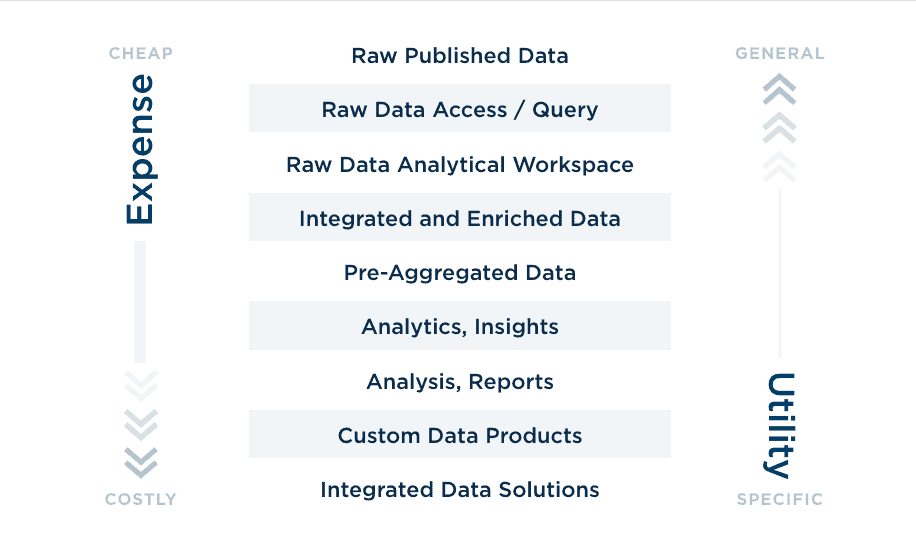

Just like any product, you can sell raw material in some form. In the case of data, it can be shipped in bulk via FTP or provided through an API. But one of the most common misconceptions is that a company can only monetize raw data. That isn’t the case. Because of its unique aspects, data can be packaged in numerous ways. In fact, data products get more valuable when you travel down the list in the figure below, using data to enrich other data or create analytics or insights or custom data products or even integrate data into suppliers’ or partners’ systems. Just as with other raw materials, the more you process data, the more expensive and exclusive—and valuable—it becomes.

To put this in relatable terms, think about wheat. Few consumers (outside of a small number of processors) go to the fields to buy raw wheat. Most go to the store to buy wheat that’s processed into flour. Or, further along the value chain, they buy bread that has been baked from the processed flour or, a step further, a sandwich. At each step, the product is more consumable. The market becomes smaller, the cost becomes greater, but the value increases as you combine a raw material with other raw materials to make a product.

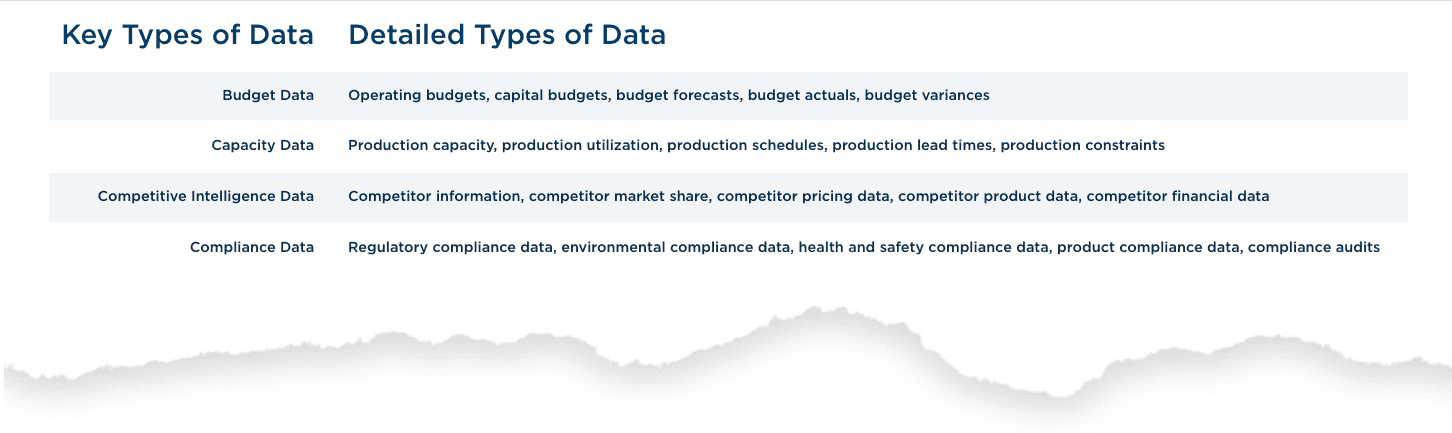

There are literally dozens of types of manufacturing data that may have value in some form of packaging along the spectrum above.

Getting Started or Back on Track

Whether you’re just starting or have explored data monetization but stalled, your organization will need an approach grounded in creating both momentum and value. Again, this is a process, not a one-time activity. It will also require a dedicated leader or team to own and support the process. West Monroe breaks data monetization into about a dozen discrete steps that fall into three basic phases:

1. Generate and prioritize ideas

2. Define the use case or data product requirements and features, collaboratively with stakeholders inside and outside of the business

3. Engineer, introduce, learn from the results and feedback, and improve continuously using rapid iterations to shorten the time to value

If this looks familiar, it is. It comes directly from well-honed R&D and product management playbooks.

Ideation workshops or exercises should start with your organization’s business drivers and identify those where you have the most potential for creating impact with data and analytics. Get a cross-functional group in a room to bring as many perspectives to the table as possible. And aim to develop as many ideas as possible.

One way to frame an ideation exercise is to identify situations where it would be valuable to have more prescriptive, predictive, or diagnostic insight. In manufacturing, considerable effort still goes into reporting on the past—what was sold or how costs fluctuated last quarter. What’s more valuable is understanding why you only sold that much, how much you’re going to sell next quarter, or how you could sell even more.

Another potential starting point is to identify data with the greatest potential value inside and/or outside your organization. Characteristics of highly monetizable data include such things as degree of control or ownership, uniqueness (others do not have data like it), meaningful context, security, accuracy, and availability. If you have data that meets many of these characteristics, compartmentalize it and make sure you begin treating and managing it as an asset, even as you develop your strategy for monetizing it.

Take inspiration from what other organizations are doing, both in and beyond the manufacturing sector. We recommend referencing Data Juice for real-world stories, including several from consumer and industrial products organizations.

Finally, look for other business or IT initiatives already underway that can help in gathering, preparing, or using data in new ways. This is often a way to accelerate new initiatives that may otherwise be challenging to get off the ground.

“Characteristics of highly monetizable data include degree of control or ownership, uniqueness, meaningful context, security, accuracy, and availability. ”

As you begin to prioritize ideas, employ a feasibility assessment that considers factors such as complexity, cost, and magnitude of benefits. One way to compare and rank ideas is to plot them according to impact and complexity. Those with low complexity and high impact are candidates for rising to the top of the priority list.

Be prepared for bottlenecks

There will always be challenges—cultural, technical, poor data quality or governance, and privacy and legal considerations (perceived and real) among them. We often see organizational issues—including core business priorities that don’t encourage data monetization, accounting standards that don’t (yet) recognize data as an asset, and lack of experience and skills—as some of the biggest hurdles. At least some of these—such as building the right skills and foundational data integration, master data management, and storage or computing capacity—will require investment. It may pay to bring in expertise in areas such as data literacy, data management, and change management to accelerate key changes and avoid costly missteps.

And be ready to measure

As the old adage goes, you can’t manage what you don’t measure. Organizations tend to manage things like data volume and speed. Few measure data quality characteristics such as potential value, business relevancy, cost, impact on business performance, market value, and impact on the organization. Research shows that only 11% of organizations know the cost of their data, only 12% calculate the value of their data assets, and only 21% measure the business impact of data quality improvements. Further, only 4% have developed ways of measuring data value in monetary terms with an assigned dollar value, only 7% are now beginning to measure data value against data-driven services, and nearly a third don’t have measures in place to value the increasing volumes of data that digital technologies create.

If you’re going to proceed down the path of data monetization, you will need an approach for measuring the value. We recently worked with a client, a leading manufacturer of agricultural machinery, to develop an approach for understanding the return on its more than $100 million invested in data and advanced analytics capabilities and to justify new investments. This effort employed our thought leadership on the economics of information—or “infonomics”—to create a practical framework that the company is using to measure the value potential of digital and data products.

Ride the Wave

With the sudden emergence of generative AI, we believe people will someday remember 2023 in the same way we remember getting on the World Wide Web for the first time. This development has brought new attention to data and its potential value in all sectors, including data-rich manufacturing. We’ve seen interest in this sector pick up considerably in the past several months and expect that will only intensify as new capabilities emerge. If you are just beginning down the path toward data monetization or have started but stalled, now is the time to get focused. Manufacturers that do catch this wave and ride it to begin exploring data monetization will find themselves in a good position to benefit. M

About the authors:

Doug Laney, Innovation Fellow, Data & Analytics Strategy, West Monroe

David McGraw, Senior Manager, Consumer & Industrial Products, West Monroe

Tim Wrzesinski, Director, Technology, West Monroe

Achieving Data Mastery through Literacy and Standardization

Setting clear objectives and ensuring cohesiveness can enable manufacturers to be deliberate and intentional in executing a data strategy.

TAKEAWAYS:

● Manufacturers must first determine an objective for data mastery and prioritize potential quick wins as the first step.

● Data from customers, suppliers, and the shop floor must be harmonized to standardize inputs, KPIs, and other important metrics.

● Manufacturers must also assess their teams’ data literacy and then determine what training is necessary to develop organizational cohesiveness.

Manufacturers understand that data will be foundational in developing increasingly efficient factories of the future, an essential tool to guide better decision-making at every level of the business. As digitization becomes more commonplace on factory floors and data becomes progressively central to operations, manufacturers need to be ever more intentional about how they tap into that data.

That intentionality can be more challenging than it seems on the surface. There are two foundational efforts that can help manufacturers on this front: setting clear objectives for how the business wants to use data to its fullest extent and ensuring teams across the organization have a cohesive level of data literacy. Both efforts enable the organization to be more deliberate in execution.

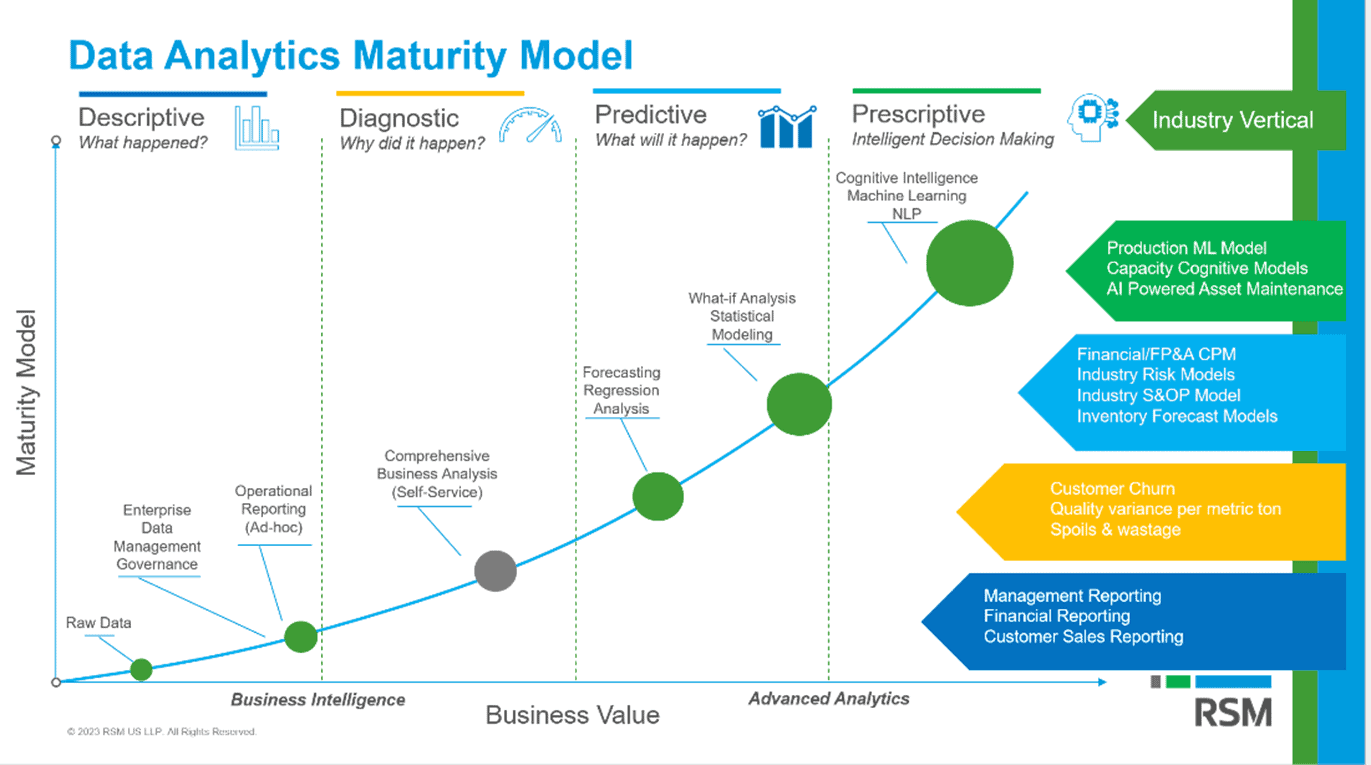

The first mission, determining an objective, may seem straightforward enough. But with how ubiquitous data has become throughout manufacturing operations and production processes, teams may find it challenging to rank their priorities. While predictive machine learning processes may be appealing, for instance, implementing such processes can be more time-consuming and challenging than, say, identifying manual processes where data might help to increase workers’ efficiency. Identifying potential quick wins should be top of mind for leadership teams assessing how to improve their data strategy.

The company’s data maturity level will play an important role in setting this objective. Manufacturers that find themselves in the earlier stages of weaving data analytics throughout their operations will likely have different goals than those already using more advanced, predictive data capabilities.

Harmonizing Data Sources

Customer data, supplier data, and data generated on the shop floor all converge to create an enormous amount of potential for manufacturers looking to make their operations exponentially smarter and more efficient. But if those data sources aren’t harmonized to speak the same language, essentially, then it will be difficult to harness that information in a meaningful way.

Data-driven decision making is at the heart of the Industry 4.0 journey, and connectivity among machines, products, employees, suppliers, customers and processes across the value chain is the key to unlocking the value of this data.

“Manufacturing leadership teams need to identify which functions of the business could benefit the most from data and then talk to those teams about their biggest pain points.”

Companies need to standardize various inputs, key performance indicators and other metrics so teams can manage, compare, and report on data cohesively throughout various business functions. This allows for cross-training, improvement across different manufacturing sites and standardization of best practices for broader, companywide benefit. Especially for middle market and smaller manufacturers that don’t currently compare metrics between facilities, standardization is an important step in improving data management and governance.

Here are some specific ways companies can standardize their data across various sources:

- Establishing data owners: Ensuring data inputs are consistent starts with establishing ownership for various data sources. Manufacturers should determine which individuals and/or teams essentially own which data channels and how they can be good stewards of that data. This is also a key effort in standardizing and harmonizing KPIs.

- Implementing a data catalogue or dictionary: Having a reference guide is crucial to boosting the accessibility of data and becomes more important as an organization builds out its analytics capabilities. Having such a catalogue can ensure teams use their time more efficiently and have a common understanding of data and where it is coming from.

- Equipping teams to succeed: If one facility uses different metrics than another and the business wants to switch to using standard metrics across the organization, leadership teams need to understand the implications for employees and provide training as appropriate. We’ll look at workforce implications more in-depth below.

Bridging the Data Literacy Divide

Hand in hand with standardizing data across production facilities and other sources, manufacturers need to ensure their employees’ data capabilities and literacy are consistent across teams, locations and the broader ecosystem, which may involve suppliers and other partners. It’s common for there to be a data literacy divide among teams, and for some employees to feel more comfortable leveraging data than others.

An assessment can be a critical first step in determining team members’ data literacy levels and can allow leadership teams to see what work and training can bring everyone onto a level playing field.

“Manufacturers of all sizes need to hone their workforce’s data mastery skills and streamline data across operations before they can tap into more advanced capabilities.”

Once such an assessment has taken place, there are several important steps organizations should take to bridge the data literacy divide:

- Education and buy-in: Some employees may not see the full potential of data within the organization. This is where leadership teams need to educate their workforce on why harnessing data matters for the future success of the company. Getting specific with examples here can be useful; for instance, explaining how adopting consistent downtime codes across facilities can make employees’ jobs easier is one way to communicate the value of data literacy and cohesive data mastery across teams.

- Training: Once leadership teams have buy-in from employees, organizations need to assess what types of training employees need and how their needs may vary. A tailored approach can be useful here to bridge the gap between perspectives; some team members may see data as the main way to solve every problem, some may be skeptical about its practical uses, and some may need to experience using data analytics tools to solve problems in real time in order to see their full potential.

- Assessing needs throughout the business: While it’s important to make training available widely, manufacturing leadership teams also need to identify which functions of the business could benefit the most from data and then talk to those teams about their biggest pain points. Finance, supply chain operations, and the shop floor production operations — especially those using Industrial Internet of Things devices and connected infrastructure — are some areas where it may benefit organizations to zero in on.

The Bigger Picture

Teams that are in the thick of training employees on data or implementing new technologies might lose sight of how to track and/or communicate the return on investment of those efforts to senior leadership, but determining that ROI can ensure all stakeholders understand the importance of data literacy, tools and training to making the overall business more efficient.

Manufacturers of all sizes need to hone their workforce’s data mastery skills and streamline data across operations before they can tap into more advanced capabilities. Setting clear intentions and objectives is the critical first step to increasing an organization’s data analytics maturity level and strengthening data governance throughout operations. M

About the authors:

Ravi Bodla is a Data and Analytics Director at RSM US LLP.

Jacob Friess is a Data Analytics Supervisor at RSM US LLP.

Unlocking Data-Driven Manufacturing’s Power

The challenge of decoding and using data to drive strategic outcomes and unlock value

TAKEAWAYS:

● Data has the power to optimize and scale manufacturing operations, enable the workforce, and boost performance.

● Manufacturers have struggled to build a business model that captures data’s value and seamlessly integrates data into day-to-day functions.

● Organizations that empower workers to be part of their data transformation strategy can gain a competitive edge.

Effective use of data is increasingly important for manufacturing organizations. The EY CEO Imperative Survey revealed 70% of manufacturing sector respondents see digital innovation as a transformation driver for their companies.¹ However, few manufacturers have been able to successfully navigate this complicated domain. Many continue to struggle with connecting equipment, systems and factories. Others collect data lakes that require extensive effort to extract meaningful insights. Ongoing growth through acquisition has exacerbated the opportunity as global organizations often acquire companies at different stages of technological development. With disparate machines, systems, siloed architectures and data models, time is spent trying to capture and make sense of data rather than taking actions that drive business needs.

The need to effectively use data has never been greater – or more urgent. Ongoing global disruptions are driving more on-shoring and near-shoring of manufacturing in markets with higher-cost labor, which demand more productivity. At the same time, changing customer expectations and unreliable material sources are intensifying the need for agility. These challenges are compounded by ongoing labor and skills shortages that highlight the need to utilize, attract and retain talent by creating more engaging and impactful worker experiences.

“The need to effectively use data has never been greater – or more urgent”

Today’s market requires a data-driven manufacturing approach. The focus is on capturing the right data, modeling it for effective insights, and empowering workers with the information they need to optimize day-to-day operations. Additional priorities include, upskilling personnel, and enhancing work processes in ways that strengthen performance and boost value.

Leading with value

At its core, data-driven manufacturing is about leveraging business outcomes based upon intelligent data. The focus is on connecting and capturing data from the manufacturing floor to the enterprise layer, linking that data to unique business requirements and then identifying actionable insights that can improve overall business competencies.

Making the shift from a reactive to a proactive data-driven operation typically requires investment in connecting legacy equipment, mapping infrastructure, integrating systems, and developing end-to-end data and cloud strategy. Priority use cases will need to be defined and operating systems will likely need to be upgraded. This effort should be underpinned by well thought-out architecture, data management processes, and orchestrated change management processes. It is about managing data as a product, and supporting each role, function, and level on that individual’s personal journey map. All of this must also be connected to tangible business outcomes, not just KPI improvements.

Companies that are unable to link data and technology investments to business results often feel trapped in “pilot purgatory.” They are always searching for answers, but find it difficult to justify the additional investments needed to scale. Traditional operational excellence programs may yield improvements, but the lack of sufficient data and insights likely prevents these improvements from being fully sustained over time. Cost-control programs that have been in place for some time may see their benefits begin to plateau. The missing piece to maximizing these benefits could be data-driven insights.

“Companies that are unable to link data and technology investments to business results often feel trapped in ‘pilot purgatory’”

Being able to effectively identify, monitor and realize the value derived from intelligent data investment requires more than identifying costs and tracking KPIs. It starts with a fundamental shift in thinking that data-driven insights are essential to enabling the strategies that have already been laid out, and not as siloed IT, engineering or operations programs that compete for resources. Organizations must begin to connect the dots to see how these digital enablers create new capabilities that support better business outcomes, and how those business outcomes translate to achieving strategic business objectives.

EY recently worked with a global industrial products manufacturer that was struggling to justify infrastructure and system upgrades. These investments were necessary to capture and display real-time overall equipment effectiveness (OEE) visibility in and across their plants. However, business leaders were unable to see how it connected to a core strategic pillar of protecting market share in increasingly competitive markets. By developing a business case that linked the investments to a new enabler (OEE visibility), to new capabilities (proactive problem solving), to a business outcome (increasing labor productivity to offset increasing raw material prices), and to helping achieve the strategic objective (enabling prices to stay low to prevent competitors from taking market share), they were finally able to align on the importance of the program. As a result, the first pilot site was able to properly identify and categorize issues that had never been captured, which accounted for nearly 75% of all production losses. Now, they are systematically working on actions to eliminate these losses.

Navigating the application and data modeling landscape

Once there is alignment on data’s value potential, the complicated work begins to figure out how to collect the data and effectively use it. Organizations need to develop a strategy to capture data from brown or green field sites, interconnect siloed systems, develop end-to-end data and cloud and data management strategies, and develop new business workflows. It begins with a data readiness assessment for each facility, which is mapped across the standardized IT and OT architectures to gain visibility of the data readiness gaps. With advancements in edge, IoT, and OT cyber security solutions (which runs across all systems), data gaps can be bridged, and meaningful data can be extracted from different machines and systems. The data ingestion happens via IoT protocols (MQTT, API, OPC-UA, etc.) and traditional proprietary protocols, and is integrated with the organization’s IT enterprise layer.

With business use cases at the forefront, a modern technology data stack (data capture, ingestion, compute, and storage) and powerful ML/AI capabilities, intelligence can be extracted to demonstrate actionable insights. The data analytics and reporting can be visualized using modern business intelligence or the organization’s preferred tools. Cyber-security plays a huge role and is embedded across all levels of the architecture, ensuring proper authentication, and mitigating the risk of unnecessary data replication.

“Data-driven manufacturing provides those unique capabilities where data insights can happen at different layers of edge, cloud, or on-premises systems”

Data-driven manufacturing provides those unique capabilities where data insights can happen at different layers/stages of edge, cloud, or on-premises systems. The data can be processed in real-time, near-real-time or can follow a cold path route followed by ML/AI processing for insights, depending on the use case. Every customer’s data-driven initiatives are different. Comprehensive tools, advanced technologies and use case accelerators can be brought into the digital journey.

In another use case, EY recently worked with a global pharmaceutical manufacturer to assist in standing up their own connected analytics capabilities. The manufacturer built data pipelines to stand up a rapid proof-of-concept at a facility, deploying to end users with training and validation to enhance before scaling to the broader network. A focus on connectivity, data modeling and analytics enabled the manufacturer to provide the right information to the right people at the right time. All investments were supported by processes that required value to be planned and proven on a small scale before being rolled out enterprise-wide.

This led to a nearly 40% increase in product yield and a 60% reduction in unplanned production stops.

Keeping people at the center

Even with a solid business case and state-of-the-art technologies, real value and improvement lies in employees’ hands, hearts, and minds. It is critical to keep people at the center of all data-driven initiatives, and manufacturers must maintain focus on how new capabilities will upskill and enable workers at all levels. New research indicates that giving specific focus to a series of complex human factors can increase the probability of success to more than 70%.² Each member of the organization will play at least one role as a data generator, data analyzer, or data consumer. Depending on the employee’s function, responsibilities and roles, outlining the journey map of how these new data capabilities will impact them and including them in each step of the process will be critical for adoption and sustainment.

“Almost 60% of manufacturers surveyed by the NAM are creating or expanding internal training programs to address skills shortages through adaptive upskilling”

In a study by EY and The Manufacturing Institute, research showed industry leaders recognize that increasing business performance by asking more from their existing workforces is not enough.³ Seventy-four percent of leaders surveyed indicate that the skills needed for manufacturing jobs are changing rapidly and 82% shared they are seeking new and innovative ways to invest in the careers of their workforce. The study also found that almost 60% of manufacturers surveyed by the National Association of Manufacturers (NAM) are creating or expanding internal training programs to address skills shortages through adaptive upskilling. These adaptive skill programs are giving manufacturers new ways to educate and align their manufacturing operations to data-driven transformation journeys. The goal is to keep pace with the speed of innovation, create iterative value, and evolve based on the new insights that data provides to the organization.

Summary

Data is emerging as the strategic currency of the digital age. With rapidly growing demand for modernized manufacturing systems, companies can use data-driven problem solving to gain a competitive advantage that will expedite their digital transformation journey.⁴ Data is a critical component to inform an organization’s path and building an organization that can meet the market’s needs and expectations. It can help companies see their way through the challenges and complexities of doing business in today’s world. It can also provide a plan built around creating value, leveraging digital tools and engaging people at each step of the journey toward fulfilling the organization’s mission. M

Article references

1 Why industrial companies need to lead business model innovation, www.ey.com/en_us/advanced-manufacturing/why-industrial-companies-need-to-lead-business-model-innovation

2 The CIO Imperative: Is your technology moving fast enough to realize your ambitions? www.ey.com/en_us/consulting/tech-horizon-survey

3. How adaptive skills can play a pivotal role in building the manufacturing sector of the future, www.ey.com/en_us/advanced-manufacturing/the-manufacturing-institute-adaptive-skills-study

4. How do you harness the power of people to double transformation success? www.ey.com/en_gl/consulting/how-transformations-with-humans-at-the-center-can-double-your-success

About the authors:

Manan Bawa: Senior Manager, Technology Consulting, Data & Analytics, EY

Manan Bawa is part of the data and analytics team with a strong focus on the advanced manufacturing and mobility sectors. With a 13+ year career in managing key products and technical transformations, Bawa has delivered superior results for billion-dollar projects and high-profile organizations. He is a proven, versatile leader known to spearhead emerging technologies, develop sustainable and smart factories, and produce cost-effective deliverables within the advance manufacturing, power and utilities, energy, CPG, oil and gas, tech, retail, and mobility sectors.

Robert Calloway: Americas Manufacturing and Mobility Technology Leader, EY

Robert Calloway brings 33 years of experience to help organizations develop and execute digital transformation journeys that leverage data and technology to both optimize business operations and create value and growth.

Zakir Hussain: Partner, Americas Data Leader, EY

Zakir Hussain leads a best-in-industry team to deliver technology implementations for his clients across sectors. For more than two decades, Zakir’s clients have benefited from his team’s experience and expertise in technology and data modernizations – uniquely positioning each to advance and accelerate their growth initiatives.

Greg Wagner: Data-Driven Manufacturing Solution Leader, EY

Greg Wagner is a transformation leader at EY who specializes in implementing data-driven manufacturing capabilities with clients. He possesses a background in Lean Six Sigma and quality, asset reliability and integrity, operational risk management and digital manufacturing. Wagner has more than twenty years of consulting and industry experience working in leadership, operations and technical functions within the chemicals, oil and gas and specialty manufacturing industries.

How Best Practices in Data Analytics Drive Maintenance Maturity

Insights that convert into actions can improve equipment reliability, span the enterprise, and boost the bottom line.

TAKE AWAYS:

● Using data and analytics for condition monitoring can eliminate unplanned downtime and allow for improved equipment reliability.

● Centralizing maintenance roles and utilizing remote support can help manufacturers alleviate labor scarcity and maximize their technical teams.

● Machine health monitoring can trigger corrective actions to be scaled across multiple production lines or multiple sites.

Manufacturers are acutely aware of how machine health affects production throughput, particularly plants operating in a throughput-constrained mode. Without sustainable equipment uptime, schedules are missed, orders go unfulfilled, revenue is lost, and unplanned labor and repair costs are incurred.

A significant factor impeding the achievement of operational goals is the widespread, protracted shortage of asset reliability and maintenance talent. Fortunately, technology can alleviate this challenge.

The burgeoning depth and breadth of condition monitoring analytics technologies offered by countless solution providers aims to eliminate unplanned downtime. The core value of machine condition monitoring is twofold: (1) drive best practices in reliability and maintenance; and (2) mitigate the skills gap now and into the future. Its primary goal is harvesting analytical insights directly from machines to identify the opportune time to service degrading critical equipment and components — not too early, nor too late.

“Gaining maximum value requires putting the data and analytics to good use.”

Mastering how the condition data is harnessed, analyzed, and operationalized is key. With digitalization boosted by the industrial IoT, such as wireless condition monitoring sensors, plants can collect and centralize for analysis unprecedented quantities of real-time, streaming asset condition and performance data, along with batches of intermittently connected or locally captured data. Gaining maximum value from this approach requires putting the data and analytics to good use.

Operationalizing Data Analytics

Many plants lack the internal resources to leverage machine condition monitoring for troubleshooting and repairs, let alone navigate the complexities of developing scalable analytics solutions. The prior model of staffing qualified, dedicated at every manufacturing facility is no longer sustainable.

Industrial service providers are responding to this reality by adapting and optimizing their own technology and methods, while developing new ways to provide actionable remote support to the factory floor. Over the past 12-15 years, the aging manufacturing talent pool and increasing demand for domestic manufacturing compelled leading service companies to refocus on centralizing core roles, such as predictive maintenance specialists, reliability engineers, and high-level positions.

This development is driving a cultural shift in manufacturing. Internal plant maintenance teams are not inherently inclined to ask for help, but once they begin accepting virtual support, they can transition from their singular plant focus and leverage their skills out to other locations.

Machine health monitoring is also a paradigm shift for the remote support providers, who now actively pull condition data for analytical insights and translate it into action on the factory floor. For instance, when an alert is received at a centralized technology center that an asset condition threshold has been breached at a certain plant, an expert can reach out to the appropriate individual on the factory floor to provide crucial guidance remotely, in layman’s terms.

“The core value of machine condition monitoring is twofold: (1) drive best practices in reliability and maintenance; and (2) mitigate the skills gap now and into the future.”

Rather than details such as the frequency, hertz, and amplitudes of the waveform, what a technician really needs to understand is, for example, that it looks like a specific coupling is coming loose. In this example, that would mean they need to take that machine out of service, validate that the motor is meeting its alignment specifications and everything is in safe working order, and then torque the coupling to its proper specification. Additional details or step-by-step instructions can be provided by the remote service expert to the asset-facing technician via a mobile device.

Moreover, this new approach to monitoring and analytics is driving significant innovation in maintenance automation processes. A simple example is instead of regularly pumping grease into an asset, data analytics from that piece of equipment can trigger a command to an auto-lubricating device bolted onto the machine to automatically inject the correct amount and type of grease into the equipment. This optimizes the process while also eliminating the need to involve a maintenance technician.

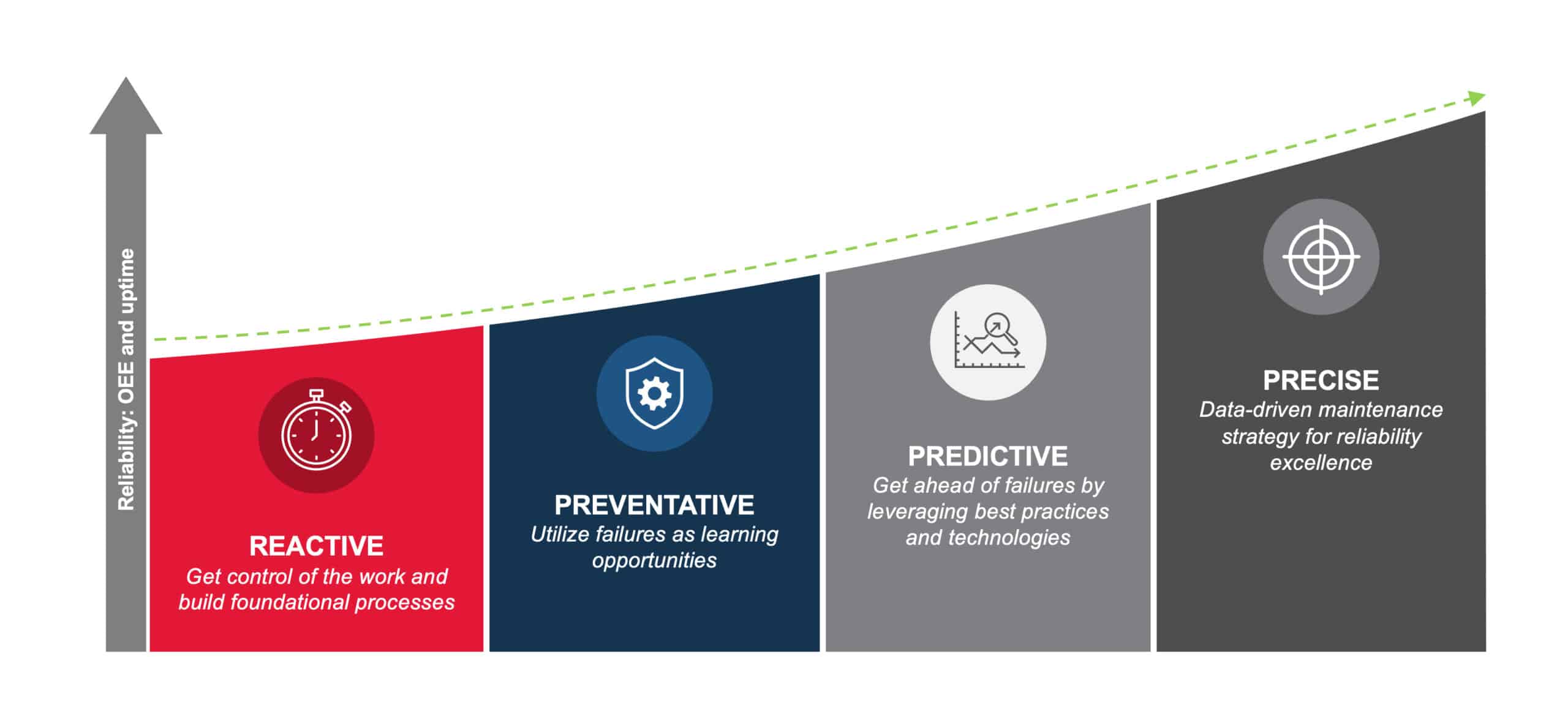

Figure 1 – Accelerating Maintenance Maturity

The Evolution of Maintenance Philosophies

Maintenance philosophies have changed markedly over the years (Figure 1). For a long time, maintenance meant running equipment until it breaks, and then fixing it, though this caused excessive unplanned downtime. When preventive maintenance practices emerged, time- and usage-based plans and routes were developed to keep the equipment in better condition, though the risk of downtime from over- or under-maintenance was still a concern.

Condition-based maintenance practices flourished when skills gaps intensified the need for labor efficiency. Having sensors continuously monitor and measure machine condition parameters and trigger alerts when a given threshold is met allows scarce labor to be applied to situations that actually need attention.

“Internal plant maintenance teams can utilize virtual support to transition from a singular plant focus and leverage their skills out to other locations.”

The latest realm of maintenance maturity is predictive maintenance — applying condition analytics and prognostics to predict when an asset is likely to fail, forecast the asset’s remaining useful life, and plan maintenance processes, people, and parts with precision to get the maximum life out of the equipment and components. Ideally, this approach leverages not only real-time condition monitoring data, but also historical trends and contextual information such as environmental conditions, process output, and maintenance histories.

Continuous condition monitoring analytics are central to the highest level of maintenance maturity, known as precision maintenance. It allows the work to be predicted and stretched out for as long as possible, maximizing the utilization of time and labor while maintaining the highest asset availability and throughput opportunity.

Extending Maintenance Optimization

Condition monitoring analytics enable plants to optimize their asset maintenance practices and migrate to an enterprise-wide predictive maintenance philosophy. Even non-critical assets that remain on route-based preventive maintenance schedules can benefit from predictive analytics. This is because manufacturing facilities frequently operate identical or similar types of equipment across multiple lines within a plant, and across any number of sister plant locations.

Specifically, any machine health finding that triggers a corrective action can be leveraged across other assets that have, or are developing, a comparable condition. Additionally, the knowledge gained from condition analytics and root cause identification can help to refine maintenance plans and intervals for all equivalent equipment. Extrapolating the findings to additional equipment in this manner optimizes both preventive maintenance schedules and predictive maintenance activity, further reducing unplanned downtime and extending the mean time between failures.

“The knowledge gained from condition analytics and root cause identification can help to refine maintenance plans and intervals for all equivalent equipment.”

A good case in point is when a specific lubrication issue at a plant was identified as the root cause of unplanned downtime. A little digging into their maintenance processes revealed that the preventive maintenance plans did not include the appropriate tasks to prevent the lubrication condition. That deficiency affected not just that single piece of equipment, but all equipment of that type, across all facilities. The results of that initial finding led to adjusting all the maintenance plans for 26 pieces of equipment across 12 facilities, increasing efficiency and preventing similar failures.

Reaping Strategic Benefits

The advantages of mastering this strategy are manifold. Consider a plant that purposely overheats aggregate to make sure it is completely dry. It may consume twice as much natural gas than is really needed to properly manufacture the product. From a financial perspective, passing that extra cost onto the consumer creates some competitive challenges for the manufacturer. From a sustainability perspective, excess emissions and gas transport requirements create a larger carbon footprint. With proper temperature monitoring, such challenges can be avoided.

Here are three of the primary benefits of operationalizing condition monitoring analytics:

- Planning and scheduling: Having access to machine health data analytics enables data-driven prioritization of work planning and scheduling for consequential labor and cost efficiencies. Online condition monitoring allows issues to be addressed as they arise, based on detectable early warning signs, with well-planned and strategically timely corrective actions. Since time- and cycle-based maintenance plans are conducted regardless of an asset’s actual condition, changes go undetected between routes, and random failures are routinely missed.

- Equipment reliability: Continuous machine health monitoring allows plants to move quickly on resolving predicted failures, maximizing uptime rather than reactively repairing failed equipment or components. Monitoring can reveal sudden large changes such as those attributed to a process change or machine crash, or gradual changes over time, including micro trends. By implementing AI and machine learning algorithms based in statistical process control, the degree of change can be tracked on an ongoing basis, and insights can be gleaned to determine reliability engineering needs and root causes.

- ESG and sustainability: Actively monitored and well-maintained equipment tends to operate in a highly efficient and effective manner. Likewise, when environmental conditions such as humidity, temperature, and cleanliness of the air are continuously monitored and proactively maintained, the benefits to human and machine health are great. Conversely, improperly maintained equipment running under production load is more prone to energy waste, raw material waste, scrap, quality defects, minor stops, equipment outages, or catastrophic failure.

Consider Monitoring as a Service

Many plants want to move to a condition-based mindset but lack the engineering and development capabilities in maintenance and IT to pull together a robust package on their own. Choosing remote condition monitoring as a service may be the answer for plants that are short on time and internal technical talent.

Industrial service providers with extensive experience in predictive technologies are adept at designing, implementing, and managing fully integrated condition monitoring analytics solutions. Those with the added capability of providing centralized, remote support for hundreds of manufacturers in multiple industries are uniquely well versed in operationalizing analytics in plants and across plant sites. M

About the author:

Micah Statler is the Director of Operations at Advanced Technology Services

Operationalizing Analytical Insights

Manufacturing Leadership Journal content and MLC resources are exclusively available to MLC members. Please sign up for an account or log in to view this content.

AB InBev Uses Smart Manufacturing for Award-Winning Results

What does it take to be a digital transformation champion? Anheuser-Busch InBev can tell you.

The world’s largest brewer won four Manufacturing Leadership Awards in 2022, including the highly coveted Manufacturer of the Year. (The honors are given annually by the Manufacturing Leadership Council, the NAM’s digital transformation arm.) The MLC chatted with AB InBev Global Vice President Marcelo Ribeiro recently to get his insights on the processes, technologies and strategies driving the company’s success.

Business transformation drivers: “We have a dream at ABI, which is ‘to create a future with more cheers,’” said Ribeiro. “[That means] a clear strategy to lead and grow, to digitize and monetize our ecosystem and to optimize our business.” Here are a few ways AB InBev is pursuing that dream:

- Developing and delivering products that give consumers what they want, when they want it

- Making sure the supply chain can adapt quickly to consumer needs

- Increasing capacity without compromising safety, quality or sustainability

Rising to challenges: “The future is becoming less predictable,” Ribeiro said. “We need to prepare for that, so we have to build a more resilient, flexible supply chain.” Additional opportunities include:

- Moving from transactional relationships with vendors and suppliers to partnerships

- Looking beyond operations and across the entire supply chain to meet sustainability goals

- Creating a collaborative manufacturing ecosystem that fosters the sharing of ideas

Meeting the digital future: Ribeiro says that ABI’s digital strategy has three key aspects:

- Making data more accessible and available to frontline workers

- Creating a template for digital technology that can be easily tailored to the unique needs of each business

- Using advanced analytics to contextualize data and discover where it can best be applied to aid decision making

Leaders required: Ribeiro noted that leadership is essential for making this vision a reality.

- “It is critical to empower the front line,” he said. “Leaders should be focused on providing the resources to allow people to do the work and achieve excellence themselves. In the end, people are key for any business transformation.”

Find additional insights into AB InBev’s digital transformation in DIALOGUE: AB InBev’s Award-Winning Dream, or make plans to attend Rethink, where Ribeiro will present a keynote address on “Building Your Enterprise into a Digital Transformation Champion.”

AI in Manufacturing: 11 Focus Areas to Consider

Manufacturing Leadership Journal content and MLC resources are exclusively available to MLC members. Please sign up for an account or log in to view this content.

E-Cycling Helps Manufacturers Generate Business Value

Electronic waste is a big problem.

In 2019, the world generated a record 53.6 million metric tons of discarded electronic and electrical devices, according to a Global E-waste Monitor report. That’s an increase of 21% in just five years. But there’s more: The figure is expected to double by 2050, hitting 120 million tons annually.

The good news is that manufacturers can be an active part of the solution. Though their bread and butter has typically been bringing new products to market, manufacturers are now also developing end-of-life processes for goods to mitigate environmental impact, according to Bright Machines Vice President of Industrial Solutions Adam Montoya, writing in the Manufacturing Leadership Council’s Manufacturing Leadership Journal. (The MLC is the digital transformation division of the NAM).

The challenge: complex components. Disassembling a product is not nearly as straightforward as assembling it, according to Montoya. Take a server, for example. A company might know what’s inside it based on its original configuration, but memory or processor upgrades could have changed over the course of its life.

- When a lot of change has taken place, the dismantling process is unique to each server, making it complex and difficult to automate.

The solution: intelligent disassembly. Improving the end-of-life process for electronics requires intelligent disassembly, a combination of smart technology and a different way of thinking, says Montoya. Here’s how it works:

- Automation technology that uses AI and advanced vision systems interprets the contents of a particular component and compares it against the original blueprint.

- Next, the system assesses the presence and location of components within the unit.

- It then sorts, separates and removes components so they can be reclaimed or recycled.

The bottom line: Manufacturers stand to realize many benefits from intelligent disassembly. Components with sensitive data can have machine-driven proof of destruction. Systems with usable parts can be repurposed rapidly.

- Ultimately, it’s an important way for manufacturers to collectively reduce carbon footprints and electronic waste while delivering business value, says Montoya.

For more on this topic, read Rethinking End-of-Life Technology Value in the Manufacturing Leadership Journal. And to learn more about how manufacturing leaders are undertaking digital transformations, join the MLC at its Rethink conference in Marco Island, Florida, on June 26–28.