Survey: Sustainability Momentum Surges Dramatically

Manufacturing Leadership Journal content and MLC resources are exclusively available to MLC members. Please sign up for an account or log in to view this content.

Ten Takeaways from M in 2030 Project A Lens on the Future Panel

With the recent release of the Manufacturing in 2030 Project survey A Lens on the Future, MLC assembled an expert panel of speakers to discuss the results and bring context to the survey findings.

Moderated by David R. Brousell, the MLC’s Co-Founder, Vice President and Executive Director, the panel included Dennis McRae of West Monroe, Greg Wagner of EY, Chirag Rathi of Infor, and Joe Zakutney of NTT DATA.

Here are ten key takeaways from the discussion:

1. 84% of survey respondents expect an increased pace of digital adoption in the next decade

Dennis McRae, West Monroe’s Senior Partner and Practice Leader, Consumer & Industrial Products, noted that the acceleration rate depends on the size of the company, but he said the biggest thing is if you haven’t started your Manufacturing 4.0 journey in a meaningful way, now is the time to do it to maintain competitiveness.

“One of the first things you can do is really establish a team focused on digital with the right leaders, the right innovators, and also the right disruptors who can really challenge and do what leadership needs to get done,” McRae said.

2. 58% of survey respondents have autonomous factory operations on their radar by 2030

Chirag Rathi, Senior Director, Industry and Solution Strategy at Infor, pointed out that the desire for autonomous operations is not new and that General Motors was talking about this in the 1980s. Citing deep-learning and self-learning algorithms in machine learning, digital twins, blockchain, and autonomous transportation, he sees autonomous operation as a game changer, but he cautioned that full autonomy is unlikely in many circumstances.

“The cost of doing full autonomy in most industrial manufacturing processes might be too high,” he said. “So you will have part autonomy in several manufacturing arenas where the business case makes sense, but it will be a decision made on a case-by-case basis.”

3. 76% believe manufacturing should adopt an AI code of ethics

For Joseph Zakutney, NTT DATA’s Vice President, Manufacturing Industry Consulting and Digital Transformation, thinking about AI’s future means protecting against biases and cyberattacks, while accounting for safety.

“Procedures will need to be put in place to make sure that we’re complying to [a code],” he said. “We need to make sure that the software that we are releasing is fair, reliable, explainable, takes data protection and government regulations into consideration, and is focused on the well-being of society.”

4. Almost half of respondents indicated they expect workforce shortages to continue through 2030

Traditionally, manufacturing doesn’t have the best image according to Greg Wagner, EY’s Data Driven Manufacturing Leader. It is considered dirty, loud, and can be physically intense at times, but Wagner pointed out that those seeking purpose-based work should be attracted to manufacturing. The old adage of “being a cathedral maker and not a bricklayer” fits here, according to Wagner.

“If we change the paradigm and what we’re looking for, the types of job experiences we can give people, and use automation to get rid of some of those menial tasks that people don’t enjoy and free up their capacity to focus on bigger problem solving, it will mean more impactful types of roles,” Wagner said. “That’s going to really start to attract people and start to soften some of that gap we see right now in hiring.”

5. 81% of manufacturers are looking for greater speed and flexibility

When we think about speed and flexibility, what people really want is responsiveness, according to Wagner.

“If we really want to be able to respond quicker, we need to know what’s going on and we need to invest in better end-to-end visibility of what’s happening within our factories and what’s happening across our network so that we can be more adaptive and have the right insights to drive that change,” he said.

McRae added, “There’s a big opportunity for manufacturers in terms of connecting with their customers, building that client experience, and really monetizing a lot of the data that’s already in the business.”

6. By 2030, 50% of respondents believe digital adoption will be a game changer.

For Rathi, we’ll be closer to Industry 5.0 by 2030 with hyper-customization, responsive and distributed supply chains, and business model innovations. In fact, Rathi said we already have the building blocks to make this a reality.

“We have certainly got a lot of the raw materials to make that transformation happen,” he said. “So we will have a lot of transformative changes by that time period.”

7. Digital acumen is important across functions and at various leadership levels

One challenge McRae sees is getting everyone on the same page using the same language so that data assets are understood across company levels by all who manage data and products in the business.

“It’s not just around different levels, but also across functions,” added Wagner, noting that there is a wide array of digital understanding and how those technologies can be applied.

8. Hiring for a digital background versus a subject matter expert depends on the project

“I think we’re seeing the rise of data scientists and citizen data scientists at some organizations. At the same time a lot of data DIY products are becoming available, and they will become more prevalent by 2030, meaning that people with subject matter expertise will be able to basically design and develop their own data science projects,” Rathi said. Because of that, he believes subject matter experts will be in higher demand in most cases vs. data scientists.

9. For companies slowing down their digital projects due to the economy, focusing on specific things can help prevent losing ground

“Digital adoption is really a people play right now,” said Zakutney. “I’d stay focused on people and process, because ultimately, that’s what you’re going to end up automating [when funding comes back].”

“You can’t quit your digital investments,” added McRae. “If you don’t become digital, you’re going to be left behind. At the same time, prioritizing those digital investments specifically around areas that are going to improve your customer experience and take costs out over the next few years are going to help you win.”

10. Beyond the panel discussion, the survey report provides insightful data about the future of manufacturing

The MLC’s Manufacturing in 2030: A Lens on the Future research survey includes front-line insights from over 260 senior manufacturing industry executives, spanning multiple functional roles, and representing large-, medium-, and small-sized manufacturing companies from multiple industry sectors. Armed with this rich combination of real-world predictions and forward-thinking understandings, the MLC hopes that manufacturers can better plan their longer-term future and find ways to enhance their value, competitiveness, and contribution to society. Download the complete survey data and report.

The manufacturing industry has spent a lot of time, effort and money on making its processes more efficient over time. And now the industry is investing in the Industry 4.0 philosophy to minimize wastage and downtime, leveraging technologies including 3D printing, digital twins, and predictive maintenance. Powering all of these investments is data.

Late last year I had a number of conversations with manufacturing professionals who manage products throughout their lifecycles – from the 3D CAD design phase, through review, fabrication, sales and marketing, and even further into customer usage and after-sales. They each told similar stories of breakdowns in the processes for creating, distributing, and consuming content that transfers vital knowledge about their products. In addition, they all identified significant negative impacts stemming from these problems. Errors, delays, and missed sales opportunities were frequent complaints.

I came away wanting to know more about these problems, their outcomes, and the underlying causes. What is driving ineffective product documentation workflows and processes at organizations that otherwise appear to be investing heavily in efficiency-based initiatives and cutting-edge tech?

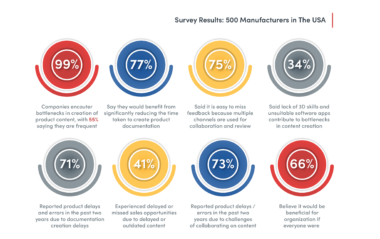

In a bid to find out, my company, Canvas GFX, surveyed over 500 manufacturing professionals across a broad range of verticals, including automotive and electric vehicles, aerospace and defense, new space tech, industrial machinery, and more. The results showed these challenges exist widely across the manufacturing sector, suggesting an endemic and interconnected problem.

We’ve dubbed this problem Product Communication Disorder. For many companies, Product Communication Disorder is perceived, managed – and often tolerated – as a series of departmental workflow challenges. The data suggests the problem cannot be solved unless assessed and addressed with a company-wide perspective.

Where have manufacturers gone wrong?

There are three distinct stages within documentation and knowledge transfer where problems arise, the first being the creation of product content.

As it stands, creating product communication content is time-consuming and complicated, requiring input from multiple team members across an organization. Our research highlighted how critically deficient current workflows are, with clear room for improvement. The stats lay the issue bare, with over 95% of manufacturing industry professionals reporting that projects or products at their company had suffered errors or delays as a result of inefficient workflows for the creation of product communication.

But the problem runs deeper than content simply being late or too time-consuming to create. While the data says these are both true, our survey also suggested that the processes underpinning the creation of content are themselves flawed. For more than one in three respondents (36%) workflow bottlenecks stemmed from too many people being involved in content creation. Meanwhile, the lack of skills or software needed to be able to properly visualize 3D models, the basis for many documentation illustrations, was cited by one third of respondents.

Collaboration is another area fraught with challenges. In fact, 73% of respondents in our survey said they had experienced product or project errors or delays in the past two years as a result of difficulty collaborating on content.

Just as content creation at manufacturing companies is fragmented in terms of departments, skills and software, the collaborative process also appears to want for some kind of central management. According to almost three quarters of survey respondents, a primary problem appears to be too many channels (including email, Microsoft Teams, Slack, and other voice and video calling solutions) being used to manage collaboration, review and feedback on product content. The result of this vital communication happening across a range of channels according to 3 in 4 respondents is that it is easy to miss feedback on important documentation and content.

Lastly, the survey revealed serious concerns around the ability of workers to access the most up-to-date documentation materials. For many organizations this appears to be a struggle, while the problem is aggravated by managing a range of different content formats. It’s vital to remember that consuming content is what this entire process is about.

Worryingly, 85% of respondents said that outdated documentation in circulation had resulted in errors and delays over the last four years, and over a third (36%) said their company struggled to manage the rate at which content becomes outdated. More alarming still is the large proportion of respondents who conceded that their company has difficulty ensuring everyone who needs access to content is able to access the most up-to-date version of each document (54%).

Solidifying Industry 4.0 gains

The overarching issue is that manufacturers spend heavily to update their processes to reduce defects and ensure products make it to market on time, documentation issues are continually undercutting those investments.

Perhaps the starkest illustration of the problem lies in the fact that 73% of respondents felt that inefficiencies in their product communication processes were undermining gains made through other technology initiatives.

But it’s not all doom and gloom, and there is a silver lining here. The findings pointed to evidence that manufacturing companies are looking to cure the problem, rather than simply manage the pain. While the data is clear, so are the actions companies can take.

By addressing their problems in product documentation, companies can take a huge leap in realizing the full potential that Industry 4.0 offers and maximize their investments in it.

About the author:

About the author:

Patricia Hume is Chief Executive Officer of Canvas GFX.

POV: Empowering Sustainable Ideas

Manufacturing Leadership Journal content and MLC resources are exclusively available to MLC members. Please sign up for an account or log in to view this content.

Morgan Advanced Materials Case Study

Morgan Advanced Materials’ thinkGREEN program helps identify and implement green technologies and processes and pursue continuous improvements.

For the past 10 years, Morgan Advanced Materials’ plant in St. Marys, Pa., has been developing and implementing projects designed to reduce the site’s energy intensity, water use, as well as landfill and hazardous waste disposal. This was to help Morgan Advanced Materials achieve one of its core corporate values: “to use advanced materials to make the world more sustainable, and to improve the quality of life” by minimizing the environmental impacts of its own manufacturing processes on resource consumption, air emissions, waste generation, and water discharge.

The results of these efforts at the St. Marys facility, and its sister sites worldwide, inspired the company to develop a new, global corporate thinkGREEN initiative. Launched in 2020, thinkGREEN sets 2030 corporate goals and 2050 aspirations based on a 2015 baseline, directing attention to identifying and implementing green technologies and processes, and pursuing continuous improvements corporate wide. It is patterned after Morgan’s established thinkSAFE initiative and accompanied by a substantial capital investment in enabling solutions.

“Every improvement project has beneficial impacts, but three completed at St. Marys really hit it out of the park.”

— Carrie Lenze

The initiative is already bearing results for Morgan, which develops innovative materials such as thermal ceramics, molten metal crucibles, electrical carbon, seals and bearings, and technical ceramics. The St. Marys facility, which is part of the Seals & Bearing division, has reduced its hazardous waste, water usage, and landfill waste, became more energy sustainable — and improved safety and saved costs along the way. These impressive results earned Morgan the Manufacturing Leadership Council 2022 Award in the Sustainability and the Circular Economy category, which Mike Koscho, Morgan’s Global Director of Operations, calls “a great testament to the progress which we are making against our five environmental, social, and governance (ESG) improvement objectives and targets to improve our performance as a group.”

A Model Plant: St. Marys, Before and After

“Sustainability and environmental stewardship are integrated into Morgan’s daily operations. Every improvement project has beneficial impacts, but three completed at St. Marys really hit it out of the park,” says Carrie Lenze, North America Operations Director.

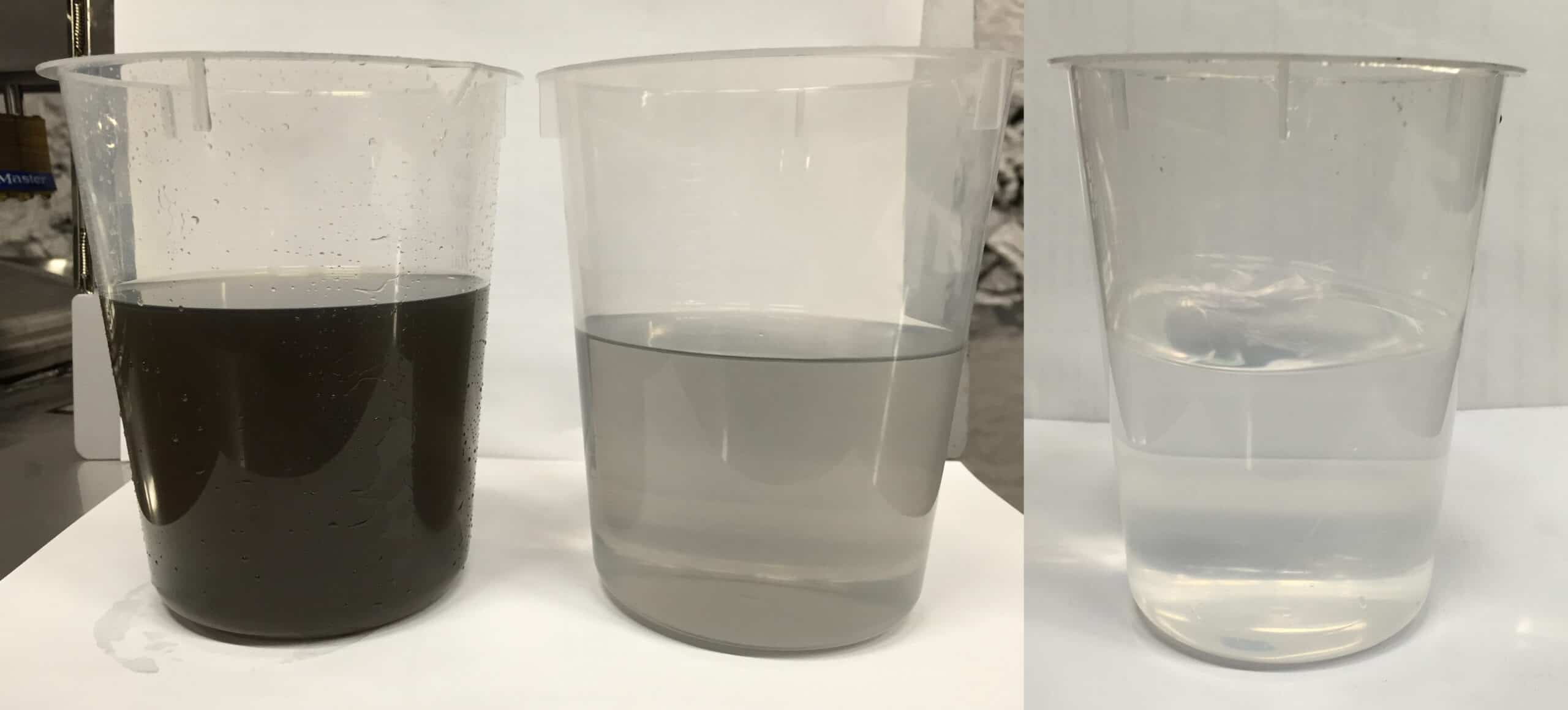

Hazardous waste: The St. Marys plant used to generate and ship about 60 drums of hazardous, flammable waste material annually, mainly due to its use of acetone in a cleaning station. It eliminated acetone from its waste stream by installing an on-site still in 2016 that cleans, distills, and returns the reclaimed acetone to the manufacturing process, leaving just the waste resins from the cleaned acetone to be discarded. This waste stream has been reduced to only four to six drums per year.

While the 2016 recycling and reuse of acetone on-site initially was deemed an environmental project to reduce Morgan’s hazardous waste exposure and prevent acetone from being trucked on highways, it also was a safety project due to acetone’s flammability. A small capital project to plumb the wash tanks together and install a manifold system and air diaphragm pumps made it completely hands-off from a material handling standpoint, eliminating the risk of spills, and avoiding the risk of injury. Ultimately, it is also a cost-saving project, having saved St. Marys about $35,000 in acetone costs in 2021 alone through recycling.

Water consumption: The plant has also dramatically reduced its consumption of city water, which initially was 24 million gallons per year — ranging from 35,000-40,000 gallons per day in the winter to more than 100,000 gallons per day in the heat of summer. Seasonally, water was as much as 25% of the plant’s utility costs, mainly because its old one-pass cooling water system had city water flowing into the building, through all the various equipment that needed cooling, and then back out to the creek. A 2017 cooling tower project allowed the plant to recycle the vast majority of the city water by implementing completely self-contained, treated, non-contact cooling water systems, rust inhibitors to protect the pipes, and biocides to prevent microbial growth in the water.

The 2017 cooling tower project was not initiated because the area is water stressed, but rather because St. Marys is a recreational area with very high-quality trout waters. This made the plant subject to discharge limits from the state’s Department of Environmental Protection. When temperature limitation changes meant the plant had to discharge water to the city sewer rather than returning it to the local water table, recycling it became the obvious solution. The $350,000 cooling tower project reduced the plant’s city water usage by almost 90%, from 24 million gallons to 2 to 2.5 million gallons per year.

Landfill waste: Another challenge was the landfill waste associated with St. Marys contact cooling water used for wet grinding operations. The water is contaminated with the carbon grinding residue, and formerly the carbon swarf was removed using a settling tank and filter press arrangement, creating wet, heavy filter cake sludge that needed to be trucked to a landfill. With the new, more automatic inline filter system installed in 2020, the maintenance labor hours to operator the filter press were virtually eliminated. It is now as simple as changing the roll of filter paper and emptying the hopper. The new Oberlin filtration system has a belt of filter material with a self-contained pressurized cavity that is fed into a pressure chamber. When the filter cake builds up on the filter media in the pressure chamber, a blowdown process uses compressed air to clear the water contained in the filter cake, making it 50% dryer while leaving less weight in the hopper and recapturing water from the process.

The primary value with the new system is the maintenance savings which are estimated to be approximately $85,000 per year. Additional waste disposal cost savings from in avoiding wet filter cake sludge due to the improve blown down process on the new system is also significant. On a tonnage basis, sending dry carbon instead of wet carbon and eliminating water weight from the landfill load reduced the plant’s landfill bill by $5,000-6,000 per year. The 2020 project also is saving the plant about 100 gallons of water per day and the grinding water is a little cleaner. A true win, win, win.

While these three projects are standouts, they are just the tip of the iceberg at the St. Marys plant. Among other consequential projects was a 2020 LED lighting upgrade of an older 2012 T8 to T12 conversion project that was completed when LED lights were cost prohibitive. The 2020 LED upgrade yielded, conservatively, around a million kilowatt-hours per year of savings. The 2013 replacement of a dozen dust collector rotary air locks that ran 24/7 with a new, Vac-U-Valve assembly, a completely mechanical, passive system, reduced electricity usage and saved the company $5,000-6,000 per year. The planned 2022 locker room shower upgrade is largely intended to modernize a long- standing eyesore and improve morale, though it is also expected to save St. Marys about 400,000-500,000 gallons of water a year with more water-efficient fixtures. It is also a multiple energy improvement project focused on modernization of HVAC, windows and doors, plant mechanical systems, industrial ovens, and process equipment. For instance, the upgrade of multiple small batch curing ovens has yielded a 50% reduction in electrical energy consumption due to improved insulation packages and controls.

In addition to the specific energy intensity reduction project undertaken by the St. Marys facility, it is also worth mentioning that both the Morgan Seals & Bearing St. Marys and Coudersport sites participate in the Emission Free Energy Certificate program. In this program, Morgan pays a little more for their electricity to ensure it is sourced solely from CO2-emissions-free sources. The upcharge is then invested to the strengthen the grid with additional green energy sources for the future. This is our way of not only expressing what is important to Morgan but also paying it forward at the same time.

Director NA Operations Carrie Lenze emphasizes that sustainability and environmental stewardship are integrated into Morgan’s daily operations. “Our St. Marys team is proud to make a big positive difference for our employees, our communities and our planet.”

Partnering for a Sustainable Future

Morgan’s partner for outsourced industrial maintenance, Advanced Technology Services (ATS), has supported the St. Marys plant throughout many of its environmental impact reduction efforts. For instance, ATS helped with commissioning some of the site’s new, efficient technologies, such as the Oberlin inline filter system, new compressed air dyer, and is responsible for keeping the equipment up and running at an optimal level.

ATS also handles routine tasks such as filter changes and performing preventive and predictive maintenance on the plant’s old and new equipment, such as using thermographic imaging to look for hot spots and predict failure conditions in time to make corrections before failure occurs.

Recently, ATS technicians initiated and completed air leak inspections, which led to a discussion with St. Marys about how even small, unintentional air leaks can lead to large costs over time, and how air nozzles used purposely in larger volumes might blow all the time when the air is only needed maybe 15% of the time. As a result, in support of Morgan’s cost savings initiatives for 2022, ATS and St. Marys are working together to implement continuous improvement activity in the plant’s air management, such as adding a solenoid valve to only blow air inside a CNC machine during cutting operations, to dust off a part or clear a drill bit or cutting tool.

“Together, the thinkGREEN initiative, modern technologies and tools, and ATS services are helping to make Morgan’s vision a reality,” says Lenze.

Extending Sustainability Company-wide

“Raising awareness of Morgan’s sustainability priorities across all its global sites is key to expanding thinkGREEN’s scale across the operational footprint and advancing the company’s long-term business goals,” says Lenze. “St. Marys has a long history of sharing information about its successes with its fellow North American sites in Coudersport, Pa., and Dunn, N.C., and those sites have been implementing similar environmental initiatives. Now, with thinkGREEN, knowledge sharing is global.”

thinkGREEN was born out of Morgan’s long-standing commitment to helping its customers, especially those operating energy-intensive processes, to reduce energy consumption, emissions, and operating costs. However, with thinkGREEN, these objectives are extended to the company’s own environmental impact corporate-wide. Specifically, in defining its Environmental, Social, and Governance (ESG) commitments to Protect the Environment, Morgan established long-term aspirations and 2030 goals to improve the group’s performance.

“Together, the thinkGREEN initiative, modern technologies and tools, and ATS services are helping to make Morgan’s vision a reality.”

— Carrie Lenze

Among the company’s aspirations are to be a CO2 net-zero business by 2050 (in line with the Paris Climate Agreement); using water sustainably across the business; and improving the efficiency of processes at all manufacturing sites to reduce waste. In addition, it aims to move from its 2015 baseline to achieving, by 2030, a 50% reduction in Scope 1 and Scope 2 CO2 emissions; a 30% reduction in water use in high and extreme stress areas; and a 30% reduction in total water usage.

Morgan is already making quantifiable progress toward these goals far beyond its work at the St. Marys plant. For example, Morgan’s absolute greenhouse gas (GHG) emissions (~Scopes 1 and 2) are down by 22% compared to 2018 levels and 15% compared to 2019 levels.

Morgan’s broad-based improvement program covers energy procurement, process improvements, and behavioral changes in its plants. Additionally, the company is focused on the circular economy to enable a healthier balance between the environment, economy, and society. This includes initiatives that increase resource efficiency, prolong the useful life of materials, design out waste, and minimize the consumption of finite resources.

It also recognizes an opportunity to move into the hydrogen economy, such as transitioning from using natural gas to clean, hydrogen-fueled sources to heat some of Morgan’s baking and sintering operations, which will reduce the carbon elements of burning natural gas. Phasing out fossil fuels and replacing them with hydrogen sources will also help mitigate climate change because the combustion of hydrogen releases water vapor, not carbon, into the atmosphere. In the first half of 2021, the company transitioned to carbon-neutral energy in a number of its sites.

Reaping the Returns on Sustainability Investments

“thinkGREEN’s 2030 goals are a journey of environmental improvement projects across the enterprise, much like those completed and continually being improved at St. Marys,” says Lenze. Morgan has committed to investing about $12.5 million annually, globally, toward the improvement innovations and is now tracking and quantifying projects, developing new projects, and freely sharing best practices at a corporate level.

Morgan is already seeing returns on this corporate-wide investment with significant reductions in energy costs along with reducing the company’s carbon footprint. In 2011, Morgan had $27.1 million in sales and $1.27 million in utility costs, which was 4.68% of sales. In 2019, the company had $26.9 million in sales and $831,000 in utility costs, or just 3.10% of sales. Had the utility costs continued to be 4.68% of sales from 2011 to 2019, the total costs would have been $1.6 million higher than the actual totals over the eight-year time span.

“Morgan is already seeing returns on its corporate-wide investment with significant reductions in energy costs along with reducing the company’s carbon footprint.”

Despite the pandemic and ensuing economic changes, Morgan controlled its utility costs. Though sales declined from $27.1 million in 2019 to just over $21 million in 2020, a 20% loss, its utility costs stayed down at about $720,000. Moreover, its energy intensity actually dropped on the electrical side during this period, down from just over 1,000 kW per $1,000 of sales to about 936 kW per $1,000 of sales.

Additionally, the company has more than offset price inflation, including some very significant increases in its water rates, by reducing resource consumption and by the purchasing team’s ability to keep the electricity and natural gas rates fairly steady.

“The significant successes at St. Marys in areas such as conserving energy and natural resources, reducing pollution and hazardous waste, reclaiming materials, and establishing an environmentally safe workplace and community, provide insights into future potential corporate achievements,” says Lenze. “Already, the initiative is accelerating environmental improvements across the enterprise, driving significant cost savings, and increasing Morgan’s profitability and competitiveness, while also advancing its stature as a good corporate citizen.” M

Company Fact File

Name: Morgan Advanced Materials

Sector: Chemicals & Related Products

HQ location: Windsor, U.K.

Revenues: $1.1 billion (2021)

Employees: 7,800 Employees

Web url: www.morganadvancedmaterials.com

About the author:

Sue Pelletier, a contributing editor with the Manufacturing Leadership Journal, is a seasoned writer/editor with experience in online, social media, e-newsletter, tablet app, book and e-book, and print publications.

Creating a Listening Culture

Manufacturing Leadership Journal content and MLC resources are exclusively available to MLC members. Please sign up for an account or log in to view this content.

Manufacturing in 2030 Megatrend: Ride the Power Curve

Get the Latest News

Get involved

Digital manufacturing is built on just five “cornerstones”—and the work done in those areas in the next decade and beyond will largely determine the success or failure of key aspects of manufacturing’s technological future, according to the Manufacturing Leadership Council, the NAM’s digital transformation arm.

The MLC says that developments in electronics, computer systems, communications technologies, software and cyber infrastructure will have a direct impact on advancements made in human-machine interaction, automation and robotics, and autonomous operation. We break these down below:

Electronics: Intel predicts that by 2030 it will be able to incorporate 1 trillion transistors on a single semiconductor chip.

- Manufacturers will need that kind of power to enable computer systems and software to process much larger data volumes as they connect more plant equipment and people within their business ecosystems.

Computer systems: Manufacturers should expect a changing computer landscape as biological, physical and digital systems converge to offer more options.

- Quantum computing and nanocomputing offer potentially greater computational ability, which will allow manufacturers to process more data faster.

- Meanwhile, traditional computers will become lighter, thinner and more flexible. Different user interfaces, such as voice recognition, will progress.

Communications technologies: The years ahead will see manufacturers adopt 5G-based networks, which offer higher bandwidth and lower latency than prior technology.

- Communications technology suppliers are already working on 6G networks, expected to become commercially available in 2030.

Software: Next-generation software applications, in addition to web and mobile capabilities, will support voice, wearables, touch and AR/VR to a greater extent than ever before.

- These applications will be driven increasingly by artificial intelligence.

Cyber infrastructure: The cyber infrastructure that has been in development for the past two decades has allowed for separation between data and physical computing sources (i.e., cloud computing.)

- Looking ahead, an infrastructure that brings together data from all sources with business and technology tools will facilitate innovation, R&D, operating models and business growth.

Manufacturing in 2030 Project: Ride the Power Curve is just one of the megatrends identified by the Manufacturing in 2030 Project, a future-focused initiative of the MLC. For details on more megatrends, industry trends and key themes for Manufacturing in 2030, download the MLC’s new white paper “The Next Phase of Digital Evolution.”

How Digital and Sustainability Alignment Can Drive Value

Transformational journeys can go hand in hand to improve competitiveness and performance.

Nearly a quarter of U.S. greenhouse gas emissions come from industrial sources. Under mounting pressure to respond to investors, consumers, regulators, and employees alike, manufacturers have elevated sustainability to a board/C-suite level issue. In the January 2022 Climate Action 100+ report, 87% of companies reported having board-level oversight of climate change. While nearly 4,000 companies are acting on climate change, only one-third of them have set a net-zero emissions commitment, a near even split between enterprise (800 out of Global 2000) and mid-market (700 out of millions of SMEs).

A significant majority (87%) of respondents in the 2021 MLC M4.0 Sustainability and Net Zero survey said they believe the industry has a special responsibility to society to become more sustainable. Above all else, it’s the right thing to do — but it’s also a matter of business viability. Various studies, such as that by the IBM Institute for Business Value, find that consumers increasingly make buying decisions based on sustainability and are willing to pay more for products branded as sustainable or socially responsible, particularly Generation-Z and high-income shoppers.

Manufacturers are answering the call. In last year’s MLC sustainability survey, about a third of respondents said they already have publicly shared net-zero targets. Additionally, management’s focus on sustainability and net zero strategies increased at a third of companies. We are interested to see how that metric moves in this year’s survey, given recent economic developments.

Above all else, sustainability is the right thing to do — but it’s also a matter of business viability.

Anecdotally, we’ve heard from several manufacturing clients that sustainability initiatives and investments will have to take a back seat as their organizations prepare for the prospect of a recession or slowdown. Given sustainability’s overall impact on future business competitiveness, that’s a concern.

Maintain Momentum, Despite Uncertainty

The factors that initially made sustainability a top-tier priority are not going away. Driving toward net zero will be a long journey, likely over many decades with peaks and troughs in the business and economy over time. Focusing on sustainability can be beneficial for navigating rough economic periods — for example, reducing waste can also improve the cost of goods sold. And when the economy does turn positive, companies that can demonstrate progress will only have strengthened their competitive position.

Manufacturers already are seeing the value of becoming digital, because digital businesses perform better. We believe that aligning the digital journey with the sustainability journey can advance both goals and drive greater overall return on investments.

Focus Beyond the Four Walls of Manufacturing

Moving toward net zero certainly starts inside the factory walls. This is where being digital comes in. In the 2021 MLC sustainability survey, 52% of respondents said they believe M4.0 technologies will be significant to reaching sustainability targets.

Approaching digital manufacturing with a sustainability lens can help reduce waste, emissions, and costs. Industrial IoT sensors can be used to gather data that enables insight into optimizing energy usage. This allows companies to reduce energy costs and the associated emissions.

Similarly, AI-powered process controls can reduce defect rates, which in turn reduces waste. For example, Schneider Electric’s smart factory in Lexington, Kentucky, leveraged Industry 4.0 technologies to capture greater energy consumption granularity and leveraged IoT connectivity with power meters and predictive analytics to optimize energy cost. The result? Reduced energy consumption by 26%, net CO2 by 30%, and water use by 20 percent.

There are also significant opportunities to add to the impact outside of the factory and across the value chain:

Supply chain: Stakeholders hold manufacturers responsible not just for their own environmental footprint but also for their suppliers’. Establishing a strategy for sourcing sustainable products is key to reducing Scope 3 emissions. For example, Flex set sustainability goals in 2021 that included the commitment that a portion of customers and suppliers share responsibility for reducing Scope 3 emissions. The company invited preferred suppliers to disclose emission data through a questionnaire and then used that insight to provide appropriate education and resources to its suppliers. In the first year alone, 29% of preferred suppliers established their own emissions reduction targets.

Aligning the digital journey with the sustainability journey can advance both goals and drive greater overall return on investments.

Green IT: Enterprise technology accounts for 1% of global greenhouse emissions. This is driven primarily by the production of end-user devices such as laptops, printers, and smartphones. It’s important to work with vendors to reduce these emissions by employing green initiatives such as optimizing device use to extend the life cycle, consolidating the applications footprint, and moving to cloud providers that power data centers through renewable energy.

Circular economy: A growing number of manufacturers are committing to a circular economy. Dow recently announced its accelerated commitment to deliver 3 million metric tons per year of circular and renewable solutions by 2030. The running shoe company On offers a subscription-based model through which customers wear the shoes for a certain period of time and then return them. Used shoes are disassembled, recycled, and used as raw materials for new shoes.

Smart products: Smart products are not just digitally connected. They employ data and analytics to improve the performance of a physical product over time. For example, a smart thermostat in a facility has connected motion sensors that record activity levels. Analytical tools then use that data to learn patterns and optimize settings, helping reduce the facility’s electricity consumption. Philips is using digital technology to capture product life cycle information to reduce waste and extend the life of its products such as X-ray machines. According to the IDC, by 2024, 80% of global manufacturers will incorporate environmental sustainability into their product life cycle management process and ecosystem, improving sales by 3%.

Large manufacturing enterprises are making advancements in most of these areas. While the mid-market may not have the resources that larger companies do, some companies — such as the Cooley Group — are setting the pace for peers.

Getting on the Track to Net Zero

We see opportunities to advance both digital and sustainability goals by focusing on four key areas:

Strategy: The journey begins here. In the 2021 MLC survey, half of the respondents said their company has a formal corporate sustainability strategy in place, up from 39% in 2019.

We believe a sustainability strategy should include:

- A moonshot vision (here’s a great example from Patagonia: “Build the best product, cause no unnecessary harm, use business to inspire and implement solutions to the environmental crisis”)

- Ambitious goals such as net zero ahead of competition, zero waste

- A data-driven estimate of emissions footprint around Scope 1, 2, and 3

- Inventory of current and future sources of emissions

- Climate mitigation initiatives

- Roadmap and an execution plan to meet your objectives

These goals and the roadmap should be communicated through sustainability reports and become part of standard operating procedures.

Sustainability metrics require many pieces of data from many sources, and that data often resides in many formats.

With our clients, particularly manufacturing companies, most are early in the adoption curve where they are formulating their sustainability strategy and finding ways to embed it in their organization.

Data: To manage change and demonstrate progress, you must be able to measure the impact of your efforts. This remains a barrier for many organizations. Sustainability metrics require many pieces of data from many sources, and that data often resides in many formats. This is a significant effort that requires a high degree of manual activity for most.

Manufacturers need to accelerate their ability to use data for the good of the business, not just sustainability. A good starting point is an assessment that identifies the data required to measure total emissions, determines where that data comes from, and documents how you access and gather it today. You can then look for opportunities to automate data collection.

For example, if you need utility information for many locations, create an app that pulls in the necessary information rather than having someone collect it via email. Such improvements are simple solutions that don’t require a substantial amount of time or new investment.

Data governance is also critical, and often overlooked. It’s focused on managing data assets and is critical around sustainability-related data sets such as energy or supplier data to enable data-driven decision-making. This is particularly important because you can’t improve what you can’t measure.

We believe a common set of governance principles such as the Data Management Association (DAMA) framework help organize the function and enables it to understand sustainability goals, identify data sources, and build the right framework for automation.

Begin looking at how to use analytics to increase impact and progress toward goals as data capabilities mature. Keep it simple, but know that the potential is vast. For example, Vestas Wind Systems, a Danish wind turbine manufacturer, used data and analytics and modeling grids with weather data to pinpoint the optimal placement of each turbine. The analysis not only helped reduce the time required for site development, it also reduced energy costs for utilities and consumers.

Begin looking at how to use analytics to increase impact and progress toward goals as data capabilities mature. Keep it simple, but know that the potential is vast.

More mature data capabilities will also enable you to reap sustainability benefits from smart products. For example, John Deere is connecting their farm equipment, such as tractors and combines, to help farmers make the right choices on fertilizer and pesticide usage and conserve water during irrigation.

People and leadership: Being digital is not just about technology. It is equal parts people and processes. In the 2021 MLC Sustainability survey, more than 60% of organizations said they have a dedicated sustainability team, up from 51% in 2019.

Elevated leadership, with a senior executive designated to oversee reporting and progress — if not specific initiatives — is also critical. Many large organizations have an established senior leader, such as a chief sustainability officer, but it’s still common to see responsibility for action embedded in different functions such as IT or procurement. A senior leader must have the influence and authority to generate support from various department heads.

Don’t underestimate the organizational change management required. Employees should understand the “why” associated with changes — for example, how new automation is not only driving efficiency but also reducing waste or emissions. Effective change and communication initiatives can also help engage interested employees in driving awareness and action among colleagues.

Supply chain: Increasing visibility into the supply chain has become a top priority for many organizations in light of recent disruptions. The same steps your organization is taking to engage suppliers in a digital supply chain can also provide a platform for gathering the data you need to measure overall corporate environmental impact. While the focus today is on improving capabilities for tracking and reporting supplier data, that will change. We expect that the standard will soon be demonstrating how you’re reducing environmental impact with preferred suppliers with strong sustainability metrics.

If you aren’t doing so today, it is time to begin working with Tier 2 and Tier 3 suppliers to track and report against sustainability targets. Don’t leave it up to them to determine what to report. Set out your requirements, and then provide guidance and support in fulfilling those requirements.

Effective change and communication initiatives can also help engage interested employees in driving awareness and action among colleagues.

Tools such as a portal for entering information can help reduce effort on both sides—without significant investment. As you progress in establishing methods for tracking and reporting, consider incentives, such as preferred status, for good reporting practices and/or metrics. As you enter new supplier relationships, do so with an eye toward building reporting and metrics into new agreements. Procurement should move beyond cost-benefit analysis for sourcing to include sustainability-related metrics such as embedded emissions and year-over-year change — as well as third-party rating/certification on labor use for manufacturing.

Finally, if your organization is a supply partner to larger manufacturers, be open to dialogue and willing to collaborate to meet mutual goals.

Keep Going

While economic pressures on costs are understandable, pausing efforts will impede progress, and demonstrating progress will be even more critical than it is now when the economy returns to a growth mode. Look for opportunities to continue delivering small wins, working in tandem with efforts to become digital across all aspects of the business. If your focus is scattered due to too many priorities or you’re unsure where to begin, find outside expertise to help advance areas that may be holding you back — such as your ability to gather and use data to manage and measure against goals. M

About the authors:

Randal Kenworthy is a Senior Partner, Consumer & Industrial Products, at West Monroe

Durgesh Patel is a Senior Manager, Consumer & Industrial Products, at West Monroe

Dialogue: Intel’s Sustainable Vision

Manufacturers have a huge opportunity to create products that will drive global sustainability and make their businesses stronger, says Intel CSO, Todd Brady.

“I strongly believe that good business and sustainability practices go hand in hand.”

Todd Brady, Chief Sustainability Officer and Vice President, Global Public Affairs, Intel Corporation

Co-founded in 1968 by semiconductor pioneers Gordon Moore and Robert Noyce, and later led by the company’s third original employee, Andy Grove, during the high-growth 1980s and 90s, Intel Corporation is now the world’s largest semiconductor manufacturer with revenues of $79 billion and supported by 121,000 employees around the world.

Intel’s long tradition of focusing on and reporting its own sustainability performance over the last few decades has seen the company consistently ranked as a corporate environmental leader in industrial sustainability by numerous organizations, from Forbes to Dow Jones. In addition to successfully adopting its own internal sustainability programs, Intel has also become a leading initiator in numerous non-competitive coalitions aimed at driving more sustainable practices across broader industrial ecosystems.

In our latest interview with an industry thought-leader, Intel’s Chief Sustainability Officer, Todd Brady, talks to the MLC’s Executive Editor Paul Tate about the company’s own internal progress on environmental targets, the critical importance of harnessing digital technologies and AI in its sustainability efforts, engaging employees, suppliers, and even competitors in the process, and the pivotal role manufacturing can play in developing the products the world needs to meet urgent climate goals and create a more sustainable future.

Q: What excites you most about your role as Chief Sustainability Officer at Intel?

A: I strongly believe that good business and sustainability practices go hand in hand. The most rewarding part of that is making a difference in our day-to-day operations, our impact on the world, and our bottom line and the viability of the business. I truly believe that by making our operations more sustainable, we are making our business stronger. That’s something that really incentivizes me and gets me moving forward.

Q: What’s driving Intel’s sustainability initiatives?

A: Intel has been setting sustainability goals for several decades now, since around 1994. We set our latest round of goals and initiatives in 2020 with a 10-year vision of where we want to be by 2030. These cover key themes such as net zero greenhouse gas emissions, which we aim to achieve by 2040, net positive water, and zero waste to landfill. So, as we manufacture and make our products, how can we have a net zero or even net positive impact on the environment and the communities in which we operate? That’s the overall vision that we’re trying to achieve with these goals.

Q: What progress have you made so far?

A: We want to achieve net zero greenhouse gases by 2040 in our Scope 1 and 2 emissions. To do that, we’ve set a number of milestones. The first is to use 100% renewable energy globally by 2030. We’re a little over 80% today and we anticipate we’ll be about 90% by the end of this year. We’re already 100% renewable in the US, Europe, Israel, and Malaysia.

“We’ve set a number of milestones. The first is to use 100% renewable energy globally by 2030. We’re a little over 80% today and we anticipate we’ll be about 90% by the end of this year.”

We also have a goal for Scope 3 greenhouse gas emissions for our supply chain that is a 30% reduction. We’ve taken a number of steps with our suppliers to engage and collectively work towards that goal. We see these sustainability issues as non-competitive and that we all need to work on collectively, both with our supply chain and with our competitors, at times.

Another goal is around water and our water use. Our goal is to be net positive water, so for every gallon of water we bring in and use in our manufacturing process, we’re returning a gallon or more water back to the community. We do that in two ways. One is by recycling, reclaiming, and reusing our water internally, and we’ve invested upwards of a billion dollars in that over the past decade. The second is by doing projects outside of Intel in the community, with NGOs, with government agencies, with farmers, and others, to support water conservation measures that put more water back into local streams and aquifers where we operate. This year we have just achieved net positive water in three locations where we operate – the US, India and Costa Rica.

Q: Does meeting some of these targets also involve adopting new circular economy approaches?

A: Yes. The circular economy is a big focus for us. We have goals as part of our 2030 framework, for example, to be zero waste to landfill and to upcycle over 60% of our manufacturing waste. The reason for that, again, goes back to the concept of tying together sustainability and the business. We need to look at our waste streams not as waste, but as something of value and not to look at them as something that we need to discard or get rid of. So, we’ve created a number of circular economy type solutions for a variety of different waste streams. Some of our fluoride waste streams are repurposed into cement. Some of our phosphorous waste streams are repurposed into fertilizer. Some of our solvents are recovered and either reused or resold as high value materials. Copper is another example. We use a lot of copper in semiconductors, so we have an extensive copper reclamation process and then we sell that for a profit into the reclaim market to be reused.

I think it’s about a change of mindset – not looking at waste as something that’s discarded, but instead looking at what value we can we get from it. That reduces our costs, and in some cases, generates a new revenue stream. And the more we look at it, the more we find new opportunities to create those circular loops.

Q: You mentioned that working closely with partners and competitors in broader, industry-wide ecosystems is important to making change happen. What role has Intel played in instigating these initiatives?

A: We’ve initiated a number of different coalitions over the years. Again, we have a history of doing this because we see these sustainability topics as non-competitive where collectively we need to work as an industry to solve some of the biggest challenges we face.

A couple of examples. Way back in 1998, we pulled the industry together to start working on reducing chemicals called perfluorocarbons, one of the greenhouse gases. As an industry, we committed voluntarily to reduce the overall emissions of those gases over time. For one company alone, it’s impossible to do. But working together, we have made significant reductions and even exceeded the goals we all set.

“It really is endless when you start thinking about all the different ways companies can use digital technologies to monitor, control, and then optimize their equipment, their operations, and how they are doing business.”

Another example is removing the lead from our products. When the European Union established the RoHS directive restricting hazardous substances, like lead, cadmium, chromium, and other heavy metals, again, that required us to come together as an industry and we helped form various coalitions looking to develop alternative solders to the traditional tin lead solder that was used in electronic products.

And last month, we launched the Semiconductor Climate Consortium across the industry, a new carbon initiative with 60 other companies where we’re working with all of our supply chain to tackle the remaining carbon emissions that we have as an industry and how we can go about doing that. So again, collectively we can accomplish much, much more by working together as an industry than we can independently.

Q: Do these groups deliver practical outcomes for their members, like new sustainability methodologies or tools?

A: Yes. For example, another industry group we’re involved in with MIT and many other IT companies, big OEMs, is called PAIA – Product Attribute to Impact Algorithm. It’s a carbon footprint methodology for calculating the lifecycle carbon footprint of electronic products. From there, companies can then figure out how to reduce that carbon footprint further. We’re strong believers in having that kind of open architecture so that we can all use the same standards and methodologies as we go forward.

Q: How important are digital technologies to driving the future of sustainability, both for companies and globally?

A: I believe digital technologies are a critical tool to help make the industry, and the world, more efficient and reduce its carbon emissions. While we’ve focused a lot on the carbon footprint of the company and the broader semiconductor industry, at the same time, we need to look at what we call the handprint, which is what we can actually do with our products to make the world more sustainable. I think that’s where IT industry is in a very unique situation because digital products can, and will, help make the world much more energy efficient and reduce carbon emissions.

A report out of Europe by GeSI a few years ago called SMARTer2030 estimated that for every ton of carbon emissions produced by the IT industry, there was the opportunity to reduce the world’s emissions by 10 tons, almost a 10 to one return, by enabling smarter manufacturing, smarter buildings, smarter infrastructure, smarter transportation, smarter agriculture, you name it. All of those are enormous opportunities. We can already see it happening by applying digital technologies in both our own operations and in many of our customers.

Q: Which digital technologies are making the most sustainable impact at Intel?

A: There are many, many different examples. Take some of the new office buildings that we’ve built. These have been designed from the ground up to be smart buildings, integrating sensors throughout to monitor and control everything from lighting to HVAC and all the facility systems. Many of these are now LEED Platinum certified buildings, achieving anywhere from 30 to 50% reductions in the amount of energy being used, as well as reductions in water consumption. By monitoring the building in real time and understanding where the people are, where you need lighting, where you need cooling, heating, etc., you can make significant savings.

“Tapping into our people and their innovation is critical, because the engineers and technicians on the ground are the ones that know what’s going on within the business, within our operations.”

Another example would be in our manufacturing process. We have some big industrial equipment in use, and again, we’ve added additional sensors and monitoring and networking to optimize the performance. In our manufacturing and fabrication facilities we have a number of large industrial chillers which provide essential cooling, with maybe 20 or 30 chillers in a particular location. They are most efficient when they’re running near capacity, as opposed to very low load, and traditionally each of those chillers operated independently. Now we can link them all together and make them virtual, and by using AI and algorithms, we can optimize those chillers by changing the load depending on demand and monitor that in real time. Again, we’re seeing 20 to 30% less energy usage by integrating digital technology.

And as we dig into more and more sustainability opportunities using smart technologies including AI, we have been able to achieve very fast returns on investment of five years or less, often three years or less, and sometimes within a year. It really is endless when you start thinking about all the different ways companies can use digital technologies to monitor, control, and then optimize their equipment, their operations, and how they are doing business. Again, it’s that link between sustainability and good business.

Q: How are you engaging Intel’s workforce in this smart sustainability strategy?

A: Let me give you one example. When we started our energy efficiency program over a decade ago now, we did a call out to all our engineers around the world and said, “If you have an idea about how to make us more efficient, save money, and reduce our environmental impact, send it to us. We’ll fund it and take it from there. But it’s got to have a positive ROI and it’s got to have a positive environmental impact.”

I was blown away by how many ideas came forward. I think in the first year our budget was a million dollars – and we used it all up, just like that! Fast forward to today, and we’re now investing $30 million dollars a year on various energy efficiency projects, which are driven by our people, and by the engineers and the technicians who bring forward those ideas. Tapping into our people and their innovation is critical, because the engineers and technicians on the ground are the ones that know what’s going on within the business, within your operations.

The second example is that we’ve tied our employees’ bonuses to sustainability for over a decade. Everyone in the company is directly linked to our sustainability performance as a company. No matter what their role, whether it’s an attorney, a technician, a marketing person, whatever, there’s an incentive to think, “How can I help drive forward Intel’s sustainability agenda?” At the end of the day, everyone’s bonus is tied to how we do it and what we achieve. That’s another way we’ve been able to engage our people across the company.

Q: So, what level of priority do you think other manufacturing leadership teams should now be putting on sustainability for the years ahead?

A: There are many things driving the business case for sustainability today. One is simply driving efficiency in your own operations. They have a direct RoI and deliver cost savings and performance improvements in many areas.

But broadening the lens, our customers today absolutely expect us to be working on sustainability. And we also expect our own suppliers to be focused on sustainability too. It’s part of our supplier report card. When we judge our suppliers on how they’re doing, we look at their cost, we look at quality, we look at schedules, and whether they are meeting all of those core business aspects. But we also rate them and judge them on their sustainability performance. And we see the same from our own customers as well. So, for most manufacturers now, whatever product you’re producing, your customer wants a sustainable product to sell to their end customer, the consumer of that product. That’s becoming increasingly more evident as we talk on a regular basis with all our customers.

“I think the biggest challenge for the future is how do we continue to grow, both as Intel and as an industry, but continue to be more sustainable?”

The third area is with investors. I’ve been meeting with socially responsible investors, ESG investors, for almost 20 years now and I’ve seen a definite shift from a couple of decades ago. Back then there were only a handful of companies focused on socially responsible investing. Today it’s a who’s who of the investment community. You can’t find a big investment company that does not have an ESG research team. Increasingly, investors want to know that they are investing money in a company that is sustainable, is improving, and is thinking about how they can take actions to do so.

Lastly, governments. Sustainability regulations are increasing all around the world. We have many different proposals both in the US and the EU around climate reporting, CSR reporting, and so on. These are all raising the expectation that we are transparent as companies in terms of what our climate impact is, and what we’re doing to reduce that impact over time.

So, with all of those drivers, it is very clear that sustainability is not simply the issue of the day, but it’s becoming the norm and an expectation for all companies on how they will operate in the future.

Q: You mentioned scoring your suppliers on sustainability, increasingly important for Scope 3 reporting in the future. Does Intel actively help supplier companies, especially the smaller and medium sized suppliers who may not have the budgets or skills, to improve their own sustainability footprints?

A: It’s a great point because it’s easy to look to Intel or other multi-billion-dollar companies and say, ‘Well, you can induce sustainability because you have the resources.’ So, one of the things that we’ve done is to create supply chain summits and sustainability summits. We’ve held those for several years in Asia where we have a lot of our supply chain and a number of smaller companies and development companies who have asked for our help. At these summits we sit down and talk through what our expectations are, and what the various challenges are. It’s also a great opportunity for our suppliers to network together and learn what each other is doing. We’ve also held seminars and webinars on a variety of different topics to help our supply chain, and we’ve formed coalitions around supply chain improvements too.

“As we look forward to 2030, 2040, 2050, we as manufacturers now need to be looking ahead at where the world is going and produce the products that the world needs to address the planet’s sustainability challenges for the future.”

As we look at our own supply chain, renewable energy is a big opportunity. As a company, over half of our supply chain emissions are associated with energy use. So, I think driving more renewable energy sources and making those more readily available, are a significant opportunity and one that we, as manufacturers, should take advantage of.

Q: Looking ahead, what would you highlight as the greatest business challenges and opportunities for the manufacturing industry over the next five years?

A: I think the biggest challenge for the future is how do we continue to grow, both as Intel and as an industry, but continue to be more sustainable? We need manufacturing. Manufacturing is critical for the world and for global economic development. But how do we decouple that growth from increased resource usage? The expectation is certainly that we need to do that. We’ve got to all collectively get our greenhouse gas emissions down to zero. The issue is, how do we not grow our footprint as rapidly as we grow our businesses, and then continue to drive that at speed?

On the flip side, I think the big opportunity for the IT sector, and other manufacturing sectors as well, is that our innovation and products can be used to help make the world more sustainable. Look at renewable energy: we need renewable energy to achieve climate goals. But that renewable energy needs to be run on a smart grid because renewables are produced intermittently. You can’t have the same grid and controls that you have for a traditional coal fire power plant or natural gas plant that’s running 24/7. You need smarter technology to be able to route that green energy where it’s needed, and how it’s needed. So, there’s a big opportunity for new products and new services to get us there.

As we look forward to 2030, 2040, 2050, we as manufacturers now need to be looking ahead at where the world is going and produce the products that the world needs to address the planet’s sustainability challenges for the future.

Q: Finally, if you had to focus on one thing as a watchword or catchphrase for the future of manufacturing, what would that be?

A: For me, there are two things: sustainable manufacturing to make the business stronger and decoupling growth from an organization’s environmental footprint.

As an industry, we need to grow our businesses, and grow economically, but we need to decouple the environmental impact of economic growth. To do that, leaders have got to think out of the box. They have to think differently. By spending a little bit of money outside the company and partnering with key organizations or companies to create more sustainable approaches, organizations can achieve far more than they ever could by themselves in their own operations.

That out of the box thinking is really what’s needed as we go forward into the future. M

FACT FILE: Intel Corporation

HQ: Santa Clara, CA

Industry Sector: Semiconductors, computing, automation, AI

Sales: $79.02 Billion (2021)

Net Income: $19.87 Billion (2021)

Employees: 121,000 Employees

Presence: Global

Production Sites: 10 Primary Manufacturing Sites

Website: www.intel.com

EXECUTIVE PROFILE: Todd Brady

Title: Chief Sustainability Officer and Vice President, Global Public Affairs, Intel Corporation

Nationality: American

Education: BSc degree in chemical engineering, Brigham Young University; Masters’ degree in environmental engineering, University of Illinois, Urbana-Champaign.

Languages: English, Italian

Previous Roles Include:

– Global Public Affairs Director, Intel Corporation

– Corporate Sustainability Director, Intel Corporation

– Global Environmental, Health and Safety Director, Intel Corporation

– Corporate Environmental Director, Intel Corporation

– Product Ecology Manager, Intel Corporation

– Environmental Engineer and Manager, Intel Corporation

Other Industry Roles/Awards/Board Memberships

– Top 20 Sustainability Leaders, Sustainability Magazine

– Top 10 Outstanding Leaders, Advancing Science and Technology in Research/Business/Policy Pursuits, –

Scientific American

– #1 Most Sustainable Company, Barrons

– America’s Most Responsible Companies, Newsweek

– CDP “A” Ranking for Climate and Water

– Corporate Knights, Global 100 Most Sustainable Corporate Citizens

– Dow Jones Sustainability Index, North America Index

– Just Capital, Just 100

About the author:

Paul Tate is Co-founding Executive Editor and Senior Content Director of the NAM’s Manufacturing Leadership Council.

Technology Is at Center of ESG Efforts

Manufacturing Leadership Journal content and MLC resources are exclusively available to MLC members. Please sign up for an account or log in to view this content.