Sessions marked with an asterisk (*) are available through the virtual event.

Monday, June 27, 2022

8:30 a.m. – 4:45 p.m. Annual MLC Meeting/Council Day

5:00 p.m. – 6:15 p.m. VIP Exhibit Hall Tour

6:30 p.m. – 8:00 p.m. Welcome Networking Reception

Tuesday, June 28, 2022

7:15 a.m. Registration, Continental Breakfast and Exhibition

8:00 a.m. Welcome and Introductions

8:10 a.m. Opening Address: The Race for Digital Advantage *

- David R. Brousell, Co-Founder, Manufacturing Leadership Council

8:30 a.m. Keynote: How Corteva is Using Data to Feed the World *

- Balaji Venkataraman, Vice President, Manufacturing and Technology, Corteva

Agriculture is nearly as old as humankind itself but keeping up with today’s global food demand requires modern innovations. Corteva Agriscience, the winner of the 2020 Manufacturing Leadership Awards Large Enterprise Manufacturer of the Year, is utilizing machine learning data science techniques and advanced analytics to create more sustainable and efficient means of farming and food production. By developing capabilities in agile team management, data engineering, and AI implementation, Corteva is moving forward in its digital journey and improving its ability to pivot along with continuously changing business needs. This transformation is also helping Corteva reduce emissions, increase use of sustainable packaging, reduce waste, and other sustainability advances.

9:00 a.m. Fireside Chat: Looking at Supply Chain Strategy Through a New Lens*

- Cynthia D. Farrer, Senior Vice President of Global Operations and Integrated Supply Chain, Allegion

- Ken Engel, Senior Vice President, Global Supply Chain North America, Schneider Electric, USA

In conversation with: Paul Tate, Co-Founding Executive Editor and Senior Content Director, Manufacturing Leadership Council

As a result of the pandemic, many manufacturing companies are rethinking their supply chain strategies, shifting to a much greater emphasis on supplier risk management and supply chain resiliency. The goal: enabling greater supply chain continuity. Learn how Allegion and Schneider Electric are developing their new strategies in a time of protracted disruption.

9:30 a.m. Networking and Refreshment Break

10:00 a.m. Reality Check: How to Avoid Pitfalls and Drive True Business Value with M4.0 *

- Jai Sundararaman, Vice President of Business Transformation, Intertape Polymer Group, and Member, MLC Board of Governors

As manufacturers proceed with their M4.0 journeys, clearly understanding the challenges with identifying and measuring business value, partnering with vendors, extracting insights from data, and having the right talent are key factors for success. This session will reveal the 10 most important lessons for a successful M4.0 journey.

10:30 a.m. Executive Interview: Thoughtful Data Contextualization for Manufacturing 4.0 Success *

In the era of Manufacturing 4.0, many companies have taken on a data modernization (and data monetization) exercise to reach the next level of business and process efficiencies.

But it is not easy to achieve those end goals without having a deep and contextualized look at what the data is telling you. Data is most powerful when viewed through the right lens – i.e., when analyzed and filtered for a company’s unique business needs, then advanced toward actionable insights. This discussion will examine recent findings, best practices, and real-world success stories for data contextualization, including practical and relevant IT+OT data integration along with the what, why, and how for creating the right M4.0 data strategy.

- Rajesh Devnani, Vice President, Industrials, Metals and Transportation, Hitachi Vantara

- Fabio Luiz, Vice President and General Manager, High Voltage Services, North America, Hitachi Energy

In conversation with: Penelope Brown, Senior Content Director, Manufacturing Leadership Council

11:00 a.m. Meet the Innovators: 1:1 Briefing Sessions, Networking Break

12:25 p.m. Networking Lunch featuring Topic Tables

1:35 p.m. Concurrent Interactive Think Tanks

Best Practices Forum: Building More Resilient Supply Chains

The pandemic has up-ended supply chains around the world, forcing manufacturers to rethink their strategies to ensure greater resilience. This session will explore best practices on the deployment of digital tools and ecosystems to help empower companies to create more agile and resilient supply chains that provide the end-to-end visibility and flexibility needed by all supply network partners.

Co-Facilitators:

- Lonnie Miller, Senior Manager, Industry Consulting, Manufacturing, SAS Institute Inc.

- Scott Pete, Lead, Discrete and Process Industry Solutions, SAS Institute Inc.

MLC Moderator:

- Penelope Brown, Senior Content Director, Manufacturing Leadership Council

Case Study: Extracting Insights from Plant Floor Data

As IT and OT technologies converge at the hands of operators and management responsible for progress on the front line of operations, new digitally connected processes have emerged with powerful insights that can not only enrich equipment performance monitoring but also unlock breakthrough improvements in overall factory efficiency and quality. This case study will look at how leveraging plant floor IT and OT data can be mastered to achieve breakthroughs in bottom-line performance, with speed and at scale.

Facilitator:

- Todd Earls, Vice President, Information Technology, Eaton Corp.

- Howard Heppelmann, Divisional Vice President and General Manager, ThingWorx IoT Solutions, PTC

- Craig Sutton, Vice President, Industry 4.0, Eaton Corp.

MLC Moderator:

- Sue Pelletier, Contributing Editor, Manufacturing Leadership Council

Expert Panel: Culture as a Key Success Factor in Digital Transformation

Digital transformation demands a responsive and data-empowered business culture. Traditional hierarchical management and siloed teams are less attractive to a younger, more digitally savvy workforce and struggle with the agility required to respond quickly, missing out on opportunities for collaboration, better performance, and improved competitiveness. This expert panel will examine how to create business cultural transformation and the benefits of undertaking this necessary change.

Panelists:

- John Brinegar, Director, IOT Solution Development, Hitachi Vantara

- Steve Fuller, Partner, People Advisory Services, EY

MLC Moderator:

- David R. Brousell, Co-Founder, Manufacturing Leadership Council

Case Study: Logistics Optimization with Quantum Computers

Complex optimization problems make up a large part of the manufacturing problem space across every part of the value chain, such as materials procurement, robotics, plant maintenance, route optimization, pricing, staffing, scheduling, and more. In a recent research study, over half of the manufacturers surveyed already had a program to explore how quantum systems could be applied to their business problems. This session will provide an overview of some of the most promising quantum use cases in logistics, introduce the concept of classical-quantum hybrid computing and provide guidance on assessing the suitability of quantum for different types of applications.

Facilitator:

- Alexander Condello, Director of Algorithms, Performance and Tools, D-Wave

MLC Moderator:

- David Van Engel, Senior Director, Council Development, Manufacturing Leadership Council

Best Practices Forum: How to Reduce Cyber Threats

As the Colonial Pipeline case in 2021 clearly demonstrated, cyber-attacks have serious consequences not only to the companies targeted but for society at large. This Think Tank will look at best practices companies can adopt to reduce their vulnerability, manage cyber risks effectively, secure their data assets, and better protect their IP.

Facilitator:

- Dharminder Debisarun, Worldwide Industry Security Architect for Manufacturing, Internet of Things and Transport, Palo Alto Networks

MLC Moderator:

- Jeff Puma, Content Director, Manufacturing Leadership Council

Expert Panel: Forging IoT Ecosystems

MLC research indicates that 80% of manufacturers have already invested in IIoT or will do so in the immediate future. How can they get the most from those networks? The right ecosystem is essential to collecting the right data and leveraging streaming analytics that can have the most business impact. This expert panel will examine considerations for building a robust network that can deliver effective results.

Panelists:

- Jeremy Gibbs, Chief Revenue Officer, FORCAM

- David McGraw, Senior Manager, Consumer and Industrial Products, West Monroe

- Andrew Scheuermann, Chief Executive Officer, Arch Systems

MLC Moderator:

- Paul Tate, Co-Founding Executive Editor and Senior Content Director, Manufacturing Leadership Council

2:40 p.m. Networking and Refreshment Break

3:10 p.m. Executive Interview: AI and Enterprise Applications *

What role will artificial intelligence play in the many enterprise applications – ERP, PLM, SCM, Quality, MRO –that run today’s factories and plants? Will AI help manufacturers using these applications make better decisions faster? Will AI automate basic routines, freeing up users to engage in higher level analytics? This session will focus on the benefits and challenges of AI-powered enterprise applications and what their use in manufacturing might mean in the years ahead.

- Paul Dunn, Vice President, Applied Innovation, Infor

In conversation with: Paul Tate, Co-Founding Executive Editor and Senior Content Director, Manufacturing Leadership Council

3:40 p.m. Case Study: Fostering Data Literacy: The What, Why and How *

- Dr. Steven Moskowitz, Director, Digital Transformation, Entegris, and Former Chairman, Innovation Research Interchange (IRI)

- Valerie Logan, CEO and Founder, The Data Lodge

One of the foundational requirements for successful digital transformation is the ability to manage and analyze data from all aspects of operations and use it effectively to improve decision-making processes. But cultural issues often constrain manufacturing organizations from achieving this goal. Now, the emerging discipline of data literacy offers a way to overcome cultural hurdles.

In this session, we will:

- Demystify the concept of data literacy

- Understand what makes up a data literacy program, and the practical ways to get started

- Hear why Entegris (a manufacturer of advanced materials and process solutions for the semiconductor and other high-tech industries), is embracing data literacy to advance its Manufacturing 4.0 journey

4:10 p.m. Panel Discussion: Avoiding a Digital Divide

Moderator: David R. Brousell, Co-Founder, Manufacturing Leadership Council

Panelists:

- Dr. Irene Petrick, Senior Director, Industrial Innovation, Intel Corporation

- Chuck Wetherington, President, BTE Technologies LLC, and SMM Chair, NAM Board of Directors

- Val Zanchuck, President, Graphicast, and Member, MLC Board of Governors

Digital transformation can mean very different things for manufacturing companies of different sizes. For smaller companies, expertise and resources can be issues. For larger companies, complexity and inertia can be constraints. But for the industry to succeed with M4.0, all companies need to be able to take advantage of the digital opportunity. Representatives from small, mid-size and large manufacturing companies will share their perspectives on how the industry can avoid a digital divide.

5:00 p.m. Rethink Content Day 1 Concludes

5:15 p.m. Cocktail Reception

Wednesday, June 29, 2022

7:15 a.m. Registration, Continental Breakfast and Exhibition

8:00 a.m. Welcome and Introductions

8:10 a.m. Keynote: Using Lean to Prepare for M4.0 *

- Chuck Wetherington, President, BTE Technologies LLC, and SMM Chair, NAM Board of Directors

BTE Technologies, a supplier of physical rehabilitation equipment and services, is undertaking its digital journey using lean disciplines as a foundation. This session will explain BTE’s vision for the future, what it hopes to achieve with M4.0, and the challenges it sees along the way.

8:40 a.m. Case Study: Pfizer’s Digital Transformation Journey – From Theory to Scale *

- Mike Tomasco, Vice President of Digital Manufacturing, Pfizer

Pfizer, the $81 billion pharmaceutical and biotechnology company, will share the journey of Pfizer Global Supply’s transition from a digitally-siloed operation to a world-class, digitally-enabled operation. This journey involved experimentation, failure, a transition to scaled agile ways of working, and, ultimately, the transition from pilot purgatory to large-scale global transformation.

9:10 a.m. Panel Discussion: Next-Generation Manufacturing Leaders Speak Up *

Moderator: Penelope Brown, Senior Content Director, Manufacturing Leadership Council

Panelists:

- Hayley Dwight, Director, Business Architecture and Change Management, Cooley Group

- Katelyn Kelsey, Mobility Technology Engineer, Digital Operations Center, Dow, Inc.

- Daniel Shrives, Research Engineer, Saint-Gobain North America

If the adage holds true – “turbulent times make skilled sailors” – then today’s up-and-coming manufacturing leaders are developing a remarkable skill set. Disruption has become the new expectation and there are no comprehensive training manuals for today’s version of on-the-job learning. In this panel discussion, some of manufacturing’s leaders of tomorrow will share what companies should prioritize now to get in position for a better future, what are the most important leadership skills to have in times of change, and what lessons they’ll bring with them for the rest of their career.

9:50 a.m. Networking and Refreshment Break

10:20 a.m. Case Study: How Corning Crafted ‘A Common Digital Framework’ for M4.0 *

- John McGirr, Senior Vice President of Manufacturing, Corning Incorporated, and Member, NAM Board of Directors

Corning, the $14 billion manufacturer of glass, ceramics, and materials, has undertaken a comprehensive digital transformation strategy. The manufacturing digital strategy includes the company’s new M4.0 Framework, designed to establish a common set of factory digital solutions throughout Corning. The Framework allows Corning to articulate the digital applications, IOT and essential infrastructure capabilities that all plants need to deliver their business strategies. This session will explain how Corning defines the concept of a digital factory, what “good” looks like, and how the strategy provides a playbook for legacy upgrades and greenfield investments.

10:50 a.m. Fireside Chat: A Chief Digital Officer’s Perspective on Smart Manufacturing *

- Bob Border, Chief Digital Officer and Chief Information Officer, Ingredion

- Prasoon Saxena, President, Manufacturing Business Unit, NTT DATA

In conversation with: David R. Brousell, Co-Founder, Manufacturing Leadership Council

A data-driven manufacturer delivers value through seamless integration of reliable digital platforms and services connecting people, processes, and information. This entails increasing visibility of data from the shop floor and leveraging digital capabilities to automate processes, improve operational KPIs, and deliver business results. In this session, learn how Ingredion Incorporated, a $6 billion global manufacturer of ingredients such as sweeteners, starches, and biomaterials, has embraced smart manufacturing and digitization. The company’s Digital Plant initiative has focused on replacing manual or paper-based processes with digital and mobile-enabled solutions as well as decreasing reactive maintenance, unplanned downtime, and planned maintenance costs. The program’s benefits, challenges and future goals will be discussed.

11:20 a.m. Meet the Innovators: 1:1 Briefing Sessions and Award Winner Tables

12:45 p.m. Networking Lunch featuring Topic Tables

1:50 p.m. Concurrent Interactive Think Tanks

Best Practices Forum: Maximizing Returns from 5G Networks

5G networks can enable a high-powered, high-speed manufacturing environment with lower latency and the ability to connect more sensors and equipment than on previous generations of wired and wireless networks. This session will explore current use cases for 5G on the plant floor and considerations for its deployment.

Facilitator:

- Allen Roberts, Manager, 5G, AT&T Business

MLC Moderator:

- Sue Pelletier, Contributing Editor, Manufacturing Leadership Council

Expert Panel: Digitizing the Innovation Process

This session will examine how digital technologies are transforming traditional innovation and ideation processes in manufacturing to help inspire exponential thinking in new product and service design, revolutionize production operations, embrace more sustainable practices, and empower individual employee creativity.

Panelists:

- Elizabeth Baron, Enterprise Solutions Executive, Unity Technologies

- Christopher Lebeau, Global Director of IT, Advanced Technology Services, Inc. (ATS)

- Adrian Wood, DELMIA Strategic Business Development and Marketing Director, Dassault Systèmes

MLC Moderator:

- Penelope Brown, Senior Content Director, Manufacturing Leadership Council

Case Study: The Growing Footprint of Additive Manufacturing

Additive manufacturing has proven to be competitive for low-volume production and mass customization of industrial-grade parts. Manufacturers are using it to develop custom tooling and assembly aids at factories for example. This case study will look at how additive systems are being used to make parts, what advantages have resulted, and what future applications may be in the wings.

Facilitator:

- Jeff Hemenway, Vice President, Business Segments, Stratasys

- Patrick Price, Application Engineer, Stratasys

MLC Moderator:

- David Van Engel, Senior Director, Council Development, Manufacturing Leadership Council

Best Practices Forum: Getting the Most from Machine Learning

Machine learning, a subset of artificial intelligence, enables machines to learn from past data or experiences without being explicitly programmed. The benefits of doing so have become clear to manufacturers: nearly half of respondents to an MLC survey late last year said they have invested in the technology. This session will explore how manufacturers can get the most from the ML systems.

Co-Facilitators:

- Baskar Radhakrishnan, Senior Director of Industry Solutions, Manufacturing, NTT DATA

- Shamlan Siddiqi, Vice President Consulting and Digital Transformation Services, NTT DATA

MLC Moderator:

- Todd Boppell, Chief Operating Officer, National Association of Manufacturers

Best Practices Forum: The Future of Teamwork

To win in manufacturing today you need to design, iterate, and deliver the best products faster than everyone else. And you’ve got to do it with a diverse and distributed workforce, operating in a globally dispersed ecosystem, against a backdrop of generational change and high employee turnover. How effectively your teams, stakeholders, and customers collaborate and interact will define your success – which makes adoption of new communication technologies not just a journey of discovery, but a competitive necessity.

Co-Facilitators:

- Becky Darsch, Chief Revenue Officer, Canvas GFX

- Patricia Hume, Chief Executive Officer, Canvas GFX

MLC Moderator:

- Jeff Puma, Content Director, Manufacturing Leadership Council

Case Study: How AR/VR Can Empower Front-Line Workers

A deep dive look into one company’s advanced deployment of augmented and virtual reality technologies to help transform operational activities and empower front-line workers with access to the data and visual tools they need to continually improve performance and create innovative new insights.

Co-Facilitators:

- Sheila Cullers, Senior Client Partner, Unity Technologies

- Mike Ray, Client Partner, Unity Technologies

MLC Moderator:

- Paul Tate, Co-Founding Executive Editor and Senior Content Director, Manufacturing Leadership Council

2:55 p.m. Networking and Refreshment Break

3:25 p.m. Lightning Rounds: ML Award Winners Present *

Get a deeper look at some of this year’s top projects from the Manufacturing Leadership Awards. Featuring presentations from:

- AB InBev – Structured Analysis of Downtime and Asset Performance Management Tool

- General Motors – Factory ZERO: GM’s Launchpad to an All-Electric Future

- Johnson & Johnson – Advance Case Management Digital Case Coordination

- Protolabs – Protolabs Revamped Digital Thread

4:30 p.m. Content for Rethink 2022 Concludes

Manufacturing Leadership Awards Gala

6:00 p.m. ML Awards Cocktail Reception

7:30 p.m. ML Awards Gala and Dinner

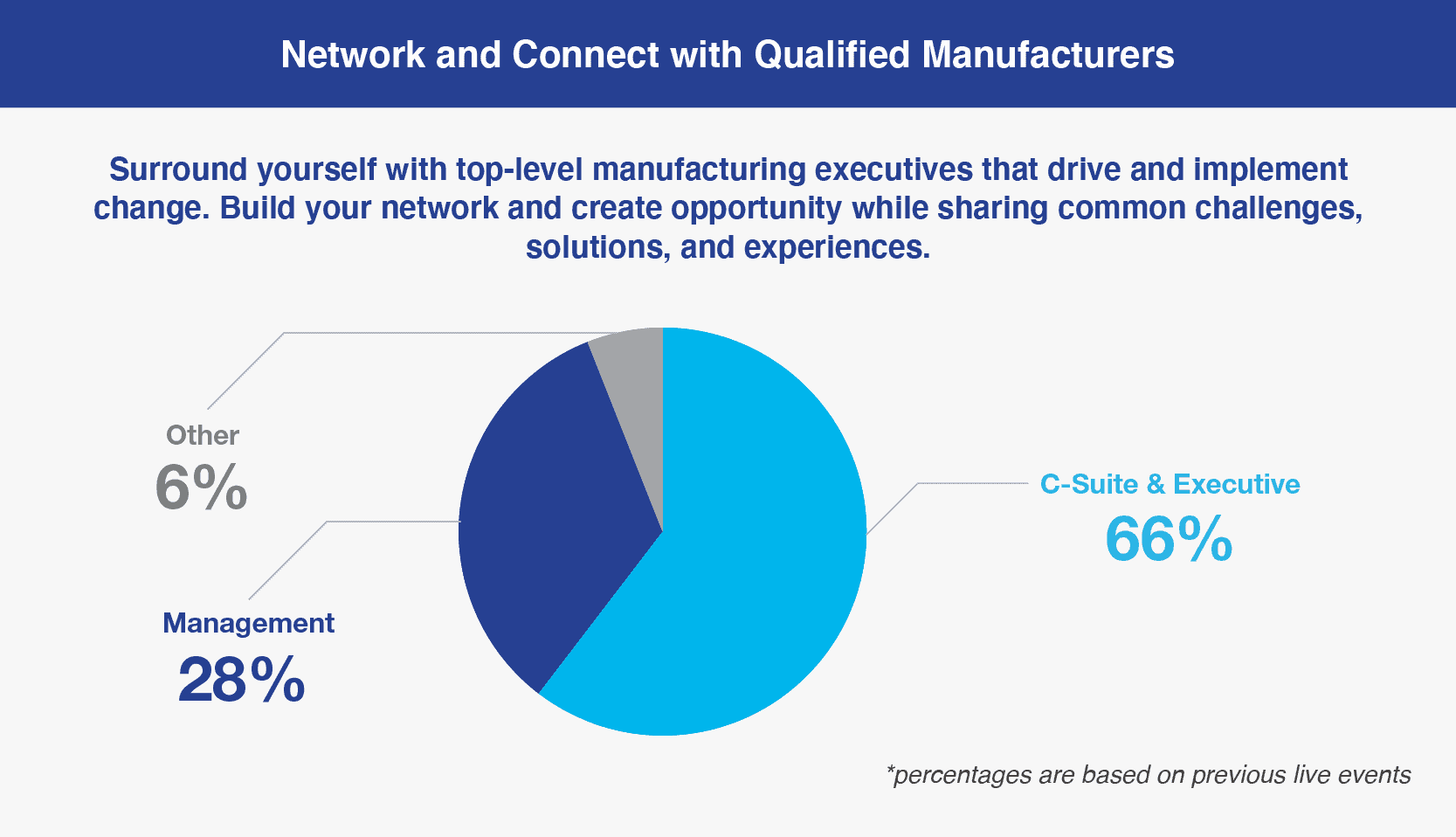

Need we say more? Spend several days building relationships and connecting with like-minded executives both in and out of the event sessions.

Need we say more? Spend several days building relationships and connecting with like-minded executives both in and out of the event sessions. Hear from industry experts with curated content throughout the event, including real-world case studies, panel discussions, research insights, executive interviews and more!

Hear from industry experts with curated content throughout the event, including real-world case studies, panel discussions, research insights, executive interviews and more! Participate in our personal 1-on-1 meetings to understand how different solutions can help you overcome your current business challenges.

Participate in our personal 1-on-1 meetings to understand how different solutions can help you overcome your current business challenges. Collaborate, engage, share and learn with your peers in our interactive Think Tank sessions. With a dozen topics to choose from, you are certain to walk away with new insights and ideas.

Collaborate, engage, share and learn with your peers in our interactive Think Tank sessions. With a dozen topics to choose from, you are certain to walk away with new insights and ideas. No matter where you are in your digital transformation journey, Rethink will help you understand how technologies can accelerate your journey, provide real-world insights and access to the manufacturing organizations leading the way.

No matter where you are in your digital transformation journey, Rethink will help you understand how technologies can accelerate your journey, provide real-world insights and access to the manufacturing organizations leading the way. A Rethink exclusive! Hear the highlights from each of our event partners during the Rethink custom VIP tour. In two minutes or less, you’ll gain quick insights and know where you’d like to take the opportunity to understand more.

A Rethink exclusive! Hear the highlights from each of our event partners during the Rethink custom VIP tour. In two minutes or less, you’ll gain quick insights and know where you’d like to take the opportunity to understand more. Join small group table discussions during lunch to discuss specific industry topics around some of the biggest challenges facing manufacturers today.

Join small group table discussions during lunch to discuss specific industry topics around some of the biggest challenges facing manufacturers today. Connect with some of the top Manufacturing Leadership Award project winners and gain firsthand insights into their award-winning projects during our lightning round sessions and meet n’ greet tables.

Connect with some of the top Manufacturing Leadership Award project winners and gain firsthand insights into their award-winning projects during our lightning round sessions and meet n’ greet tables. Located along the tranquil waters of the Gulf of Mexico on a white sand beach, the JW Marriott Marco Island Beach Resort offers a luxurious setting for our first in-person Rethink since 2019!

Located along the tranquil waters of the Gulf of Mexico on a white sand beach, the JW Marriott Marco Island Beach Resort offers a luxurious setting for our first in-person Rethink since 2019!

Advanced Technology Services, Inc. (ATS), is a leading industrial services provider with over three decades of proven experience in technology-driven industrial maintenance and MRO asset management. Through a technically skilled workforce, best-in-class processes, and Industry 4.0 technologies we deliver asset health and productivity to many leading process and discrete manufacturers. ATS is headquartered in Illinois with regional offices located throughout the U.S., Mexico and U.K.

Advanced Technology Services, Inc. (ATS), is a leading industrial services provider with over three decades of proven experience in technology-driven industrial maintenance and MRO asset management. Through a technically skilled workforce, best-in-class processes, and Industry 4.0 technologies we deliver asset health and productivity to many leading process and discrete manufacturers. ATS is headquartered in Illinois with regional offices located throughout the U.S., Mexico and U.K.

The Manufacturing Leadership Awards Gala caps off Rethink with a celebration of the industry’s most innovative and forward-thinking companies and their achievements in Manufacturing 4.0. This fun and exciting black-tie event includes a cocktail reception, sit-down dinner, and recognition of the 2022 Manufacturing Leadership Award winners. High Achievers, Manufacturing Leader of the Year, and the Manufacturers of the Year will be announced on stage. Join us for the celebration!

The Manufacturing Leadership Awards Gala caps off Rethink with a celebration of the industry’s most innovative and forward-thinking companies and their achievements in Manufacturing 4.0. This fun and exciting black-tie event includes a cocktail reception, sit-down dinner, and recognition of the 2022 Manufacturing Leadership Award winners. High Achievers, Manufacturing Leader of the Year, and the Manufacturers of the Year will be announced on stage. Join us for the celebration!