Dialogue: Driving AI at Scale at Schneider Electric

Without AI, the manufacturing industry will never be able to achieve the levels of efficiency, insights, and sustainability it needs for the future, believes Schneider Electric’s Chief AI Officer, Philippe Rambach.

“AI is going to be pervasive. It will be everywhere. It’s transforming our company and it’s transforming the way our customers operate. I believe AI will have an impact on everything over the next few years.”

Philippe Rambach Chief AI Officer, Schneider Electric

In 1836, brothers Adolphe and Joseph-Eugene Schneider took over an iron foundry in Le Creusot, in the Bourgogne region of France. Two years later, they founded Schneider-Creusot, the company that would eventually become Schneider Electric.

Now a $37 billion global enterprise, today Schneider Electric focuses on digital automation and electrification systems, supported by a network of over 160 manufacturing sites, and more than 135,000 employees worldwide.

In 2021, Schneider appointed its first ever Chief AI Officer, Phlippe Rambach, who now runs a dedicated AI team of 250 AI experts and data scientists focused on global hubs in Paris and Grenoble, France, Bangalore in India, and Boston in the U.S.

In our latest interview with an industry thought-leader, Schneider’s CAIO Philippe Rambach talks to the MLC’s Executive Editor Paul Tate about the company’s strategic goal of developing AI at Scale, how the power of AI can unleash massive operational improvements in industrial efficiency, and why he believes the world will never be able to manage the energy transition it needs to meet global climate goals without AI to help make it happen.

“We always start from the use case with the goal of delivering real business value. What do our businesses need to do, and out of everything they have to do, where can AI help?”

Q: What’s your role at Schneider Electric?

A: I’m the first ever Chief AI Officer of Schneider Electric, and I’m sure I won’t be the last one. My role is to make sure that we leverage AI as much as we can, first for everything related with internal efficiency, customer satisfaction, and all our internal goals. But also, that we leverage AI to help our customers reach their goals to be more sustainable and more efficient by helping them to digitize and electrify. In every aspect, AI is a key component to making that happen.

Q: What excites you most about that role?

A: There are a few things. First, as a planet, we face the dilemma of industrial sustainability, of dealing with climate change. I am amazed how much AI can contribute to solve that. At Schneider, we’ve been working on sustainability for many years, but now AI is significantly accelerating that effort. AI’s potential to help solve some of the most important global problems makes me really excited. It’s like, “Wow! We now have a great tool that we can leverage to do a lot of great things.”

The second is around transformation. AI is going to be pervasive. It will be everywhere. It’s transforming our company and it’s transforming the way our customers operate. It’s a way to touch everything in our own company and everything in our customers’ businesses. I believe AI will have an impact on everything over the next few years. That excites me.

The third is more personal. My background is in deep mathematics and science. After 15 years in a company, you start to do a lot more on the business side, and you think, “Okay, maybe technical jobs are gone forever.” But this job is one of the few where you have both a technical dimension, because to do AI at scale you need to understand what it is and go beyond the smoke and mirrors, but at the same time you need a very strong business understanding. That’s exciting because there are not that many jobs where you have a really strong conjunction of technical and business ideas.

Finally, recent developments over the last five years in technologies like large language models (LLMs) have rapidly become techniques that everybody is using. There are very few domains in engineering where you go that fast from hardcore scientific research into a full speed use. And that’s amazing.

Q: What’s driving Schneider’s overall AI strategy today?

A: Our strategy is what we call “AI at Scale”. That’s what’s driving all of this. That means we always start from the use case with the goal of delivering real business value. We never say, “Oh, there is a new tech, like OpenAI or ChatGPT, what could we do with that?” We always start from what do our businesses need to do, and out of everything they have to do, where can AI help?

I still see many companies who start from the technology, do a couple of pilots of what they can do with it, and then try to sell it internally. We have taken a reverse approach where we start with the business, sit with them with an internal AI consultant, understand their challenges and their goals, and then identify where AI can help.

Then we select our use cases clearly around the business value. That’s not always measured in terms of euros or dollars. It can also be carbon emissions, or customer satisfaction, whatever the business value is. We have many more use cases than we can deliver, of course, so we focus on the largest use cases with the largest impact. And then, to make sure we can do that successfully at scale, we create a joint squad where we merge people from our AI hub with people from the lines of business or key functions.

So, we deploy at scale. Never think pilot. Always think, “What do I want to deliver at scale, and how do I get there?”

“Business value is not always measured in terms of euros or dollars. It can also be carbon emissions, or customer satisfaction, whatever the business value is.”

That’s a very different approach than many companies have taken with what they call the Digital Factory, where they are in a kind of a customer/supplier relationship where the business says, “I want that,” and the digital factory does it. The AI hub is not organized that way in Schneider. We really work on a hub and spoke model where we identify the use case together – the AI hub brings all the AI knowledge, but the line of business brings the domain knowledge and everything else. In the end, the business value, the business deployment, and the ownership, stays with the business.

Q: How is the AI function currently structured within Schneider?

A: There’s now a team of around 250 AI experts and data scientists in Schneider, and we’ll be at around 300 by the end of the year. Those experts are focused around three main locations – Paris and Grenoble in France, Boston in the U.S., and Bangalore in India. These were chosen because we wanted to be where we had access to the right pool of talent, such as universities and so on, where Schneider is strong geographically and would be attractive to data scientists seeking a career where they can be involved in many different things, and where we have strong domain knowledge so they can work closely together with our business teams.

We also made the decision, very early when we first started, to have somebody in charge of “Responsible AI”, a digital risk leader, or a data officer. If you start an AI initiative, and then after six months you have big crisis of ethics, of responsibility, you can kill all your efforts. That’s one recommendation I would make to other companies; start with this kind of function to make sure that what you do is responsible and is ethical for the future.

Q: What approach do you take to developing new AI solutions?

A: During the process of development, we do pilots to check if it all works, of course, but when we develop things, we know we always want to have this at scale from the very beginning, so we are always asking what do we need to do to reach that? It’s probably more difficult to implement this way, but it gives us a much better chance of making an impact and ensuring solutions are used at scale. So far, it is working pretty well.

We also have traditional gate review process. We do ideation, exploration, incubation, all of that. But at each gate review we check two things. We check, from a technical point of view, if we can solve the issue. Do we have enough data? Is the algorithm good enough? But we also check if we still have the business value. We have stopped projects for both reasons, either because technically we couldn’t deliver, or because the business members of the squad were saying, “Yeah, the idea initially looked super nice, it works well, but finally we don’t really know how to use it and bring it in at scale.”

One outcome we didn’t really plan for, but that also works very well, is that we began to realize that by approaching development this way, we never actually develop new stand-alone AI products. We always develop features in existing products because people do not want yet another tool. What they want is the tool that they are using today to manage their solution, their software, or whatever it is, and we create AI features within that tool, almost trying to have people forget it’s AI. That’s another important way of developing effective AI solutions that can be easily adopted at scale.

“AI is another tool to help people achieve set goals, and that will mean change. So, the first question is, are you used to change?”

Q: What AI use cases would you highlight in Schneider so far?

A: Like a lot of companies, we use ERP systems in our factories containing thousands of supply chain parameters, minimum order quantity, lead time, etc., which you may update quarterly, or if you’re a little lazy, yearly, or sometimes never because it’s such a big effort. We have developed the concept of self-healing supply chain using AI to automatically and continuously update those critical parameters to update the overall supply chain. When you manage over 150 factories, thousands and thousands of suppliers, hundreds of thousands of ordering lines, delivery lines, references, and all of that, without AI it’s almost impossible to do. It’s too complicated. That’s brought us lots and lots of efficiency.

It’s the same logic in the production facilities themselves. Very often you buy a machine or set up a process and you set your parameters during your first tests. But then, until there is a big drift, you don’t review those parameters at all. But things do drift. Things do change. With AI we have implemented a system that, at the automation level, for example, continuously updates the parameters of the production line to ensure better yield, better quality.

In sustainability, AI can also make a huge difference. One of the big impacts of moving to a more electrified, decarbonated world is the growth of what we call “prosumers” – companies that not only use, but also produce electricity, like a large factory that has solar panels and maybe wind generation or other systems to ensure power reliability. We have developed a solution to automate the choice to decarbonate that energy usage by helping companies forecast the need for energy in the next few hours, or days, and then decide between using the power it generates directly to run the factory, store it in a battery for later usage, or even sell it to the grid. By deploying such solutions in our buildings, for example, our headquarters in Grenoble is now carbon net zero. So, AI has had a big impact on sustainability.

Those are just some examples of how AI can really help manufacturing companies become more efficient, sustainable, and resilient. There are many more.

Q: Once you’ve developed these new AI systems, how do you then operationalize the data and insights they produce to drive real improvements across the company?

A: It’s a very good question. First, we decided at an early stage to put a lot of investment in building a strong AI platform to create trust among our people that data will not leak and that we will monitor model and data drift and all of that. So that’s one thing.

But the biggest part is more about cultural change and acceptance. The first thing you need to look at is what your company is doing and how it is operating. AI is another tool to help people achieve set goals, and that will mean change. So, the first question is, are you used to change?

“I think globally, as an industry, we need to make sure that everybody in our companies has an understanding of what AI means.”

We are lucky at Schneider that our production sites and factories already have a very strong culture of lean and change management. If you are in a company with no culture of lean, maybe it’s better to implement lean before implementing AI. It is also lucky that Schneider already had a strong data culture with data lakes, data governance, a data organization, and we had extensive digitization. AI needs data and it comes at a certain point in a digitization journey. If you’ve done zero digitization, maybe you should better start with some digitization first.

So, in Schneider, we already had a good culture of change management, data management, and digital progress. However, in addition to that, I am a strong believer that we need, and we have still work to do on this, everybody in a company to understand something about AI. Starting from the worker, right up to the CEO. They don’t need to understand the same things, of course, but they need to have some level of understanding, adequate for their job. So, some will go on a six-month training course if they are doing in-depth data development. But some will just need a two-hour explanation.

In my younger days I was in charge of Six Sigma deployment, and I think we need to get back to that kind of initiative with AI, with levels like green belts, or black belts, and overall training of the basic concepts.

We are now trying to find the best ways to address everybody in our company, so we have segmented the Schneider population into five main groups and use change management processes, communication, and other targeted ways to engage and educate those groups. Some of them go to hardcore training at a digital and data academy, while some are invited to monthly talks about AI. We still have work to do on that. It’s a long journey, but it’s a super important journey.

I think globally, as an industry, we need to make sure that everybody has an understanding of what AI means.

Q: What other challenges keep you awake at night?

A: Sometimes I think how, by applying AI in buildings, we could save 30% of their carbon footprint just by doing simple things that are not super complicated. We know how to do that. We just have to do it. That’s probably the biggest challenge: how do we make things happen for real and fast?

“I really believe that small additional investments in AI solutions, in domains like energy optimization and industrial automation, can unlock the value of the large investments companies have already made in the cloud and in data gathering.”

Internally, that means how we work with our line of businesses in Schneider to embed, as quickly and as seamlessly as possible, AI-based solutions in the offers we bring to our customers in our catalog software? Externally it means how we can help our customers around energy optimization, around sustainability, and around industrial process optimization, to really be much more efficient and sustainable using AI? Those are the kinds of challenges that keep me awake at night.

Also, many companies have already made lots of investments in their data and the cloud, but they often don’t get much return on that. I really believe that small additional investments in AI solutions, in domains like energy optimization and industrial automation, can unlock the value of the large investments companies have already made in the cloud and in data gathering. So, what also keeps me awake at night is to see that potential of untapped efficiency, where probably 90% of the investment has already been made, and all they need is the last 10% to really get a return.

And a new one for me, which is a bit scary right now, is the speed at which fundamental technologies like LLM and OpenAI are now coming. In a large company, it takes time to do stuff. If the technology is moving so fast, how and when do we decide to stop what we are doing and either take on the latest technology, or stay with the one we’re using? For example, we have put a lot of money into developing chatbots, and we’ve now decided we are going to switch quickly to the new LLMs because the benefit is so big. That means we may have to bin a lot of things we’ve done in the last three months. The fundamental technology is moving so fast. How can companies develop applications when the fundamental technology is changing every six months? Are we going to be able to cope with that? Some of the answer is in being super agile, but that’s a big challenge that I see in the future for many companies.

Q: In light of the pervasive and cognitive nature of AI, do you feel the industry now needs a Code of Ethics for AI? If so, who should be involved in creating that?

A: For me personally, I believe technology needs regulation. There is no doubt about that. But every technology needs regulation. When we invented cars, it didn’t take us long to realize we needed a highway code. And with things like generative AI, it has become so easy to create text or a voice that sounds human, that sounds credible. If we don’t put some regulation around this, and make people responsible, it may be misused to say something that is simply not true. That shouldn’t be allowed. It has to be society’s choice what those regulations cover, of course, so politicians need to listen to the tech people and create a basic legal framework, which society democratically accepts, at a political level. Then, as individuals or as organizations, we also need to develop our own ethics which should go beyond what the legislation says. At Schneider, for example, we already have our own ethical code that goes beyond AI and beyond current legislation. So yes, we need regulation. We need the politicians to make the basic hard rules because not everybody is always good or nice in this world. Then as companies we need to apply that minimum level, but also develop our own codes of conduct depending on what we believe in, like sustainability, or fairness, which will impact our own codes.

Q: Looking ahead, what would you highlight as the greatest opportunities for manufacturing industry for the rest of the decade?

A: I really believe that energy optimization, decarbonation, and electrification are massive opportunities for manufacturing, and AI will be critical for those. If we want to decarbonate the planet, we need industries to electrify much more, to be more efficient, to use less energy, and to create less waste. That requires a combination of digitization and AI to optimize our processes. But if you still produce your energy using carbon-based sources like oil or gas, you will not solve the issue. So, the next step is to electrify, supported by decarbonated energy production and green electricity. But for a consistent green energy supply to be delivered from multiple sources – wind, solar, batteries, consumers selling to the grid, and so on – we need to optimize a complex electrical landscape. And without AI, that is not feasible. I don’t believe that the energy transition can happen without AI and digitization because the model will become so complicated.

“The fundamental technology is moving so fast. How can companies develop applications when the fundamental technology is changing every six months? Are we going to be able to cope with that?”

The second thing where I see AI bringing a lot to our factories and industrial processes is by helping us have a much more global view of things and the implications of every decision. For example, could you perhaps better balance machine running times with carbon savings by starting to run a machine fifteen minutes later with minimum production impact? This is where AI can really help a lot in focusing and optimizing processes. For me, AI in the future will help us to have a much broader view of what’s happening across the whole manufacturing process.

Q: What key leadership skills, attributes, and roles do you feel that senior industry executives now need to lead successfully in an increasingly data-driven world?

A: I think senior leaders need to make an effort to learn at least a basic knowledge of what AI is, how it works, and what it does. To make it less “magic” and to give them more confidence that they will make better decision by using AI on the data, than by trusting their intuition. That’s probably one of the most important cultural changes we need among management. Some are there already, but I think we still have work to do. When we get there, as an industry, we’ll have made a giant step in efficiency across entire organizations.

They will also need to support the changes brought about by AI. As with other technologies, the most difficult aspects will be deployment, adoption, and overall change management. The role of leaders is critical here.

Q: Finally, if you had to focus on one thing as a watchword or catchphrase for the future of manufacturing, what would that be?

A: I believe that energy transition, sustainability, and carbon reduction will simply not happen without AI. There’s too much data, too much complexity, and too many parameters. Globally, there is no way the world can do that without AI to help us reach those critical climate goals for the future. M

FACT FILE: Schneider Electric SE

HQ: Rueil-Malmaison, Paris, France

Industry Sector: Digital Automation and Energy Management

Revenues: $37.2 billion (€34.2 billion, 2022)

Net Income: $3.84 billion (€3.5 billion, 2022)

Employees: 135,000+ Employees (2022)

Presence: Worldwide

Production: 162 Manufacturing Sites Worldwide

Website: www.se.com

EXECUTIVE PROFILE: Philippe Rambach

Title: Senior Vice President, Chief AI Officer, Schneider Electric

Nationality: French

Education: Graduate, Ecole Polytechnique, Palaiseau, Paris, France; industrial engineering, Ecole Nationale des Ponts et Chaussées, France

Languages: French, English, German

Previous Roles Include:

– Senior Vice President, Industrial Automation, Commercial Business, Schneider Electric

– Senior Vice President, Industrial Controls and Drives, Schneider Electric

– Vice President, Australia Industry Business Unit, Schneider Electric

– Vice President, Drives Business Line, Schneider Electric

– President, Schneider Electric-Toshiba Inverter Joint Venture

– Director, Customer Care and Services, Areva T&D

– Vice President, Project Division, Niscayah

– Director, Industrial Partnerships, Sagem

– Lead Program Manager, Johnson Controls International

– R&D Manager, Sagem

– Production Manager, Sagem

Other Industry Roles/Awards/Board Memberships

– Chairman of the Board, Vamp Oy, Finland (2010-2012)

About the author:

Paul Tate is Co-founding Executive Editor and Senior Content Director of the NAM’s Manufacturing Leadership Council.

Empowering Employees in the Manufacturing 5.0 Era

Transformational success depends on developing effective workforce strategies to prepare employees for a world of closer human/machine collaboration.

TAKEAWAYS:

● The constant flow of data from converged IT and OT systems helps employees identify potential bottlenecks and optimize operational efficiency.

● As the demand for skilled manufacturing workers increases, companies are exploring alternatives to traditional education and apprenticeships, such as on-the-job training for high school students.

● To appeal to Millennials and Gen Z, manufacturers must effectively communicate their mission and culture, emphasizing their products’ societal benefits, commitment to sustainability, and social responsibility.

The manufacturing landscape is undergoing a massive transformation driven by global changes, differences in work ethic, and rapid technological advancements. Gartner research shows that 80% of CEOs are increasing digital technology investments to counter current economic pressures, including inflation, scarce talent, and supply constraints. As a result, companies must focus on leadership, organization, culture, and people to thrive in this new era, ensuring a collaborative and innovative workforce.

Understanding the essential aspects of the upcoming era of Manufacturing 5.0, the importance of involving employees in change management, adapting to evolving workforce needs, and fostering a culture that attracts the younger generation, are now critical for manufacturers.

Manufacturing 5.0

Manufacturing 5.0 focuses on reintroducing the “human touch” to modern manufacturing processes and systems. While Manufacturing 4.0 heavily relies on digitization, connectivity, and automation technologies often replacing human tasks, Manufacturing 5.0 recognizes the importance of human skills, creativity, and decision-making in the digital transformation process. It emphasizes the collaboration between humans and machines, leveraging cognitive technologies like AI and ML to augment human capabilities rather than replace them. The goal is to create more meaningful and satisfying work experiences while harnessing the benefits of these advanced technologies to create a more flexible, adaptive, and sustainable manufacturing environment. Overall, Manufacturing 5.0 represents a paradigm shift in the manufacturing industry by emphasizing the symbiotic relationship between humans and machines, leveraging advanced cognitive technologies in new ways, and focusing on agility, sustainability, and data-driven decision-making.

The Changing Role of Employees

The need for proficient manufacturing shop floor employees has surged, prompting companies to investigate alternatives to conventional education and apprenticeships. One such alternative is on-the-job training. The effectiveness of this approach in countries like Germany has inspired other nations to contemplate implementing similar strategies. On-the-job training provides hands-on experience and skills, allowing employees to adapt quickly to the ever-changing requirements of the manufacturing industry.

Shop floor employees today need to comprehend and utilize the analysis of the growing volumes of shop floor information, in conjunction with input from advanced information technology systems that drive demand, to make crucial and timely decisions. They must understand the business more deeply than merely executing a manual task. Improved, straightforward, and seamlessly integrated information facilitates real-time data, analytics, and insights, empowering shop floor employees to make more data-driven decisions, optimize operations, and reduce downtime.

“The importance of involving employees in change management, adapting to evolving workforce needs, and fostering a culture that attracts the younger generation, are now critical for manufacturers.”

There are a number of key factors to address in this digitally enabled employee transition.

Demographic Shifts: The aging population and the retirement of experienced workers in many countries have exasperated the skills gap within the manufacturing sector. This change has intensified the demand for skilled labor, driving companies to devise new methods to train and educate their shop floor workforce. A 2020 report by the World Economic Forum predicted that 50% of employees worldwide will need reskilling by 2025, emphasizing the significance of inventive and flexible training models to keep pace with the rapid transformations in the manufacturing sector.

COVID-19 Influence: The pandemic disrupted traditional educational institutions, hastening the adoption of online and remote learning. This led to a re-examination of formal education and training models as the manufacturing sector seeks pioneering approaches to equip workers with the skills needed to face industry challenges.

Economic Hurdles: Global economic difficulties have also resulted in an increased emphasis on efficient and effective workforce development strategies. Companies are searching for cost-effective methods to train and upskill their shop floor employees, making on-the-job training an appealing option.

Bridging the IT/OT Gap: The expectations and skills of manufacturing employees are rapidly evolving as the world transitions to Manufacturing 5.0 and to the world of Open AI. Substantial modifications in plant floor Operational Technology (OT) are necessary to enhance productivity. Integrating the shop floor with Information Technology’s (IT) back office has become critical in informing decision-making processes. This convergence is the bedrock of adopting various advanced technologies, including Artificial Intelligence (AI), automation, sensors, and computer vision, to improve worker safety and overall transformation and innovation. As the world of manufacturing undergoes this transformation, organizations must actively involve their employees to upskill rather than cross-skill to bridge this gap. Coupling technical skills with soft skills is now required to achieve transformation success.

What has changed?

Well, everything. While on one end of the spectrum, we have the zenith of technologies waiting to be embraced; while the other end is still struggling with legacy systems and companies blindly investing in technologies with little to no ROI. While there is a massive shift to develop hyper-automated factories, many companies still need a structured plan to drive this transition.

Not only that, but the challenge today is also to prepare, and have a plan, to replace the aging workforce. Next, companies need to understand and identify what percentage of its workforce are replaceable with robots or collaboration bots and which human repetitive tasks can be replaced.

Fifty three percent of respondents to a recent TalentNeuron survey for example, said that the inability to identify needed skills was the No. 1 impediment to workforce transformation. Thirty-one percent reported that they also need help to identify those market-leading skills.

Fuelling Workforce Transformation

However, as robotics, automation, and AI continue to advance, they will not eliminate the need for labor on the shop floor. Instead, they will transform the kind of workforce required. According to World Economic Forum’s “Future of Jobs Report 2020” that gathers the insights from the largest companies worldwide on the changing nature of work; by 2025, humans and machines would share equal task loads, with 85 million jobs worldwide being displaced by automation and AI, while 97 million new roles will be created. This means an increase in labor as more new jobs emerge.

The rapid development of robotics, automation, and artificial intelligence (AI) has led to more sophisticated machines that can perform tasks previously handled by humans. This caused a shift in the labor market, where new skills and expertise are required to keep up with these changes. While AI could increase labor productivity there is a need to upskill and reskill shop floor workers to adapt to the changing labor market.

“Improved and seamlessly integrated information facilitates real-time data, analytics, and insights, empowering shop floor employees to make more data-driven decisions.”

As machines become more capable of performing tasks, there is also an increasing demand for shop floor workers who can manage, develop, and maintain these systems. This transformation in the labor market signifies an evolution in the skill set needed for employees. Shop floor employees now require specialized training in robotics, automation, and AI to develop the skills necessary to work with these technologies. Much of the activity will be provided by machine manufacturers, while additional training can be accessed online.

Embracing Change and Sustainability

The manufacturing industry must adapt to the changing workforce, technology, and global landscape challenges. As a result, companies must foster a culture of continuous learning, innovation, and adaptability, prioritizing trust and employee well-being.

As the workforce becomes more diverse, companies must also ensure that their culture and policies are inclusive and provide equal opportunities for all employees. By embracing diversity and promoting inclusion, companies can tap into their employees’ unique skills, perspectives, and experiences, leading to improved innovation and performance.

As manufacturing undergoes a technological revolution characterized by adopting Manufacturing 5.0, automation, and digitalization, companies must invest in upskilling and reskilling their workforce to adapt to new technologies and processes to stay competitive. This requires fostering a continuous learning and innovation culture, where employees are encouraged to keep up-to-date with the latest industry trends and developments.

As the global market becomes increasingly interconnected, manufacturers face increasing competition, economic fluctuations, and regulatory pressures. Companies must develop strategies to navigate these challenges while maintaining sustainable practices considering environmental, social, and economic factors.

Companies should also prioritize confidence and employee well-being by providing supportive work environments, encouraging open communication, and offering resources for mental and physical health. A strong focus on employee well-being can improve productivity, retention, and company performance.

Finally, as shop floor employees reduce manual tasks and become machine managers using computers, operational technology, and information technology, their ability to work remotely will improve. That being said, envisaging a hybrid work model for shop floor employees can be challenging because of the nature of the work and the need for continuous production. Supervisors are already using phones to keep track of machine operations over multiple shifts, especially in process manufacturing and, more often, in discrete Manufacturing, where machine productivity requires 24/7 operation. Implementing periodic shifts for shop floor employees can help the manufacturing industry transition to a hybrid work culture.

Change Management, Done right.

As manufacturers begin to navigate these fundamental operational and workforce changes, there some basic guidelines that may help leaders adopt more enlightened workforce cultures.

Open Communication: The successful implementation of advanced technologies largely depends on the involvement of employees in change management. Therefore, organizations must focus on a culture of open communication. Shop floor employees are often the best source of information on productivity and quality improvements. Companies should encourage employees to share their thoughts, concerns, and ideas. This establishes a sense of ownership and commitment among the workforce. Based on research conducted by McKinsey, the likelihood of a successful transformation increases 5.8 times when CEOs convey a persuasive and overarching narrative of change. Furthermore, the chance of success rises 6.3 times when top executives disseminate consistent and unified messages about the change initiative.

“Younger employees are often passionate about environmental sustainability and may be more inclined to work for companies committed to reducing their ecological footprint.”

Reward Cross-Skilling: Organizations must invest in training and reward skill development programs to equip their workforce with the knowledge and skills required to adapt to higher analytical skills driven by new technologies. This enhances employee capabilities and ensures a smooth transition to the new systems.

Leadership through Mentorship: Companies should also provide their employees with the necessary support and resources during the transition. This includes mentorship, guidance, and the availability of resources to address any challenges or issues that may arise.

Internal Communication: Organizations must emphasize adapting to new technologies and their potential benefits as part of their internal communications strategies. This can be achieved through awareness campaigns, workshops, and presentations highlighting the value these technologies bring to the organization regarding efficiency, productivity, and safety.

A study conducted by the Boston Consulting Group found that organizations that successfully implemented change initiatives like these were 3.5 times more likely to effectively communicate the benefits of change to their employees, resulting in increased employee buy-in and support for the changes.

Attracting a Younger Workforce

The younger generation, often called millennials and Gen Z, tends to prioritize working for companies and non-profits that have a clear, positive impact on society. To appeal to this demographic, manufacturers must communicate their mission and culture effectively, emphasizing how their products contribute to the greater good.

A strong mission statement that reflects the company’s core values and goals can resonate with younger employees, who are often driven by a sense of purpose in their work. This generation seeks to make a difference, and by aligning the company’s mission with societal benefits, manufacturers can create a more attractive workplace for young professionals.

A company’s culture is the set of shared values, beliefs, and practices that shape the work environment. A positive, inclusive, and empowering culture can be a significant draw for younger employees who prioritize work-life balance and personal development. In addition, manufacturers can improve employee satisfaction and engagement by promoting a healthy work culture.

“Companies should encourage employees to share their thoughts, concerns, and ideas. This establishes a sense of ownership and commitment among the workforce.”

Younger employees are often passionate about environmental sustainability and may be more inclined to work for companies committed to reducing their ecological footprint. Manufacturers can appeal to these values by adopting eco-friendly practices, investing in green technologies, and promoting transparency around their sustainability initiatives.

The younger workforce is also attracted to companies that take an active role in addressing social issues and contributing to the communities in which they operate. Manufacturers can showcase their commitment to social responsibility by engaging in philanthropy, volunteer programs, and community partnerships. These initiatives help attract and retain young talent and enhance the company’s reputation and brand image.

The Way Ahead

The transition to Manufacturing 5.0 has brought about significant changes in the manufacturing landscape, requiring companies to adapt to evolving technologies, workforce demographics, and global challenges. To thrive in this new era, manufacturers must involve their shop floor employees in change management, invest in training and skill development programs, and foster an open, collaborative, and innovative culture. In addition, manufacturers can attract and retain the younger workforce, who drive innovation and success in the industry by embracing diversity, prioritizing employee well-being, and adopting sustainable practices. M

About the authors:

Neha Aggarwal is Assistant Vice President and Head, Vertical Strategy Group at Birlasoft.

Paul Menig is a Senior Business Consultant at Birlasoft.

What Got You Here, Won’t Get You There

To move into the digital future, manufacturing leaders must lead with disruption and innovation.

TAKEAWAYS:

● Transformation starts with leadership.

● Employee-wide upskilling development is needed.

● How to instill a learning culture.

The manufacturing industry continuously faces new challenges in an ever-changing landscape. Leaders must contend with increasing demands to adopt sustainable practices, the need for greater data security, rising customer expectations, and difficulties around recruiting and retaining talent as skilled workers approach retirement.

This complex landscape requires disruptive and adaptable manufacturing leaders ready to navigate uncertainty and introduce new ways of working designed to fit shifting priorities.

To do this, leaders will need to look inward to identify the behaviors that will support and empower workers, upskill current employees, and cultivate a culture of constant learning.

Transformation Starts With Leadership

The new transformative, disruptive manufacturing leader will need to pivot away from “business as usual” to a digital-first “change as usual” mindset. They must understand and embrace data, be able to role model digital behaviors, leverage the strengths and behaviors of the team and individuals to retain competitive advantage, and bridge the gap between the now and ever-changing digital future.

Contrary to popular belief, leadership is not a stand-alone, isolated activity. The new leader must be able to ideate, innovate, and create future solutions while leading, empowering, and engaging teams undergoing transformation. This leader should encourage people to think and operate outside the box. In an industry that is heavily product driven, this new paradigm will need to be applied with caution given the reduced margin of error within this sector.

“The new leader must be able to ideate, innovate, and create future solutions while leading, empowering, and engaging teams”

PA Consulting recently surveyed over 300 business leaders across the U.S., U.K., and Europe to explore the behaviors driving the new way to lead. The finding revealed that over the next five years, the following behaviors will be critical to success:

- Nurture human optimism by helping people create a positive mindset and approach, tapping into people’s innate capacity to adapt to new and complex situations with innovation and creativity.

- Empower teams to innovate by inspiring people to understand their customers’ desires and giving them the space and permission to imagine and deliver value-creating responses.

- Build evolving organizations by creating environments where rapid change is the norm, and where aware, inclusive, and responsive teams can make a success out of change.

- Seek inspiration in surprising places by applying new perspectives and a broader lens to both existing technologies and evolving challenges.

An overwhelming majority of surveyed leaders recognized the importance of those behaviors as essential to leadership now and in the future. Moreover, these behaviors are linked to 70% and 74% better outcomes in performance and societal outcomes, respectively.

Driving Economic Optimism Through Upskilling and Learning

To lead systematic change and deliver organizational transformation at pace, businesses must ensure that all employees are prepared and ready to face the challenges of the 21st century. Indeed, being disruptive isn’t just about thinking differently, it’s about having a stable and secure organizational foundation to take risks and adapt. To do so, leaders must prioritize building new talented teams, upskilling and transforming the learning capability.

The World Economic Forum’s Future of Jobs Report states that due to the growing uptake of technology and automation, half of all employees will need reskilling by 2025. This remains particularly relevant within manufacturing where operationally intensive companies begin to enter a new era of automation reliance. In Europe and the U.S., demand for physical and manual labor for repeatable and predictable tasks within the sector is predicted to decline by nearly 30% over the next decade. In contrast, the requirement for digital skills (coding analytics for example) is predicted to almost double. Finally, demand for high-level social and emotional skills will continue to increase as global partnerships and supply chain complexity expand. Such significant workplace trends present real challenges, and opportunities, to manufacturing firms.

Create a long-term vision for growth

In this context, leaders can no longer rely on a reactive and short-term people strategy but must look to develop a long-term vision for growth, which recognizes the importance of an adaptable and cognitively mobile workforce. The economic incentive remains paramount and clear: retention and training are, and will continue to be, a more sustainable and effective employee policy than hiring new employees. Moreover, shifts in societal and workplace attitudes will only strengthen this approach and the expectation that employers must do more to retain their current workforce where possible. In light of this clear momentum shift, what can leaders do to guide this skills transition and drive progress?

“Employees should be encouraged to embark on their own upskilling journey through conversations and development plans”

Companies must ensure that any upskilling forms part of a larger digital strategy. Acquiring top talent remains a common barrier to achieving digital strategies, and success in either requires a combined approach that sees upskilling as a critical cog in the wider digital wheelhouse. Here, leaders must engage with serious discussions around workforce planning and resource allocation to design effective upskilling capability.

Reward and incentivize training

Upskilling and reskilling must be widely promoted and resourced at all levels to ensure enterprise-wide adoption. Leaders must consistently communicate its value, actively endorse and support opportunities, and identify risks of reduced adoption. Where possible, employers should look to reward and incentivize upskilling activity (both compensatory and non-compensatory). At the very minimum, employees should be encouraged to embark on their own upskilling journey through regular career development conversations and bespoke development plans. Flexible learning and additional staff development products such as microlearning and flexible time off should also be reviewed in order to see a noticeable shift in this area.

Leaders should work closely with learning and development (L&D) teams who have a wealth of learning resources, training skills, and valuable workforce data on required future skills and learning needs. Leaders should also discuss emerging trends, business needs and skill requirements to inform the L&D teams’ programs and middle leadership layer. A strategic response to this upskilling challenge will inform leaders and encourage staff to take up opportunities to upskill and grow. Developing an online opportunity marketplace or talent-seeking resource hub can help to meet business needs and develop individuals and teams.

Finally, upskilling provides numerous benefits to both employees and organizations. The meaning and importance of work have changed over time and research has shown that the main motivating factor is no longer money. More people are reevaluating their priorities, looking at their work-life balance and wanting their work to be meaningful, purposeful, and in harmony with their beliefs and values. When aligned with organizational beliefs, mission, and values, the power of upskilling is even stronger.

Cultivating a Life-Long Learning Culture and Digital Mindset

Manufacturing 4.0 is primarily anchored in interconnectivity which is underpinned by insights garnered from automation, machine learning (ML), big data analytics, and real-time data. Moving into a digitally enabled era means that there is an ever-greater expectation of delivering innovative products to the market at speed. This means that success ultimately lies in how well organizations are able to move their people to become truly innovative, agile, and collaborative in order to overcome increasingly complex structures and meet future customer demands.

“It is crucial for leaders to cultivate a foundational culture of life-long learning and a digital mindset”

Organizations going through such Manufacturing 4.0 digital transformations will recognize that, alongside investing in new technologies and upskilling/reskilling employees in how to use them, it is apparent that technological advances and the unexpected changes they bring are here to stay. To be unequivocally fit for the future, therefore, it is crucial for leaders to cultivate a foundational culture of life-long learning as well as a digital mindset that will inspire their teams and enable them to find creative solutions at an unprecedented pace.

Create a psychologically safe environment

Creating a life-long learning culture and a new digital mindset requires the right platforms and resources to provide more informal, on-demand, and bite-size learning opportunities that can be accessed alongside day-to-day work, and also an environment of psychological safety. Like evolving learning approaches, performance and development conversations are now also occurring both more frequently and informally, to meet the real-time nature of new or changing demands.

For manufacturing in particular, a move to greater automation can create substantial changes physically (from the shop floor to an office setting) as well as behaviorally (towards a fail-fast agile learning mindset), and this can create psychological unease. The uncertainty presented by inevitable technological and societal developments will require leaders to be proactive in offering a leadership style that is more sensitive, adaptive, and empowering so that their teams feel heard and supported through these shifts. In turn, this authentic approach to investing in employees and providing recognition of their intrinsic value will also help to retain and attract talent in these challenging times.

Transformation is now commonly viewed as being more of a journey than an end point. The long-term capability and culture of life-long learning will need authentic leadership to generate a psychologically safe environment that motivates teams to evolve, grow, and disrupt so that businesses don’t just survive but truly thrive. M

About the authors:

Nigel Lowe is a Partner and people and change expert at PA Consulting

Nini Ali-Khan is a change management expert at PA Consulting

Shanton Wilcox is a Partner and America’s Leader in Manufacturing at PA Consulting

The Evolution of Manufacturing Jobs

Networking technology is driving transformation and empowering leaders through both growth and disruption.

TAKEAWAYS:

● Digital transformation and the evolution of manufacturing jobs rely upon enhanced connectivity.

● The workforce evolution isn’t just about how jobs are done but also who is doing the jobs.

● Business leaders can find success through employee training and digital transformation that leverages networking technology.

This is a different manufacturing industry than even a decade ago. What got the industry here today, will not get it where it needs to be tomorrow.

Manufacturing leaders are grappling with how to adapt and grow in an environment that is undergoing constant disruption by advances in technology, globalization, and shifting customer demands.

The Evolution of Manufacturing Jobs

In the past, manufacturing jobs primarily involved manual labor and repetitive tasks on assembly lines. Today, these jobs are evolving to include a higher degree of automation, digitization, and skilled labor. This same transformation is happening in other industries and even at AT&T.

What are the factors contributing to this radical sea change?

- Automation and robotics: The rise of automation and robotics in manufacturing has led to a reduction in the need for manual labor. Tasks that were once performed by humans are now being handled by machines, allowing workers to focus on higher-value tasks that require specialized skills and expertise.

- Advanced manufacturing techniques: The adoption of advanced manufacturing techniques, such as additive manufacturing (3D printing) and computer numerical control (CNC) machining, has led to a greater need for skilled workers who can operate and maintain these sophisticated technologies.

- Digital transformation: The manufacturing industry’s digital transformation has created a growing demand for workers with expertise in data analytics, machine learning, and other digital skills. As manufacturers increasingly rely on data-driven decision-making, workers must be able to interpret and analyze complex data sets.

- Globalization: As companies continue to expand their operations across borders, there is an increasing need for workers who can navigate the complexities of global supply chains and communicate effectively with colleagues and partners around the world.

This evolution is not just about how jobs are done. It is also about who is doing them. The shift toward some jobs requiring higher levels of education and less physical strain has helped create more opportunities for women in the industry.

“Although men still hold the majority (67.9%) of U.S. manufacturing jobs, the Census Bureau’s Job-to-Job (J2J) Flows Explorer shows that from 2010 until the pandemic struck in 2020, the share of women in manufacturing jobs rose in every working-age category,” according to an October 2022 U.S. Department of Commerce report. “In 2021, the data show the numbers going back up to pre-Covid levels. Certain age groups show an even higher spike than before the pandemic. For example, 8.6% of the people who went into manufacturing jobs were women ages 55 to 64 before the pandemic but increased to 9.1% in 2021.”

“Advanced connectivity is critical for driving innovation, improving efficiency, and enabling new ways of working”

While there has been progress in getting more women in the industry, there is more work to be done including taking a proactive approach to providing and seeking out opportunities for women and encouraging women to lean in to be comfortable while not placing artificial limits on others. And once a woman has her foot in the door, she should send the elevator back down for others who are waiting in the lobby for their opportunity.

The Role of Enhanced Connectivity

Enhanced connectivity, enabled by technologies like 5G and fiber-optic networks, is playing a crucial role in this manufacturing jobs evolution and the industry’s digital transformation. The increased speed, bandwidth, and reliability of these advanced networking solutions provide numerous benefits for manufacturers, including:

- Real-time data exchange

- Accelerated decision-making

- Improved collaboration

- Support for IoT and Industry 4.0

- Remote monitoring and control

- Enhanced supply chain visibility

- Support for remote work and distributed teams

- Scalability and flexibility

- Reduced latency

By embracing enhanced connectivity solutions like 5G and fiber-optic networks, manufacturers can unlock a range of benefits that help them adapt to the changing nature of manufacturing jobs and stay competitive in the digital age. This advanced connectivity is critical for driving innovation, improving efficiency, and enabling new ways of working in the manufacturing industry.

More than just 5G and Fiber

Other networking technologies, from IoT to cybersecurity, are also playing crucial roles.

IoT devices and sensors connected via networking technology collect real-time data on production processes, equipment, and environmental conditions. This data enables manufacturers to monitor their operations closely, identify potential issues, and optimize their processes for greater efficiency and productivity.

Networking technology has facilitated the widespread adoption of cloud computing in the manufacturing industry. Cloud-based platforms and services allow companies to store, process, and analyze vast amounts of data, streamline their operations, and enhance collaboration among employees and external partners.

As manufacturing operations generate massive amounts of data, edge computing has emerged as a valuable solution to process and analyze this data close to its source. Networking technology enables edge computing by connecting devices and systems at the edge of the network, reducing latency, and ensuring real-time analysis.

“Leaders must be proactive in adapting strategies and practices to this new reality and workforce”

With the increasing need for connectivity by manufacturing operations, the importance of robust cybersecurity measures has become paramount. Networking technology plays a critical role in securing data and communication channels, protecting businesses from potential cyber threats and ensuring the confidentiality, integrity, and availability of information.

Meanwhile, networking technology has revolutionized supply chain management in the manufacturing industry by facilitating real-time communication, data exchange, and collaboration between various stakeholders, such as suppliers, logistics providers, and customers. This enhanced connectivity allows companies to optimize their supply chains, minimize disruptions, and respond rapidly to changes in demand.

How Business Leaders Can Respond

That is a lot of disruption! It is exciting, but it also creates unique challenges that previous manufacturing leaders never encountered. Today’s leaders cannot be laggards. They must be proactive in adapting strategies and practices to this new reality and workforce. Here are some steps they can take:

- Invest in employee training and development: As the nature of manufacturing jobs evolves, it is essential for companies to invest in ongoing training and development programs that help workers acquire the necessary skills and expertise. This includes providing access to online courses, workshops, and industry conferences focused on networking technology, automation, and digital skills.

- Embrace digital transformation: Business leaders must recognize the importance of digital transformation and embrace the adoption of advanced technologies, such as IoT, cloud computing, and edge computing. This involves not only investing in new technologies but also developing a culture of innovation and continuous improvement within the organization.

- Foster a culture of open communication: Encouraging communication and collaboration across the organization is crucial for adapting to the evolving nature of manufacturing jobs. Leaders should provide employees with the tools and platforms they need to share ideas, ask questions, and collaborate with their peers, both internally and externally.

- Leverage data-driven decision-making: As manufacturing becomes increasingly data-driven, leaders must learn to leverage data and analytics to make more informed decisions. This involves investing in data analytics tools and platforms, as well as training employees to use them effectively.

- Prioritize cybersecurity: With the increasing reliance on networking technology and connectivity, it is crucial for business leaders to prioritize cybersecurity. This includes implementing robust security measures, such as firewalls, intrusion detection systems, and encryption, as well as educating employees about cybersecurity best practices.

- Build strong relationships with external partners: In a globalized economy, it is essential for manufacturers to build strong relationships with external partners, such as suppliers, logistics providers, and customers. Networking technology can help facilitate these relationships by enabling real-time collaboration and information sharing.

- Prepare for the future of work: The manufacturing industry is continually evolving, and business leaders must be prepared for future changes to the nature of work. This includes staying informed about emerging trends and technologies, such as advancements in networking technology, as well as being open to new ways of working and managing talent.

In conclusion, the evolution of manufacturing jobs – driven by technological advancements, globalization, and changing customer demands – is significantly impacting the industry. Networking technology is at the heart of this transformation, enabling businesses to adapt and thrive in this new environment.

By investing in employee training and development, embracing digital transformation, and leveraging the many benefits of networking technology, business leaders can position their organizations for success in manufacturing’s future. It is essential for leaders to stay informed about emerging trends and technologies, be prepared to adapt their strategies and practices, and seize the opportunities presented by this rapidly changing landscape. M

About the author:

Andrea (Ande) Hazard is Vice President, Manufacturing and Transportation Solutions for AT&T Business where she leads a team of sales professionals, technical architects and engineers delivering AT&T products, services and global solutions to enterprise clients. Her organization focuses on the manufacturing, transportation, logistics and consumer packaged goods industries, ensuring an integrated, enterprise-wide customer experience for their clients.

The Best Tool for Employee Retention? Listening to Them

Soliciting feedback is key to bridging the gap between what workers want and what employees offer.

TAKEAWAYS:

● Compensation, health care and retirement perks are typically the top priorities of what employees want most, regardless of industry.

● Giving employees a clear framework for defining their career paths could be one area ripe for improvement.

● Employees want opportunities to be heard, and for their employers to take their feedback into consideration.

Manufacturers have been grappling for years with how best to fill thousands of job openings on factory floors and white-collar positions, and economic headwinds are only adding more challenges to hiring within the sector.

As of March, the manufacturing sector contracted for the fourth consecutive month, according to data from the Institute for Supply Management. Also in late March, the RSM US Manufacturing Outlook Index—a composite index based on surveys of business sentiment conducted by six regional Federal Reserve banks—showed manufacturing activity was 1.8 standard deviations below normal. RSM’s index can be considered representative of the general direction of national manufacturing activity.

“That slowing leads us to think that firms will do their best to hold onto their workforce, minimizing the loss of employment in the coming quarters even if there were to be a recession,” RSM Chief Economist Joe Brusuelas wrote in an article that month.

“A recent survey reveals where employee priorities lie and generational nuances within the workforce — valuable insights that can help manufacturers boost retention.”

One aspect of addressing recent hiring challenges may seem obvious: Companies should listen to what employees say about their priorities and what they want most from their jobs. Proprietary data collected by advertising, technology and data company Big Village on behalf of RSM US LLP in 2022 reveals where those priorities lie and generational nuances within the workforce — valuable insights that can help manufacturers develop strategies that can boost retention for the increasingly digital factories of the future.

Understanding Employee Priorities

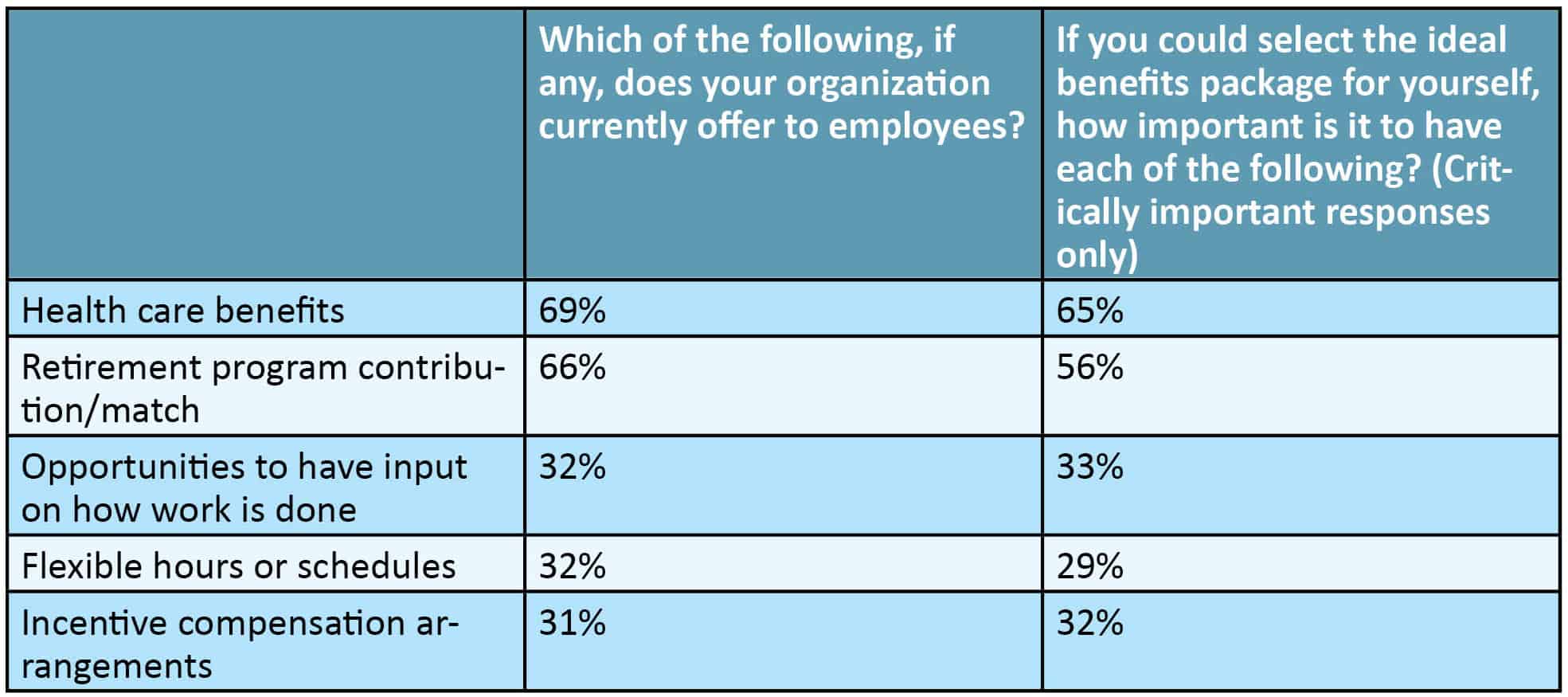

Compensation, health care and retirement perks are typically the top priorities of what employees want most from their employers, regardless of industry. But data from the Big Village and RSM survey shows how manufacturing sector respondents value the benefits their organization currently offers, compared to the importance of various benefits if respondents could create their ideal benefits package.

For instance, 29% of manufacturing sector respondents said above-market compensation would be critically important in their ideal benefits package, but only 13% of respondents said their employer offered such compensation. (The online survey was conducted among a sample of adults ages 18 and older in the United States who reported having at least one job.)

In numerous categories, the number of respondents who said their organization currently offered a given benefit was comparable with the number who said that benefit would be part of their ideal compensation package (Figure 1).

Figure 1: Manufacturing Sector Respondent Answers, RSM US Survey

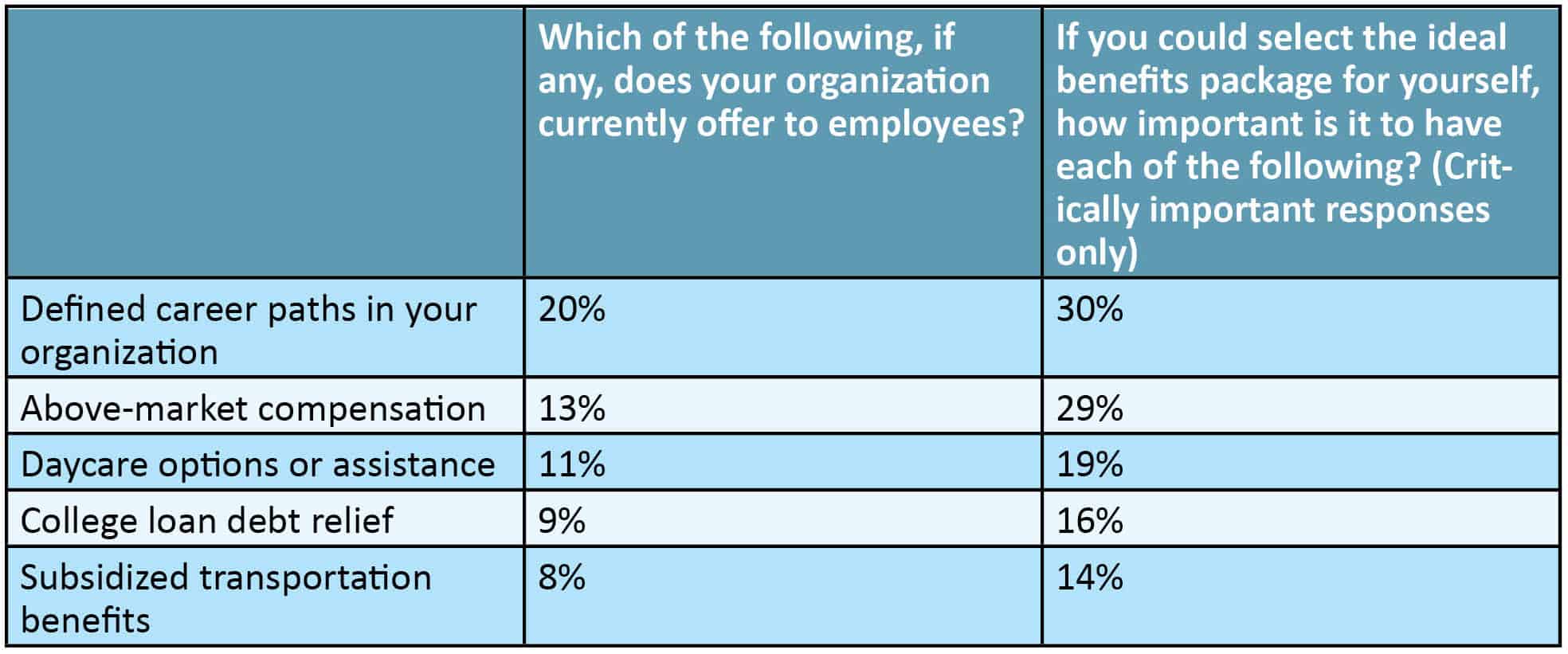

For some categories, though, the gap between what the employer currently offered and what would be in the ideal benefits package was wider (Figure 2).

Figure 2: Manufacturing Sector Respondent Answers, RSM US Survey

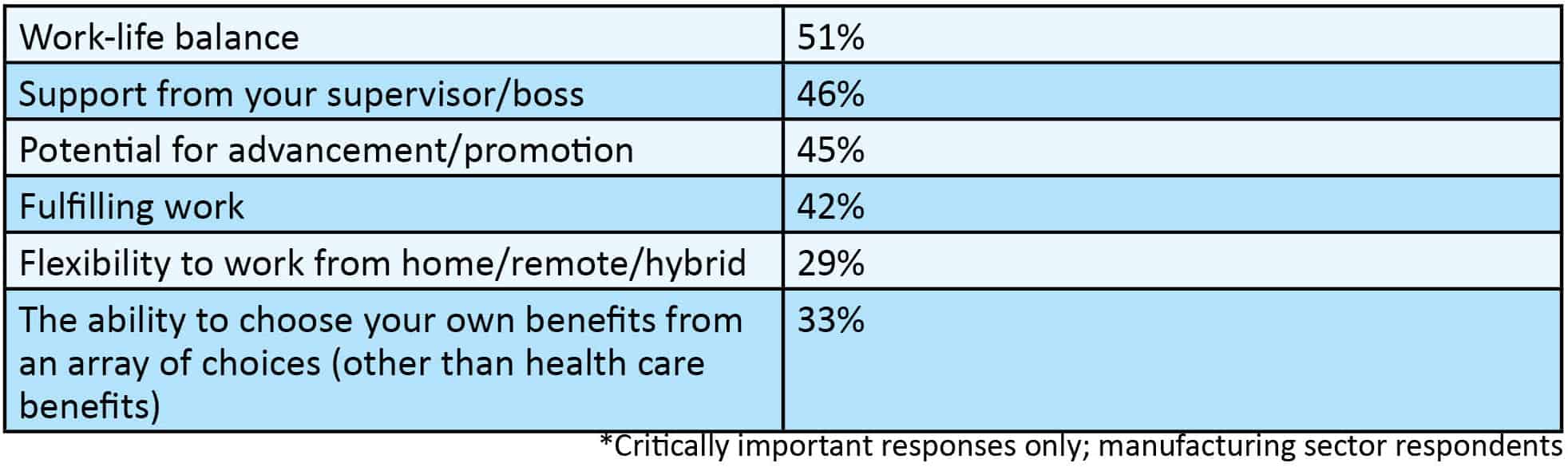

Along with competitive compensation packages, the data seems to indicate that giving employees a clear framework for defining their career paths could be one area ripe for improvement. Responses to other parts of the survey underscore this further; manufacturing sector respondents said that if they could have the ideal job, the three most important factors would be work-life balance, support from their supervisor/boss, and the potential for advancement/promotion (Figure 3).

Figure 3: If you could have the ideal job, how important of a role would each of the following play?*

For an accurate assessment of employee priorities and desires, manufacturers might consider conducting a similar survey among their teams. Leadership teams can then use the resulting data to develop or adjust employee compensation and benefits packages, rather than guess what workers want.

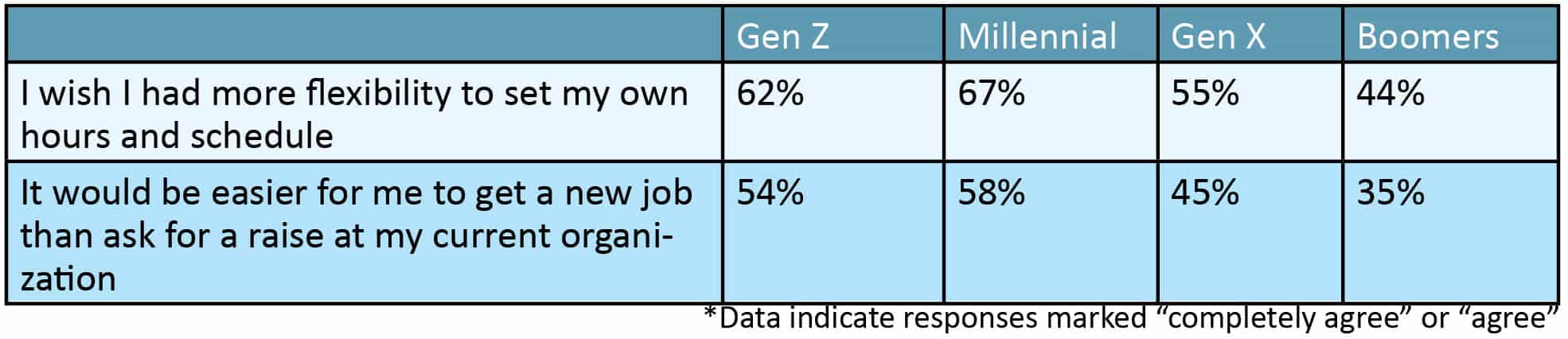

Generational Shifts

Understanding millennial and Gen Z perspectives on their jobs and employers will also become increasingly important as the presence of those cohorts rises in the labor force. Among all respondents — including those in the consumer products, technology, business and professional services, construction, financial services, and other sectors — significantly more members of the Gen Z and millennial cohorts wanted flexibility compared to their older counterparts.

Figure 4: To what extent do you agree with the following statements?*

Millennials were also significantly more likely than others to report:

- They would recommend their current organization to a friend (52% vs. 37% Gen Z, 43% Gen X, 37% boomers)

- Employee recognition programs are a critical benefit (32% vs. 24% Gen Z, 25% Gen X, 13% boomers)

- Consistent feedback on their performance is critical (36% vs. 27% Gen Z, 26% Gen X, 16% boomers)

- Collaboration with co-workers is critical (39% vs, 30% Gen Z, 28% Gen X, 21% boomers)

- Gen Z and millennials are significantly more likely than Gen X and boomers to report that they were actively applying for a new job/role, with 24% of Gen Z respondents, 30% of millennials, 14% of Gen X respondents and 6% of respondents in the baby boomer generation.

Those figures—even though they are respondents from all industries, not just manufacturing—should make clear just how important retention efforts are for any business.

Workforce Ownership in the Factory of the Future

Manufacturers need to respond to what workers want and give them a clear path for success if they aim to build a workforce that has longevity and adaptability for the future. Here are some of the most important areas we believe companies should zero in on:

- Flexibility: The pandemic may have thrust flexibility into the spotlight, but it is now table stakes for manufacturers that want to draw top talent. Flexibility isn’t just about remote work or adjustable schedules; workers also want to have the ability to navigate childcare and other obligations of daily life in a way that meshes well with their job. Manufacturers should assess where they may be able to improve options for workplace flexibility, for both factory floor and white-collar workers.

“Manufacturing sector respondents said the three most important factors in an ideal job would be work-life balance, support from their supervisor/boss, and the potential for advancement/promotion.”

- Compensation: Salary or wage considerations have always been one of the most important considerations for workers seeking employment, but two factors in particular right now require companies to provide competitive pay; inflation putting stress on consumer wallets and the manufacturing sector competing more and more with other industries (such as technology) for talent. Leadership teams should review compensation packages and adjust to align with the market and competitors.

- Career path: Employees do not want to remain stagnant in any position, and our survey results above indicate the importance of organizations offering employees defined career paths. For manufacturers, this might include intentional digital skills development, clear frameworks for improvement, continuing education to understand the implications of the factories of the future, and mentorship programs. Manufacturing companies should help employees chart their future within the organization based on their goals and talents.

Perhaps one of the clearest takeaways from the workforce shifts of the last three years is that employees want opportunities to be heard, and for their employers to take their feedback into consideration. Manufacturers that take a strategic approach to gathering and addressing employee feedback will have a competitive edge as the sector continues to evolve. M

Survey Methodology

The online CARAVAN® survey was conducted by Big Village among a sample of 2,017 U.S. adults ages 18 and older who are employed. Of these, 175 reported working in the manufacturing sector. Data collection occurred from Sept. 23 through Oct. 6, 2022.

About the authors:

Marni Rozen is a management consulting director at RSM US LLP.

Jason Alexander is a partner and national manufacturing sector leader at RSM US LLP.

Welcome New Members of the MLC June 2023

Introducing the latest new members to the Manufacturing Leadership Council.

Introducing the latest new members to the Manufacturing Leadership Council.

Anupam (Anu) Khare

Global Chief Information and Digital Officer

Oshkosh Corporation

![]()

www.oshkoshcorp.com

![]()

www.linkedin.com/in/anupamkhare/

Kevin Goering

Partner, North American Manufacturing Lead

McKinsey & Co.

www.mckinsey.com

![]()

www.linkedin.com/in/kevin-goering/

Holly Becker

Director, Commercialization

ATS Global

www.ats-global.com

![]()

www.linkedin.com/in/holly-elyse/

Frank Hopkins

Project Manager

Faith Technologies

www.faithtechnologies.com

![]()

www.linkedin.com/in/frank-hopkins-01625490/

Suresh Palanisamy

Professor and Director, Manufacturing Futures Research Platform

Swinburne University of Technology

www.swinburne.edu.au

![]()

www.linkedin.com/in/suresh-palanisamy-6b4a3250/?originalSubdomain=au

Ergun Hepvar

Director, Corporate Innovation

International Paper

www.ip.com

![]()

https://www.linkedin.com/in/ergun-hepvar-0a447a/

Fernando Garcia

Director, Sales

Ubisense

![]()

https://ubisense.com/

![]()

https://www.linkedin.com/in/fernando-a-garcia-74581612/

MLC Members can view the full MLC Member Directory here.

How ALOM Triumphs in a Tight Labor Market

How can manufacturers recruit and retain employees amid a skills gap that leaves hundreds of thousands of manufacturing jobs unfilled every month? ALOM Technologies Corporation—a global supply chain management services and solutions provider based in Fremont, California—has an answer: focus aggressively on company culture.

The results are in and ALOM’s program is a remarkable success, leading to workforce and revenue growth for the company over the past few years. This achievement led ALOM to be named a finalist for the Manufacturing Leadership Awards, given every year by the Manufacturing Leadership Council (the NAM’s digital transformation division). Here’s a sneak peek into how they did it.

The program: After being named an essential business in 2020 due to its medical supply chain infrastructure, ALOM turbocharged its existing culture program, called DOING—which stands for Development, Opportunity, INclusion and Growth—to support staff recruitment and retention in a challenging labor market.

- The program had existed since 2018 and was based on ALOM’s longstanding cultivation of values-driven purpose. When the company expanded it during the pandemic, it enabled ALOM to build a higher performing team across multiple locations.

The details: ALOM has employed several strategies for reinforcing its cultural values, aiming to instill a sense of purpose and belonging in job candidates and veteran staff alike. These include:

- Showcasing their commitment to diversity, inclusion and sustainability both inside the organization and in recruitment efforts;

- Redefining the ALOM People Team mission and structure to emphasize staff development over compliance;

- Working to address employee wellness through stress and mental health education and resources; and

- Instituting a staff development online portal called ALOM University that empowers rapid onboarding, training and advancement.

The results: The program has been an extraordinary success, helping to increase ALOM’s workforce and strengthen the company’s bottom line at the same time. In 2021 alone, the company achieved:

- 70% workforce growth;

- 60% revenue growth;

- A 6% decrease in employee attrition for 2021, as compared to 2018; and

- A 65% reduction in recruitment days to fill open positions.

Looking ahead: ALOM isn’t done yet. This year, the company is working on a digital transformation effort, called DOING DX, designed to make all of ALOM’s tech systems and business processes more efficient and effective.

- It will focus on staff recruiting, performance management, supplier management and evaluation, team building, mentoring and much more.

The last word: “When I started ALOM 26 years ago, I was determined to build a supply chain company that did right by everyone,” said President and CEO Hannah Kain.

- “This has become the foundation of ALOM’s corporate culture. We believe in using the supply chain to help the world be a better place—for the environment and for every person, supplier and company. Experiencing our values in action instills a sense of pride and belonging in our staff that helps us attract, build and retain an exceptionally talented team.”

Get involved: Want to learn more about this successful workforce effort, as well as a whole host of other innovations by leading manufacturers? Join the MLC for its Rethink summit in Marco Island, Florida, on June 26–28. Sign up here.

At Hershey, a Sweet History and Saltier Future Powered by Digital

From its namesake chocolate bars to the immensely popular Reese’s Cups, The Hershey Company has been a maker of beloved confections for many decades. But no matter which variety is your personal favorite, Hershey’s powerhouse combination of manufacturing, fulfillment and distribution keeps those famous brands coming to store shelves and to the consumers who love them, generation after generation.

Nearly 100 Manufacturing Leadership Council members took part in a tour encompassing two Hershey facilities: the West Hershey plant in Hershey, Pa., and their nearby Annville Fulfillment Center in Annville, Pa., which is also Hershey’s first fully digital facility.

As a $10 billion publicly traded company, Hershey is perhaps most famous for its chocolate brands and other confections, but it also has expansion goals to evolve into a leading snacking powerhouse. To that end, it has acquired several brands of salty snacks, including Skinny Pop Popcorn, Pirate’s Booty puffs and straws, and Dot’s Pretzels. Its nearly 4,000 SKU brand portfolio is carried out through 21 plants (14 in the United States, seven internationally), roughly 950 global ingredient and packaging suppliers, 60 contract manufacturing and contract packaging partners, 34 distribution centers, and 143 freight carriers.

One thing that leadership emphasized on the tour was Hershey’s move from “best in cost” to “best in class.” Fulfilling Hershey’s vision as a snacking powerhouse means focusing on people-first manufacturing, which includes skill development, career advancement and teambuilding; innovating through technology, including through its digital factory strategy; and a focus on reliability. But in addition to its future aspirations, Hershey also needed to respond to evolving market and operational conditions – the company saw more volume growth during the pandemic, but retirements meant that its mean labor tenure decreased significantly, while lead times for packaging and capital equipment lengthened. Those shifts means that the company was left with a need to respond faster.

Investment in transformation capabilities has been essential. The company has moved away from conventional lines with single-purpose assets and focused SKU portfolios with complex line changeover requirements to advanced technology lines that can handle diverse SKUs with faster cleaning and changeover capabilities. Overall, Hershey’s digital factory strategy is focused on four areas: data capture and analysis to facilitate rapid problem identification and resolution; physical automation; a digital backbone (encompassing universal data architecture), and digital quality to bring forth a paperless shop floor. The company performs mass customization at scale through robotics and digital integration.

During the visit to the West Hershey production plant, which originally opened in 1990, attendees got an inside look at some of the production lines in the world’s largest and most technologically advanced chocolate manufacturing plant (750,000 square feet). It takes 26,000 cows to supply the milk needed to produce the Hershey’s Kisses (70 million a day), chocolate bars and syrup made here – one million pounds each of milk chocolate and Hershey’s Syrup each day. There is no storage for intermediaries at this facility – as soon as products are made, they are put onto a truck.