Dotson Iron Castings’ Story of Survival and Advancement

When a company traces its history back nearly 150 years, its story is likely one of continuous change and evolution. For Dotson Iron Castings of Mankato, Minn., it is also a story of survival, innovation and respect for people.

During the Manufacturing Leadership Council’s recent plant tour, Dotson’s leaders shared elements of this story and gave visitors a firsthand look at its production practices and culture.

Overcoming Obstacles

With its roots dating back to a blacksmith shop founded in 1876, Dotson Iron Castings has persevered through early product failures, a 1937 bankruptcy, the 1980s recession, a 2017 fire, and the COVID-19 pandemic, and emerged stronger due in part to the company’s leadership, people and culture.

With its roots dating back to a blacksmith shop founded in 1876, Dotson Iron Castings has persevered through early product failures, a 1937 bankruptcy, the 1980s recession, a 2017 fire, and the COVID-19 pandemic, and emerged stronger due in part to the company’s leadership, people and culture.

In its early history, the company offered diversified products including an automobile, a tractor and its best-seller, the Little Giant Trip Hammer. The company also dealt in brass, aluminum, and steel. Since 1983, the 125,000 square foot foundry has focused solely on ductile iron primarily for the industrial, agriculture, and truck industry segments. By focusing on this single product, Dotson has become an iron casting and Manufacturing 4.0 leader.

Innovating for the Future

As the company has evolved, its leadership and employees have created a culture that respects people and encourages innovation. The company’s Manufacturing 4.0 journey has seen Dotson implement data generation and collection systems including a FARO Quantum Scan Arm that takes 3D measurements to inspect product quality. Other innovations showcased during the MLC tour include machine monitoring data, automated charging in the melt process and automatic mold pouring.

On the sustainability front, the company continues to find new ways to reuse energy and materials. It takes a tremendous amount of energy to reach iron’s 2700 degrees Fahrenheit (1482° C) melting point, which in turn creates heat energy that Dotson captures and uses to heat its facility in winter months, including an in-ground heating system to keep its loading dock area free from ice and snow – both common for Minnesota. The company reuses excess iron that is removed from castings in the finishing process and also reclaims the sand used in its molds, eliminating almost 70% of the non-recyclable waste leaving its facility.

Recognizing an Iron-Willed Team

When an electrical contractor caused a fire that destroyed all the company’s molding lines in 2017, it took Dotson six weeks to rebuild its operation. Rather than send workers home, company leaders kept its frontline workers employed in the cleanup process or by sending them out into Mankato to complete community service work.

When an electrical contractor caused a fire that destroyed all the company’s molding lines in 2017, it took Dotson six weeks to rebuild its operation. Rather than send workers home, company leaders kept its frontline workers employed in the cleanup process or by sending them out into Mankato to complete community service work.

After rebuilding and reopening the foundry, the company’s then-owners, Denny Dotson and Jean Bye, envisioned and built a new worker-focused space with showers, changing areas, lockers, upgraded break areas including an outdoor terrace, and a more welcoming reception area. The company calls this new space the “Club House,” and it serves as a further indication of the company’s commitment to its people.

More than Just a Tour

For MLC’s plant tour participants, the visit to Dotson Iron Castings included more than just a tour of the foundry and Club House. Visitors had the opportunity to network with fellow Manufacturing 4.0 professionals, participate in one of three breakout sessions, and ask questions both during the tour and a capstone panel discussion.

The breakout sessions dove deep into key topics facing both Dotson and participants alike: IT/OT Convergence, Energy Efficiency in an Energy Intensive Industry, and The Employee Center and Next Generation Workforce Influence. Dotson’s leadership team shared its experiences and answered questions, shedding light on the company’s continuing evolution.

The breakout sessions dove deep into key topics facing both Dotson and participants alike: IT/OT Convergence, Energy Efficiency in an Energy Intensive Industry, and The Employee Center and Next Generation Workforce Influence. Dotson’s leadership team shared its experiences and answered questions, shedding light on the company’s continuing evolution.

The event culminated with a wide-ranging panel discussion featuring nine representatives of the host company. The panelists fielded audience questions about workforce turnover, technology innovation, and how the company has perpetually overcome challenges.

The Dotson Iron Castings tour showcased how the company – forged in fire – has equipped its employees with the right technologies and created a culture that is poised to build on its 147-year history.

All photos courtesy Dotson Iron Castings

The Surprising Keys to Manufacturing Digital Transformation

From IT and HR to finance and leadership, the keys to successful digital transformation lie in a cross-functional approach

Few would argue that automation and digital transformation (DT) are not critical to the future of industrial automation. According to Gartner, 80% of manufacturing CEOs are increasing investments in digital technologies — led by artificial intelligence (AI), Internet of Things (IoT), and data and analytics — to counter economic pressures and to drive growth and profitability. Meanwhile, a 2023 MLC survey of manufacturing leaders indicates that 85% see an increase or no change to their companies’ Manufacturing 4.0 investment despite economic concerns.

And yet Gartner reports only 8% of industrial organizations say their DT initiatives are successful.

Eight percent?

It is a dismal number. Why so few?

It is tempting to pin the blame on technology snags. But technology is rarely the issue. Most organizations nowadays are engineering-led. They tend to jump on new technology right away. It’s cool and fun, and the solutions typically are readily available in the market.

Digital transformation initiatives in manufacturing fail because of organizational readiness. Or more specifically, the lack thereof.

To be clear, both organizational readiness and technical readiness are critical. But companies are generally better off when it comes to technical readiness due to the aforementioned reasons, and because they have a history of technology investments and the requisite skilled workers. With that as a backdrop, we advise industrial manufacturers to adhere to the following best practices when implementing digital transformation initiatives, with a particular emphasis on managing various organizational readiness issues, which span from the cultural to the financial.

Digital transformations should be cross-functional — but led by manufacturing operations

Digital transformation teams should be cross-functional, with representation from manufacturing, engineering, supply chain, and material operations. But cross-functional DT teams should be led by manufacturing operations. Why? Because manufacturing ops understands the floor — specifically, the problems on the floor and how to drive value.

IT is partner #1

Manufacturing operations and IT have to work hand-in-hand, with IT responsible for reliability, security and data — the latter of which is obviously the fuel for data-driven manufacturing. There are several best-practices specifically when it comes to the data.

- Data must be centralized so that the entire organization is working off of one source of truth.

- Data should be collected according to the problem you are trying to solve. Data isn’t free, so you do not need to collect it all. Start with the problem on the manufacturing floor, and let that dictate the data you collect.

- Data should be driven down to the appropriate people to make the appropriate decisions. Think through any data user — operator, team leader, quality leader, maintenance leader — and their standardized work. Then design your system to get the correct data in their hands for their jobs. (We will come back to some of the implications of getting this wrong.)

Don’t forget HR

HR support is critical in a few regards. First, HR can lead on the critical task of bridging the gap between newer, younger employees and older employees. Our workforce is transitioning and changing, and we are getting many new employees who have a great understanding of the technology and who bring new ways of thinking. At the same time, we have our older workers – I often refer to them as our “oak trees.” They really know how the floor runs and how it operates. Companies need both, and both can learn and benefit from each other.

HR’s other critical role is bringing team leaders and operators on the floor along on the journey. People will have concerns with any DT initiative. Will I get left behind? Is this going to replace me? Is Big Brother watching me? From day one, companies need to engage the floor — operators, team leaders, quality operators, maintenance operators — and make sure that they understand why the company is bringing technology in, the purpose, and how it is ultimately going to make their lives better and their jobs easier.

Be realistic about finances

Digital transformations are often under-capitalized. Ongoing costs are overlooked. Companies need to carefully account for expenses like ongoing maintenance costs, integration work, data collection and potential downtime. Many of these add-on costs aren’t properly captured in the budgeting process and later bite companies during implementation.

Leadership must protect the culture and drive decentralized data-driven decision-making

Leaders must embrace the transformation and ensure that digitization doesn’t degrade or destroy company culture.

First, leaders should never allow “data hoarding” at the top of the company, falling into the trap of thinking, Now I can solve all of these problems myself. Empower the right people with the right data to do their jobs. Problem-solving and continuous improvement should advance as long as data is being drive down to the right level of the organization.

Second, leaders must bring the operator along on the journey so they understand why the organization is making changes. This is similar to HR’s role mentioned above, but the questions that leaders answer are different. Why a wearable? How are these changes going to make me more effective and my job better? Leaders must not only manage the change — they have to inspire the workforce in the process.

Ultimately, company leaders should ask themselves, How do I make sure that we stay true to the philosophies that we learned from the Toyota Way — Kaizen and Genchi and Genbutsu … teamwork, respect and challenge? Culturally, nothing really has to change in the digitized world. The key is staying true to the philosophy of operator and team leader first, while driving data-driven decision-making throughout the organization.

About J.R. Automation

JR Automation, a Hitachi Group Company, partners with industrial manufacturers all over the world to design, build, and integrate advanced automation solutions — from assembly automation, dispensing, and vision systems to process design, controls engineering, and software integrations. We have built custom technology solutions for every application, process and industry, and helped ensure our customers were organizationally ready for the change.

About the Author:

Mike Lashbrook is Vice President Digital Solutions and Senior Vice President, M&A Connected Industry, JR Automation, a Hitachi Group Company.

Manufacturing Leadership Awards Kick Off 20th Season

For two decades, the Manufacturing Leadership Awards have recognized outstanding manufacturing companies and their leaders for their groundbreaking use of advanced manufacturing technology. What started out in 2005 as a modest 50-person gathering in New Orleans has evolved into one of the industry’s most exciting celebrations.

This past June, the Manufacturing Leadership Awards Gala honored an impressive 163 projects and leaders, in front of an electrified crowd of 450 guests. The program’s growth is a testament to the momentum of Manufacturing 4.0 technologies and their success in creating performance improvements and boosting competitiveness.

With more manufacturers adopting digital and data-driven methods every day, there is still much to celebrate. The program’s 20th season is now open for nominations, with expectations running high for another amazing show in 2024.

A proud heritage: Past winners from the Manufacturing Leadership Awards include companies and leaders from nearly every industry, from 10-person shops to multinational enterprises, located all around the world.

- Each entry is reviewed by a judging panel made up of industry experts with extensive experience in technology transformation. The top-scoring projects are selected as category finalists, and the category winners are revealed at the awards gala.

- Finalists and winners report that the awards have helped them gain new customers, boosted employee morale and team camaraderie and encouraged their executive leadership to continue investing in digital technology initiatives.

- Since the program’s inception, more than 1,000 leaders and projects have been honored for their achievements.

A wide range of candidates: The awards program welcomes submissions from small and medium-sized enterprises, as judges look for the overall level of impact that projects have had on a company’s operations—not the dollar amount of their investments.

- If technology has measurably helped a company improve its operational performance, upskill employees or enter new business markets, those projects are excellent candidates for award nominations.

The categories: Over the years, the awards have encompassed an evolving list of categories, currently at nine for projects and two for individuals.

- Project categories include AI and Machine Learning, Collaborative Ecosystems, Digital Network Connectivity, Digital Supply Chains, Engineering and Production Leadership, Enterprise Integration and Technology, Operational Excellence, Sustainability and the Circular Economy, and Transformational Business Cultures.

- Individual categories include Digital Transformation Leadership, for established manufacturing operations executives who lead Manufacturing 4.0 initiatives, and Next-Generation Leadership, for up-and-coming operations leaders aged 30 or younger.

Get involved: All manufacturers in any location and of any organizational size are eligible and encouraged to apply. Program details, rules and instructions for how to submit a nomination are available on the MLC website. Entries are due Jan. 17, 2024.

Getting Tech Investments to Stick and Deliver ROI

Four fundamentals for realizing maximum potential and business value from technology investments

TAKEAWAYS:

● Despite economic challenges, global digital transformation spending is set to soar by 2026, emphasizing its resilience-building role and response to workforce issues.

● Manufacturers aim to enhance digital maturity by 2030, with 91% planning higher tech spending, including a 20% focus on AI.

● Extracting tech value remains tough, with limited focus on business cases. Max ROI needs strategy, proof, execution, and staff engagement.

Despite continuing economic concerns, the pace of digital transformation is not slowing. By one projection, global spending on digital transformation is projected to reach $3.4 trillion by 2026 — representing a 57% increase from 2023. Transformation is key to building agility and maintaining growth amid challenges such as a shrinking labor force.

Most manufacturers view themselves in the middle in terms of digital maturity. But by 2030, they expect digital operations to deliver tangible benefits in the form of speed and flexibility, customer satisfaction, and financial returns.

To support their digital aspirations, manufacturers expect to increase technology investment relative to current levels. In research for the Manufacturing in 2030 Project, 91% of organizations said they expect to increase spending on technology — 29% expect increases to be “significant.” Moreover, 20% expect investments in artificial intelligence (AI) to increase by at least 50%.

Expectations for return on investments are high. But in the Manufacturing Leadership Council’s 2023 Digital Leadership Survey, one finding stood out: There is relatively little focus on the value derived from technology. Only 16% said their executive management team wants to know the business case for and payback from digital transformation, and only 14% said management wants to know which digital use cases will drive the most value for the investment.

If manufacturers are to get maximum value from their technology investments — including forays into AI and other emerging digital capabilities — they must be laser-focused on value and their approach to delivering it.

Why manufacturers have struggled to derive value from technology

It is hard to fault those who are struggling to maintain the trajectory of digital transformation amid a procession of major — if not generational — macroeconomic challenges. These issues of the moment are critical and have commanded attention. That said, short-term focus often creates a fragmented approach to longer-term strategy. And present cost-containment imperatives run the risk of derailing critical projects — particularly those in early stages that have not yet produced a return on investment. When the markets rebound and attention shifts from cost to growth, manufacturers that have paused or cut critical projects will be behind.

Continuously evolving technology trends can also cause transformation to stray from “the plan.” There is perhaps no better example of this than the recent surge in interest around generative AI and its potential to assist with challenges such as worker shortages and the need to do more with less. The fact is, this technology does not necessarily have immediate impact potential for all manufacturers, but many have probably shifted resources away from critical initiatives to explore it.

“When the markets rebound and attention shifts from cost to growth, manufacturers that have paused or cut critical projects will be behind”

Risk aversion is another big factor — most notably, cyber concerns that have impeded the full convergence of information technology and operational technology (IT/OT) necessary to create insights for the digital factory. Additionally, IT/OT integration requires effective collaboration with the IT function, which historically has focused on managing spend and securing data. This doesn’t always create a return on investment, and in some cases works against it.

Finally, many manufacturers have struggled to scale up new technology initiatives. The World Economic Forum’s Global Lighthouse Network recently looked at this issue. More than two-thirds (70%) of manufacturing companies worldwide are currently stuck in pilot mode when it comes to digital transformation projects. It is hard to maximize value from technology when it is only used on a small scale.

How to maximize the potential and business value of technology

Value does not come through technology alone. It is the product of the organization’s approach to investing in it and capabilities for deploying it. Here are four fundamentals that are at the center of maximizing potential and return on investment.

1. Determine the projects that are foundational enablers – and do not let them get derailed by short-term thinking

There is a tendency to look at every project as a discrete investment and try to prove the return. When it comes to evolving technologies in manufacturing, there are many interrelationships. Some technology investments are “nice-to-haves” when you look at them alone, but they are “need-to-haves” when it comes to the bigger picture. It may be hard to calculate a direct return on investment because their real value comes through their enablement of other capabilities.

A good example is master data management. A project to clean up and restructure data does not necessarily produce a return on investment. Alone, it looks like just another cost. But it is a necessary step for building analytics that will help your organization identify problems, increase reporting accuracy/timeliness, or even enable advanced strategies such as data monetization. It is beneficial to couple projects or investments in a way that makes it easier to understand the impact and justify the investment.

This is why technology transformation requires long-term vision and the ability to move toward it with pace. Having a macro, multi-year picture that shows how discrete projects connect, and which ones are vital to building the foundation that enables long-term value creation.

“Some technology investments are ‘nice-to-haves’ when you look at them alone, but they are ‘need-to-haves’ when it comes to the bigger picture”

This long-term perspective is particularly critical in the current economic environment – with the temptation to cut budgets or delay spending in the interest of cost containment. When it comes to these foundational enablers, be thoughtful in asking and answering the question: If we cut or delay investments now, what happens to processes and plans down the road? Many times, we have seen scenarios where it costs more to fix things later, or to accelerate stalled capabilities. Furthermore, short-term thinking in order to balance cost, timeline, and ROI today may exclude future options and inadvertently paint the organization into a corner later.

2. Identify the right investment opportunities — and use data to build conviction in their materiality by demonstrating the ROI

Beyond the foundational enablers, technology decisions and investments should always be grounded in business strategy and the imperatives that are driving the need for change and new technology — whether that is reducing cost, making more product, increasing sales, improving response time, or eliminating defects.

Evaluating and prioritizing opportunities should involve a value identification exercise that:

- Identifies current issues and diagnoses the causes

- Explores how technology can solve issues and create new value

- Establishes a baseline that allows you to measure future impact and value creation

- Defines your method for measuring impact on the P&L statement; anyone can pick metrics, but metrics don’t always measure return on investment

Many manufacturers struggle with the ROI part — specifically, demonstrating technology’s projected ROI to secure approval for investment. For one thing, it is not uncommon for the value or return from new technology to lag. Consider the generative AI example: Maximizing value from this capability requires time to build up the skills, the tools, and the capabilities for the payoff to really materialize.

Demonstrating ROI also requires being able to bridge the gap between the art of the possible and the realities of today. Data is key. You must be able to analyze data to translate potential into quantifiable operational and financial outcomes. Ideally, this analysis should use your own operational data rather than simply market benchmarks, which lack consistency in calculation and do not account for unique aspects of your business.

“If you are piloting a digital solution on one line or in a lighthouse facility, design it in a way that makes it simple to deploy to the rest of your operation and start planning for expansion to other lines or facilities”

This is a critical step, and there is a tendency to try to address it internally. For many, it is a matter of cost. Keep in mind that this is new territory for many in manufacturing, so consider carefully whether you can do it effectively on your own or consider external expertise. Some questions to ask include: How mature are our data and analytics capabilities? Do we have the bandwidth or expertise internally? How quickly can we get it done versus having an external resource?

3. Bridge the gap between strategy and execution

Even if a company can effectively identify value potential, delivering it is another matter. The 2023 Digital Leadership survey revealed measured anxiety about organizational vulnerability due to current levels of preparedness. More than one-half of respondents (59%) consider their organization to be moderately vulnerable. One statistic was telling: 33% believe their executive management team is not at all prepared to lead and manage digital transformation. This was up from 10% in the 2022 survey.

Improving execution requires several factors:

- An effective management system and structure to guide progress

- Clear execution plans with clear definitions of responsibility

- Tracking to capture progress, assess value, and inform timely adjustments based on what is and is not working

In particular, an effective management system facilitates execution by integrating people across functions, establishing proper controls within processes, and providing structure and oversight for developing the right capabilities. This system also plays a critical role in fostering positive behaviors such as a bias for action, sense of accountability, willingness to challenge the status quo, reliance on data, and others.

For manufacturers, one big execution opportunity is improving the ability to scale successful pilots. There are many ways to do so. If you are piloting a digital solution on one line or in a lighthouse facility to see how it works and assess return, design it in a way that makes it simple to deploy to the rest of your operation and start planning for expansion to other lines or facilities. In addition, look for additional applications for technologies in which you have invested, such as your IIoT or cloud platform, FactoryTalk, AWS SiteWise, or others. Since digital operations produce data and data enables insight, look at the insight you are deriving from implementing digital technologies and ask, “What else could we learn with additional analysis?” Always be looking to learn and grow.

4. Bring your people along

A big element in bridging the strategy-execution gap is people. This deserves its own point. Wherever you are on your digital journey, do not underestimate the need to bring people along.

Giving people digital tools and systems enables them to look at information and make good, timely decisions. But you must engage leaders, employees, and teams in the process — rather than just handing off new technology — so they understand how and why to use it. Without that knowledge, they will not own or embrace technology, and you will miss out on additional innovations that they can bring as users of the technology. That is how value is created and grows.

“You must engage leaders, employees, and teams in the process — rather than just handing off new technology — so they understand how and why to use it”

Dedicated attention to this not only creates enterprise value, but also career potential and longevity for employees and aids in addressing one of manufacturing’s biggest challenges: retention.

This is a big opportunity many companies are missing. The digital journey must have a change management strategy and plan. Yet 60% of manufacturers do not have a change management strategy to support their digital strategy.

An adequate training/learning approach is also critical. Manufacturers cannot fall back on traditional “blanket” training formats. Instead, look to techniques that really imbed knowledge and understanding such as personalized coaching plans or instructions and help screens built into the tools for reference when employees need it most.

The real value comes with the right approach to deployment

Value realization is about more than the technology itself. In fact, the four fundamentals described above really have little to do with technological features and functions at all. Establishing them requires effort, and some of it is hard — and often unfamiliar — work for manufacturers. But do these well, and you will see exponential growth in the business value and potential from your technology investments. M

About the Authors:

Randal Kenworthy is Senior Partner, Consumer and Industrial Products, West Monroe

Kris Slozak is a Director, Consumer & Industrial Products, West Monroe

M2030 Perspective: FOMO Can Spark Next Digital Revolution

What the past tells us about an AI and ML enriched future

TAKEAWAYS:

● Manufacturers can leverage AI/ML strategies to overcome the prohibitive cost related to data-driven decision-making.

● AI and ML are business investments not technology investments.

● In the future, AI will drive people, process and technology changes that deliver manufacturing ROI.

Past is prologue when it comes to AI

More than two and a half decades ago the world was in a state of panic and desperation over technology. The situation was simple: business solutions that ran supply chain, financial, and payroll systems – to name a few – could have a basic flaw in how dates were stored, and on January 1, 2000, they could simply stop working and business would stop working. The Y2K problem led to a massive investment in IT spending, turbo charging the technology capabilities that brought about the recent advancements in artificial intelligence and machine learning (AI/ML).

Then as it is now, we have a disruptive concept that threatens to upend business as usual, and executives can no longer avoid the hard discussions on how to prioritize technology investments. Then as it is now, we have a juxtaposition of business and technology interests intersecting a common goal of relevance and sustainability. The difference is that with artificial intelligence the fear of missing out is driven by excitement and opportunity.

“The difference between artificial intelligence and the Y2K problem is that with AI the fear of missing out is driven by excitement and opportunity”

The concept of data-driven decision-making, which is the basis of leveraging AI/ML in manufacturing, is not new but it has been relatively unattainable due to costs. Manufacturing is a people-driven enterprise that needs to maximize efficiencies to keep costs down and react to customer demands. The challenge is how to balance business operations with the disruption in leveraging new systems and process, balancing the potential skill gaps in using automated systems, and driving towards measurable business outcomes. As we move toward the year 2030, AI/ML can be the unifier of all those goals if manufacturers can map executive goals and business outcomes to people, process, and technology.

People power to drive top-down transformation

With the popularity of topics around generative AI and ability to access technology infrastructure for various back-office automation tasks there is urgency to innovate to stay ahead. The change that occurred since last year is driven by awareness, access, and actionable insights in the manufacturing space driving pragmatic business innovations. Executives have greater awareness of how to leverage AI/ML in business operations and are empowering their teams to invest in digital strategies around automation and efficiency. IT and business leaders within organizations are finding common cause in terms of goals for improving supply chains, understanding customer behavior, improving product quality, and investing in sustainable practices. The general concerns and narrative that AI may replace people is shifting to how AI is helping teach the workforce and automate complex production processes. While common misconceptions around AI sophistication and the practicality of certain use cases still exist, the urgency of change is overcoming the stagnant comfort of the predictable. As we move towards 2030, we will see more broad adoption of these technologies to work side-by-side and seamlessly in performing business actions severely reducing manual repetitive tasks.

Pragmatic solutions to drive maximum ROI

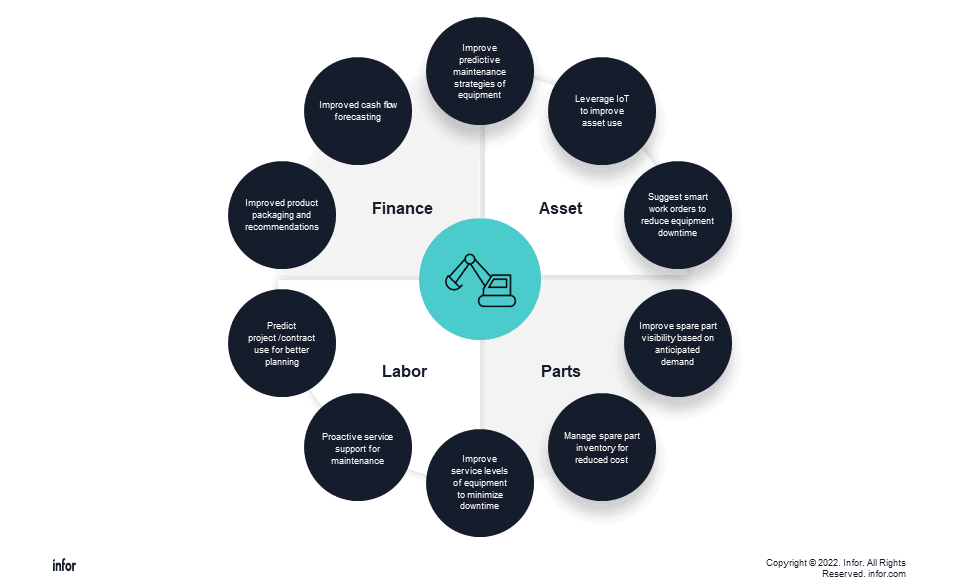

Concepts like Industry 4.0 drive business goals towards automated dark factories heavily leveraging IoT sensors that constantly improving plant output. Looking beyond factory operations, AI/ML solutions can optimize entire value chains as illustrated in a sample view of an equipment as a service manufacturer/distributer.

Figure 1: Leverage AI/ML solutions to drive enterprise value in manufacturing and after-market service.

The benefits earned from leveraging AI/ML solutions to track asset management and performance, labor, and financial planning are an example of data-driven decision-making and leveraging “one version of the truth” in business operations with clear ROI.

Considering these use cases can be setup very quickly and incrementally, they can drive manufacturers’ changes and urgency to adopt measurable business innovations.

Investment in business versus technology

Manufactures, like other businesses, are loathe to spend money on IT for the sake of re-platforming the business. Perception of IT spending as a costly task changes significantly with AI/ML-powered solutions.

The target goals for these solutions are business productivity, plant scrap reduction, financial visibility, and improved revenue, which are markedly more impactful than purchasing a new business application. Other tangible business applications are better customer and employee experience driven by personalized and contextual actions. The implicit benefits of cloud-based architecture and improved cyber security are attractive but not as much compared to improved margins and responsive business operations. Focusing on technology as a means for better business results is a big difference in driving future investments in the next several years. Manufacturers will invest in approaches that drive better, transparent, explainable, and faster time to value that provide seamless decisions between different business systems with more emphasis on action versus interaction. Focus will be on how automated decision-making results in improved productivity versus the current focus on user experience and complex manual tasks.

Bringing digital revolution 2.0 into focus

As manufacturers begin adopting data-driven decision-making tools, the current AI/ML strategies will change to adapt to more complex ecosystems. While we already have focus on sustainability and automated decision-making, the future will bring more emphasis on circular economy value chains involving leveraging data across different companies across the product lifecycle and responding proactively to customer needs. By 2030, this will open up an avenue to track products, customer use, recycling, and maintenance, which will expand business opportunities for new product development and new manufacturing processes. This will ultimately and hopefully lead to digital revolution 2.0! M

About the author:

Sandeep Anand is Senior Director of Decision Analytics and Science Platform at Infor. He has over 15 years of experience building and delivering AI/ML solutions. Experience includes solutions around yield/scrap, supply chain improvements, and smart asset management strategies. He leads the AI/ML practice at Infor, a leading enterprise cloud solutions provider.

Strategic Scalability: The Key to Realizing Your Factory of the Future

Merging new tech with established operations requires a thoughtful approach and a roadmap for sustainable expansion.

TAKEAWAYS:

● A strong technology strategy that addresses the organizational workforce, engineering processes, and effective technology solutions is vital for manufacturing resilience.

● For long-term success, a phased implementation strategy often outperforms rapid adoption of cutting-edge technologies.

● Effective scaling involves swiftly adapting your technology strategy to the unique demands of each operational setting, while establishing a repeatable foundational framework.

In an era characterized by rapid technological evolution and intensifying global competition, manufacturers must not only adapt but strategically reimagine and restructure their manufacturing processes to survive. This journey is unique for every industry sector, individual organization, and manufacturing facility, but often begins with a unified vision for digital transformation and the “Factory of the Future.” This vision is anchored by disruptive technologies such as the Internet of Things (IoT), artificial Intelligence (AI), hyper-automation, and advanced robotics, all aimed at achieving significant gains in efficiency, flexibility, and competitive advantage.

While these new technologies hold the promise of transforming traditional manufacturing into highly agile, customer-centric operations, many manufacturers struggle with their adoption—stifled either by a lack of vision or a failure in execution. These misconceptions or missteps can hinder the progression towards fully digitalized operational environments. The integration of these technologies demands a nuanced, continuous approach underscored by a well-defined strategic framework. In this article, we provide comprehensive guidance on how to formulate, implement, and scale technology strategies that cater to both immediate operational objectives and overarching long-term goals.

Crafting the Strategy: Bridging Today and Tomorrow

To build the factory of the future, organizational leadership must first delineate what the future looks like for their organization. This foresight isn’t about predicting exact technological trends, but rather about understanding where the industry is moving and where an organization’s capabilities lie. The intersection of industry trends and an organization’s core competencies gives birth to its unique technology strategy.

“The intersection of industry trends and an organization’s core competencies gives birth to its unique technology strategy.”

Unfortunately, in their enthusiasm for technology adoption, many manufacturers overlook the foundational step of strategic planning. Failing to plan is essentially planning to fail. This lack of foresight often leads to a fragmented technology landscape, where isolated, high-cost investments yield little impact on overall operations. Conversely, an effective strategy adopts a comprehensive approach that integrates technology, human resources, and operational processes. Central to this strategy are clearly defined objectives—be they cost reduction, quality enhancement, or customer satisfaction—that align with the broader organizational mission and vision.

Developing a coherent strategy includes the following components:

- A detailed assessment of your current manufacturing capabilities, processes, and workflows;

- A robust risk assessment and mitigation plan;

- An assessment of existing skill sets within the organization;

- An analysis of the readiness of the current systems to integrate new technologies; and

- An analysis of the financial implications of the technology roadmap.

Through this rigorous exercise, leaders can identify the most critical technologies that will provide a quick win while serving as a foundation for future scalability. Using this information as a baseline, your technology strategy will evolve from a simple shopping list of the latest technologies into a more comprehensive roadmap that addresses identified gaps and leverages the strengths of existing operations.

Executing the Strategy: A Phased Approach

Navigating the journey from traditional manufacturing processes to the factory of the future is a multidimensional challenge that requires both visionary leadership and grounded pragmatism despite the inclination to adopt cutting-edge technologies in the pursuit of an “overnight overhaul.” This urge to quickly integrate innovative technologies often misleads manufacturers into thinking that speed is a proxy for success. By taking a more systematic and phased approach that compartmentalizes such a massive undertaking, organizations can mitigate risk strategically and allocate resources judiciously, ensuring they maintain operational stability while they improve technological capabilities iteratively. A phased approach also offers the agility and flexibility that are paramount in today’s volatile business environment, without sacrificing the thoroughness and attention to detail that manufacturing firms require. Creating a digital backbone is a prerequisite for success and taking the “start small, scale up” approach drives the ability to make an immediate impact on operations.

According to a 2023 survey conducted by Deloitte, nearly 62 percent of manufacturing firms that opted for an overnight digital overhaul experienced significant operational disruption, compared to just 28 percent of those that implemented a phased approach. While the allure of an expedited transformation is understandable—especially given the competitive edge it promises—these numbers make a compelling case for incremental change. The same Deloitte survey found that 45 percent of companies that opted for rapid transformations incurred unexpected costs that exceeded their initial budget by 20 percent or more.

“Creating a digital backbone is a prerequisite for success and taking the “start small, scale up” approach will enable manufacturers to make an immediate impact on their operations.”

Beyond the statistical backing, a phased approach allows for real-time adjustments and optimization, providing a “safety net” of sorts that can help mitigate unforeseen challenges and expenses and simultaneously align well with the complexities and intricacies of manufacturing. The production process often involves multiple layers of interdependent systems and workflows; a change in one area can have ripple effects across the entire operation. By employing a phased approach, executives can monitor the impact of changes more closely and adjust strategies as needed without disrupting the entire ecosystem. For industry leaders and executives, this approach offers a harmonious blend of innovation, strategic risk management, and astute financial planning. It fosters a smoother transition and higher rates of adoption among employees, creating a rapid—tangible and intangible—time to value.

Ensuring Seamless Execution: The Importance of Integration

Ever-advancing technologies that continue to change the shape of manufacturing are fundamental drivers for reimagining processes, operational efficiencies, and customer satisfaction. Taking small steps to strategically incorporate them into an organization’s operational ecosystem is only the beginning of the journey.

Once a well-articulated strategy is in place, attention must shift to integration, and here the sequence of execution is just as crucial as the technologies selected. While it is tempting to chase the allure of disruptive technologies, indiscriminate adoption often leads to redundant systems, wasted investment, and a complicated, unmanageable technology stack.

System integration is the cornerstone of operational effectiveness in any modern factory setting. A host of variables—including the persistence of legacy systems, data siloing, and a multigenerational workforce—can serve as impediments to the successful enactment of an industrial transformation strategy. The role of human capital and procedural methodologies is non-negotiable in the successful integration of emergent technologies. Multidisciplinary teams, comprising experts in operational technology, data science, and on-the-ground operations, are indispensable for calibrating collective initiatives toward a common engineering objective. The robustness of any digital architecture is fundamentally reliant on three key pillars: 1) seamless technological integration, 2) uniform data governance protocols, and 3) adaptive human resource strategies. Incongruence in any of these domains risks compromising the operational efficacy of the overarching strategy.

Successful integration is not just a catalyst for competitive advantage, it’s a determinant for survival.

In the 2023 Manufacturing Trends Report, Alithya revealed that companies effectively integrating the right technologies with their operational dynamics have experienced a surge in productivity by an astounding 27 percent, and a subsequent reduction in operational costs by nearly 19 percent. What the manufacturing organizations leading the charge in transformation have in common is that they have each cultivated a culture of innovation and integrated these innovations into the very fabric of their operational DNA.

Scaling a Technology Strategy: A Blueprint for Future Readiness

Characterized by fluctuating demand, raw material availability, and geopolitical uncertainties, a manufacturer’s ability to effectively scale a technology strategy is tantamount to achieving operational agility and sustained growth. Scaling is not merely a replication of solutions that have demonstrated value in a small-scale setting; it is an intricately planned endeavor that aligns technology with business objectives, regulatory frameworks, and workforce capabilities. Contrary to popular belief, it does not merely refer to deploying more of the same technology across an enterprise. It involves understanding the contextual intricacies of each operational environment and adapting the foundational strategy to the idiosyncrasies accordingly.

“Your factory of the future vision is not a linear path but a complex, multi-dimensional journey. It requires an integrated approach, focusing equally on technologies, human factors, and processes. ”

What works well in a controlled, small-scale environment may face unexpected challenges when applied across multiple locations or larger operational scales. The foundation of effective scaling is a well-defined technology architecture that adheres to modular design principles and allows components to be added or replaced without disrupting the entire operation. This foundation is essential for project success. This process of using open, yet defined standards ensures that the architecture remains flexible and eases the burden of incorporating new technologies without excessive alterations or a complete overhaul. This symbiosis not only enhances data-driven decision-making but also promotes a culture of continuous innovation, and essentially creates a scalable ecosystem that accommodates growth while maintaining optimal performance levels.

Are You on the Right Path?

Your factory of the future vision is not a linear path but a complex, multidimensional journey. It requires an integrated approach, focusing equally on technologies, human factors, and processes. Successful technology strategies are built on the pillars of organizational alignment, an understanding of your operational ecosystem, and robust governance with a focus on scalability and futureproofing.

Developing transformation strategies are ultimately less about technological adoption and more about transformational amalgamation. It’s not simply adding technology to existing processes but reshaping those processes around new capabilities. For example, AI-driven analytics do not merely speed up data processing; they revolutionize decision-making algorithms. Similarly, advanced robotics are not just about automating tasks, they reimagine the workflow. Thus, in the quest for the factory of the future, it’s crucial to see technology as a dynamic catalyst for organizational evolution.

Manufacturing success is not determined merely by the adoption of cutting-edge technologies, but by a multifaceted approach that synergizes internal capabilities with strategic external partnerships. This synergy allows for the seamless integration of modular solutions into the existing technology infrastructure. Concurrently, it is imperative for executives to foster an organizational ethos that views technology as the critical fulcrum for navigating present challenges and capitalizing on future opportunities. This integrated approach accelerates the return on investment and also augments the firm’s competitive edge in innovation. As we stand on the cusp of a revolution driven by technological capabilities we are only beginning to understand, the existential question for manufacturing leaders is no longer about whether to invest in digital transformation, but rather how to delineate a strategy that judiciously chooses the appropriate technologies and partnerships for transformative and sustainable execution. M

About the authors:

Holly Becker is Director of Commercialization, ATS Applied Tech Systems, LLC

SURVEY: Manufacturers Go All-In on AI

A growing number of manufacturing organizations have brought AI to the shop floor, and as usage grows, so do aspirations for its future impact, a new MLC survey reveals.

There were two open-ended questions at the close of the Manufacturing Leadership Council’s 2023 Transformative Technologies survey. The first: Which single technology is currently having the most impact on your manufacturing operations?

Of the 171 respondents to this year’s survey, 19 cited AI or machine learning, the most commonly mentioned response, with four of those mentioning generative AI specifically. Not far behind were manufacturing execution systems, with 13 responses. Rounding out the pack were automation and data analytics with about 10 responses each. Honorable mentions went to cobots, vision systems and ERPs. Some respondents elaborated on the power of system consolidation and broader data access.

Far more consensus was seen, however, on the second open-ended question: What technology do you believe will have the most future impact on your manufacturing operations? For this question, 79 respondents mentioned AI or machine learning (or their cousin, predictive analytics), with robotics and digital twins also receiving multiple, if far fewer, mentions.

This tracks with the 40% of respondents who said they have adopted AI widely or at least on a pilot basis, with another 53% saying they were either researching use cases of developing a plan for implementation.

The MLC has been closely following the AI groundswell in manufacturing, with more use cases continuing to emerge. Most are currently using it for process improvement or predictive maintenance, and many plan to broaden its use in their supply chain, distribution, and sustainability efforts.

Read more below on the results of this survey:

Part 1: Strategy and Organization

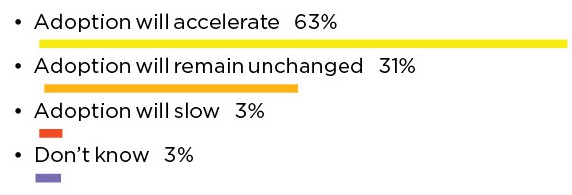

While almost 90% of respondents to last year’s Transformative Technologies survey said they expected M4.0 technology adoption to increase, this year’s response shows a more measured approach to investment – possibly due to economic headwinds faced by many manufacturers.

1. Do you expect your company’s rate of M4.0 technology adoption to increase or decrease over the next two years? (Check one)

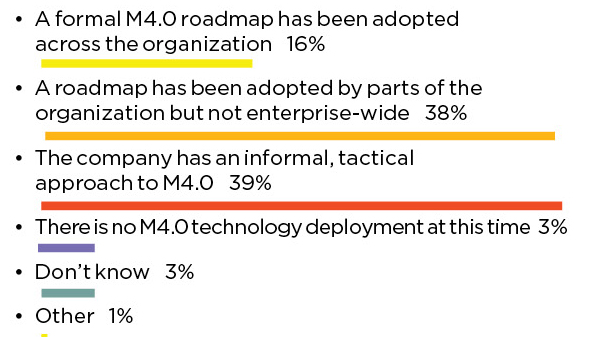

Many companies continue to take a fragmented approach to M4.0 – just 16% say they have an organization-wide technology roadmap. Far more either only have partial strategies or an informal approach to M4.0 deployment.

2. Which statement best describes the current status of your company’s M4.0 technology roadmap or strategy? (Check one)

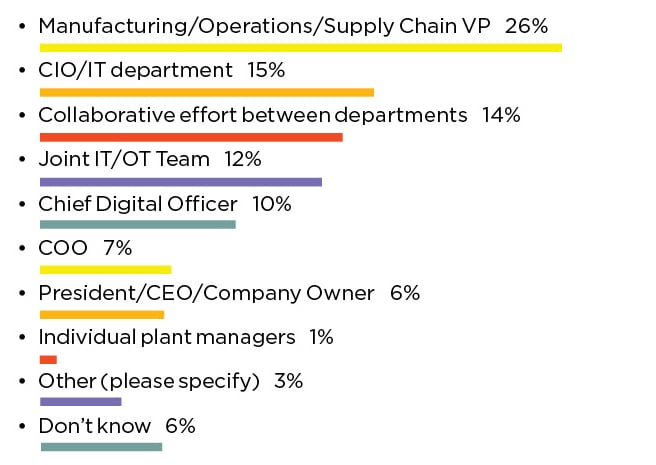

The person in charge of M4.0 strategy is most frequently an operational VP, followed by the CIO/IT department or a collaborative effort between teams.

3. Who is responsible for leading and implementing your M4.0 strategy? (Check one)

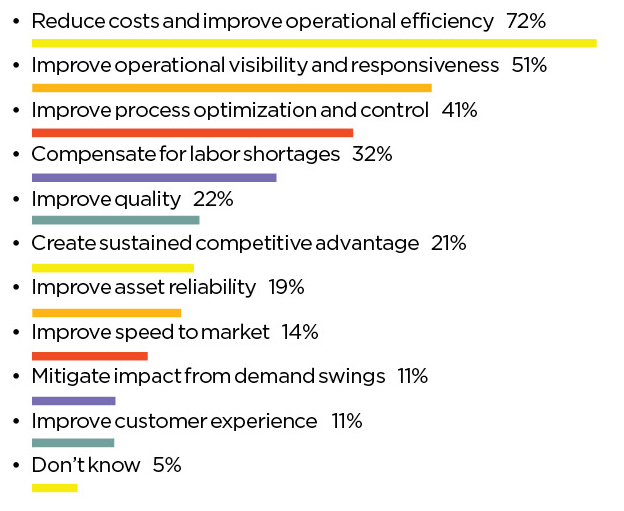

At the end of the day, the bottom line rules – most respondents said that reducing costs and improving efficiency were the top reason for investing in M4.0.

4. What are the most important reasons your company invests in transformative M4.0 technologies? (Check top 3 reasons)

Part 2: Technology Investment Plans

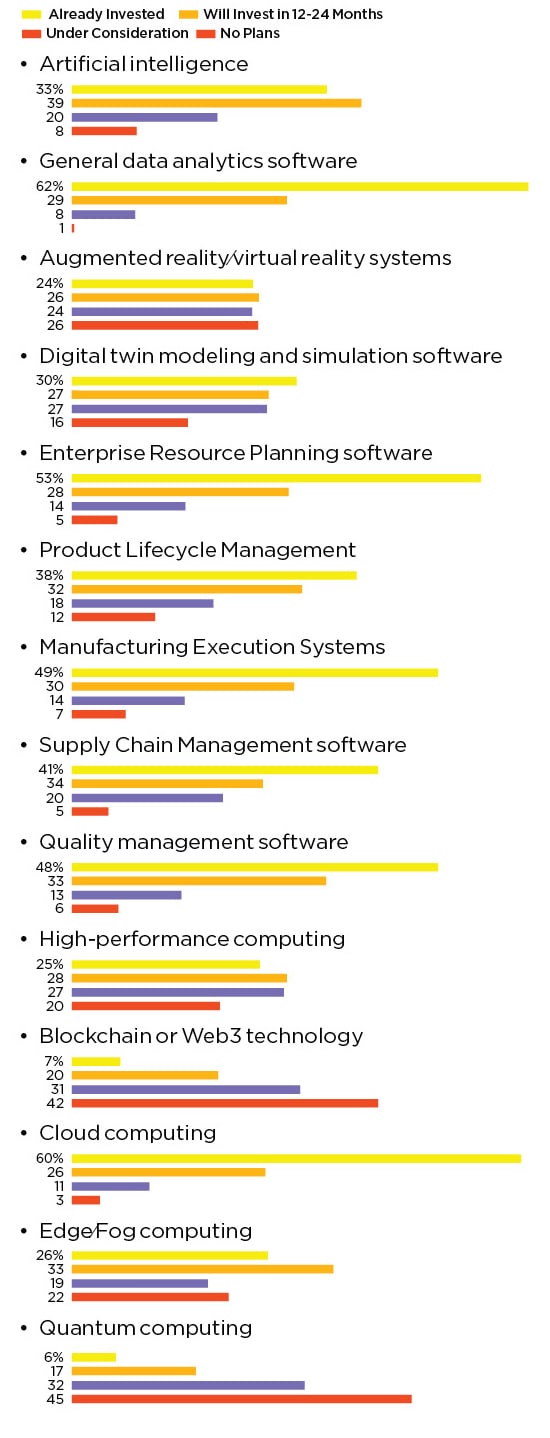

Presently, the most common OT/IT investments are data analytics software, cloud computing, ERP planning software, and MES. Strongest near-term plans (12-24 months) are in AI and supply chain management software followed by edge computing and product lifecycle management. Additionally, about a third are considering digital twins and quantum computing for longer-range plans.

5. What are your company’s investment plans for the following OT/IT-related technologies? (Check one in each column)

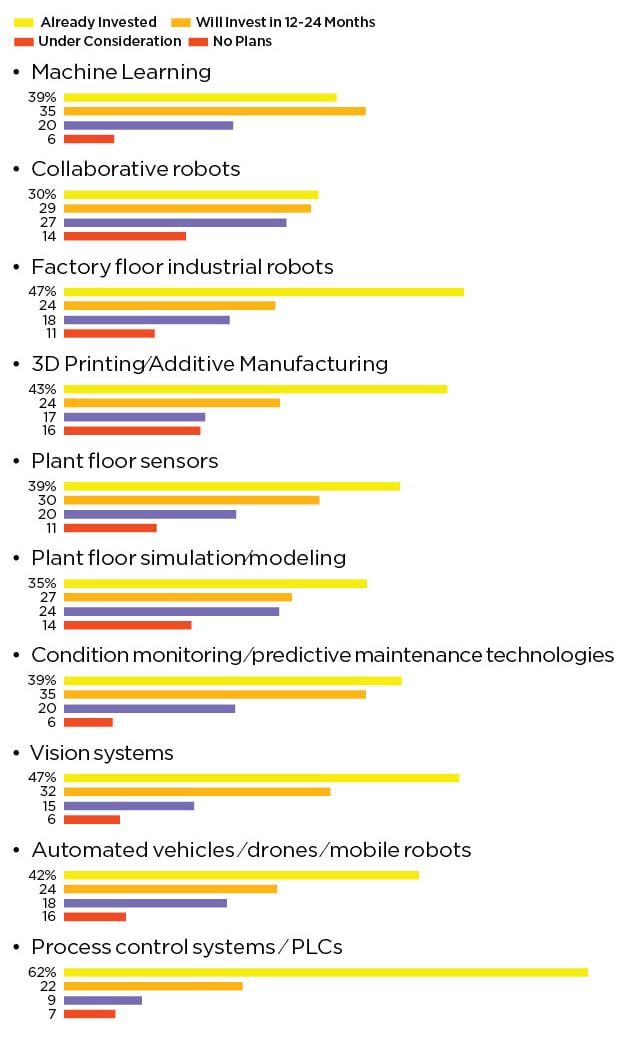

For production technologies, process control systems are in the lead for current investments while nearly half say they have industrial robotics and/or vision systems in place. Other popular technologies are additive manufacturing and AGVs or mobile robots. In the near-term manufacturers indicate plans to implement machine learning and condition monitoring technologies.

6. What are your company’s investment plans for the following production technologies? (select one)

Part 3: Adoption of AI and Machine Learning

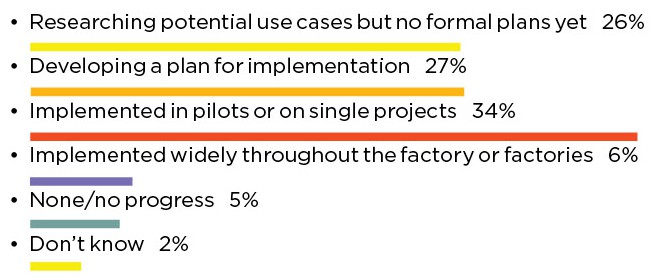

Drilling specifically into AI, over a third of respondents said they had implemented AI in pilots or on a single project (34%), with almost as many saying they were developing a plan for implementation (27%), a slight uptick compared to last year’s responses on AI usage. Very few say they have implemented it widely (6%), while even fewer said they had made no progress toward adopting AI (5%).

7. Where does your company stand today in adopting AI in manufacturing operations? (Check one)

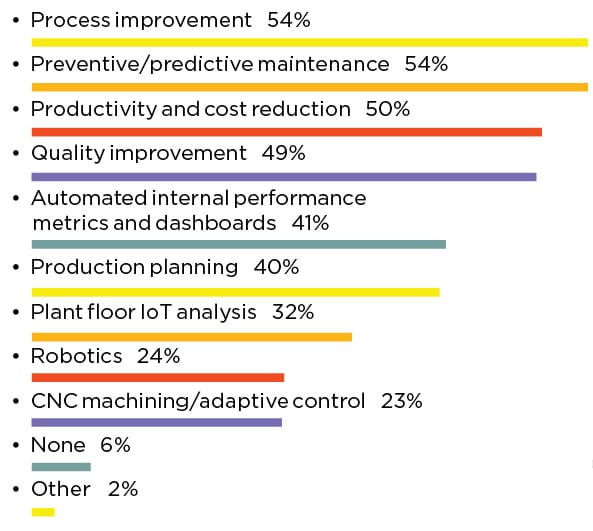

The current key applications for AI usage are process improvement, preventive/predictive maintenance, productivity/cost reduction, and quality improvement.

8. What are the key application areas for AI and Machine Learning technologies in your manufacturing operations? (Check all that apply)

Outside of manufacturing operations, respondents say the greatest number of current AI use cases are in sales and customer intelligence followed by product design and development. Within the near term, manufacturers expect to broaden its use within distribution and logistics, supply chain, sustainability, and procurement.

9. In what other areas of the organization are you deploying AI and Machine Learning, or planning to deploy over the next two years? (Check one option for each area)

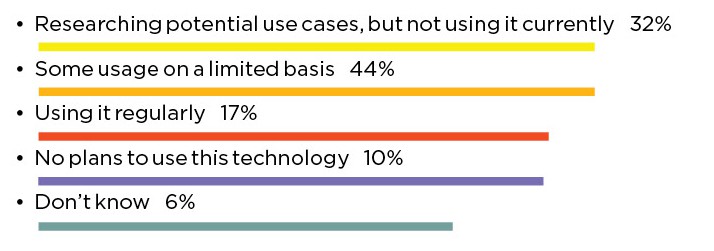

Asked specifically about generative AI technologies like ChatGPT or Bard, 44% indicated they are using it on a limited basis and 17% said they are using it regularly. 10% say they have no plans to use it at all.

10. What is your organization’s position on using generative AI like ChatGPT or Bard? (Check one)

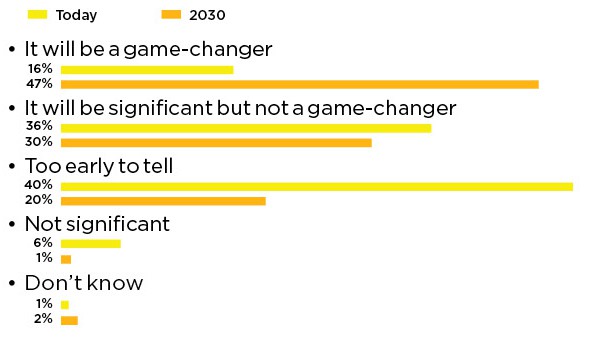

Views on the impact of AI in manufacturing show that while many already see it as significant (36%), nearly half of respondents felt it will be a game-changer by the year 2030 (47%).

11. Overall, what is your current assessment of the potential of AI and Machine Learning, both today and by 2030? (Check one in each column)

Part 4: Impacts and Challenges of Transformative Technologies

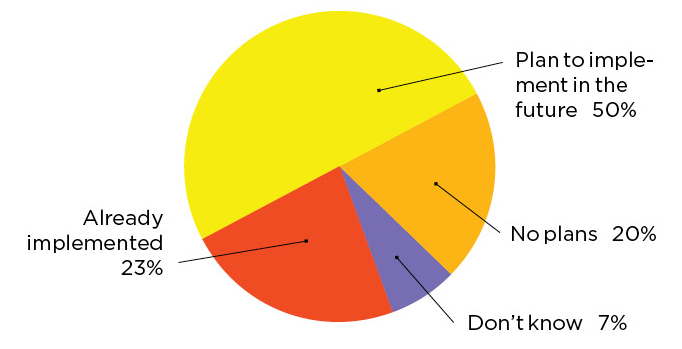

When it comes to sharing data across functions of the enterprise, the digital thread is coming –only 23% of manufacturers have one currently, but 50% say they have plans to implement it in the future.

12. Has your company implemented a digital thread to share data generated by one or more of the M4.0 technologies you have adopted across multiple functions? (Check one)

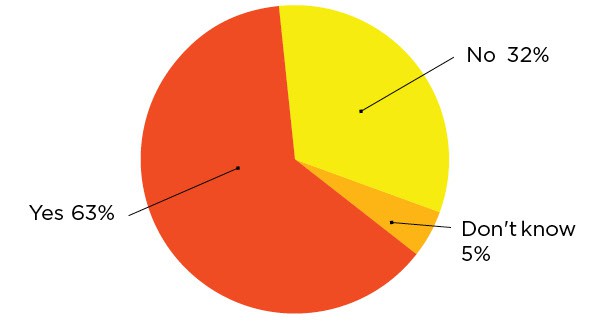

The trend toward workplace flexibility, likely emerging out of necessity during the pandemic, hasn’t fully abated – 63% say they have invested in technology meant to allow for remote operations.

13. Has your company made technology investments with an eye toward allowing greater workforce flexibility (i.e. remote operations)?

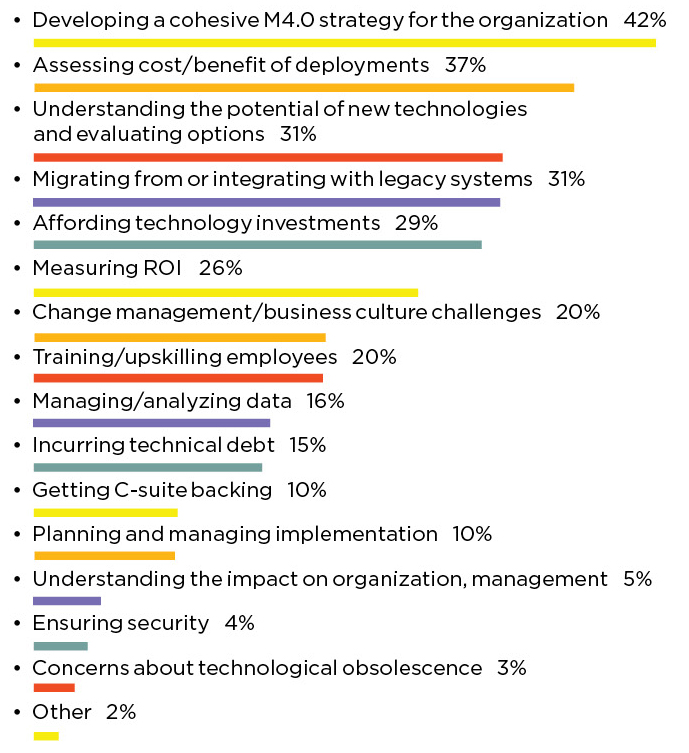

When asked what their most pressing challenges were related to M4.0 adoption, the top responses were developing a cohesive strategy (42%), assessing the cost and benefit of deployments (37%), understanding and evaluating new technologies (31%), and migrating from or integrating with legacy systems (31%). M

14. What are your top three challenges related to adopting and using M4.0 technologies? (Select top three)

About the author:

Penelope Brown is Senior Content Director for the Manufacturing Leadership Council.

Survey development was led by the MLC editorial team with input from the MLC’s Board of Governors.

How Immersive Technologies Make Manufacturing More Efficient

Immersive technologies strengthen asset management and bolster smart factories.

TAKEAWAYS:

● Higher levels of reliability, speed, and productivity as well as enhanced safety and compliance are benefits of immersive technologies in smart factories.

● Immersive technologies reduce training costs and increase new-hire productivity with real-time, interactive, on-the-job training.

● Tools like augmented reality and virtual reality enhance maintenance practices, reduce downtime, lower maintenance costs, and enhance manufacturing performance.

While manufacturing automation could be considered the original smart factory technology, it is certainly far from the last. Transformative technologies are making inroads at all levels of plant operations, including equipment maintenance and repairs.

Not long ago, industrial maintenance was primarily a laborious, reactive function routinely performed after the damage was done or the asset ran to failure. This changed with the advent of Industry 4.0 technologies, which made the maintenance of complex and increasingly sophisticated equipment more proactive, predictive, and to some extent even automated. Using smart maintenance tools and practices helps manufacturers avoid costly equipment failures and unplanned production downtime, and enables plants to increase performance and throughput and boost the bottom line.

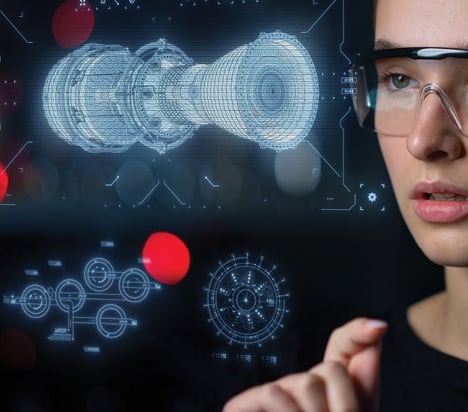

Immersive technologies such as augmented reality (AR), virtual reality (VR), and mixed reality (MR) are prime examples of smart maintenance technologies. Providing an immersive reality experience to technicians and reliability engineers is transformative in terms of improving maintenance efficiency and effectiveness. In turn, immersive technologies drive smart factories to higher levels of reliability, speed, and productivity while enhancing safety and compliance.

Immersive Technologies Explained

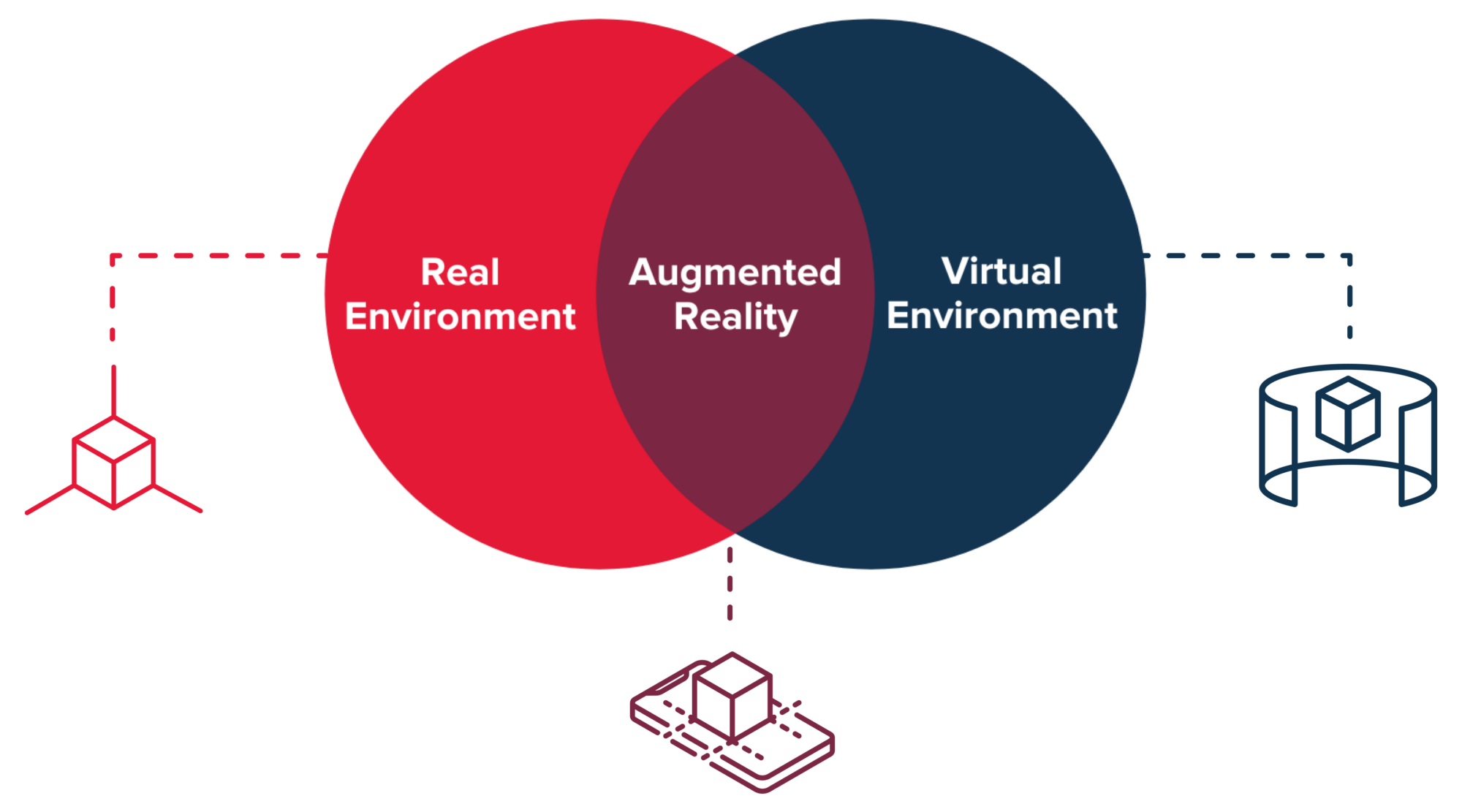

Immersive technologies extend and deepen the information available from which manufacturers can make decisions and take action. Digital or simulated reality supplement a technician’s perceived reality in the real world. There are three immersive technologies commonly used: augmented reality, virtual reality, and mixed reality

Augmented Reality

AR augments the scope of information available to technicians beyond what their senses, memory, work orders, inspection checklists, or other materials normally at hand provide. It takes live video of the real asset or environment via a camera-equipped phone, tablet, or wearable such as goggles and glasses (for a hands-free approach), and then overlays these additional digital images, graphics, notes, or other supporting materials over the real-world setting—on demand, in real-time, through a head-up display. Hand gestures, eye tracking, and voice recognition are among the ways a technician can request supplemental data and imagery and take it into immediate consideration.

“Augmented reality stands out for its hands-free, real-time data access, empowering technicians with unparalleled insights on the shop floor.”

To further facilitate maintenance and inspection, AR with audio capabilities enables real-time communication with remote experts, anywhere in the world, who can assist by answering questions, diagnosing problems, or guiding the technician through specific tasks—without incurring the time and travel costs of an on-site visit. AR stands out for its hands-free, real-time data access, empowering technicians with unparalleled insights on the shop floor.

Virtual Reality

VR headsets bring technicians into a completely virtual world, separate from their physical surroundings, so they can actively and safely interact with the virtual environment.

VR is frequently used in manufacturing to simulate real components, machines, processes, or facilities, and the virtual environment then becomes a maintenance training and troubleshooting aid. It provides a “hands-on” experience without putting the employee or equipment at risk of errors. VR also serves as a design and optimization aid for reliability engineers, who can simulate and improve conceptual assets or environments before seeking investment in the physical solution. VR solutions with remote collaboration capabilities enable more effective discussions because the participants can interact with the virtual components and “see” how they might work in a real-world setting—compared to simply studying technical drawings or CAD models.

Virtual reality’s potential for cost savings through remote access to parts and machinery is a game-changer for communication and training processes, offering greater timeliness and efficiency.

Mixed Reality

MR blends the capabilities of AR and VR. It allows users to interact with both real-world and virtual objects at the same time, or to have touchpoints to the real world while immersed in a virtual world. As an example, a technician working on a pump can call up the work history and a digital twin of a component for additional context (AR), and then manipulate the digital twin (VR) to explore different ways to tackle the problem before applying the best option to the pump.

Each of these immersive technologies enhances maintenance practices by delivering the right information at the right time, with minimal effort. Using tools like these to reduce downtime and maintenance costs elevates manufacturing performance.

Figure 1: AR/VR Explained

Positive Influence on Maintenance and Manufacturing

Applications for immersive technologies in maintenance are widespread and growing rapidly. This trend is not surprising considering the increasing sophistication of industrial machines and the risks of failure. Smart factories are gaining extensive efficiencies and operational benefits from immersive maintenance practices across the board. We highlight seven specific benefits:

- Maintenance: Industrial maintenance, troubleshooting, diagnostics, and inspections are more accurate when technicians can see, right in front of the equipment being serviced, digital aids such as instructional notes with arrows prompting them through the task at hand. Immersive reality makes the old ways of digging up supporting or historical materials or working with incomplete information, antiquated. Immersive technologies improve maintenance quality, repair time, and the first-time fix rate while reducing scrap and rework.

- Operations: Operator rounds are more effective when the operator can call up historical data to evaluate whether the present conditions are anomalous.

- Training: Learning and practicing maintenance tasks in a virtual space, and refreshing and reinforcing knowledge using augmented means, protects employees and equipment by ensuring those doing the work have every opportunity to do their jobs correctly. Immersive technologies reduce training costs and increase new-hire productivity with real-time, interactive, on-the-job training. It facilitates knowledge transfer from more experienced personnel and enables remote coaching and upskilling to keep up with changing technologies, processes, and standards.

- Safety and regulatory compliance: Manufacturers can avoid safety incidents when technicians can troubleshoot problems in a virtual environment without having to disassemble the equipment. Lockout/tagout procedures and safety data sheets cannot be missed when they appear in front of the technician’s eyes. Simplifying the way records of performed work are captured ensures proper documentation is available for audits.

“Virtual reality’s potential for cost savings through remote access to parts and machinery is a game-changer for communication and training processes, offering greater timeliness and efficiency.”

- Reliability engineering: When a virtual playground for experimentation and improvement exists, design for reliability and asset optimization initiatives can thrive.

- Cost control: Immersive technologies have immediate cost benefits in addition to the extensive savings that come from improving asset reliability, efficiency, safety, and reducing downtime. In one example, Advanced Technology Services (ATS) observed that instead of having an original equipment manufacturer (OEM) provide in-person maintenance support that would have required two full days (16 hours) at $250 per hour, enabling remote OEM support using AR integrated with Microsoft Teams saved the manufacturing plant thousands of dollars.

- Recruiting: Modern maintenance technologies and processes are appealing, particularly to the younger generation, and highly beneficial in recruiting and retaining talent. AR, VR, and MR help to close maintenance skills gaps by enabling the development of a global technical workforce that communicates as if they were all present locally. Lessening the dependence on the experience of individual technicians is more important than ever with the rapid advancements being made in manufacturing technology. Advanced controls, sensors, networking functions, and robotic processes are just the beginning as the industry moves toward Industry 4.0.

Tooling for Future Factories and Industry 5.0

The factories of the future are smart. According to PwC, one-third of manufacturers have already embraced smart factory technologies, and the numbers are set to grow even more in the next few years. The statistics speak volumes about the significance of maintenance technology in modern manufacturing.

Immersive reality is among the technologies leading the way to the next industrial revolution. With immersive technologies gaining momentum, Gartner’s prediction that 75 percent of large enterprises will integrate AR and VR in the next few years emphasizes the importance of staying ahead of the game for manufacturers.

Take the Plunge

Thanks to innovative, transformative solutions such as immersive technologies, maintenance technology will continue to play an outsized role in strengthening modern manufacturing. But with so many compelling devices and virtually unlimited applications to choose from, assessing, prioritizing, and implementing solutions that will have the greatest effect is challenging without the right know-how.

To simplify the process and expedite the rewards, look for an industrial technologies service partner like ATS that has extensive experience in the latest industrial technologies and maintenance and reliability expertise to help manufacturers improve uptime and save costs. Partnering helps factories keep their equipment running reliably and efficiently when internal resources are limited, and it facilitates the adoption of digital transformation to give manufacturers a competitive edge.

About the authors:

Chris LeBeau is the Chief Technology Officer at Advanced Technology Services. He works with industrial maintenance experts and technology leaders to enable Industry 4.0 strategies and maximize the value of technology to manufacturers.

Micah Statler is the Director of Industrial Technologies at Advanced Technology Services. He is responsible for the strategy, execution and delivery of technology-driven maintenance solutions.

The Industrial Metaverse May Be Closer Than You Think

Nearly 80% of manufacturing executives seem confident that the metaverse will transform aspects of manufacturing in the next five years, a new Deloitte/MLC study reveals.

TAKEAWAYS:

● Executives say that the Industrial Metaverse offers new ways to solve a variety of pressing challenges they face in the near term.

● Attracting and retaining top talent and building resilience and visibility in supply chains are top goals.

● Among the chief challenges with the Industrial Metaverse are cybersecurity, data protection and IP, brand, and safeguarding personal information.

In May 2023, Deloitte and the Manufacturing Leadership Council (MLC) embarked on a study to better understand the industrial metaverse and its applications in manufacturing. This article presents some of the key highlights from the resulting publication “Exploring the industrial metaverse” (referred to as “the study” in this article), including findings that the majority of manufacturers surveyed are already progressing on their industrial metaverse journey and are deriving benefits from even partial adoption.

A Paradigm Shift

The industrial metaverse is the convergence of individual technologies that, when used in combination, can create an immersive three-dimensional virtual or virtual/physical industrial environment. As technology evolves, the industrial metaverse will likely allow access to these immersive 3D environments from any internet-connected device, including virtual reality (VR) and augmented reality (AR) devices, as well as smartphones, tablets, laptops, and equipment, from anywhere in the world.

A majority of manufacturing executives surveyed[1] are bullish on the potential of the industrial metaverse in the near term. More than 70% of surveyed executives believe that in the next five years it will have a high rate of adoption in the manufacturing industry. Nearly 80% are confident that the metaverse will transform R&D, design, and innovation and enable new product strategies.[i]

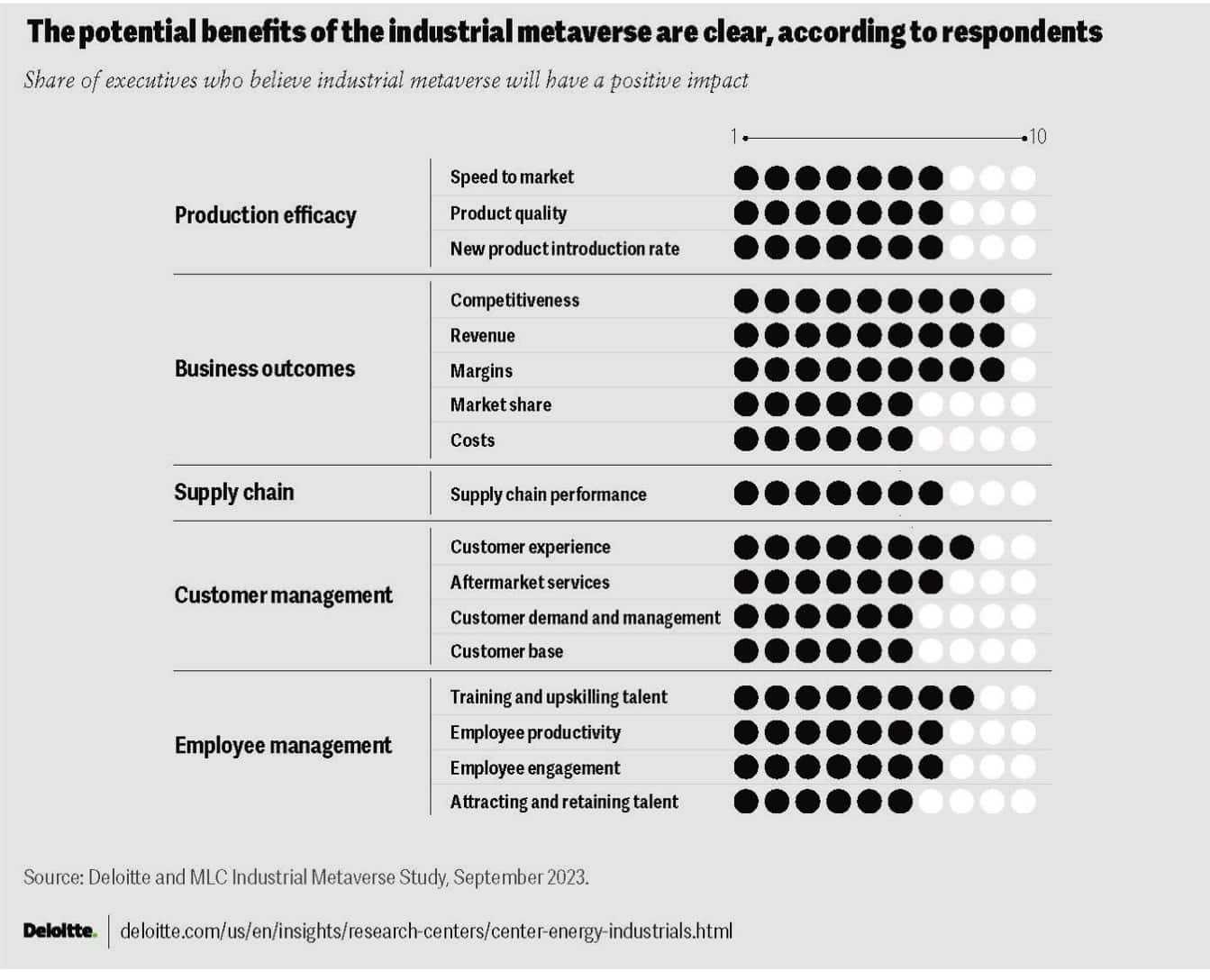

Surveyed executives generally agreed that the industrial metaverse offers new ways to solve a variety of pressing challenges they face in the near term, such as attracting and retaining top talent, and building visibility and resilience into their supply chains (figure 1). They tend to view the industrial metaverse as a pathway to future value realization through improved new product introduction rates and new customer experiences and services. Respondents also expect a broad positive impact across the business and are confident that the industrial metaverse will improve key business outcomes such as competitiveness, market share, revenue, and costs, among others.

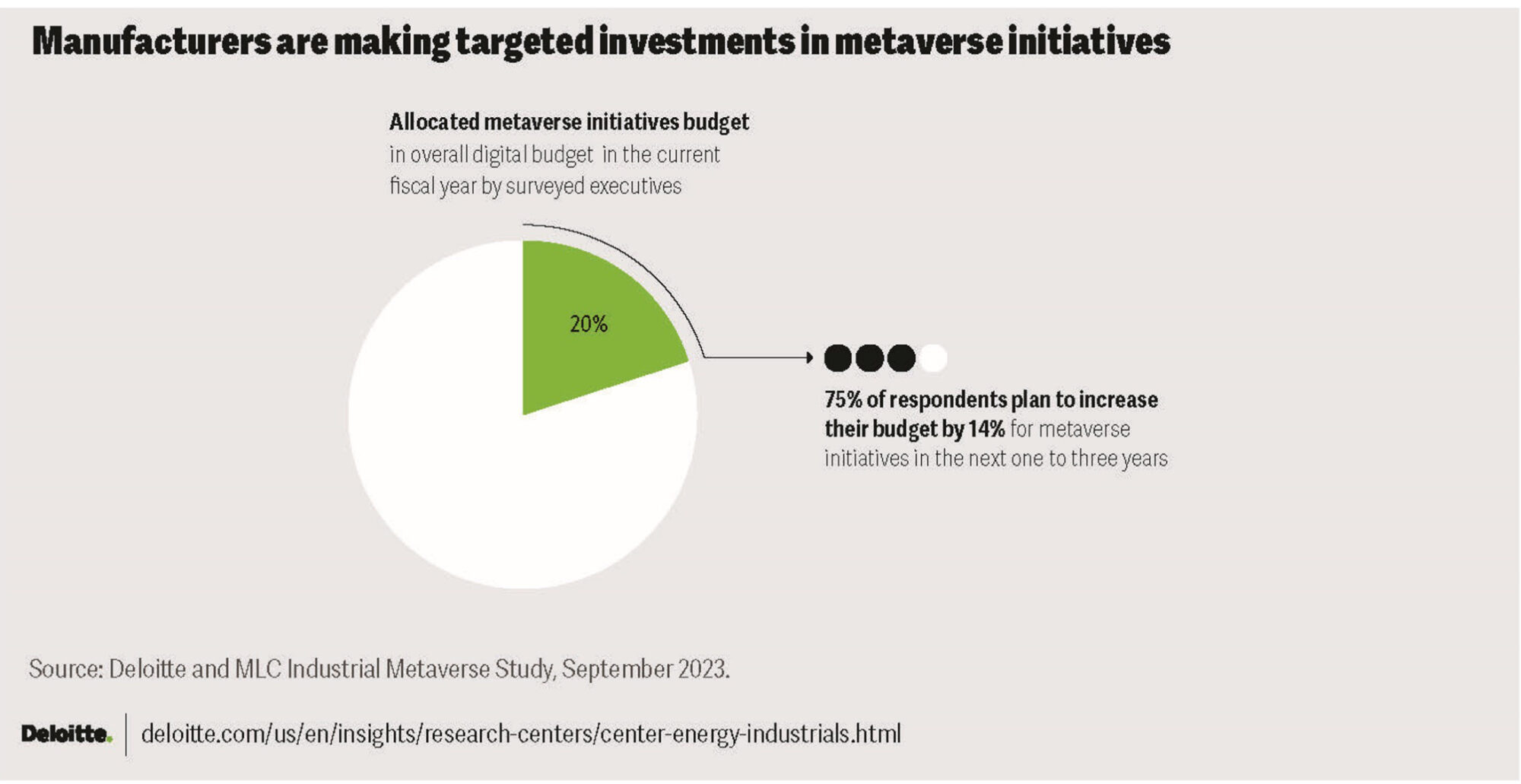

However, the study results indicate that manufacturers aren’t just betting on the future, they seem to be building it. Some respondents shared that they have already made significant investments in metaverse initiatives, and nearly three quarters plan to increase their investments over the next 1–3 years (figure 2).

Building on Smart Factory Momentum

Through digital transformation, smart factory solutions have generally allowed companies to collect important data from their processes, products, assets, and operators and perform advanced analyses to generate valuable insights, and then augment human intelligence with machine intelligence to implement significant and sustainable improvements. These advancements have resulted in greater asset efficiency, enhanced product quality, reduced costs, and increased safety and sustainability.[ii]

In a previous Deloitte paper that focused on how manufacturers can derive value from smart factory technologies,[iii] four primary ecosystems were introduced: production (quality sensing, factory asset intelligence, product development, etc.), supply chain (supply network mapping, digital warehousing, control towers, etc.), customer (aftermarket services, virtual product experiences, etc.), and talent (recruiting, training, etc.).[iv] Within the production ecosystem, a set of eight use cases were introduced, aptly named the “Great 8,” as the most prevalent use cases for smart factory technologies that manufacturers are operationalizing. Because of the scope of what the industrial metaverse can offer—connection to data-rich, immersive 3D environments from anywhere there is a broadband internet connection—its potential value stretches far beyond just the production ecosystem and the Great 8 use cases.

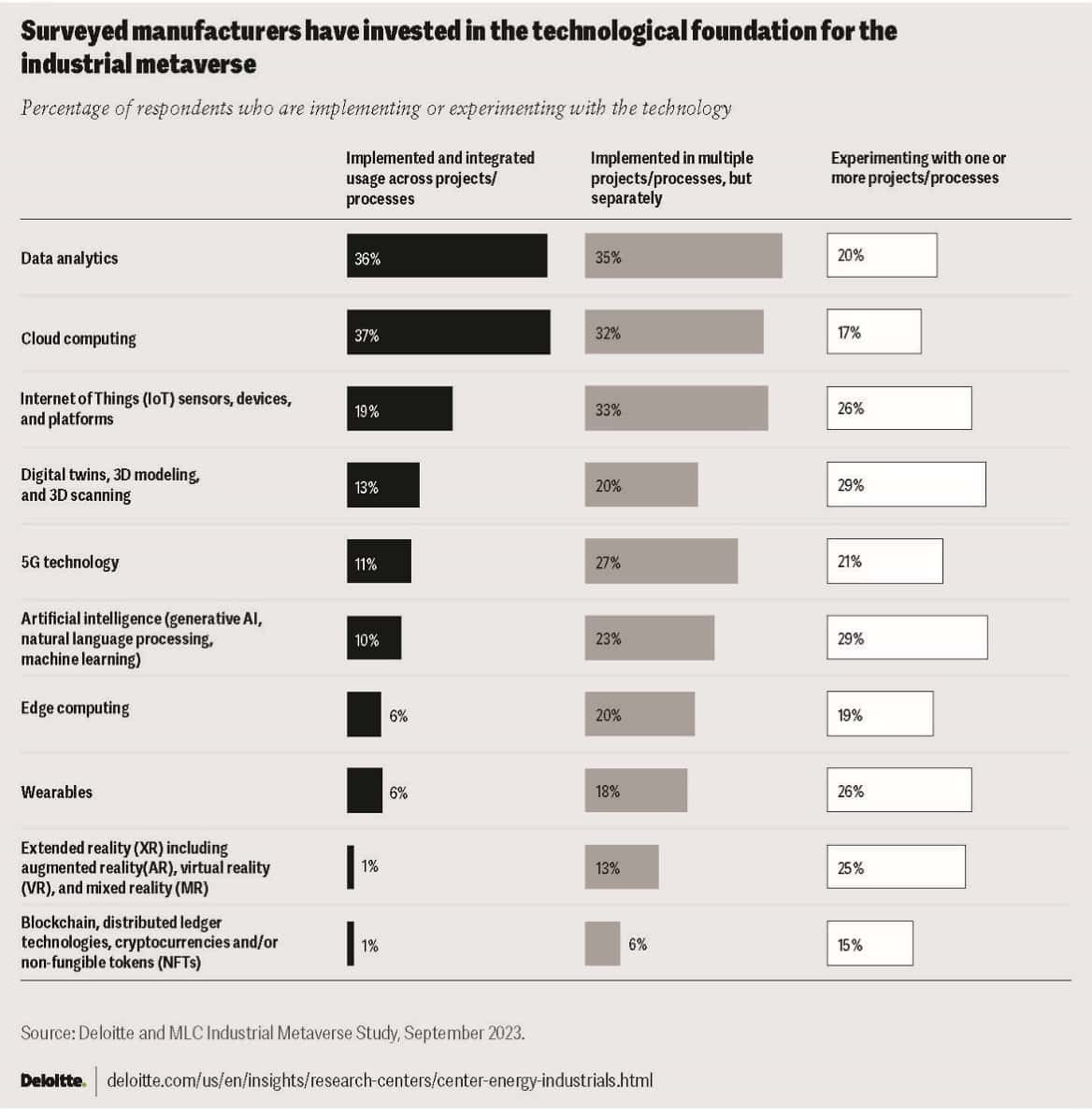

The manufacturing industry appears well-positioned for the adoption of the industrial metaverse. Given their continued focus on digital transformation and their journey toward the smart factory, the majority of companies surveyed have made significant investments and are already using the foundational technologies that power the industrial metaverse. Companies are generally either implementing technologies like data analytics, cloud computing, AI, 5G, and Internet of Things technologies across multiple projects and processes, or they are currently experimenting with one-off projects (figure 3). The same is true for digital twins, 3D modeling, and 3D scanning, which can all serve as building blocks for the immersive 3D environments of the industrial metaverse.

The study shows that not only do most manufacturers seem to have a strong technology foundation in place, many of the surveyed respondents are already combining and leveraging these technologies today to implement industrial metaverse use cases and create value.

Manufacturers Appear to be Driving Toward Adoption

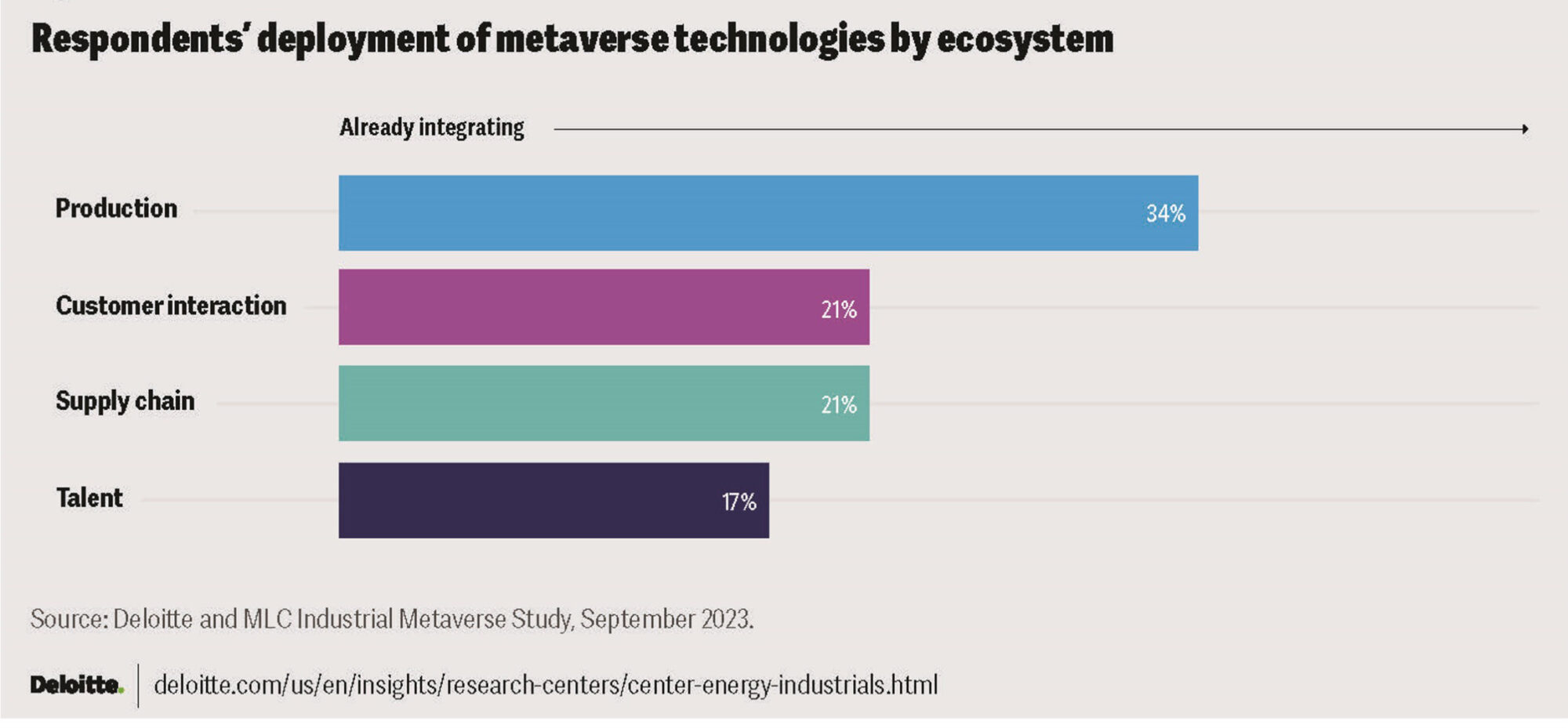

Nearly all (92%) of surveyed executives said that their company is experimenting with or implementing at least one metaverse-related use case and, on average, they are currently running more than six. Building on their smart factory efforts and leveraging the foundational technologies already in place, the production ecosystem was the most common for use case implementation, with more than one-third of respondents already integrating metaverse technologies, followed by the customer, supply chain, and talent ecosystems (figure 4).

Respondents then shared the primary use cases they are implementing using metaverse technologies. The study provides the complete details about these use cases, including their definitions, prevalence of implementation amongst surveyed respondents, the primary benefits derived, and some examples of use cases in action. Process simulation and real-time monitoring/digital twin were the two most common use cases overall, and the remaining production-focused use cases were also prevalent. Immersive training ranked third, followed by supply chain management and immersive customer experiences, demonstrating a healthy distribution of use cases across the talent, supply chain, and customer ecosystems.

The use cases and case examples that companies have reported seem to demonstrate that manufacturers are deriving value today from implementing industrial metaverse initiatives. However, they may still feel that there are challenges and risks to overcome to move toward its full adoption.

Cyber, Data Protection Are Important Risks

Cyberthreats are pervasive and can have a disastrous effect on a company if not properly mitigated. Implementing the industrial metaverse will likely bring new challenges since it derives its unique power from making proprietary 3D data about parts, products, facilities, etc., available to a variety of internal users, customers, and suppliers. It does this by allowing users to access the data through a myriad of interaction technologies over the internet, such as AR/VR devices, tablets, and phones.

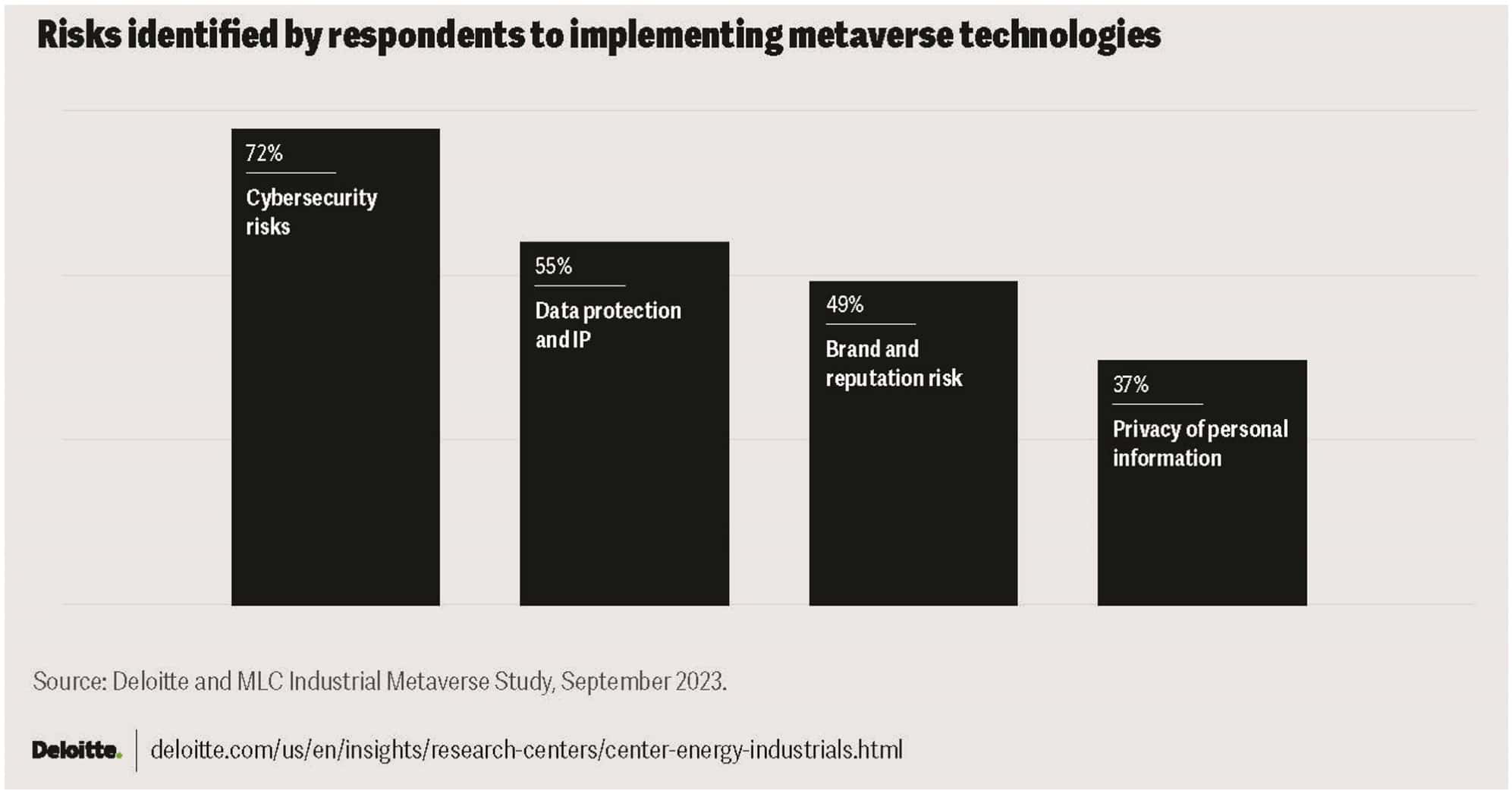

One executive mentioned that because the metaverse will require significant data management; data protection, privacy, and security is a concern.[v] In fact, more than 70% of the respondents agree that cybersecurity is one of the greatest risks associated with implementing metaverse-enabling technologies (figure 5). Rounding out the top four are respondents’ concerns about protecting data and IP, brand, and personal information, all of which can be compromised in a cyberattack.

Digitalization has required manufacturers to drive collaboration between informational technology and operational technology to create an effective cybersecurity approach.[vi] Companies should develop capabilities to identify and address risk in an information technology (IT)–operational technology (OT)–interaction technology (ET) environment. One executive explained that his company is working to establish OT security capabilities and standards for how to review equipment efficiently, following the company’s IT policies, so that the operations and engineering teams can more quickly pilot and implement new equipment. This includes ET, especially since they are typically low cost (<$5,000) and don’t rise to the same level of review priority for IT as, say, a muti-million-dollar software package.[vii]

While cybersecurity risk may increase with the industrial metaverse, the study suggests that manufacturers generally believe the value it will deliver outweighs the risk, especially with the right mitigation strategies in place.

Unleashing the Power of the Industrial Metaverse

The 2023 Deloitte and MLC Industrial Metaverse study indicates that manufacturing executives seem not only confident that the industrial metaverse may hold great promise for the industry – some are already taking what’s next and transforming it into what’s now. In many cases, they are driving forward with metaverse use cases and appear to be deriving significant value across the organization. The study identifies a three-pronged approach that can be used by a broad spectrum of companies to identify, initiate, and scale industrial metaverse initiatives.

About the authors:

Paul Wellener is a Principal within the US Industrial Products & Construction practice with Deloitte Consulting LLP. He has more than three decades of experience in the industrial products and automotive sectors and has focused on helping organizations address major transformations.

John Coykendall is a vice chair, Deloitte LLP, and the leader of the US Industrial Products & Construction practice. John has more than 25 years of consulting experience focusing on global companies with highly-engineered products in the A&D, Industrial Products and Automotive industries.

Kate Hardin, executive director of Deloitte’s Research Center for Energy and Industrials, has worked in the energy industry for 25 years. She leads Deloitte’s research team covering the implications of the energy transition for the industrial, oil, gas, and power sectors.